Siemens 6 Series Compact Operating Instructions

Continuous gas analysis

Hide thumbs

Also See for 6 Series:

- Compact operating instructions (37 pages) ,

- Operating instructions manual (74 pages) ,

- Installation and operating instructions manual (68 pages)

Table of Contents

Advertisement

Quick Links

Continuous gas analysis

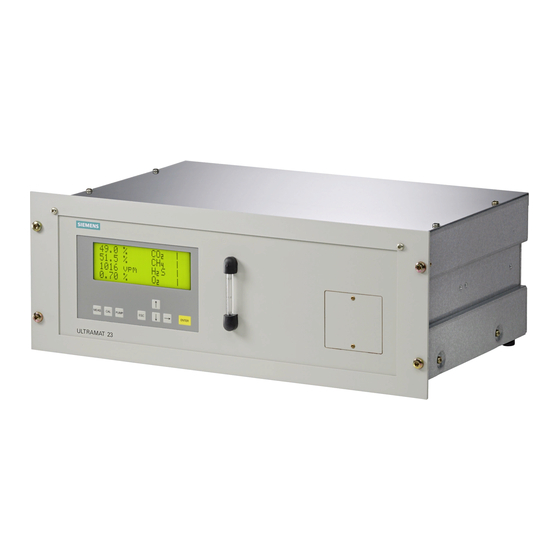

Gas analyzers series 6, ULTRAMAT

23, SIPROCESS GA700, SITRANS SL

and LDS 6

Safety instructions

Compact Operating Instructions

7MB2***, 7MB3***, 7MB6***, 7MB8***

09/2018

A5E45779403002-01

Introduction

General information

Application planning

Assembly/installation

Connecting

Commissioning, operation,

maintenance and servicing

Decommissioning and

disposal

1

2

3

4

5

6

7

Advertisement

Table of Contents

Summary of Contents for Siemens 6 Series

- Page 1 Introduction General information Application planning Continuous gas analysis Assembly/installation Gas analyzers series 6, ULTRAMAT 23, SIPROCESS GA700, SITRANS SL Connecting and LDS 6 Safety instructions Commissioning, operation, maintenance and servicing Compact Operating Instructions Decommissioning and disposal 7MB2***, 7MB3***, 7MB6***, 7MB8*** 09/2018 A5E45779403002-01...

- Page 2 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 3: Table Of Contents

Table of contents Introduction ............................5 Purpose of this document ....................5 General information ..........................7 Information on industrial use ....................7 Application planning ..........................9 Assembly/installation .......................... 11 Gas analyzers OXYMAT 6/OXYMAT 61/OXYMAT 7 ..............12 Laser gas analyzers SITRANS SL and LDS 6 ................12 Connecting ............................ - Page 4 Table of contents Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01...

-

Page 5: Introduction

Introduction Purpose of this document This document is a summary of instructions for safe handling of SIEMENS AG gas analyzers. These instructions are only applicable in conjunction with the relevant documents (operating instructions, device manual, operating instructions, compact operating instructions) of the... - Page 6 Introduction 1.1 Purpose of this document Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01...

-

Page 7: General Information

General information WARNING Improper device modifications Risk to personnel, system and environment can result from modifications to the device, particularly in hazardous areas. • Only carry out modifications that are described in the instructions for the device. Failure to observe this requirement cancels the manufacturer's warranty and the product approvals. Information on industrial use NOTICE Use in home environment... - Page 8 General information 2.1 Information on industrial use Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01...

-

Page 9: Application Planning

Application planning WARNING Risk of explosion due to improper use A device in the standard version must never be used in hazardous areas. Explosive gas mixtures (e.g. flammable gases together with air or oxygen in a potentially explosive ratio) must not be measured with this analyzer. If the sample gas could contain flammable components above the lower explosion limit (LEL), we recommend that you only use analyzers with piped gas paths. - Page 10 Application planning WARNING Harmful substances in the condensate The condensate at the sample gas cooler or condensation trap can be corrosive, depending on the composition of the sample gas (e.g.: through SO , NO, H S, HCl, etc.). When you dip litmus paper into the condensate it will turn red.

-

Page 11: Assembly/Installation

Assembly/installation CAUTION Device damage The device can overheat or materials become brittle through the influence of UV radiation. • Protect the device from direct sunlight. • Make sure that the maximum permissible ambient temperature is not exceeded. Read the information in the technical specifications of the respective manuals! NOTICE Incorrect installation The device can be damaged or destroyed or its functionality impaired through incorrect... -

Page 12: Gas Analyzers Oxymat 6/Oxymat 61/Oxymat 7

Assembly/installation 4.2 Laser gas analyzers SITRANS SL and LDS 6 Gas analyzers OXYMAT 6/OXYMAT 61/OXYMAT 7 NOTICE Magnetism Devices of type OXYMAT 6 or OXYMAT 61 or OXYMAT 7 emit magnetic stray fields. This is why reason magnetically sensitive devices should not be installed in the immediate vicinity of these devices. -

Page 13: Connecting

Connecting Electrical connections WARNING Missing PE/ground connection Risk of electric shock. Depending on the device version, connect the power supply as follows: • Power plug: Ensure that the used socket has a PE/ground conductor connection. Check that the PE/ground conductor connection of the socket and power plug match each other. •... -

Page 14: Gas Connections

Connecting 5.2 Gas connections NOTICE Incorrect supply voltage Device damage due to improper electrical connection. Before connecting the device, ensure that the mains voltage corresponds to the one on the type plate of the device! • Always lay the power cable separately from the signal cables! Note Mains disconnection device It must be ensured that there is an easily accessible mains isolating device in the immediate... -

Page 15: Commissioning, Operation, Maintenance And Servicing

Commissioning, operation, maintenance and servicing General information CAUTION Loss of degree of protection Damage to device if the enclosure is open or not properly closed. The type of protection specified on the nameplate is no longer guaranteed. • Make sure that the device is securely closed. WARNING Commissioning and operation with pending error If an error message appears, correct operation in the process is no longer guaranteed. - Page 16 WARNING Impermissible repair, maintenance and servicing of the device Repair and maintenance work may only be performed by personnel authorized by Siemens. WARNING Impermissible spare parts and accessories Damage to device and danger of explosion in hazardous areas! The use of inadmissible spare parts and accessories means that the device will no longer be safe to operate.

- Page 17 Commissioning, operation, maintenance and servicing 6.1 General information WARNING Hot, toxic or corrosive process media Risk of injury during maintenance work. When working on the process connection, hot, toxic or corrosive process media could be released. • As long as the device is under pressure, do not loosen process connections and do not remove any parts that are pressurized.

-

Page 18: Gas Analyzers Oxymat 6 And Oxymat 7

To reset the pressure switching point of the reference gas pressure switch • Contact the Service. • Have the pressure switching point of the reference gas pressure switch adjusted by a Siemens technician or someone trained for this scenario. ULTRAMAT 23 gas analyzer WARNING... -

Page 19: Laser Gas Analyzers Sitrans Sl And Lds 6

Commissioning, operation, maintenance and servicing 6.4 Laser gas analyzers SITRANS SL and LDS 6 CAUTION Danger to eyesight. This device emits UV radiation. • Never look directly into the light beam, otherwise there is a risk of injury to the eye, especially when using focusing devices (e.g. - Page 20 Always mount the purge device first before installing the sensors to prevent the optical components from being damaged during the rest of the mounting process. Use sensors equipped for this particular purge procedure for optimum results. These are available from Siemens. NOTICE Damage due to overpressure during sensor-side purge If the sensor purge lines are connected to the process purge lines, check valves may need to be used to ensure that process gas cannot enter the purge line if a purge gas supply fails.

-

Page 21: Decommissioning And Disposal

Decommissioning and disposal WARNING Incorrect disassembly The following risks may result from incorrect disassembly: - Injury through electric shock - Risk through emerging media when connected to the process - Risk of explosion in hazardous area In order to disassemble correctly, observe the following: •... - Page 22 Decommissioning and disposal Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01...

-

Page 23: Index

Index Disassembly, 21 Modifications correct usage, 7 improper, 7 Safety instructions General information, 9 Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01... - Page 24 Index Safety instructions Compact Operating Instructions, 09/2018, A5E45779403002-01...

Need help?

Do you have a question about the 6 Series and is the answer not in the manual?

Questions and answers