Summary of Contents for Vag EKN H-Series

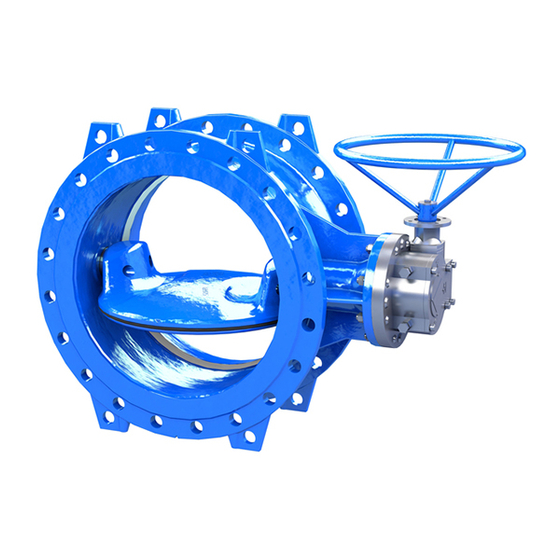

- Page 1 Operation and Maintenance Instructions ® VAG EKN Butterfly Valve H, M and B-Series KAT 1310-B Edition 6_21-03-17...

-

Page 2: Table Of Contents

7.3 Maintenance work and replacement of parts 7.3.1 Design 7.3.2 Recommendations for the replacement VAG reserves the right to make technical changes and use mate- of parts rials of similar or better quality without express notice. The pictu- res are non-binding. -

Page 3: General

• These Operating and Maintenance Instructions apply to all ty- Arbitrary alterations of this product and the parts supplied with it pes of the VAG EKN® Butterfly Valve including all material and are not allowed. VAG will not assume any liability for consequen- coating varieties tial damage due to non-compliance with these instructions.When... -

Page 4: Storage

® Butterfly Valves sized DN 900 and larger are pro- vided with suspension bores located above the flange. As shown in Picture 3, they can be used to lift the VAG EKN ® Butterfly Valve. For valves that have been factory-packed in transport crates (wooden crates), the centre of gravity of the entire unit must be taken into account. -

Page 5: Applications

If in doubt, consult the manufacturer to inquire about the appropriate sealing materials for your application. According to EN 593 Table 3, VAG EKN ® Butterfly Valves are de- signed/sized for the following velocities in liquid media: 3.3 Performance limits... -

Page 6: Permissible And Impermissible Modes Of Operation

Example of a limit curve of the VAG EKN ® Butterfly Valve At a pressure of 5 bars and a flow velocity of 8 m/s, the hydraulic moment of the flow around the disk is so high that a PN 16 VAG EKN®... -

Page 7: Special Type With Uvv Safety Interlock

/ pressure side secured side / pressure side Double-sided Fixed stop lock fixed stop (≥DN800) side facing away from the shaft side facing the shaft Movable bolt Fioxed stop VAG Operation and Maintenance Instructions • 7... -

Page 8: Installation Into The Pipeline

• If the valve is used in contaminated media, a filter with a suita- ble mesh size must be provided upstream of the valve in order to prevent malfunction. VAG Operation and Maintenance Instructions • 8... - Page 9 Butterfly Valve an inspection valve, an elbow, T- pieces and Y-filters should be provided as otherwise irregular- • A damping zone between the branch/elbow and the valve is flow may disturb the proper function of the VAG EKN ® Butterfly ideal.

-

Page 10: Gear Positions

Picture 11: Vertical installation of the VAG EKN ® Butterfly Valve • C: Flow on the side away from the shaft, seat surface on the 4.2.2 Gear positions... -

Page 11: Installation Position

(with the gear facing up or down) in the pipelines. In case of valves with larger nominal diameters, a special design of the valve must be selected due to the load of the disk. Please consult VAG before placing your order. permissible... -

Page 12: Assembly Instructions And Fittings

VAG does not as- sume any liability for consequential damage caused by dirt, shot-blasting gravel residues etc. -

Page 13: Actuators

Section 1.1 needs to be observed and the external nue operation very carefully, never use excessive force and repeat source of energy must be switched off and isolated. washing, if necessary. Picture 14: Gearbox markings VAG Operation and Maintenance Instructions • 13... -

Page 14: Assembly Of The Electric Actuator

Couplings and connections must never be disassembled when they are under pressure. To butterfly valves equipped with a VAG HYsec hydraulic brake- and-lift unit, the order-related operating instructions apply in each Servicing, maintenance and inspection work as well as the repla- case (see KAT-B-5512). - Page 15 Bearing bush zinkfreie Bronze Spacer bush 1.4301 Hexagonal A4-70 screw Threaded pin A4-70 EPDM oder O-Ring EPDM oder O-Ring EPDM oder O-Ring Adjustment C 45 K spring Picture 17: Serie H Design and sub-assemblies VAG Operation and Maintenance Instructions • 15...

-

Page 16: Replacement Of The Profile Seal

• Turn the butterfly valve (2) into closed position • Unfasten the hexagonal nuts at the gear flange and pull the gear off the shaft (7) • Loosen the threaded pin and pull off the coupling. Pull the ad- VAG Operation and Maintenance Instructions • 16... -

Page 17: Tightening Torques For Screws

M 12 4 Nm 8 Nm 15 Nm 28 Nm Table 2: Tightening torques of bearing flange / fixing screws Picture 22: Replacement of O-ring - Step 5 Picture 24: Anzugsmomente Lagerflansch / Fixierschrauben VAG Operation and Maintenance Instructions • 17... - Page 18 Seat of the valve polluted by Flush valve, dismantle, if necessary, and clean seat area deposits High operating forces Valve is dry in pipeline, no medi- Valve can be operated more easily when wet um present VAG Operation and Maintenance Instructions • 18...

- Page 19 Phone: +49 (621) 749-0 Fax: +49 (621) 749-2153 info@vag-group.com http://www.vag-group.com Service Our service hotline can be reached 24/7 world-wide. In case of emergency, please contact us by phone. Service hotline: +49 621 - 749 2222 Service per email: service@vag-group.com www.vag-group.com info@vag-group.com...

Need help?

Do you have a question about the EKN H-Series and is the answer not in the manual?

Questions and answers