Summary of Contents for Huazheng Electric Manufacturing HZJQ-X1

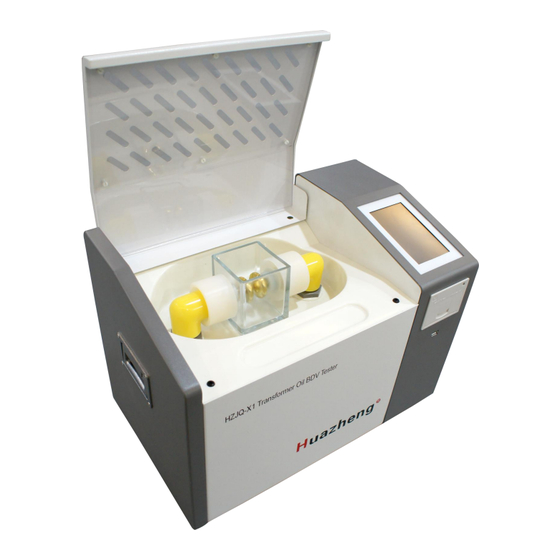

- Page 1 HZJQ-X1 Transformer Oil BDV Tester Huazheng Electric Manufacturing (Baoding) Co., Ltd...

- Page 2 Dear us er: Thank you for choosing HZ JQ- X1 Tr ansfor mer Oil BD V Tester. We hope that this inst rum ent can mak e your work eas ier and more enjoyable, so that you can get the feeling of off ice aut omat ion in the test and analysis work.

-

Page 3: Table Of Contents

Contents I. Overview............................2 II.Key Function And Feature...................... 2 III. Major Technical Indicators....................3 IV. Operational Approach......................3 V. Precautions..........................12 VI. Maintenance..........................13 VII. Oil Cup Cleaning Method and Common Fault Clearances..........13 VIII. Packing List..........................15... -

Page 4: Overview

I. Overview Many power systems, railway systems, large-scale petrochemical plants and enterprises have a lot of electrical equipment whose internal insulation are mostly oil-filled insulation type, and therefore, test on insulating oil dielectric strength is common and necessary. To meet the needs of the market, we have developed and produced a series of insulating oil dielectric strength testers according to national standard GB/T507-2002, industry standard DL429.9-91 and the latest Electric Power Industry Standard DL/T846.7-2004 by ourselves. -

Page 5: Major Technical Indicators

USB,can export the test data. III. Major Technical Indicators Output voltage: 0~80KV (optional) Voltage distortion rate: <3% Boost er capacit y: 1. 5K VA Measuring accur acy: ± 3% Supply voltage: AC220V±10% 50Hz±1 Hz Power: 200W Applicable temperature: 0℃~45℃ Applicable humidity: <75%RH Overall dimension: 460×280×320 IV. - Page 6 ② Setting of system parameters: Press “Settings” key and enter the following interface:...

- Page 7 1) St andard select The us er can choose the st andard of test ex ecution ac cording to the need. If you choose "Cust om" , you can choose boos t condit ions accor ding to ac tual needs. The user -def ined int erf ace is as follow s...

- Page 8 Volt age of boos ting stop: 10 ~ 80k V St anding tim e: 0~ 15min Int erval of boos ting: 0~ 5m in St irr ing Tim e: 0~ 120s, CON T Boost ing frequency: 1~ 10 Voltage boosting rate: 0.5 kV/s~5.0 kV/s If ot her st andards ar e select ed, take the pow er st andard DL/ T 846.

- Page 9 2) Syst em set (1)A ut otype: ON/ OF F , select by but ton. (2)Time sett ing :When the inst rument time is not ac curat e, can be adjust ed (3) Device Calibrat e Generally, us ers do not need to calibrat e the inst rument (4) Device Inf ormat ion.

- Page 10 Af ter the stat ic time is ov er, ent er the boost int erf ace aut omat ically. Click "st art " but ton to skip the stat ic ent ry and ent er the boos t inter f ace. Click “...

- Page 11 If you click the "S top" but t on, then st op the rise volt age If you click the "Rise" but t on, then the volt age rises If you click the “fall ” but t on, then volt age dr op The first test ended, ent er the delay int erf ace...

- Page 12 Af ter the delay, the next test st art s unt il the boos ting fr equency is reached. Finally, the result is show ed as follow s:...

- Page 13 Click “Sample No ” to ent er the sample number ④ Dat a Query Pr ess the “ Quer y ” key to ent er the follow ing int erf ace:...

-

Page 14: Precautions

Click the "P gUp" or "PgD n" but t on to flip pages to display test dat a at diff erent test times. Click the "P rint" but t on to pr int test dat a displayed on the curr ent int erf ace. Click on the "D el"... -

Page 15: Maintenance

casing af t er the pow er is swit ched on to av oid accident s. 3) The pow er shall be cut off imm ediat ely if any abnor mal ev ent is found dur ing the oper at ion. 4) New oil cup or cleaning the oil cup should be 24 times br eakdown af t er test ex ecution. - Page 16 b) Cover the cup mouth with a piece of glass cleaned by pet r oleum et her. Shake the cup ev enly for one minut e wit h cer t ain force. Pour aw ay the lef t oil sam ple and then the test st art s. 2.

-

Page 17: Packing List

③ Check at t ract ing of high-v olt age contact s. ④ Check br eak of high- voltage line. 3) Pr int er failure ① Check plugging of pr inter pow er line. ② Check plugging of pr inter dat a line. VIII.

Need help?

Do you have a question about the HZJQ-X1 and is the answer not in the manual?

Questions and answers