Summary of Contents for Kohler KD45V20

- Page 1 Operation and Maintenance Manual Translation of the original instructions Diesel engine KD45V20 From serial number 2016 18 0001 33521030001_4_1 08-2018...

- Page 2 The Operating Manual facilitates the operator's familiarization with the diesel engine and prevents faults through incorrect operation. Kohler Co. will not allow any warranty claims that arise due to incorrect operation, insufficient maintenance, use of unapproved operating fluids or non-compliance with safety regulations.

- Page 3 December 2016 33521030001_2_1 2016 16 0001 Various changes April 2017 33521030001_3_1 2016 16 0001 Change of maintenance August 2017 schedule 33521030001_4_1 2016 16 0001 Various changes August 2018 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 4 Preface Operation and Maintenance Manual © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 5: Table Of Contents

General safety instructions Preventing personal injuries 2.6.1 Bruises 2.6.2 Burns and scalding 2.6.3 Fires and explosions 2.6.4 Poisoning 2.6.5 High-pressure injection (liquids at high pressure can squirt out) © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 6 5.4.2 ESP Fuel optimized — Service level 2 - Version: 2018/06-1 Maintenance schedule — ESP Emission optimized 5.5.1 ESP Emission optimized — Service level 1 - Version: 2018/06-1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 7 5.14.6 Take coolant sample and perform coolant analysis — SL120 5.14.7 Change air filter main element — SL108 5.14.8 Check state of fan drive belt drive and replace if necessary — SL118 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 8 Standard torques for cutting ring flange joints 7.1.7 Standard torques for Triple Lok® flange joints 7.1.8 Standard torques for VSTI screw plugs Special tool Terms used (glossary) Index © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 9: Service Assistance

For Kohler generating sets: – Visit the web site of Kohler CO. at KOHLERPower.com. – Pay attention to the labels and decals on your Kohler product or review the appropriate literature or documents included with the product. – In the USA and Canada, call toll-free 1-800-544-2444. - Page 10 For KOHLER-SDMO power generating units: – Visit the web site of KOHLER-SDMO at www.kohlersdmo.com. – Pay attention to the labels and stickers on your KOHLER-SDMO product or check the corresponding literature or documents included with the product's scope of delivery.

-

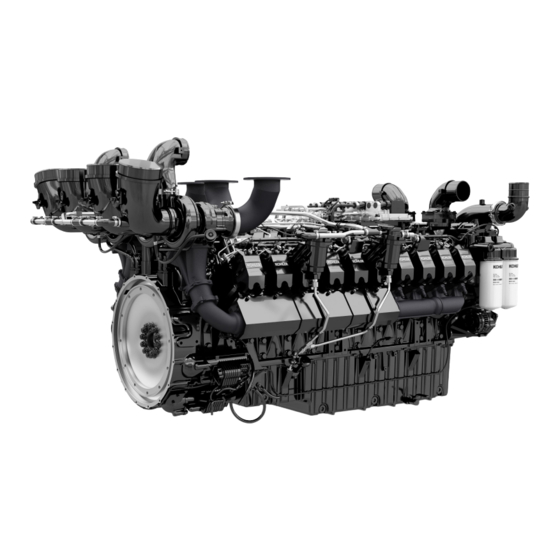

Page 11: Product Description

Oil module Fastening point for turning device Charge air line Battery charging alternator Flywheel Pressure line rail Oil drain shut-off valve Flywheel housing Engine control unit High pressure pump © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 12 V-ribbed fan belt cooling Charge air connecting line Charge air line Oil filter from charge air cooler Crankcase breather Main fuel filter Exhaust gas turbocharger Coolant connection from coolant cooling © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 13: Overview Of Sensors

Technical description 1.1.2 Overview of sensors Fig. 3: Overview of sensors Rotational speed sensor Rotational speed sensor Rotational speed sensor Service switch Temperature sensor Temperature sensor Pressure sensor © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 14: Explanation Of The Type Designation

Fig. 4: Company nameplate Engine serial number The engine serial number is stamped into the engine company nameplate and the crankcase. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 15 Engine type code: 18 = KD45V20 0001 Consecutive production number Tab. 4 Engine control unit nameplate Fig. 6: Position of the engine control unit nameplate Software nameplate Hardware nameplate © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 16 The real information can be viewed in the device display or read out using the KODIA diagnosis and service tool. Tab. 5 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 17: Technical Data

See emission control information label Emission limit stage See engine emissions nameplate 1.2.2 Cylinder head Description Unit Value Inlet valve clearance, cold 0.019 Outlet valve clearance, cold 0.023 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 18: Coolant Thermostat

V 28 Current A 140 1.2.5 Starter Description Unit Value Voltage V 24 Output per start system kW 7.8 1.2.6 Flywheel housing Description Unit Value Connection SAE 0 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 19: Safety

NOTICE indicates a hazardous situation which, if not avoided, could result in material damages. Tab. 7 Additional markings Information indicates useful information and tips. Tab. 8 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 20: Target Audience

– Operating the machine and facilities – Performance of scheduled maintenance work – Assembly, installation, assessment, adjustment, testing and maintenance – Location of defects – Recording the repair and maintenance work performed © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 21: Unauthorized Personnel

– Cleaning and maintaining equipment such as the battery charging alternator, pumps or compressors in order to prevent defects or damage to the equipment © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 22: Intended Use

Kohler Co. – Operating and auxiliary materials that have not been approved by Kohler Co. – The use of non-Kohler spare parts that have not been officially approved by Kohler Co., including the resulting consequential damages. -

Page 23: General Safety Instructions

– Fasten and secure individual parts and larger assemblies carefully with suitable lifting gear during their replacement. – Use Kohler lifting gear in accordance with its operating manual. – Observe the regulations on the lifting points. – Do not use any load handling devices that are damaged or that have an inadequate carrying capacity. -

Page 24: Burns And Scalding

– Use suitable protective equipment during work on the fuel and injection system (e.g. safety gloves, safety goggles, etc.). – Do not open any pressurized fuel lines or hoses. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 25: Electrical Energy

Wear safety shoes in the direct vicinity of the engine. Safety gloves – Protection against hot elements and chemicals Wear safety gloves during work with hot parts. (For example: shrink-fitting the crown gear on the flywheel.) © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 26: Operating Areas And Maintenance Areas

– Only those target audiences authorized as per the relevant definitions may enter the safety zones during maintenance. – Disconnect from the electrical power supply. – Wear personal protective equipment. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 27: Operating Areas

WARNING Hot parts during maintenance work. Risk of burns! Can cause severe injury or death. u Allow the engine to cool down sufficiently. u Wear personal protective equipment. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 28: Secure And Release The Diesel Engine Against Accidental Starting

– Make sure that all foreign bodies have been removed. – All of the protective devices are installed and are working properly. – Make sure that no external persons stand or walk in the danger zones. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 29: Emergency Stop

– Possible EMC radiation that may affect heart pacemakers and implanted defibrillators. People with a heart pacemaker or implanted defibrillator: keep a minimum distance of 20cm (8 inches) from the operational Diesel engine. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 30: Prevent Material Damages

– Use suitable test leads for measurements at plug connections. – Protect the engine control unit against dust and water if no mating plug has been connected. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 31: Handling, Operation

Information Engine damage due to inadequate lubrication. u The oil pressure has to build up immediately after the diesel engine is started (oil-pressure warning lamp goes out). © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 32 Check the coolant level. u Perform a visual check for any leaks in the lines. u Check for KODIA error messages. u Check for generator sets' error messages. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 33: Operating Faults

Charge or replace the battery. The battery connections are loose or Clean and tighten the loose corroded. connections. The outside temperature is too low. Take appropriate action for Winter operation. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 34 KOHLER Co. to have the engine checked. There is a fault in the electronic Read out the error memory of the system. engine control unit. Contact KOHLER Co. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 35 Kohler service representative. See "Service Assistance" section. The thermostat is faulty. Check this and replace if necessary. Contact your nearest authorized Kohler service representative. See "Service Assistance" section. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 36 Check the fuel system and the drain pre-filter. There is a leak in the charge air Contact your nearest authorized cooler. Kohler service representative. See "Service Assistance" section. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 37 Contact your nearest authorized Kohler service representative. See "Service Assistance" section. Leak in the oil cooler or oil cooler Contact your nearest authorized plate. Kohler service representative. See "Service Assistance" section. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 38 The charge air cooler is dirty. Contact your nearest authorized Kohler service representative. See "Service Assistance" section. The turbocharger outlet is faulty. Contact your nearest authorized Kohler service representative. See "Service Assistance" section. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 39: Operating Fluids And Maintenance

180 l (1.5 l per filter) 47.6 US gal (0.4 US gal per filter) Coolant 143 l 37.8 US gal Tab. 10: Fill quantities in the Diesel engine (guide values) © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 40: Lubricants And Operating Materials

HFRR < 460 µm max. 10% Biodiesel Aviation kerosene Jet A-1 HFFR < 460 µm without AEG with additive S-1750 UK Diesel BS 2869 A2 Max 10% biodiesel content Tab. 11: Approved fuel qualities © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 41: Engine Oils

The following table is intended to help select the right engine oil based on the total base number (TBN). This measurement value is important for reducing combustion gases that are greatly influenced by the sulfur content in the fuel. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 42 Basic oil change interval * Factor oil category * Factor sulfur content = change interval The basic oil change interval is defined in the maintenance tables. The factor “oil category”: Factor “sulfur content”: © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 43: Coolant

An SI-OAT or hybrid technology with ethylene glycol is to be used as coolant, since this technology provides the necessary cooling performance and cooling function for engines. Approved products: – BASF GLYSANTIN® G40™ change interval 6 years © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 44 DIN EN ISO 6.7 — 9.0 10523:2012-04 Chloride (ions) mg/l < 100 Sulfate mg/l < 100 Bacteria and toxic without constituents Tab. 15: Control parameter © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 45: Maintenance

Time between overhauls (TBO) The average period until Diesel engines have to be overhauled. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 46: Daily, Weekly And Monthly Maintenance Work - Version: 2018/06-1

SL008 Test run at more than 1/3 load. See the generator set’s Monthly operating manual. Tab. 16: Maintenance schedule — Daily maintenance activities — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 47: Maintenance Schedule - Esp Fuel Optimized

Replace coolant. For coolant formulated with Glysantin (Glysantin G48) G40, the extension up to 8000h / 6Y is possible after analysis. Tab. 17: ESP Fuel optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 48: Esp Fuel Optimized - Service Level 2 - Version: 2018/06-1

Replace the exhaust gas turbocharger rubber sleeve. turbocharger SL219 Coolant lines Check and replace coolant lines and hoses if necessary. Tab. 18: ESP Fuel optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 49: Maintenance Schedule - Esp Emission Optimized

Replace coolant. For coolant formulated with Glysantin (Glysantin G48) G40, the extension up to 8000h / 6Y is possible after analysis. Tab. 19: ESP Emission optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 50: Esp Emission Optimized - Service Level 2 - Version: 2018/06-1

Replace the exhaust gas turbocharger rubber sleeve. turbocharger SL219 Coolant lines X Check and replace coolant lines and hoses if necessary. Tab. 20: ESP Emission optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 51: Maintenance Schedule - Esp 50Hz Emission Optimized Top Power

Replace coolant. For coolant formulated with Glysantin (Glysantin G48) G40, the extension up to 8000h / 6Y is possible after analysis. Tab. 21: ESP 50Hz emission optimized top power — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 52: Esp 50Hz Emission Optimized Top Power - Service Level 2 - Version: 2018/06-1

Replace the exhaust gas turbocharger rubber sleeve. turbocharger SL219 Coolant lines X Check and replace coolant lines and hoses if necessary. Tab. 22: ESP 50Hz emission optimized top power — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 53: Maintenance Schedule - Prp Fuel Optimized

G40, the extension up to 8000h / 6Y is possible after analysis. SL120 Coolant analysis X Take coolant sample and perform coolant analysis. Tab. 23: PRP Fuel optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 54: Prp Fuel Optimized - Service Level 2 - Version: 2018/06-1

7500 alternator SL225 Viscous damper 7500 Replace the viscous damper. SL209 High pressure Replace the HP pump. 15000 pump Tab. 24: PRP Fuel optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 55: Maintenance Schedule - Prp Emission Optimized

G40, the extension up to 8000h / 6Y is possible after analysis. SL120 Coolant analysis X Take coolant sample and perform coolant analysis. Tab. 25: PRP Emission optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 56: Prp Emission Optimized - Service Level 2 - Version: 2018/06-1

7500 alternator SL225 Viscous damper 7500 Replace the viscous damper. SL209 High pressure Replace the HP pump. 15000 pump Tab. 26: PRP Emission optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 57: Maintenance Schedule - Cop Fuel Optimized

G40, the extension up to 8000h / 6Y is possible after analysis. SL120 Coolant analysis X Take coolant sample and perform coolant analysis. Tab. 27: COP Fuel optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 58: Cop Fuel Optimized - Service Level 2 - Version: 2018/06-1

10000 alternator SL225 Viscous damper 10000 Replace the viscous damper. SL209 High pressure Replace the HP pump. 20000 pump Tab. 28: COP Fuel optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 59: Maintenance Schedule - Cop Emission Optimized

G40, the extension up to 8000h / 6Y is possible after analysis. SL120 Coolant analysis X Take coolant sample and perform coolant analysis. Tab. 29: COP Emission optimized — Service level 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 60: Cop Emission Optimized - Service Level 2 - Version: 2018/06-1

10000 alternator SL225 Viscous damper 10000 Replace the viscous damper. SL209 High pressure Replace the HP pump. 20000 pump Tab. 30: COP Emission optimized — Service level 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 61: Special Tools For Maintenance Activities

Operation and Maintenance Manual Operating fluids and maintenance Special tools for maintenance activities 5.11 Special tools for maintenance activities Fig. 43: Turning device ID no. Description 10123791 Turning device Tab. 31 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 62: Preparatory Maintenance Activities

– The Diesel engine is turned off. – The diesel engine has cooled down to the ambient temperature. – Disconnect electrical power supply and secure against reactivation. – Label cut-off point. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 63: Daily, Weekly And Monthly Maintenance Work

Visually check Diesel engine for leaks, ensure that it is not damaged and that the fastenings comply with regulations. u Visually check V-space (area under high pressure pump and lines) for moisture. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 64 Overflow-oil line Pressure line Fuel line u Visually check hoses for leaks, ensure that they are not damaged, installed friction-free, and that fastening is in compliance with regulations. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 65: Checking The Engine Oil Level - Sl001

Visually check belt drive 2 for damage, friction-free installation, and regulation- compliant fastening. 5.13.2 Checking the engine oil level — SL001 Oil dipstick and oil filler neck are located on the right as seen from the flywheel. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 66 Fill the oil through the oil filler neck 2. u Do not fill the Diesel engine with oil to above the “max” mark. u Clean the refueling cap, place on the filler neck and tighten. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 67: Check Coolant Level - Sl001

Perform maintenance and inspection work on the cooling system only when the Diesel engine has cooled down. u Wear protective equipment. Fig. 49 See generator set manual for procedure to check coolant level. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 68: Check The Ventilation Holes On The Water Pump - Sl003

The primary fuel filter with water trap and manual fuel feed pump is some distance from the Diesel engine and is attached differently depending on the device design. See the generator sets' operating manual for the procedure. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 69 Avoid open flames or other ignition sources when performing maintenance or inspection work on the fuel system. u Perform maintenance and inspection work only when the Diesel engine has been shut down. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 70: Maintenance Activities

5.14.2 Replace diesel engine oil and oil filter — SL121 Make sure that: q The Diesel engine is horizontal. q The Diesel engine is turned off. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 71 Open oil drain shut-off valve 1. u Drain the oil into the container provided. u Close oil drain shut-off valve 1. u Dispose of oil (observe country-specific regulations). © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 72 Screw on new oil filter 1 until the sealing contacts the oil module. u Tighten oil filter 1 by hand 1/2 of a revolution. w Torque 25 Nm. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 73: Replace The Oil Separator Filter Insert Of The Crankcase Breather - Sl107

5.14.3 Replace the oil separator filter insert of the crankcase breather — SL107 Make sure that: q Four new oil separator filter inserts with new O-rings are on hand. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 74 Operating fluids and maintenance Operation and Maintenance Manual Maintenance activities Crankcase breather position Fig. 55: Crankcase breather position Crankcase breather © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 75 Pull off hose clamps 1 and hose from the regulating valve (cover) 2. u Loosen lever screws 3. u Remove regulating valve (cover) 2. u Pull off filter insert 4. Install oil separator filter insert Fig. 57: Install filter insert © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 76: Replace Main Fuel Filter - Sl105

Avoid open flames or other ignition sources when performing maintenance or inspection work on the fuel system. u Perform maintenance and inspection work only when the Diesel engine has been shut down. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 77 Pay attention to the special instructions for working on the common rail system, see the “Safety” chapter. u Lightly oil the sealing ring on the main fuel filter. (Use engine oil). © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 78: Replace The Primary Fuel Filter - Sl106

5.14.6 Take coolant sample and perform coolant analysis — SL120 CAUTION Hot coolant! Risk of burns! Can cause injuries. u Turn off engine and let it cool down. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 79: Change Air Filter Main Element - Sl108

– Rubber nodules in the base of the belt – Dirt and/or stone deposits – Ribs broken off the base of the belt – Transverse cracks on the back – Transverse cracks in several ribs © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 80 Check that the belt pulleys and tightening roller are in perfect working order and check their play (for example, worn out bearings on the tightening roller or tread wear on the belt pulleys). w Replace the damaged parts. Please contact the nearest authorized Kohler Co. customer service. Replacing the belt Make sure that: q A new belt is on hand.

- Page 81 Start the engine and let it run for 30 minutes. u Turn off engine and check pretension. Retension if necessary. u Install the fan. See the generator set’s operating manual. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 82: Check And Change The V-Ribbed Belt For The Battery Charging Alternator

A new belt is on hand. WARNING Rotating parts! Risk of injury! Can cause serious injuries. u Turn the Diesel engine off. u Secure the engine against unexpected starting. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 83 Remove fan. See the generator set’s operating manual. u Remove the V-ribbed belt (fan) 1. (For the procedure, please refer to the chapter “Check state of fan drive belt drive, replace if necessary”.) © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 84 (for example, worn out bearings on the tightening roller or tread wear on the belt pulleys). w Replace the damaged parts. Please contact the nearest authorized Kohler Co. customer service. Refer to the chapter on “Service Assistance”.

-

Page 85: Transport And Storage

Storage conditions are part of the device manufacturer. u Comply with the standard ISO 6749-1984 for transportation and storage. u Please contact the Kohler customer service if anything is unclear. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 86: Fastening During Transport

Check the maximum floor load before setting the Diesel engine down on the floor. u The weight data can be found in the technical data sheet. Information u Use only preservation media approved by Kohler. 6.1 Fastening during transport Fig. 66: Example of transport fastening / wood transport stand DANGER Mortal danger due to instability during transportation of the Diesel engine. - Page 87 If a crane is used, please use the hoisting beam. u There may be no persons within the danger zones of the Diesel engine during loading and unloading. u Pay attention to the center of gravity. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 88: Wooden Transport Stand

Mortal danger! Will cause serious injuries or death. u The Diesel engine must be securely bolted to the transport stand. Information u Wooden transport stands do not have to be returned to Kohler Co. Keep for later use. © 2018 by Kohler Co. All rights reserved. -

Page 89: Steel Transport Stand

Mortal danger! Will cause serious injuries or death. u The Diesel engine must be securely bolted to the transport stand. Information u Return the steel transport stand to Kohler Co. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 90: Suspension Device

Pay attention to the safety instructions / warnings in the Operating Manual for the hoisting beam! u Do not work under suspended loads! Fig. 69: Suspension device © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 91 Hoisting beam ID no. 12204231 Power unit support side Lifting gear Flywheel side Information u Please read and observe the safety instructions in the system description before commissioning the hoisting beam. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 92: Storage

(situated outdoors for longer periods of time or stored in damp, unventilated locations etc.). 6.7.1 Storage for over 6 and up to 24 months Please contact Field Service if planning storage over 6 months up to 24 months. © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 93: Standard Torques

M 39 3000 2210 4300 3170 5100 3770 Tab. 32 Fine thread ft lb ft lb ft lb 10.9 12.9 M 8 x 1 M 9 x 1 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 94: Standard Torques For Screw Plugs And Hollow Screws

M 38 x 1.5 M 10 x 1 M 38 x 2 M 10 x 1.25 M 42 x 1.5 M 12 x 1.5 M 42 x 2 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 95: Standard Torques For Flange Joints

M 16 x 1.5 M 18 x 1.5 M 22 x 1.5 M 26 x 1.5 M 33 x 2.0 M 42 x 2.0 M 48 x 2.0 Tab. 35 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 96 M 12 x 1.5 M 14 x 1.5 M 16 x 1.5 M 18 x 1.5 M 20 x 1.5 M 22 x 1.5 M 27 x 2.0 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 97 G 1/8A G 1/4A G 1/4A G 3/8A G 1/2A G 1/2A G 3/4A G 1A G 1 1/4A G 1 1/2A Tab. 40 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

-

Page 98: Metric Flange Joints, Series L (Light) For Aluminum

M 10 x 1.0 M 12 x 1.5 M 14 x 1.5 M 16 x 1.5 M 18 x 1.5 M 22 x 1.5 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 99: Standard Torques For Cutting Ring Flange Joints

Tighten box nut to aforementioned torque. 7.1.7 Standard torques for Triple Lok® flange joints Series Tube diameter X Thread Z ft lb ft lb inch UN/UNF Steel Stainless steel © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 100: Standard Torques For Vsti Screw Plugs

M 33 x 2 M 20 x 1.5 M 38 x 1.5 M 22 x 1.5 M 42 x 2 M 24 x 1.5 M 48 x 2 Tab. 46 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 101: Special Tool

Operation and Maintenance Manual Special tool 7.2 Special tool Description ID no. Order number TURNING DEVICE 10123791 230610006 1 Hoisting beam 12204231 230610044 Tab. 47: Special tool with identification number © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 102: Terms Used (Glossary)

"Operating and maintenance areas". Maintenance areas Maintenance areas are the safety zones that have to be accessed for maintenance work and troubleshooting. Tab. 48 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... -

Page 103: Index

Danger due to noise 25 Install oil separator filter insert 75 Design overview 11 International standard classification of occupations 20 Diesel engine 17 Diesel engine company nameplate 14 Diesel fuels 40 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01... - Page 104 2018/06-1 55 Technician 21 PRP Emission optimized — Service level 2 - Version: Terms used (glossary) 102 2018/06-1 56 Time between overhauls (TBO) 45 Transport and storage 85 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 105 Operator's manual Index Type description 14 Unauthorized personnel 21 Wooden transport stand 88 © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 106 Index Operator's manual © 2018 by Kohler Co. All rights reserved. KD45V20 33521030001_4_1 en 2018-08-01...

- Page 108 33521030001_4_1 EN 08-2018 LHID12404947 ©2018 by Kohler Co. All rights reserved.

Need help?

Do you have a question about the KD45V20 and is the answer not in the manual?

Questions and answers