Subscribe to Our Youtube Channel

Summary of Contents for Axis 4BA SERIES

- Page 1 USER MANUAL 4BA(N), 4BANA(N), 4BAF(N) , 4BAPZ(N) and 4BAPA(N) SERIES File: 2016-04-19 4BAxx bE0109 GB...

-

Page 2: Table Of Contents

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Table of contents: General description ............................4 Certificates: ..............................4 Meters ................................5 Completation ..............................7 Technical data ..............................7 Security rules ..............................10 Scale external outputs............................ 11 Connecting a computer, printer or label printer ....................13 Detailed LonG protocol description ........................ - Page 3 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.5 Weighing animals function (LOC) ......................54 18.6 Maximum value indication function (UP) ....................55 18.7 Force measuring function (nEWton) ......................56 18.8 Total weight function (totAL) ........................57 18.9 Checkweighing function (thr)........................59 18.10 Setting date and time function (dAtE) ......................62 18.11 Radio communication channel choice function (rF CHn) ................

-

Page 4: General Description

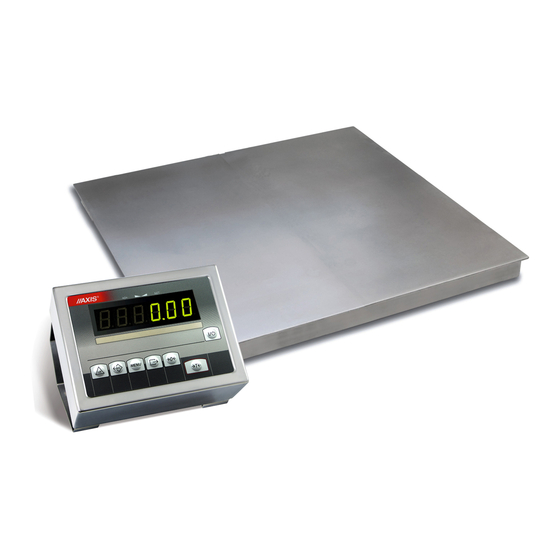

_____________________________________________________________________________________________________________________ 1. General description This manual describes scales produces by AXIS Sp. z o.o. and their basic functions. Standard execution scales are equipped with ME-01/A/LED meter and stainless steel scales with ME-01/N/LED. In case of using these meters or special meter for eg. batching meter it is essential to use proper user manual for individual meter type. -

Page 5: Meters

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 3. Meters Depending on scale’s application it can be equipped with following meter: ME-01/A/18 (LED) Standard universal ME-01 meter in aluminium (A) housing and LED display (18mm digits height). Full set of special functions (chapter 15) and standard set of keys. - Page 6 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ ME-11/N/LCD (surcharge) – meter with numerical keyboard designed to operate special functions that need inscribing data (e.g. product code, unitary mass), stainless steel housing. ME-02/N/LCD (surcharge) – designed for one-ingredient or multi- ingredient batching, numerical keys, stainless steel housing. SE-03/N/LCD (surcharge) –...

-

Page 7: Completation

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 4. Completation Basic set includes: 1. The scale 2. RS232C connector (only 4BA/N, 4BA/FN, 4BA/PAN, 4BA/PZN scales) 3. CD with user manuals 4. Warranty 5. Technical data Platform scales 4BA and 4BA/N Scale type 4BA300(N) 4BA600(N) 4BA1500(N) 4BA2000(N) 4BA3000(N) 4BA6000(N) - Page 8 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Overrun scales 4BA/NA and 4BA/NAN: Scale type 4BA300NA 4BA600NA 4BA1000NA 4BA1500NA 4BA2000NA Maximum load (Max) 300kg 600kg 1000kg 1500kg 2000kg Reading graduation (d) 100g 200g 500g 500g Verification graduation (e) 100g 200g 500g 500g Minimum load (Min) 10kg 10kg 20kg...

- Page 9 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Skid scales 4BA/PZ and 4BA/PZN: Scale type 4BA300 4BA600 4BA1000 4BA1500 4BA2000 4BA3000 PZ(N) PZ(N) P(N) PZ(N) PZ (N) PZ(N) Maximum load (Max) 300kg 600kg 1000kg 1500kg 2000kg 3000kg Reading graduation (d) 0,1kg 0,2kg 0,5kg 0,5kg Verification graduation (e) 0,1kg 0,2kg 0,5kg...

-

Page 10: Security Rules

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 6. Security rules To avoid electrical shock or damage of the scale or connected peripheral devices, it is necessary to follow the security rules below. To supply scale use socket with safety contact (scales with feeder exluded). ... -

Page 11: Scale External Outputs

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 7. Scale external outputs ME-01 meter in aluminium housing: RS232C RxD (receive) Feeder Extensometer RS232C WY TxD (transmission) mass housing 12V 1,2A WY (option) P1 (threshold I) P2 (threshold 2) P3 (threshold ) housing ground... - Page 12 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ ME-01 meter in stainless steel housing: RS232C housing Feeder Extensometer RS232C Power unit 12V Ground Separate ground connection (scales in stainless steel version) must be connected using additional conductor. Extensometers are connected permanently.

-

Page 13: Connecting A Computer, Printer Or Label Printer

If the scale is equipped with two serial joints (interfaces) Print and SErIAL function is set independently for both interfaces. If scale cooperates with a computer then the computer must have a special program. Dedicated programs are also offered by AXIS. Needed drivers and instructions can be found on the CD supplied with Axis scales. -

Page 14: Detailed Long Protocol Description

02h scale number command. To log the scale out use 03h command. For example: Using a program to test RS232 interface ( program is available in www.axis.pl / programy komputerowe ) for scale number 1 please write: $0201 to log in, then SI, and write: $03 to close communication. - Page 15 KomputerWaga: SM D1...DN CR LF (53h 4Dh D1...DN 0Dh 0Ah), gdzie: D1...DN – threshold value, maximum 8 characters WagaKomputer: without response. Connecting cable WK-1 (scale – computer / 9-pin interface): SCALE COMPUTER Connection cable WD-1 (connects scale with AXIS printer): KAFKA SCALE PRINTER...

-

Page 16: Detailed Epl Protocol Description

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Setting of internal switches of AXIS printer: SW-1 SW-2 SW-3 SW-4 SW-5 SW-6 SW-7 SW-8 Detailed EPL protocol description Transmission parameters: 8 bits, 1 stop bit, no parity, baud rate 9600bps, After using key in scale: ... -

Page 17: Balance Preparation To Work

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 8. Balance preparation to work Preparing platform, pallet and skid scales 1. Unpack balance, remove protective foils. 2. Place balance on flat, horizontal foundation, in place not subjected to mechanical vibrations and strong air movements. 3. Air bubble in level should be located in the middle position. Good Attach meter to the wall, desktop or tripod (option), choosing one of three methods 5. -

Page 18: Preparing Overrun Scales

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Preparing overrun scales 1. Unpack balance, removing protective foils. 2. Place balance on flat, horizontal foundation, in place not subjected to mechanical vibrations and strong air movements. Take care if the scale stays on all four legs. 3. -

Page 19: Preparing Foundation Scales

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 8.3 Preparing foundation scales 8.3.1 Preparing foundation CAUTION! Decision of substrate reinforcing and density is taken by building works designer. All dimensions are in millimetres. During foundation preparation follow the principles below: 1. Foundation and feet under balance legs should be made from concrete. Foundation bottom thickness should not be smaller than 100 mm. - Page 20 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Foundation frame with anchors Rama fundamentu z kotwami Stopy pod nóżki wagi Feet under balance legs Rura z PCV PCV pipe for cable na przewód Kolektor do odprowadzenia wody Water collector Fig.1 Foundation – crosssection Places for frame anchors Miejsca na kotwy ramy Obszar wolny Area...

-

Page 21: Scale Installation

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 8.3.2 Scale installation . Balance structure 2. Screws fixing the limiter 3. Screws fixing base plates 4. Limiter 5. Base plate 6. Foundation 7. Balance leg Prepare the foundation (7) according to guidelines (section 6) and engineering technique principles. Put the balances base plates (5) freely in the foundation. -

Page 22: Balance Test

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 15. Unpack the balance. Attach meter to the wall or desktop, choosing one of three methods. 16. Connect the supply cable plug to socket with protective contact with unloaded balance, which will cause autotests performing and after indication stabilization displaying of sero indication 9. -

Page 23: Accumulator Change (Me-01 Option)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 10. Accumulator change (ME-01 option) 1. Remove screws 11 holding plate 12, remove the plate. Take container with accumulators 13 and place 4 AA Extensometer Tensometr RS232C WY format accumulators. The way of packing accumulators into container is shown on the figure on the left and is also shown on the container. -

Page 24: Scale With Me-01 Meter Keys And Indicators

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 11. Scale with ME-01 meter keys and indicators LCD display version: zero stabilization weighing metrological net weight result indicator indicator indicator data Max= indicator scale keys Keys: switch-on / switch-off (standby), " tare (subtract package weight from weighed mass), ... - Page 25 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ LED display version: weight zero stabilization net weight metrological result indicator indicator indicator data Max= scale keys klawisz switch-on / switch-off (standby), " tare (subtract package weight from weighed mass), " zeroing (when the platform is empty), "...

-

Page 26: Operation Principles

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Operation principles 1. Before each measurement the balance should be properly zeroed, which is signalled by “” indicator. If the zero indication is not shown when the balance is unloaded, or "----" is displayed, press the " "... -

Page 27: Start-Up

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Start-up Leave the pan empty, plug a scale to the mains with a ground contact The scale proceeds with following start-up actions: Display test Meter type displaying Program version The scale is now ready to work. Attention: Displaying program version means positive result of all tests. -

Page 28: Weighing With Tare

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Weighing with tare If the scale is not loaded and indicator doesn’t indicate, press key. Zero indication and indicator mean that the scale is ready to work. After putting container (package) tare the scale ... -

Page 29: Scale Menu

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Scale menu All scales except for basic metrological functions: weighing and taring, have many special functions and configuration options. In order to ease using functions user can create his own (personalized) menu. Creating personalized menu: In „out of the box” scale after pressing MENU key only SEtuP option (it contains all configuration options) is available. -

Page 30: Menu Navigation Rules

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Menu navigation rules Choosing menu options: First position of scale menu shows up after pressing Menu key. The position is displayed for about 7 seconds and then the scale sequentially displays next menu positions. Choosing menu position (option) is done by ... - Page 31 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ key working method: During standard weighing key is used to switch between net and gross indication. When special function e.g. PCS is turned on, using key enables to go back to standard weighing mode. Sign „o”...

- Page 32 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ HR key working method: During normal weighing temporary (5s) readout resolution increase is possible. Return normal indication made automatically. Inscribing numerical values: Inscribing numerical values is needed in some special functions e.g. tArE function requires to inscribe tare values. Keys: 0...

- Page 33 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Menu diagram: MENU (PCS) (totAL) - personalized function menu created using SEtUP / MEnu - settings SEtUP - creating menu (” “- added to menu) MEnu - choosing product Prod ( ) o ( ) o - choosing user USEr - pieces counting function - actual unit selection...

- Page 34 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ - serial ports settings settings SErIAL - port - 1 Port-1 - transmission speed (1200, ... ,115 200 bps) bAUd - bits quantity (7 or 8) bItS - parity control PArItY - transmission type (Stab, no StAb, Auto,Cont.,rEMoVE) SEndInG - protocol (LonG, EPL, EPL_A, EPL-d, PEn-01) Prot...

- Page 35 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ - turn on/off accumulator charging (if the scale is equipped with accumulator) (bAttEry) - automatic turning off - saving accumulator power (as above) (AUto OFF) - scale start zero inscribing (factory zero) (ZEro) - restore default settings for all options dEFAULt - options only for service SErVICE...

-

Page 36: Scale Setup (Setup)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Scale setup (SEtUP) SEtUP contains all options used for setting scale work mode: MEnu – creating personalized user menu CALIb – scale sensitivity calibration AutoZEro(ing) – self-maintaining zero indication (unloaded scale) UnIt – weight unit selection ... -

Page 37: Scale Calibration (Calib)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.1 Scale calibration (CALIb) Press MENU key. Press key when CALIb function appears. The following options will be displayed: -CAL on – calibration with external recommended standard of mass (see technical data). -CAL StP – calibration with external weight, confirmation of succesive steps - MENU key, out –... -

Page 38: Autozeroing Function (Autozer)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.2 Autozeroing function (AutoZEr) When the function is activated, the scale automatically ensures stable zero indication if the pan is empty or if zero indication was acquired by pressing key. To turn on the function use MENU key and using ... -

Page 39: Weight Unit Selection (Unit)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.3 Weight unit selection (UnIt) The function allows selecting weighing unit: - CarAt (1 ct= 0,2 g) - carat, - MGrAM (1mg=0,001g) milligram, - KGrAM (1kg=1000g) kilogram, - Pound (1 lb=453,592374g) English pound, - OunCE (1oz=28,349523g) - ounce, - OunCEt(1ozt=31,1034763g) pharmaceutical ounce, - GrAIn (1gr=0,06479891g) - grain - PennYW (1dwt=1,55517384g) jewellery mass unit,... -

Page 40: Serial Port Parameters Setting (Serial)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.4 Serial port parameters setting (SErIAL) function allows setting independently communication parameters of both of serial ports Port-1 and Port-2 (executed in RS232C, RS485, USB or LAN standard): - transfer protocol (Prot): LonG – cooperation with printer or computer, EPL –... -

Page 41: Printout Configuration (Print)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.5 Printout configuration (PrInt) Function is used for printing additional information stored in scale memory, weighed product identification data and scale operator id. That information is inscribed using scale keys or scanner. After entering selected port (scale can have two ports) user may activate printout positions: - HEAdEr –... - Page 42 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Sample printout during normal weighing (all printout positions deactivated): 20.07 kg 20.04 kg 20.04 kg Sample printout during normal weighing with clock option (all printout positions deactivated): 20.07 kg 2012-11-08 10:01 20.04 kg 2012-11-08 10:01 20.04 kg 2012-11-08 10:01 Sample printout during normal weighing ( some printout positions activated): BA30 MAX: 30kg e=d=0.01kg...

-

Page 43: Setting Backlight Function (B_Light)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.6 Setting backlight function (b_LIGHt) The function is used for choosing the work mode of scale display backlight: - b_L OFF – switch backlight off, - b_L on – switch backlight permanently on, - b_L ECO – switch off after 30 seconds of inactivity (no load changes and no key operation), - b_L bAt –... -

Page 44: Analog Out Configuration (Analog)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.7 Analog out configuration (AnALoG) This option enables to set-up analog out (4-20mA or 0-10V) working method used e.g. in PLC regulators: AnG rnG – inscribing Max value AnG CFG – working mode configuration (PLUS – workmode for only positive values, MinuS – only for negative values, both –... -

Page 45: Entering Reference Zero Value (Zero)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 17.8 Entering reference zero value (ZErO) Note: This function is enabled in non-legalized scales only. ZEr0 function allows entering new value of reference zero (value referred to empty pan) without need of contacting with authorised service centre. Press MENU key. -

Page 46: Special Functions Description

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Special functions description All scales besides basic metrological functions: weighing and taring, have a set of special functions. Depending on meter type functions set differs. Below a list of functions available in standard ME-01 type meters: Products data base (Prod), ... -

Page 47: Products And Users Database (Prod I User)

This way created database, saved in *.csv extension with semicolons can be send to scale using Scale Database software and scale’s serial interface. Scale Database is available on our webpage www.axis.pl/en. Database and possibility to cooperate with external devices: printer, label printer, barcode reader and computer enables to built product identification and product archiving systems. - Page 48 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Inscribing data to base Prod and USEr options enables adding and deleting product and user data. For products database available options are: - Prod Id – searching for product in database by inscribing (or scanning) id number or barcode, - ProdCLr (shows up if product was selected earlier) –...

- Page 49 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Users database is edited by similar function named USEr and consists of several options: - USEr Id – user identification number, - USErCLr (shows up if user was selected earlier) – turns off actual user selection, - USEr nA – user name (inscribed from PC or scanner), - Prn_U –...

- Page 50 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Weighing results and data transmission from scale to computer or to printer To fully use database capabilities other options must also be used: SeriaL, LabeL (for label printer) and Print. Serial option enables to select proper transmission protocol for each port. Thereby label printer can work independently.

-

Page 51: Pieces Counting Function (Pcs)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.2 Pieces counting function (PCS) This function enables to count identical pieces, e.g. turnbuckles or buttons. A measurement is performed in two phases: - first phase - single piece weight calculation on the basis of defined pieces amount (5, 10, 20, 50, 100, 200 or 500 pieces), - second phase –... -

Page 52: Percentage Weighing Function (Perc)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.3 Percentage weighing function (PErC) 100% This function allows displaying weighing result in percents. A measurement is performed in two phases: - first phase – weighing a reference sample (100%), - second phase – measuring specific sample as a percentage of the reference sample. -

Page 53: Label Choosing Function (Label)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.4 Label choosing function (LAbEL) This function is used in scales with EPL (SErIAL function) data protocol. This protocol enables label printout with actual scale indication and chosen data from PrInt special function (variable data), for example date and time. Other data, for example company address, product name, barcode can appear on label as a constant text. -

Page 54: Weighing Animals Function (Loc)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.5 Weighing animals function (LOC) The function allows weighing animal moving on the scale. Press MENU key. When LOC function is displayed press key. following options appear display successively: - LOC oFF – leave the function, - LOC on –... -

Page 55: Maximum Value Indication Function (Up)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.6 Maximum value indication function (UP) This function allows holding maximum (or minimum) value that is indicating at the moment. Before measurement scale should be tared. Function has following options: -UP oFF – function off, -HIGH – holding maximum value, -LOW –... -

Page 56: Force Measuring Function (Newton)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.7 Force measuring function (nEWton) Function activation causes displaying result in force units (N). Press MENU key. Using key choose NEWto function. Function has several options: - nEW oFF – function off, - nEW on – measurement in Newtons, - ArM –... -

Page 57: Total Weight Function (Total)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.8 Total weight function (totAL) The function allows calculating total weight for series of measurements, which can be greater than scale capacity. It allows calculating total weight as well as average value. Press MENU key. When totAL is displayed press key. - Page 58 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ To leave the function with clearing total register, select totAL function from menu and choose tot oFF option. Scale prints the communicate informing about clearing registers. The form of standard receipt (measurement number and weight) after each measurement: Print configuration option (chapter 17.5) enables to extend standard receipt form.

-

Page 59: Checkweighing Function (Thr)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.9 Checkweighing function (thr) This function allows comparing weighing result with two programmed reference values: lower and upper threshold. Comparison result is signalled with indicators (MIN, OK, MAX) and sound signal generated when threshold values are exceeded. If comparison result is: - smaller than zero threshold –... - Page 60 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Operation sequence: Press MENU key and choose thr pressing key. The following options are displayed successively: - thr oFF – deactivate the function, - thr on – activate the function, - thr Prn – check last threshold values (press key several times), - thr CFG –...

- Page 61 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Relays connection diagram: Imax < 25mA Relays output is the open collector transoptor output with load capacity 25mA / 24V. Transmitter inputs must be protected with diodes, e.g. 1N4148. It is advised to use MS3K/P electronic board (sold separately), consisting of RM96P transmitters, with DC24V input voltage and AC250V, 3A output.

-

Page 62: Setting Date And Time Function (Date)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.10 Setting date and time function (dAtE) The function allows setting current date and time of scale internal clock and mode of its use. The function has the following options: - dAt oFF – deactivate date and time during printout of current weighing result, - dAt on –... -

Page 63: Radio Communication Channel Choice Function (Rf Chn)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.11 Radio communication channel choice function (rF CHn) Function enables choosing radio communication channel between the scale and a pilot. In scale and in pilot the same radio channels must be chosen. Function should be used when communication is disturbed by other devices that use the same communication channel. -

Page 64: Charging Accumulators Function (Battery)- Option

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.12 Charging accumulators function (bAttErY)- option bAttErY function allows switching on or off charging accumulators during work with feeder and checking their power level. The function has the following options: - bAt OFF – charging off (option required if ordinary batteries are used !!!), - bAt on –... -

Page 65: Automatic Switching Off The Scale Function (Autooff)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.13 Automatic switching off the scale function (AutoOFF) The function is helpful in scales supplied from accumulators. The function causes scale to switch off automatically. Press MENU key. When AutoOFF is displayed press key. The following options appear successively on display: - AOF oFF –... -

Page 66: Statistical Calculations Function (Stat)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.14 Statistical calculations function (StAt) This function evaluates from series of measurements (max 1000) statistical parameters of weighting process. Adding successively measurements to register is automatic and it occur after the scale is loaded and its indications stabilize. After each loading printout is made with: number of measurements, result, date and time (if clock is installed and the function is activated). - Page 67 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Order of operations: Press MENU key. When StAt is displayed press key. The following options are displayed: - StA Prn – monitoring and printout of statistical data, - StA oFF – deactivate function, - StA –...

- Page 68 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Pressing key printouts estimated values and histogram : Nominal - nominal value, Tolerance - accepted value in percentage. N - number of sample IN TOL. – number of samples in tolerance -TOL – amount of measurements under allowable lower value +TOL –...

-

Page 69: Paperweight Calculation (Pap)

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ 18.15 Paperweight calculation (PAP) This function enables to calculate paperweight of 1m of paper basing on samples of known area. For quick access, the function is accessible directly by pressing MENU key. The balance must be tared just before the measurement. -

Page 70: Maintenance And Repairs Of Small Defects

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Maintenance and repairs of small defects 1. The scale should be kept clean. 2. Take care that no dirt gets between the platform and the scale base. If found any, remove the pan (lift it up), remove dirt and then replace the pan. 3. -

Page 71: Declaration Of Conformity

INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Declaration of Conformity AXIS Spółka z o.o. 80-125 Gdańsk, ul. Kartuska 375B confirm with all responsibility that scales: 4BA300, 4BA600, 4BA1500, 4BA2000, 4BA3000 i 4BA6000 4BA300N, 4BA600N, 4BA1500N, 4BA2000N, 4BA3000N and 4BA6000N 4BA300NA, 4BA600NA, 4BA1000NA, 4BA1500NA i 4BA2000NA... - Page 72 Conformity evaluation for the Directive 2006/95/WE and 2004/108/WE was carried out by Research Laboratory of Electrotechnology Institute Division Gdańsk, accredited by PCA, Conformity T7950R0 evaluation was carried out by NMI Certin B.V. (Notified Body No. 0122). Per pro Director of AXIS Sp. z o.o.: ________________ Date: 30-10-2015 Jan Kończak...

- Page 73 INSTRUCTION MANUAL _____________________________________________________________________________________________________________________ Appendix A Information’s concerning double-range scale (options) 1. General description Double-range scale’s have capability of work with greatest accuracy in bottom measuring range part. Weighing of smallest mass is more precise. This type of scale’s have two measurement range: 55.

Need help?

Do you have a question about the 4BA SERIES and is the answer not in the manual?

Questions and answers