Summary of Contents for Contec DA12-16PCI

- Page 1 PC-HELPER Digital to Analog Output Board for PCI 16ch type DA12-16(PCI) 8ch type DA12-8(PCI) 4ch type DA12-4(PCI) User’s Guide CONTEC CO.,LTD.

-

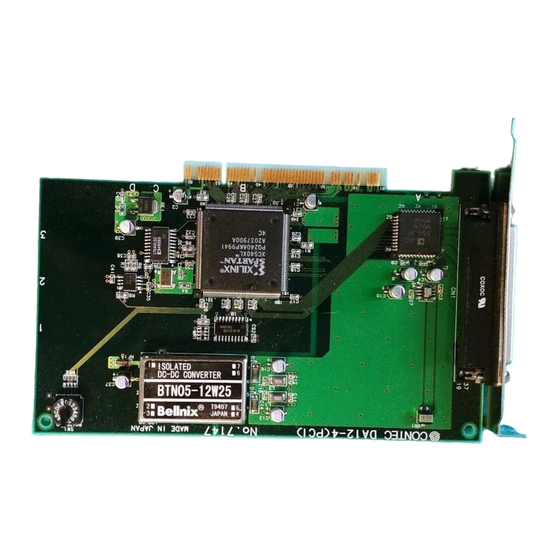

Page 2: Check Your Package

Check Your Package Thank you for purchasing the CONTEC product. The product consists of the items listed below. Check, with the following list, that your package is complete. If you discover damaged or missing items, contact your retailer. Product Configuration List - Board (One of the following) [DA12-16(PCI), DA12-8(PCI) or DA12-4(PCI)] …1... -

Page 3: Copyright

No part of this document may be copied or reproduced in any form by any means without prior written consent of CONTEC CO., LTD. CONTEC CO., LTD. makes no commitment to update or keep current the information contained in this document. The information in this document is subject to change without notice. -

Page 4: Table Of Contents

Table of Contents Check Your Package ............................ i Copyright ..............................ii Trademarks ..............................ii Table of Contents ............................iii BEFORE USING THE PRODUCT About the Board ............................1 Features ..............................1 Support Software..........................2 Cable & Connector (Option)......................3 Accessories (Option) ........................3 Customer Support ............................ - Page 5 Turning on the PC ..........................19 When Using API-AIO(WDM) ......................19 When Using API-AIO(98/PC) ......................20 Step 4 Initializing the Software........................ 24 When Using API-AIO(WDM) ......................24 When Using API-AIO(98/PC) ......................26 Step 5 Checking Operations with the Diagnosis Program..............27 What is the Diagnosis Program? ......................

- Page 6 Driver Software Install Procedure ....................63 Accessing the Help File ........................64 Using Sample Programs ........................64 Uninstalling the driver ........................64 ABOUT HARDWARE For detailed technical information ......................65 Hardware specification ..........................66 Block Diagram ............................67 Timing for Control Signal ........................68 Timing for External Sampling Clock Input Signal and “Settling Busy Output”......

- Page 7 DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 8: Before Using The Product

1. Before Using the Product 1. Before Using the Product About the Board These boards are PCI bus-compliant interface boards that performs digital-to-analog conversion. The < DA12-16(PCI) > performs D-A conversion using 16 output channels at a conversion speed of 10 µsec [100KSPS] and a resolution of 12bit. -

Page 9: Support Software

(DLL). Various sample programs such as Visual Basic and Visual C++, etc and diagnostic program *1useful for checking operation is provided. For more details on the supported OS, applicable language and new information, please visit the CONTEC’s Web site. Linux version of analog I/O driver... -

Page 10: Cable & Connector (Option)

Screw Terminal Unit (M3.5 x 37P) : EPD-37 *1 *1 PCB37P-* or PCB37PS-* optional cable is required separately. *2 "Spring-up" type terminal is used to prevent terminal screws from falling off. Check the CONTEC’s Web site for more information on these options. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 11: Customer Support

You can download updated driver software and differential files as well as sample programs available in several languages. Note! For product information Contact your retailer if you have any technical question about a CONTEC product or need its price, delivery time, or estimate information. Limited Three-Years Warranty CONTEC products are warranted by CONTEC CO., LTD. -

Page 12: Safety Precautions

1. Before Using the Product Safety Precautions Understand the following definitions and precautions to use the product safely. Safety Information This document provides safety information using the following symbols to prevent accidents resulting in injury or death and the destruction of equipment and resources. Understand the meanings of these labels to operate the equipment safely. -

Page 13: Handling Precautions

Even when using the product continuously, be sure to read the user’s guide and understand the contents. Do not modify the product. CONTEC will bear no responsibility for any problems, etc., resulting from modifying this product. Regardless of the foregoing statements, CONTEC is not liable for any damages whatsoever (including damages for loss of business profits) arising out of the use or inability to use this CONTEC product or the information contained herein. -

Page 14: Environment

1. Before Using the Product Environment Use this product in the following environment. If used in an unauthorized environment, the product may overheat, malfunction, or cause a failure. Operating temperature 0 - 50°C Operating humidity 10 - 90%RH (No condensation) Corrosive gases None Floating dust particles... - Page 15 1. Before Using the Product DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 16: Setup

2. Setup 2. Setup This chapter explains how to set up the board. What is Setup? Setup means a series of steps to take before the product can be used. Different steps are required for software and hardware. The setup procedure varies with the OS and software used. Using the Board under Windows Using the Driver Library API-PAC(W32) This section describes the setup procedure to be performed before you can start developing application... -

Page 17: Using The Board Under An Os Other Than Windows

2. Setup Using the Board under an OS Other than Windows For using the board under an OS other than Windows, see the following parts of this user’s guide. This chapter Step 2 Setting the Hardware Chapter 3 External Connection Chapter 6 About Hardware DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 18: Step 1 Installing The Software

2. Setup Step 1 Installing the Software This section describes how to install the Driver libraries. Before installing the hardware on your PC, install the Driver libraries from the bundled API-PAC(W32) CD-ROM. The following description assumes the operating system as Windows XP. Although some user interfaces are different depending on the OS used, the basic procedure is the same. -

Page 19: Starting The Install Program

2. Setup Starting the Install Program (1) Load the CD-ROM [API-PAC(W32)] on your PC. (2) The API-PAC(W32) Installer window appears automatically. If the panel does not appear, run (CD-ROM drive letter):\AUTORUN.exe. (3) Click on the [Install Development or Execution Environment] button. When using the Windows Vista, driver is automatically installed. -

Page 20: When Using Api-Aio(Wdm)

2. Setup When Using API-AIO(WDM) Selecting API-AIO(WDM) (1) The following dialog box appears to select “Driver to install” and “Install option”, “Usage of driver library”. (2) Select the "Advanced Analog I/O driver". (3) Click on the [Install] button. Clicking the [API-AIO] button under the “Detail” displays detailed information about API- AIO(WDM) and API-AIO(98/PC). -

Page 21: When Using Api-Aio(98/Pc)

2. Setup When Using API-AIO(98/PC) Selecting API-AIO(98/PC) (1) The following dialog box appears to select “Driver to install” and “Install option”, “Usage of driver library”. (2) Select “Classic Analog I/O driver”. (3) Click on the [Install] button. Clicking the [API-AIO] button under the “Detail” displays detailed information about API- AIO(WDM) and API-AIO(98/PC). - Page 22 2. Setup Executing the Installation (1) Follow the on-screen instructions to proceed to install. (2) When the required files have been copied, the “Perform a hardware setup now(API-TOOL Configuration)” and “Show readme file” check boxes are displayed. When you are installing the software or hardware for the first time: 1) Uncheck “Perform a hardware setup now”.

-

Page 23: Step 2 Setting The Hardware

2. Setup Step 2 Setting the Hardware This section describes how to set this product and plug it on your PC. This product has some switches and jumper to be preset. Check the on-board switches and jumpers before plugging this product into an expansion slot. This product can be set up even with the factory defaults untouched. -

Page 24: Setting The Board Id

2. Setup Setting the Board ID If you install two or more boards on one personal computer, assign a different ID value to each of the boards to distinguish them. The board IDs can be set from 0 to Fh to identify up to sixteen boards. If only one board is used, the original factory setting (Board ID = 0) should be used. -

Page 25: Plugging The Board

2. Setup Plugging the Board (1) Before plugging the board, shut down the system, unplug the power code of your PC. (2) Remove the cover from the PC so that the board can be mounted. (3) Plug the board into an expansion slot. (4) Attach the board bracket to the PC with a screw. -

Page 26: Step 3 Installing The Hardware

2. Setup Step 3 Installing the Hardware Windows needs to detect the I/O address and interrupt used by the board. This is called hardware installation. When using more than one board, install the boards one at a time and do not install the next board until setup is complete for the previous board. - Page 27 2. Setup (2) Specify that folder on the CD-ROM which contains the setup information (INF) file to register the board. * The name of the board you have just added is displayed. - DA12-16(PCI) - DA12-8(PCI) - DA12-4(PCI) Source folder The setup information (INF) file is contained in the following folder on the bundled CD-ROM.

-

Page 28: When Using Api-Aio(98/Pc)

2. Setup When Using API-AIO(98/PC) (1) The “Found New Hardware Wizard” will be started. Select “Install from a list or specific location[Advanced]”, then click on the [Next] button. If you are using Windows NT 4.0, the “Found New Hardware Wizard” is not started. Go to Step 4 “Initializing the Software”. - Page 29 2. Setup (2) Specify that folder on the CD-ROM which contains the setup information (INF) file to register the board. * The name of the board you have just added is displayed. - DA12-16(PCI) - DA12-8(PCI) - DA12-4(PCI) Source folder The setup information (INF) file is contained in the following folder on the bundled CD-ROM.

- Page 30 2. Setup CAUTION In Windows XP, the Hardware Wizard displays the following alert dialog box when you have located the INF file. This dialog box appears, only indicating that the relevant driver has not passed Windows Logo testing, and it can be ignored without developing any problem with the operation of the board.

-

Page 31: Step 4 Initializing The Software

- DA12-16(PCI) - DA12-8(PCI) - DA12-4(PCI) (2) The installed hardware appears under the CONTEC Devices node. Open the CONTEC Devices node and select the device you want to setup (the device name should appear highlighted). Click [Properties]. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) - Page 32 2. Setup (3) The property page for the device opens. Enter the device name in the common settings tab page and then click [OK]. The device name you set here is used later when programming. * The name of the board you have just added is displayed.

-

Page 33: When Using Api-Aio(98/Pc)

2. Setup When Using API-AIO(98/PC) Invoking API-TOOL Configuration (1) Open the Start Menu, then select “Programs” – “CONTEC API-PAC(W32)” – “API-TOOL Configuration”. (2) API-TOOL Configuration detects boards automatically. The detected boards are listed. Updating the Settings (1) Select “Save setting to registry…” from the “File” menu. -

Page 34: Step 5 Checking Operations With The Diagnosis Program

2. Setup Step 5 Checking Operations with the Diagnosis Program Use the diagnosis program to check that the board and driver software work normally, thereby you can confirm that they have been set up correctly. What is the Diagnosis Program? The diagnosis program diagnoses the states of the board and driver software. -

Page 35: Using The Diagnosis Program For Use Of Api-Aio(Wdm)

2. Setup Using the Diagnosis Program for Use of API-AIO(WDM) Starting the Diagnosis Program Click the [Diagnosis] button on the device property page to start the diagnosis program. * The name of the board you have just added is displayed. - DA12-16(PCI) - DA12-8(PCI) - DA12-4(PCI) - Page 36 2. Setup Analog output You can select the desired output channel, output range from the lists. You can also select the type of output data from among DC (constant voltage), SIN (sine wave), and Rect (rectangular wave). Diagnosis Report (1) The diagnosis report saves detailed data, including the device settings and settings for each channel, to a text file and displays the file for you to view.

-

Page 37: Using The Diagnosis Program For Use Of Api-Aio(98/Pc)

2. Setup (2) The diagnosis report contains the following data. Version of OS Device Information File Information Diagnosis results for each I/O channel Execution time measurement Clicking [Execution Time Measurement] runs the program to measure API function execution speed. The operation of this program is explained in "API function Execution Speed Measurement Program" in Chapter 5. - Page 38 The results are saved and displayed as a text file (AioRep.txt) in the install folder (CONTEC/CONTECW95). The Diagnosis Program performs “board presence/absence check”, “interrupt test”, “driver file test”, “board setting test”, and so on.

- Page 39 2. Setup (2) A diagnosis report is displayed as shown below. * The name of the board you have just added is displayed. - DA12-16(PCI) - DA12-8(PCI) - DA12-4(PCI) DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 40: Setup Troubleshooting

2. Setup Setup Troubleshooting Symptoms and Actions The board cannot be initialized. [Windows NT 4.0] The driver may not yet be activated. When your PC is running under Windows NT 4.0, set the PnP OS option in the BIOS Setup menu to “NO”. For details on BIOS settings, refer to the user’s guide for your PC. - Page 41 2. Setup DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 42: External Connection

3. External Connection 3. External Connection This chapter describes the interface connectors on the product and the external I/O circuits. Check the information available here when connecting an external device. How to connect the connectors Connector shape To connect an external device to this product, plug the cable from the device into the interface connector (CN1) shown below. -

Page 43: Connector Pin Assignment

3. External Connection Connector Pin Assignment Pin Assignment of DA12-16(PCI) CN1 Timer Output Settling Busy Output External Trigger Input Digital Ground External Sampling Clock Input Analog Ground Analog Output 15 Analog Ground Analog Output 7 Analog Ground Analog Output 14 Analog Ground Analog Output 6 Analog Ground... - Page 44 3. External Connection Pin Assignment of DA12-8(PCI) CN1 Timer Output Settling Busy Output External Trigger Input Digital Ground External Sampling Clock Input Analog Ground N.C. Analog Ground Analog Output 7 Analog Ground N.C. Analog Ground Analog Output 6 Analog Ground N.C.

- Page 45 3. External Connection Pin Assignment of DA12-4(PCI) CN1 Timer Output Settling Busy Output External Trigger Input Digital Ground External Sampling Clock Input Analog Ground N.C. Analog Ground N.C. Analog Ground N.C. Analog Ground N.C. Analog Ground N.C. Analog Ground N.C. Analog Ground N.C.

-

Page 46: Connecting The Analog Output Signal

3. External Connection Connecting the Analog Output Signal The sections below describe how to connect the signals using flat cable and shielded cable. The following figure shows an example of optional flat cable (PCA37P) connection. Connect the CN1 analog output channels and ground to the external device's input and ground. BOARD Cable Target... -

Page 47: Connecting The Control Signal

3. External Connection Connecting the Control Signal This section shows how to connect the control signal(“External Trigger Input”, “Settling Busy Output” and so on) by using a flat cable. All the control signals are TTL level signals. External Trigger Input 10kΩ... -

Page 48: Functions

4. Functions 4. Functions This chapter describes the different functions that can be implemented using the hardware and driver together. Unless stated otherwise, the driver is assumed to be API-AIO(WDM). Analog Output Function Analog output processes are classified as follows: Simple Analog Output High-functional analog output Simple Analog Output... - Page 49 4. Functions Simple analog output assumes the following conditions and settings. Resolution “Resolution” signifies the number of bits used by an analog output device to represent analog signals. The higher the resolution, the more finely the voltage range is segmented, allowing the device to convert to analog value more precisely.

- Page 50 4. Functions Output data The following equation represents the relationship between output data and voltage. Output data = ((voltage – Min. range value) x Resolution) ÷ (Max. range value – Min. range value) The value of resolution for the 12bit device is 4096; that for the 16bit device is 65536. The table below shows the relationship between output data and voltage in the ±10-V range.

-

Page 51: High-Functional Analog Output

4. Functions High-functional analog output When an analog output start command is executed by software, DA conversion is performed in synchronization with the sampling clock from when the sampling start condition is met to when the sampling stop condition is met. The analog output operation stops when the sampling stop condition is met. - Page 52 4. Functions Memory Output data can be stored in driver's memory in advance so that DA conversion can be executed repeatedly. You can select the memory type between FIFO and RING depending on the application of analog output. The memory type is selected with software. FIFO(First In First Out)format Use FIFO format if you wish to output a continuous arbitrary analog output like that shown below.

- Page 53 4. Functions Although the figure shows a single analog output channel, output from multiple channels is also possible. Sampling Start Condition The condition for controlling the start of sampling can be selected from both software and an external trigger. The conditions for controlling the start and stop of sampling are completely independent of each other;...

-

Page 54: Starting/Stopping Operation

4. Functions Repeat You can specify a repeat count to perform sampling for a specified number of times. Memory must be set to ring format if a number of repetitions is to be specified. (The number of repetitions cannot be specified for FIFO memory format.) The number of repetitions is set by software and sampling is repeated for the specified number of times. -

Page 55: Monitoring The Status

4. Functions Monitoring the Status You can use a software command to check the status of analog output operation and of the output data stored in memory. Status The current state of the device can be checked by obtaining the device status. The following types of device status are available: Analog output operating This status remains ON, after this product performs the analog output start command until the... -

Page 56: Reset

4. Functions Reset Various states can be reset by executing the following reset commands: All reset This command resets the entire device, thereby initializing the device. Status This command resets the sampling clock error status and AD conversion error status. Memory This command resets the following memory related states. - Page 57 4. Functions DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 58: About Software

5. About Software 5. About Software CD-ROM Directory Structure |– Autorun.exe Installer Main Window | Readmej.html Version information on each driver (Japanese) | Readmeu.html Version information on each driver (English) |–––APIPAC Each installer |––AIO |––DISK1 |––DISK2 |––…… |––DISKN |––AioWdm |––CNT |––DIO |––……... -

Page 59: About Software For Windows

5. About Software About Software for Windows The bundled CD-ROM “Driver library API-PAC(W32)” contains the functions that provide the following features: Analog input or output through arbitrary channels Analog input at arbitrary intervals using the internal or external sampling clock Simultaneous monitoring of the termination of analog input sampling, buffer memory usage, and interrupt events such as occurrences of errors Driver option check using a demo driver even without the board installed... -

Page 60: When Using The Api-Aio(Wdm)

When using the API-AIO(WDM) Accessing the Help File (1) Click on the [Start] button on the Windows taskbar. (2) From the Start Menu, select “Programs” – “CONTEC API-PAC(W32)” – “AIOWDM” – “API-AIO(WDM) HELP” to display help information. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 61: Using Sample Programs

The sample programs are stored in \Program Files\CONTEC\API-PAC(W32)\AIOWDM\Samples. Running a Sample Program (1) Click on the [Start] button on the Windows taskbar. (2) From the Start Menu, select “Programs” – “CONTEC API-PAC(W32)” – “AIOWDM” – “SAMPLE…”. (3) A sample program is invoked. - Page 62 5. About Software Sample Programs - Examples Analog input - SingleAi Perform single analog input from specified channel - MultiAi Perform single analog input from multiple channels - Ai Perform standard analog input using a FIFO buffer - AiPoll Perform standard analog input by polling - AiEx Perform analog input for multiple channels using a FIFO buffer - AiLong...

-

Page 63: When Using The Api-Aio(98/Pc)

When using the API-AIO(98/PC) Accessing the Help File (1) Click on the [Start] button on the Windows taskbar. (2) From the Start Menu, select “Programs” – “CONTEC API-PAC(W32)” – “Aio” – “API-AIO HELP” to display help information. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 64: Using Sample Programs

The sample programs are stored in \Program Files\CONTEC\API-PAC(W32)\Aio\Samples. Running a Sample Program (1) Click on the [Start] button on the Windows taskbar. (2) From the Start Menu, select “Programs” – “CONTEC API-PAC(W32)” – “Aio” – “SAMPLE…”. (3) A sample program is invoked. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) - Page 65 5. About Software Sample Programs - Examples Analog input - AI Uses AioInp to convert an analog signal only once and display the data. - AIBack Uses AioInpBack to perform memory-less board analog input. - AIMemory Uses AioInpBdMem to perform continuous conversion and AioReadBuf to acquire data from board memory (an example of using an external clock).

-

Page 66: Using The Utility Program

This program is a comprehensive operation check tool that can use all the features of the AioOpen, AioClose, AioSetRangeAioInp, AioInpBack, AioInpBdMem, AioOut, AioOutBack, AioDo, and AioDi functions. Invoke the tool by selecting the Start Menu – “CONTEC API-PAC(W32)” – “AIO” – “SAMPLE Analog”. [Main screen]... - Page 67 5. About Software [Analog output] [Digital input and output] DA12-16(PCI), DA12-8(PCI), DA12-4(PCI)

-

Page 68: Uninstalling The Driver Libraries

< Uninstall the device driver > Use [My Computer] - [Control Panel] - [Programs and Features] to uninstall the device driver. Select [Windows driver package - CONTEC (****)] and then click [Uninstall]. * "***" contains the driver category name (caio, ccnt, cdio, csmc, etc.). - Page 69 < Uninstall the development environment > Use [My Computer] - [Control Panel] - [Add or Remove Programs] to uninstall the development environment. Select [CONTEC API-***(WDM) VerX.XX (development environment)] and then click [Change/Remove]. * "***" contains the driver category name (AIO, CNT, DIO, SMC, etc.).

-

Page 70: About Software For Linux

# mount /dev/cdrom /mnt/cdrom Mount the CD-ROM. # cp /mnt/cdrom/linux/aio/caioXXX.tgz ./ Copy the compressed file. # tar xvfz caioXXX.tgz Decompress the compressed file....# cd contec/caio # make Compile the file....# make install Install....# cd config # ./config... -

Page 71: Accessing The Help File

Sample programs for each language are contained in the contec/caio/samples directory. For compiling them, refer to the manual for the desired language. Uninstalling the driver To uninstall the driver, use the uninstall shell script contained in the contec/caio directory. For details, check the contents of the script. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 72: About Hardware

This chapter provides hardware specifications and hardware-related supplementary information. For detailed technical information For further detailed technical information (“Technical Reference” including the information such as an I/O map, configuration register, etc.), visit the Contec's web site (http://www.contec.com/support/) to call for it. DA12-16(PCI), DA12-8(PCI), DA12-4(PCI) -

Page 73: Hardware Specification

6. About Hardware Hardware specification Table 6.1. Common specification DA12-16(PCI) DA12-8(PCI) DA12-4(PCI) Item Analog Output Non-isolated Isolated specification 16channel 8channel 4channel Number of output channels Output range Bipolar ±10V, ±5V, Unipolar 0 - +10V (Software setting by channel) Absolute max. output current ±5mA Output impedance 10Ω... -

Page 74: Block Diagram

6. About Hardware Board dimension 176.41(L) [mm] The standard outside dimension (L) is the distance from the end of the board to the outer surface of the slot cover. Block Diagram Figure 6.1 is a circuit block diagram of this product. External Sampling Clock Input External Trigger Input Analog Outputs... -

Page 75: Timing For Control Signal

6. About Hardware Timing for Control Signal Timing for External Sampling Clock Input Signal and “Settling Busy Output” Figures 6.2 and Table 6.2 shows the timing for external sampling clock input signal and “Settling Busy Output”. External sampling clock Input Settling Busy Output Figure 6.2. -

Page 76: About Calibration

6. About Hardware About Calibration This product is calibrated before shipment. Contact your retailer if the board does not provide its prescribed performance. Different in the specification The DA12-16(PCI), DA12-8(PCI), and DA12-4(PCI) are different in specifications, depending on the board number as listed below. Table 6.4. - Page 77 December 2017 Edition 3-9-31, Himesato, Nishiyodogawa-ku, Osaka 555-0025, Japan https://www.contec.com/ No part of this document may be copied or reproduced in any form by any means without prior written consent of CONTEC CO., LTD. [12252017] [09141999] Management No. A-46-070 [12252017_rev9] Parts No.

Need help?

Do you have a question about the DA12-16PCI and is the answer not in the manual?

Questions and answers