Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Mitek Hornet

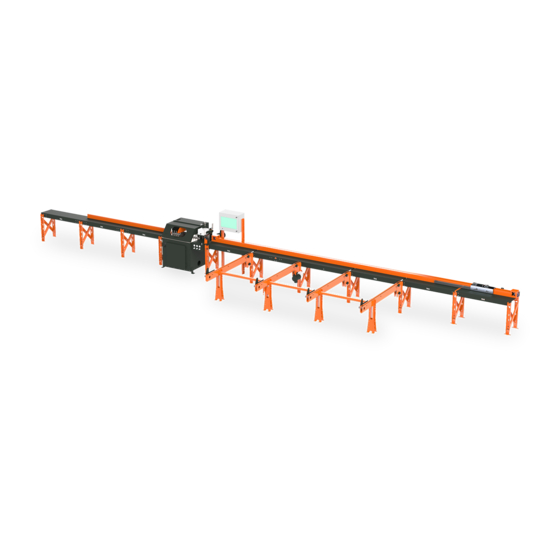

- Page 1 Operation & Maintenance Manual Hornet Linear Cut Processing Systems MiTek Component Automation PN 001128 301 Fountain Lakes Industrial Drive Creation date: 11/16/21 St. Charles, MO 63301 Phone: 800-523-3380 Created by: R. Tucker Fax: 636-328-9218 Applies to: Gen. 1 machinerysupport@mii.com...

-

Page 2: Table Of Contents

Safety, Operation, & Maintenance Manual Safety Linear Cut Processing Systems 1 Table of Contents Safety ....................................3 Safety Precautions (Read these Precautions Before Use) ..................3 Safety Features ............................... 3 2.2.1 Emergency Stop Buttons/Mechanisms ......................3 2.2.2 Safety Guards ..............................3 2.2.3 Audible Alerts .............................. - Page 3 Safety, Operation, & Maintenance Manual Safety Linear Cut Processing Systems System Settings ..............................25 6.8.1 Accessing the Settings Windows ........................25 Replacing the Saw Blade ............................... 26 Preventive Maintenance ............................... 27 Lubrication ................................27 Belt Tensioning ..............................28 Printer ................................... 29 Cleaning the Printer ..............................

-

Page 4: Safety

Safety, Operation, & Maintenance Manual Safety Linear Cut Processing Systems 2 Safety Refer to the safety manual supplied by MiTek®. 2.1 Safety Precautions (Read these Precautions Before Use) WARNING All personnel operating or working near this machine must read the safety manual. -

Page 5: System Overview

4.2 File Types Cut sets can be imported as one of these types: .xml files is generated from MiTek production software. Can also be called a Virtek® LaserMC® file. • .ehx is generated by MiTek Production software, including ShopNet™ software •... -

Page 6: Pre-Operation

Safety, Operation, & Maintenance Manual Pre-Operation Linear Cut Processing Systems 5 Pre-Operation 5.1 Passwords Windows • Interface password: Required to view or change the global settings screen • • Machine password: Required to view or change individual device settings 5.2 Pre-Operation Checks Perform the steps shown here before beginning operations: 1. -

Page 7: Powering Up The Motor Controls

Safety, Operation, & Maintenance Manual Pre-Operation Linear Cut Processing Systems 5.4 Powering Up the Motor Controls 5.5 Homing the Pusher 1. To begin homing, press the button shown below Note: If this button is flashing in color, this indicates homing is required and is the only option. 2. -

Page 8: Homing The Saw Angle

Safety, Operation, & Maintenance Manual Pre-Operation Linear Cut Processing Systems 5.6 Homing the Saw Angle Use the same process as Homing the Pusher, but from the Saw menu. 5.7 Preparing the Printer If the system is equipped with an inkjet printer, perform the following steps to maintain the best printing quality possible: 1. -

Page 9: Operation

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6 Operation 6.1 Navigating the Software 001128... -

Page 10: Customizing The Home Screen Panes

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.2 Customizing the Home Screen Panes Since there is no operator password for this software, any changes described here affect all operators. You can arrange your Home screen many different ways. Up to three different horizontal panels can be used to hold the many different panes. -

Page 11: Control Buttons Overview

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.3 Control Buttons Overview Standard Software Buttons Motor > Enable – Enables power to the motor system. • Motor > Power – Activates power to the motor system. • Escape > Halt – Stops the current command/process. •... - Page 12 Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems Optional Software Buttons (For Optional Equipment) Some buttons described here are only on machines built in 2022 or later (generation 2). Infeed Loader > Stop – Stops the infeed conveyor. •...

- Page 13 Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems Live Deck Buttons 001128...

-

Page 14: Manual Mode

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.4 Manual Mode Manual mode can be used for simple tasks such as making the pusher arm move to a given location or moving forward or reverse for a given distance. 6.4.1 Jog Pusher (Distance) The “Jog”... -

Page 15: Move Infeed Pusher (Position)

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.4.2 Move Infeed Pusher (Position) The Move function of Manual Mode can be used to move the infeed pusher to a specified position. The Move window will appear. Enter a distance, then select Go to execute and the pusher will move to the position entered. Example: •... -

Page 16: Cut-Set Mode (Optimizing) / Job Manager

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5 Cut-Set Mode (Optimizing) / Job Manager CutSet Mode is used for cutting entire lists of cut items from long stock lengths for optimal usage of material. This section describes how to use the many features for optimizing material and easily managing jobs. 6.5.1 Job Management Jobs are managed using the Job Manager window. -

Page 17: Starting A New Job / Batch

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5.2 Starting a New Job / Batch There are three methods available for starting a new cutting job: 1. Opening Files 2. Manually Entering 6.5.2.1 Opening Files To start a new cutting job by opening files, follow these steps, referring to the diagram below: 1. - Page 18 Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5.2.2 Manual Entry A manual cut list can be created as opposed to importing a job. Manual entry jobs allow the operator to build a custom cutting list. Because the manual entry job is internally created as a batch in the software, it will behave much like any other job, meaning it can be optimized, has print labels, etc.

-

Page 19: Selecting What To Cut

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5.3 Selecting What to Cut Once jobs have been created/loaded as explained in the previous steps, the operator can make selections to control what to cut at any given time. Example: A job contains all the parts of a house and has many different dimensional lumber in use. - Page 20 Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5.3.1 Selecting Stock Lengths Upon toggling any material type, a window will appear for selecting the stock length(s) to optimize cutting. Toggle on/off which stock lengths to use. The optimizer can utilize one or many different stock lengths. When multiple stock lengths are chosen, the optimizer will use all selected lengths and produce cut sets based upon whichever stock length would produce the least waste for each cut set created.

- Page 21 Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.5.3.2 Optimizing Material After all your selections have been made, press the Optimize button, and the cutting solution will appear in the “Cut Sets” panel. 001128...

- Page 22 Cut Set and shows an image of the printing that part will receive. 3. Complete/Incomplete— During normal operation the Hornet will automatically "complete" each cut set as it runs. On rare occasions, when a job fails to complete, use one of these methods to manually mark a set of cuts complete: Click the board image, and the Cut Part Details screen appears.

-

Page 23: Operating Procedure

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.6 Operating Procedure 6.6.1 Loading Boards on Infeed The saw is designed to cut boards stacked 2-high. This may be the top plate and bottom plate of the same wall panel, or it may be from different wall panels, depending on the optimization choices. -

Page 24: Cutting Procedure

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.6.2 Cutting Procedure After loading material onto the infeed, perform these steps. Steps are explained in more detail in the pages immediately following these steps. 1. Select the CUT SETS button from the software. 2. -

Page 25: Reading The Printed Data

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 5. All boards for the current Cut Set are cut, then the Cut Complete button appears. 6. Click Cut Complete, and the next Cut Set is loaded. 7. Once all Cut Sets are cut, select QUIT. 8. -

Page 26: System Settings

Safety, Operation, & Maintenance Manual Operation Linear Cut Processing Systems 6.8 System Settings 6.8.1 Accessing the Settings Windows Machine View Pane Most settings can be accessed by clicking the component in the Machine View pane. The Component Settings windows labeled in yellow require the machine password to access. •... -

Page 27: Replacing The Saw Blade

Safety, Operation, & Maintenance Manual Replacing the Saw Blade Linear Cut Processing Systems 7 Replacing the Saw Blade Supplies: • 3/8” 12-point socket Torque wrench driver • Frequency: Recommended once a week for 1-shift operations, but adjust as needed for your schedule and environment. -

Page 28: Preventive Maintenance

Safety, Operation, & Maintenance Manual Preventive Maintenance Linear Cut Processing Systems 8 Preventive Maintenance 8.1 Lubrication It is recommended to lubricate on the same schedule as your saw blade changes. 001128... -

Page 29: Belt Tensioning

Safety, Operation, & Maintenance Manual Preventive Maintenance Linear Cut Processing Systems 8.2 Belt Tensioning Two belts need to be tensioned occasionally: Saw motor belt • Saw arbor belt • Follow this graphic to tension the belt. 001128... -

Page 30: Printer

Safety, Operation, & Maintenance Manual Printer Linear Cut Processing Systems 9 Printer 9.1 Cleaning the Printer Perform these steps anytime the printer has had a break from printing for more than 30 minutes: 1. Lockout/tagout. 2. Observe these guidelines while following these steps: Press lightly (dab), no NOT wipe. -

Page 31: Ink Cartridges

Cartridges ordered from during the winter months must be shipped via air freight to ensure they are always kept above freezing temps. 9.2.2 Ordering Replacement Ink Cartridges To Order more ink, please call MiTek customer support at 800-523-3380. 001128... -

Page 32: Removing And Replacing Ink Cartridges

Safety, Operation, & Maintenance Manual Printer Linear Cut Processing Systems 9.2.3 Removing and Replacing Ink Cartridges • Always Power down the printer when changing the Print Cartridges. Use the C6 circuit breaker inside the electrical enclosure or lockout/tagout the entire saw. •... -

Page 33: Re-Using A Cartridge After An Operational Pause

Safety, Operation, & Maintenance Manual Printer Linear Cut Processing Systems 9.2.4 Re-Using a Cartridge After an Operational Pause 1. Once a cartridge has been used, follow these guidelines to improve its shelf life: o Unused for less than 1 day: Leave cartridges in machine and clean and purge before next use o Unused for more than 1 day: Remove cartridges from machine, clean as described in the cleaning section, and place in airtight container. -

Page 34: Troubleshooting

Safety, Operation, & Maintenance Manual Troubleshooting Linear Cut Processing Systems 10 Troubleshooting Problem Possible Causes Corrective Action “Go” button missing / not appearing 1. Emergency Stop Active 1. Check Emergency Stop(s) and/or after pressing “Load Set” or loading a CutBuilder Automation for cut set.

Need help?

Do you have a question about the Hornet and is the answer not in the manual?

Questions and answers