Snapmaker A250 Quick Start Manual

Rotary module

Hide thumbs

Also See for A250:

- Quick start manual (54 pages) ,

- User manual (178 pages) ,

- Quick start manual (29 pages)

Advertisement

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Snapmaker A250

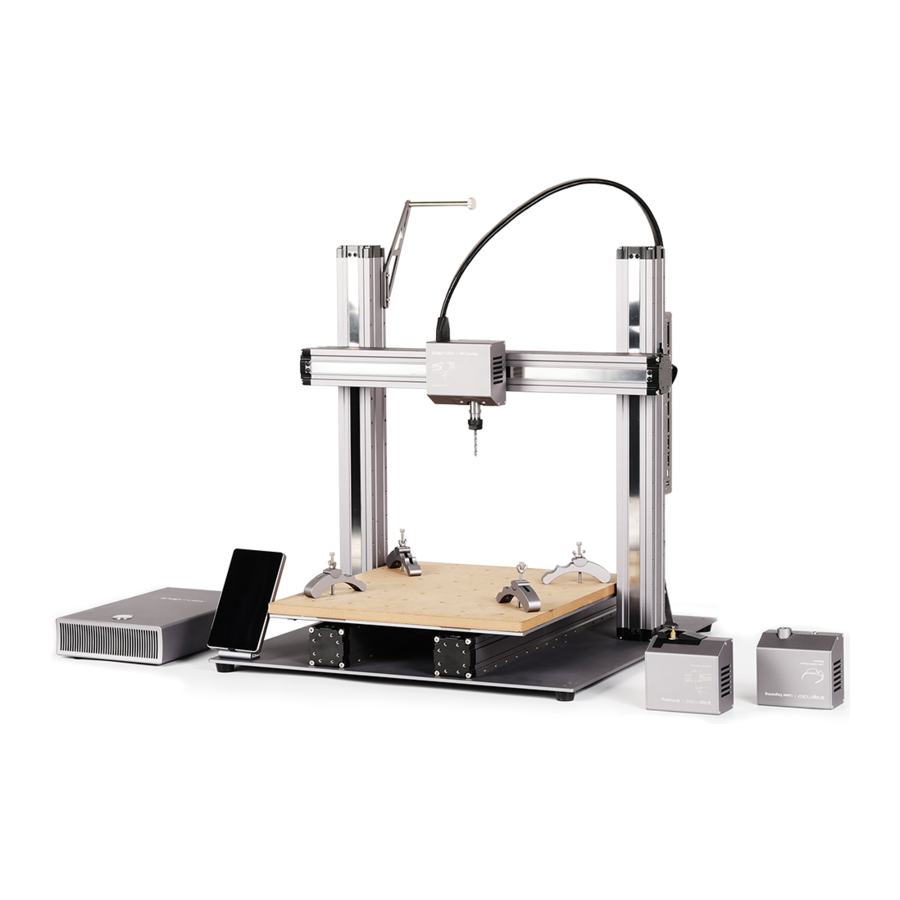

- Page 1 Rotary Module QUICK START GUIDE A250 & A350 MAKE SOMETHING WONDERFUL...

-

Page 2: Table Of Contents

CONTENTS Before You Start Machine Assembly CNC Carving Laser Engraving and Cutting Troubleshooting... -

Page 3: Before You Start

BEFORE START... - Page 4 © 2021 Snapmaker. All rights reserved. This language version of the guide is verified by the manufacturer (Original Instruction). No part of this publication, including pictures, may be reproduced or made public, whether by printing, photocopying, and microfilm or by any other means whatsoever, without the prior written permission of Snapmaker.

- Page 5 1.1 Disclaimer Please read the Quick Start Guide carefully. Failure to read this guide is likely to result in personal injury, inferior results, or damage to Snapmaker products, for which we assume no responsibility or liability. Ensure anyone who uses this product has read and understood this guide. This guide is for reference use only, and we do not guarantee or warrant the accuracy, completeness, or currency of the information provided.

- Page 6 1.3 Labels on Your Rotary Module Safety Labels Hazard Warning Location Sharp edges Do not touch On the Rotary Headstock Keep body parts away from moving parts Dangerous elements On the Rotary Headstock Keep body parts out of the motion path 1.4 Used Symbols Warning Failure to follow this instruction might result in severe personal injury.

- Page 7 Aluminum alloy Rated Power 7.2 W Supported Software Snapmaker Luban, Autodesk Fusion 360, Vectric Aspire Supported File Types .svg, .png, .jpg, .jpeg, .bmp, .dxf, .stl Supported Materials for CNC Wood, tooling and modeling board, plastic, bamboo, wax, more being tested...

- Page 8 × 1 This guide takes Snapmaker 2.0 A350 as a demonstration. All steps and illustrations apply to the assembly and use of the Rotary Module on A250 and A350.The Rotary Module for A250 is provided with two CNC materials and two laser materials.

- Page 9 You can read the Quick Start Guide or watch the video tutorials to begin your maker journey. For video tutorials, visit our official website (https://snapmaker.com): Hover over Support > Select Snapmaker 2.0 > Go to Video Tutorial. Quick Start Guide...

- Page 10 1.8.1 Software Update Download our software Snapmaker Luban from https://snapmaker.com/product/ snapmaker-2/downloads, and update it to version 3.14.0 or above. This guide takes version 3.14.0 as a demonstration to generate the G-code file. 1.8.2 Firmware Update Update the firmware to version 1.12.0 or above via Wi-Fi or USB flash drive.

- Page 11 1.8.3 Get the Screwdriver Ready Use the H2.5 bit for machine assembly and the H2.0 bit to adjust the set screw on the Tailstock. Before use, ensure the screw bit holder is put back into the handle. Quick Start Guide...

-

Page 13: Machine Assembly

MACHINE ASSEMBLY... - Page 14 01 Attach the Rotary Headstock to the Base. M4 × 8 Hex Socket Head Screw × For A350 Base × For A250 Rotary Headstock × Turn off the machine before assembly.

- Page 15 02 Attach the Base to the middle of the CNC Carving Platform. M4 × 14 Hex Socket Head Screw × 10 For A350 For A250 CNC Carving Platform × 1 For A350 For A250 If the nut is screwed out from the CNC Carving Platform, glue it back with the provided AB glue.

- Page 16 03 Connect the Rotary Headstock to the Controller. Addon 2 Do not connect or disconnect any cables when the machine is turned on.

- Page 17 Congratulations You are now ready to use! Quick Start Guide...

-

Page 18: Cnc Carving

CNC Carving 3.1 Assemble the CNC Carver 3.5 Start Carving 3.5.1 Preview the File 3.2 Generate the G-code File 3.5.2 Run Boundary 3.3 Safety Instructions 3.5.3 Attach the Tailstock 3.5.4 Check Before Carving 3.4 Origin Assistant 3.6 Remove the Finished Work 3.4.1 Select an Assistant 3.4.2 Material Settings 3.4.3 Fix the Material... - Page 20 3.1 Assemble the CNC Carver Attach the CNC Module to the Slider. Connect the CNC Module to the Controller from the behind of the X Axis, and lock the Toolhead cable into the Cable Holder. Leave enough length for the Toolhead to move. Toolhead Cable ×...

- Page 21 How It Works: Canvas The canvas in the Snapmaker Luban equals the lateral area of your material. When you input the diameter and length of your material, Luban will adjust the size of the canvas. You should put your model within the canvas. The highlighted area is where the material is clamped by the 3-jaw Chuck.

- Page 22 How to Generate the G-code File Launch the Snapmaker Luban and select CNC G-code Generator. Click Case Library, and Load the 4-axis Linkage CNC Carved Lion. In Job Type, input the length and diameter of your material. Use the default parameters in...

- Page 23 In Carving Tool, select Straight Groove V-bit. Use the default parameters in Configurations, and click Simulation to check the finished work before carving. Click Generate G-code and Export G-code to File to save the G-code file to your USB flash drive. If your machine is turned on, you can export the G-code file via Wi-Fi.

- Page 24 3.3 Initial Setup Turn on the machine, and read the Safety Instructions.

- Page 25 3.4.1 Select an Assistant Tap Toolbox, and select Origin Assistant to guide you through setting the work origin. For instructions on Bit Assistant which guides you to change a CNC bit after rough machining, refer to our User Manual: https://support.snapmaker.com. Quick Start Guide...

- Page 26 3.4.2 Material Settings Input the length and diameter of your material.

- Page 27 3.4.3 Fix the Material Loosen the 3-jaw Chuck counter-clockwise by turning two chuck wrenches. Insert one end of the material onto the 3-stepped jaws, and tighten the Chuck clockwise. Chuck Wrenches 3-jaw Chuck Leave no gap between the jaws and the material in their contact surfaces.

- Page 28 3.4.4 Attach the CNC Bit How It Works: Straight Groove V-bit The Straight Groove V-bit features a long and sharp carving edge, penetrating deep into materials and rendering high-precision creations. The extended flutes on both sides create a larger area of engagement, providing a superior carving than single flute bits. It can also clear swarf, eliminating clogging and reducing wear and tear.

- Page 29 How to Attach the Bit Select Straight Groove V-bit on the Touchscreen first. Tilt the ER11 collet into the ER11 nut until the collet snaps into place. Insert the CNC bit into the ER11 collet until the shank bottoms against the collet. ER11 Nut ER11 Collet Quick Start Guide...

- Page 30 Twist the ER11 nut onto the Toolhead, and secure the nut with open-end wrenches. 14mm Open-end Wrench 17mm Open-end Wrench Caution the sharp CNC bit.

- Page 31 3.4.5 Set the Work Origin How It Works: Work Origin Setting the work origin helps the machine find out how to carve the material. The work origin (X0, Y0) on the material corresponds to the coordinate origin (X0,Y0) in Snapmaker Luban. X0,Y0 X0,Y0...

- Page 32 How to Set the Work Origin Read the instruction on Origin Assistant on the Touchscreen, and wear the CNC Safety Goggles. Follow onscreen instructions, and manipulate the illustrated part of the straight groove v-bit to touch the material. Shank If the CNC bit bumps into the machine, turn off the machine immediately or press the Emergency Stop Button...

- Page 33 3.5 Start Carving 3.5.1 Preview the File Insert your USB flash drive into the Controller. Tap Files, and select the G-code file in USB. Preview the file, and tap Ready. Quick Start Guide...

- Page 34 3.5.2 Run Boundary Read the instruction on Set Work Origin, and ensure you have worn the CNC Safety Goggles. Use Z Offset to lift the CNC bit above the Rotary Headstock, and tap Run Boundary to check the work area. If the work area is inappropriate, reset the work origin.

- Page 35 Clamping the material with the Chuck and Tailstock improves stability and precision. If your material is long or heavy, use the Tailstock. Select two holes on the Base to attach the Tailstock. For A350 M4 × 10 Hex Socket Head Screw × For A250 Tailstock × Quick Start Guide...

- Page 36 Use the H2.0 screw bit to loosen the set screw and screw the Handwheel forward until the Tailstock Center presses against the central point of the bottom surface of the material. Align the groove on the Tailstock Center with the set screw, and tighten the set screw. Tailstock Center Handwheel Set Screw...

- Page 37 3.5.4 Check Before Carving Check the following steps before carving: Lift the CNC bit Wear the CNC Secure the CNC bit Secure the material Wear the provided mask above the material Safety Goggles You are now ready to carve. Tap Start on the Touchscreen. Quick Start Guide...

- Page 38 3.6 Remove the Finished Work Use a vacuum to clean the machine and the finished work. Adjust the Handwheel, and remove the finished work with two chuck wrenches. Caution the sharp CNC bit and jaws. To avoid scratch, you can remove the bit before cleaning.

- Page 39 Share You can share your finished work in our Facebook group and our forum! Quick Start Guide...

-

Page 40: Laser Engraving And Cutting

Laser Engraving and Cutting 4.1 Assemble the Laser Engraver 4.4 Start Engraving and Cutting and Cutter 4.4.1 Preview the File 4.4.2 Select a Mode 4.2 Generate the G-code File 4.4.3 Material Settings 4.4.4 Fix the Material 4.3 Calibration 4.4.5 Set the Work Origin 4.4.6 Check Before Engraving and Cutting 4.5 Remove the Finished Work... - Page 42 4.1 Assemble the Laser Engraver and Cutter Attach the Laser Module to the Slider. Connect the Laser Module to the Controller from the behind of the X Axis, and lock the Toolhead cable into the Cable Holder. Leave enough length for the Toolhead to move. Toolhead Cable ×...

- Page 43 How It Works: Canvas The canvas in the Snapmaker Luban equals the lateral area of your material. When you input the diameter and length of your material, Luban will adjust the size of the canvas. You should put your model within the canvas. The highlighted area is where the material is clamped by the 3-jaw Chuck.

- Page 44 How to Generate the G-code File Launch the Snapmaker Luban and select Laser G-code Generator. Click Case Library, and Load the Rotary Laser Engraved Lion. In Job Type, input the length and diameter of your material. Use the default parameters in...

- Page 45 Use the default parameters in Configurations, and tick Auto Tool Path Preview to check the finished work before engraving. Click Generate G-code and Export G-code to File to save the G-code file to your USB flash drive. If your machine is turned on, you can export the G-code file via Wi-Fi. After clicking Generate G-code in step 6 , click Load G-code to Workspace > Connect Luban to your machine via Wi-Fi >...

- Page 46 4.3 Calibration Follow the Safety Instructions to manually calibrate the focal length. For instructions on fixing the material, refer to section 4.4.4.

- Page 47 How It Works: Work Origin Setting the work origin helps the machine find out how to engrave or cut the material. The work origin (X0, Y0) on the material corresponds to the coordinate origin (X0,Y0) in Snapmaker Luban. X0,Y0 X0,Y0...

- Page 48 How to Set the Work Origin 4.4.1 Preview the File Insert your USB flash drive into the Controller. Tap Files, and select the G-code file in USB. Preview the file, and tap Ready.

- Page 49 4.4.2 Select a Mode Select a mode to set the work origin. This guide will show you how to set the work origin under the Auto Mode. For instructions on the Manual Mode, refer to our User Manual: https://support.snapmaker.com. Quick Start Guide...

- Page 50 4.4.3 Material Settings Input the length and diameter of the new material.

- Page 51 4.4.4 Fix the Material Loosen the 3-jaw Chuck by turning two chuck wrenches. Insert one end of the material onto the 3-stepped jaws, and tighten the Chuck. Chuck Wrenches 3-jaw Chuck Leave no gap between the jaws and the material in their contact surfaces.

- Page 52 4.4.5 Set the Work Origin Ensure you have worn the Laser Safety Goggles. Use X, Y, and B Offsets to Set Work Origin. You can tap Run Boundary to check the work area. If the lens hood bumps into the machine, turn off the machine immediately or press the Emergency Stop Button...

- Page 53 4.4.6 Check Before Engraving and Cutting Check the following steps before engraving and cutting: Secure the material Wear the Laser Safety Goggles Wear the provided mask You are now ready to engrave. Tap Start on the Touchscreen. Quick Start Guide...

- Page 54 4.5 Remove the Finished Work Remove the finished work by turning two chuck wrenches.

- Page 55 Share You can share your finished work in our Facebook group and our forum! Quick Start Guide...

-

Page 56: Troubleshooting

3. One by one, install the Jaw 2 and Jaw 1. Slide all jaws into channels, and keep turning the chuck wrenches until all jaws close up in the center. Channel Jaw 3 Jaw 2 Jaw 3 Jaw 2 Jaw 1 Teeth Groove Jaw 1 Spiral Scroll Plate For other types of jaw installation and what tricks they can do, refer to our User Manual: https://support.snapmaker.com. - Page 57 Resources This guide is subject to change. For the latest version of our Quick Start Guide: https://support.snapmaker.com/hc/en-us/categories/360001781913-Snapmaker-2-0. For the latest version of our User Manual: https://support.snapmaker.com/hc/en-us. For any general information or technical support: support@snapmaker.com. For any sales inquiries: sales@snapmaker.com. For product purchases: https://shop.snapmaker.com.

- Page 58 “If there is a dark now we shouldn't doubt And there is a light, don't let it go out.” — U2 There Is a Light For Douglas McLaren Livingstone and his wife. Original Instruction Y.3.B.A.0034-01 V1.0.0...

Need help?

Do you have a question about the A250 and is the answer not in the manual?

Questions and answers