Subscribe to Our Youtube Channel

Summary of Contents for Beckhoff AG3300

- Page 1 Operating instructions | EN AG3300 Economy planetary gear unit 10/11/2021 | Version 2.5...

-

Page 3: Table Of Contents

Version numbers............................... 7 Scope of the documentation .......................... 7 Staff qualification............................... 8 Safety and instruction ............................. 10 Explanation of symbols ........................... 10 Beckhoff Services ............................ 12 For your safety.............................. 13 General safety instructions .......................... 13 Product overview............................... 15 Name plate.............................. 16 Type key ................................. - Page 4 Table of contents Guidelines and Standards .......................... 65 EU conformity .............................. 65 RoHS ................................ 65 ..................................... 66 ─── AG3300 Version: 2.5...

-

Page 5: Documentation Notes

Documentation notes Disclaimer Beckhoff products are subject to continuous further development. We reserve the right to revise the operating instructions at any time and without prior announcement. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in these operating instruc- tions. - Page 6 • Use of untrained personnel • Use of unauthorized spare parts Copyright © Beckhoff Automation GmbH & Co. KG, Germany 1.1.4 The copying, distribution and utilization of this document as well as the communication of its contents to others without express autho- rization is prohibited.

-

Page 7: Version Numbers

Product properties Only the product properties specified in the current operating in- structions are valid. Further information given on the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative. Scope of the documen- Apart from these operating instructions, the following documents are... -

Page 8: Staff Qualification

Trained specialists have received specific technical training and have specific technical knowledge and experience. Trained special- ists can: • apply relevant standards and directives • assess tasks that they have been assigned • recognize possible hazards • prepare and set up workplaces ─── AG3300 Version: 2.5... - Page 9 They are familiar with relevant standards and directives. Quali- fied electricians can: • independently recognize, avoid and eliminate sources of danger • implement specifications from the accident prevention regula- tions • assess the work environment • independently optimize and carry out their work Version: 2.5 AG3300 ───...

-

Page 10: Safety And Instruction

1.6.1 DANGER Failure to observe will result in serious or fatal injuries. WARNING Failure to observe may result in serious or fatal injuries. CAUTION Failure to observe may result in minor or moderate injuries. ─── AG3300 Version: 2.5... - Page 11 In the case of documentation on a monitor screen, use the zoom function to enlarge the QR code and reduce the distance. Version: 2.5 AG3300 ───...

-

Page 12: Beckhoff Services

Beckhoff and the worldwide partner companies offer comprehensive support and service. Support The Beckhoff Support offers technical advice on the use of individ- ual Beckhoff products and system planning. The employees support 1.7.1 you in the programming and commissioning of complex automation systems. -

Page 13: For Your Safety

Use the original packaging only Use the original packaging for dispatch, transportation, storage and packing. Secure feather key against loss Secure the existing feather key against loss, for example: • during transportation or • during operation without mounted parts Version: 2.5 AG3300 ───... - Page 14 Secure the machine or plant against being in- advertently started up. See chapter: "Decommissioning" No direct skin contact with solvents or lubricants In case of improper use, the solvents or lubricants used can lead to skin irritations. Therefore, avoid direct skin contact. ─── AG3300 Version: 2.5...

-

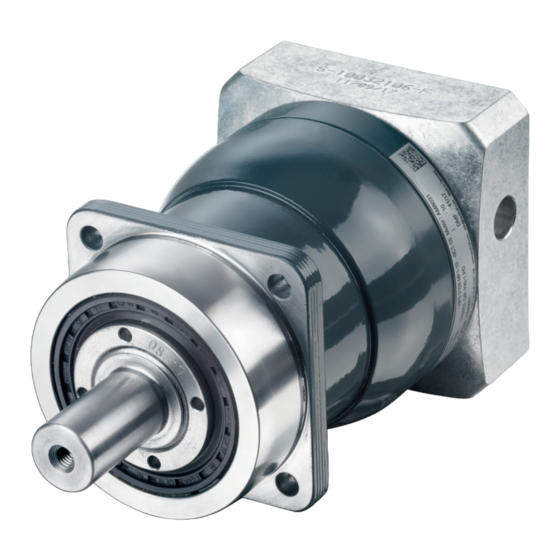

Page 15: Product Overview

Holes for the motor attachment Screw plug, mounting hole Adapter plate Through-holes on the output side Feather key [+] Output shaft with center bore Through-holes on the output side Clamping bolt Holes for the motor attachment Clamping hub Version: 2.5 AG3300 ───... -

Page 16: Name Plate

Product overview Name plate Number Explanation Serial number Lubrication Gear unit type Date of manufacture Ratio Combined motor DataMatrix code Country of manufacture ─── AG3300 Version: 2.5... -

Page 17: Type Key

Product overview Type key AG3300 – NPS015S – MF1 – 3 – 1C1 – AM803x Explanation AG3300 Gear unit series AG3300 = Economy planetary gear unit NPS Gear type NPS = Standard Size NPS 015 NPS 025 NPS 035 NPS 045... -

Page 18: Product Characteristics

Adaptation to different motor types The planetary gear unit can be adapted to different motor types with the adapter flange and a spacer sleeve. Maintenance-free ball bearings The ball bearings are lifetime-lubricated and maintenance-free. ─── AG3300 Version: 2.5... -

Page 19: Ordering Options

Ordering options are defined via the type key and must be ordered separately. The listed components cannot be retrofitted. High-torque version In addition to the standard MF version, the AG3300 planetary gear unit is available as a high-torque version. This version is specially 3.4.1 designed for applications with high torque requirements compared to the standard version and has the type key "MA". -

Page 20: Intended Use

Any type of use that exceeds the permissible values from the techni- cal data is regarded as inappropriate and is thus prohibited. 3.5.1 The planetary gear units from the AG3300 series are not suitable for use in the following areas: • Potentially explosive atmospheres without a suitable housing •... -

Page 21: Technical Data

(whether at rest or in motion). Running noise L [dB/A] The running noises are influenced, for example, by: • transmission ratio and speed • lubricants and gearing or • Installation position Version: 2.5 AG3300 ───... - Page 22 The EMERGENCY STOP torque is the maximum permissible torque at the gear unit output. It may be reached 1000 times at the most during the service life of the gear unit and must never be exceeded. ─── AG3300 Version: 2.5...

-

Page 23: Data For Operation And Environment

Beckhoff products are designed for operation under certain environ- mental conditions, which vary according to the product. The follow- ing specifications must be observed for operation and environment in order to achieve the optimum service life of the products. -

Page 24: Nps015 Mf

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5... - Page 25 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───...

- Page 26 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5...

- Page 27 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to C = 14 mm • Clamping hub diameter up to E = 19 mm Version: 2.5 AG3300 ───...

- Page 28 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to B = 11 mm • Clamping hub diameter up to C = 14 mm ─── AG3300 Version: 2.5...

-

Page 29: Nps015 Ma

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───... -

Page 30: Nps025 Mf

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5... - Page 31 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───...

- Page 32 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5...

- Page 33 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to E = 19 mm • Clamping hub diameter up to H = 28 mm Version: 2.5 AG3300 ───...

- Page 34 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to C = 14 mm • Clamping hub diameter up to E = 19 mm ─── AG3300 Version: 2.5...

-

Page 35: Nps025 Ma

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───... -

Page 36: Nps035 Mf

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5... - Page 37 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───...

- Page 38 In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5...

- Page 39 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to E = 19 mm • Clamping hub diameter up to H = 28 mm Version: 2.5 AG3300 ───...

- Page 40 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to C = 14 mm • Clamping hub diameter up to E = 19 mm ─── AG3300 Version: 2.5...

-

Page 41: Nps035 Ma

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks Version: 2.5 AG3300 ───... -

Page 42: Nps045 Mf

In relation to the shaft center at the output Maximum breakdown torque M [Nm] 2Max Temperature [°C] Maximum housing temperature + 90 Ambient temperature -15 to +40 Housing Properties Anodized; heat-treated steel Color Anthracite gray; RAL 7016 Seal Sealed bearing disks ─── AG3300 Version: 2.5... - Page 43 • All figures in millimeters • Dimensions without tolerance ± 1 mm • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to K = 38 mm Version: 2.5 AG3300 ───...

- Page 44 • Center bore according to DIN 332-DR M5x12 • Feather key 5h9x25 according to DIN 6885-A • Clamping hub diameter up to H = 28 mm • Clamping hub diameter up to K = 38 mm ─── AG3300 Version: 2.5...

-

Page 45: Scope Of Supply

Please check that the delivery includes the following items: • Gear units from the AG3300 series with packaging • Short information Screws for fastening the gear unit to the motor or the machine are not included in the scope of delivery . -

Page 46: Transport And Storage

Legal regulations for the lifting of loads When transporting individual gear units or motor/gear unit combina- tions without a hoist, adhere to the legal requirements for the lifting of loads by employees. ─── AG3300 Version: 2.5... - Page 47 • Using suitable transport slings on the gear unit with averaged center of gravity, with sufficiently dimensioned hoists • using suitable transport slings on the gear unit and on the motor with averaged center of gravity, with sufficiently dimensioned hoists Version: 2.5 AG3300 ───...

-

Page 48: Long-Term Storage

You have the possibility to store the gear unit in a horizontal position and a dry environment over a short or long period. For storage we always recommend the original packaging. Observe the conditions specified in chapter: Transport and storage. ─── AG3300 Version: 2.5... -

Page 49: Technical Description

Ingress and leakage of liquids may damage the motor. The standard installation position of the gear unit is the motor at- tachment M. Alternatively, it can be used in any other installation po- sition. Version: 2.5 AG3300 ───... -

Page 50: Mechanical Installation

The setting values are rounded to conventional scalings or adjust- ment possibilities: Screw size Quality of the screws 10.9 12.9 Tightening torque in Nm 1.15 1.68 1.97 2.64 3.88 4.55 13.2 15.4 21.5 37.5 42.5 62.5 73.5 73.5 1040 ─── AG3300 Version: 2.5... - Page 51 Mechanical installation Stainless steel in aluminum The specified tightening torques for stainless steel bolts in aluminum apply in conjunction with the matching Beckhoff servomotors. 8.1.2 The setting values are rounded to conventional scalings or adjust- ment possibilities: Quality of the bolts = strength class A2-70...

-

Page 52: Motor On Gear Unit

• Motor attachment if possible in a vertical position Clamping hub The following table provides a description of the clamping hub: 8.2.1 Infographic Position Name Clamping bolt Clamping ring Spacer sleeve Grooved motor shaft Smooth motor shaft • Clamping screw according to ISO 4762 ─── AG3300 Version: 2.5... - Page 53 Information on the screw sizes and tightening torques can be found in the table below: Quality of clamping hub bolt = strength class 12.9 Clamping hub diam- Clamping screw H Width across flats Tightening torque Maximum axial eter [mm] [mm] [Nm] force [N] Version: 2.5 AG3300 ───...

- Page 54 ► Remove the screw plug [1] from the adapter plate [2] ► Turn the clamping hub [1] until the screw [2] can be seen above the mounting hole ► Loosen the screw [2] by one turn ─── AG3300 Version: 2.5...

- Page 55 ► Coat screws [1], [2], [3] and [4] with threadlocker ► Insert bolts [1], [2], [3] and [4] and tighten evenly. ► Tighten bolt [5]. Refer to the chapter Clamping hub. ► Insert the screw plug back into the adapter plate Version: 2.5 AG3300 ───...

-

Page 56: Gear Unit To Machine

Mechanical installation Gear unit to machine No washers necessary Beckhoff recommends not using washers if the material of the screw contact surface has an adequate interface pressure. Output side Avoid damage due to stresses 8.3.1 Use suitable tools for the assembly. Mount gear wheels and toothed belt pulleys without force on the output shaft and avoid mounting by driving or hammering on. - Page 57 In the following you will find supplementary information regarding the attachment of the gear unit to a machine: Quality of the screws = strength class 12.9 Gear Pitch circle diam- Thread Tightening torque unit eter [mm] [Nm] 4.55 15.4 37.5 73.5 Version: 2.5 AG3300 ───...

-

Page 58: Commissioning

Relevant parameters Servo drive Rated current Peak current AX5000 P-0-0093 "Configured channel current" P-0-0092 "Configured channel peak cur- rent" AX8000 "Configured channel rated current" "Configured channel peak current" Servo terminal 0x7010:0B "Torque limitation" 0x2003:11 "Max current" ─── AG3300 Version: 2.5... -

Page 59: Before Operation

• Pay attention to unusual noise developments • Always check gear unit surfaces and lines for dirt, leakages, moisture or dust • Check temperature development • Check for lubricant leakage • Observe recommended maintenance intervals • Check function of safety devices Version: 2.5 AG3300 ───... -

Page 60: Maintenance And Cleaning

Use grease-dissolving and non-aggressive cleaning agents such as isopropanol for cleaning. You will also receive information about non-approved cleaning agents. Not applicable Cleaning agents Chemical formula 10.1.1 Aniline hydrochloride Bromine Sodium hypochlorite; bleaching NaCIO solution Mercury (II) chloride HgCl Hydrochloric acid ─── AG3300 Version: 2.5... -

Page 61: Intervals

Lubrication Notes on lubrication 10.2.1 Beckhoff gear units from the AG3300 series are lubricated for life. The lubricant used does not have to be renewed. If you wish to change the lubricant, contact Beckhoff Service. All gear units are lubricated for life in the factory with a synthetic polyglycol gear oil or with a high-performance grease. -

Page 62: Fault Correction

Ensure sufficient cooling Replace the motor Ambient temperature too high Ensure sufficient cooling Increased operating noises Distorted motor mounting Contact Beckhoff Service Damage to the bearings Damage to the toothing Toothed belt tension too high Check and correct toothed belt ten- sion... -

Page 63: Decommissioning

Leaking oil can cause slips and falls, resulting in serious or fatal injury. Impermissible removal of gear unit components Only Beckhoff Automation GmbH & Co. KG is permitted to disman- tle the gear unit. Contact Beckhoff Service for further information. - Page 64 The trans- 12.2.1 port costs are borne by the sender. Send the used devices with the note "For disposal" to: Beckhoff Automation GmbH & Co. KG Gebäude „Service“ Stahlstraße 31 D-33415 Verl In addition, you have the option to contact a local certified specialist company for the disposal of used electrical and electronic appli- ances.

- Page 65 EU conformity Provision 13.1 Beckhoff Automation GmbH & Co KG will be pleased to provide you with EU declarations of conformity and manufacturer's declara- tions for all products on request. Send your request to: info@beckhoff.com RoHS All homogeneous materials used in the gear unit fall below the pre- scribed limit values of Directive 2011/65/EU Annex II.

-

Page 66: Disposal

Mounting the gear unit 50 Lieferumfang 45 Transport 46 Lubrication 61 Umgebungsbedingungen 23 Maintenance 60 Merkmale 18 Motor Wartung Montieren 52 Intervallen 61 Name plate 16 Ordering options 19 Feather key 19 Output elements Mounting 56 Pictograms 10 ─── AG3300 Version: 2.5... - Page 68 More Information: www.beckhoff.com/ag3300 Beckhoff Automation GmbH & Co. KG Hülshorstweg 20 33415 Verl Germany Phone: +49 5246 9630 info@beckhoff.com www.beckhoff.com...

Need help?

Do you have a question about the AG3300 and is the answer not in the manual?

Questions and answers