Summary of Contents for Northern Lights M843NW3G

- Page 1 OPERATOR’S MANUAL OPERATOR’S MANUAL OM843NW3 For Models: M843NW3, M843NW3G www.northern-lights.com...

- Page 2 4420 14th Avenue NW Seattle, WA 98107 Tel: (206) 789-3880 Fax: (206) 782-5455 Copyright ©2021 Northern Lights, Inc. All rights reserved. Northern Lights™, and the Northern Lights logo are trademarks of Northern Lights, Inc. Printed in U.S.A. PART NO.: OM843NW3 5/21...

-

Page 3: Table Of Contents

This publication is the property of Northern Lights, Inc. It may not be reproduced in whole or in part without the written permission of Northern Lights, Inc. © Northern Lights, Inc. All rights reserved. Litho U.S.A. Publication number OM843NW3 5/21... -

Page 4: Introduction

84 mm G - GEM series base frame 3 - US EPA Tier III compliant Northern Lights marine diesel generator set with an 843 engine and a PX-312K2 generator end. US EPA Tier III. M843NW3 M843NW3G Northern Lights marine diesel generator set with an 843 engine, PX-312K2 generator end on a Gem series base frame. -

Page 5: Warranty

Safety Rules DANGER: Northern Lights generator sets and /or any other diesel powered equipment provided by NLI is not provided with spark arresting or explosion proof components, and therefore is not to be installed in the presence of combustible gases having a flash point of 43.3 Degrees C (110 Degrees F) or lower, such as Gasoline, Propane, Natural Gas or other similar fuel sources. - Page 6 Updated 4-12-17 Safety Rules (Continued) Handle Fuel Safely - Avoid Flames Wear Protective Clothing WARNING WARNING Diesel is highly flammable and should be treated with care at all times. Do do not refuel while smoking or To prevent catching anything in moving machinery, when near sparks or open flame. always wear close fitting clothes and safety equipment appropriate ALWAYS STOP ENGINE BEFORE FUELING to the job.

- Page 7 Updated 4-12-17 Safety Rules (Continued) Never check battery charge Stay Clear of Rotating Drivelines by contacting the posts with DANGER a metal object. Use a volt- meter or hydrometer. Entanglement in rotating Frozen batteries may explode drivelines can cause serious if charged.

- Page 8 Follow the procedures and use appropriate equipment exactly as recommended. WARNING Contact your Northern Lights dealer or Northern Lights Relieve pressure prior to factory for MSDS’s used on Northern Lights products. disconnecting pressurized lines. Escaping fluid under...

- Page 9 Inhaling asbestos fibers may Disposing of waste improperly can threaten the cause lung cancer. Avoid environment and lead to unsafe working conditions. breathing any dust that may Potentially harmful waste used in Northern Lights be generated when handling equipment can include oil, fuel, coolant, filters and components containing asbestos batteries.

-

Page 10: Lock Out / Tag Out Procedures

Scope During maintenance, repairs or retooling of a Northern Lights generator set, simply turning the machine off or unplugging it while it is being worked on does not give enough protection to others who are not performing the maintenance or repair. -

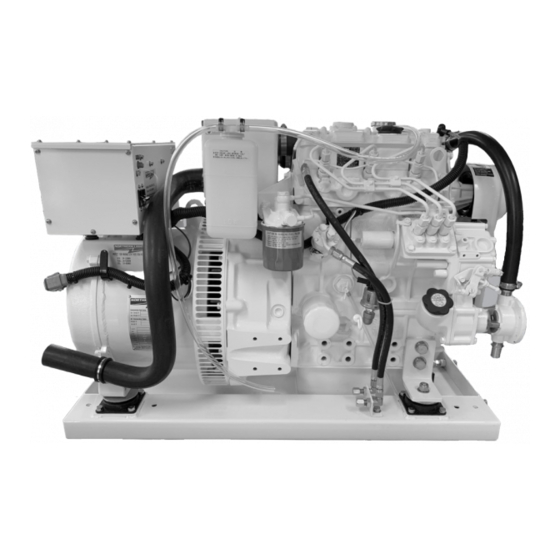

Page 11: Component Locations M843Nw3 Marine Generator

Marine Generator Component Locations Figure 1A and 2A: M843NW3 Belt Guard AC Circuit Breaker for AVR Injection Pump DC Circuit Breaker Oil Filter Oil Fill (2 Places) Coolant Recovery Tank Oil Drain Expansion Tank Seawater Pump Fuel Filter Generator Set Plate Wet Exhaust Elbow Fresh water Block Drain Air Filter (inside manifold) - Page 12 Marine Generator Component Locations Figure 1B (service side) and 2B (non-service side): M843NW3 with 2011 Base frame Fuel Injector AC Circuit Breaker for AVR Fuel Inlet & Return Coolant Fill Belt Guard Oil Dipstick Expansion Tank DC Circuit Breaker Injection Pump Oil Filter Wet Exhaust Elbow Coolant Recovery Tank...

- Page 13 Updated 10-30-19 Marine Generator Component Locations Figure 1C (service side) and 2C (non-service side): M843NW3G Gem Series (s/n: 8432-54693 and above) Oil Fill, top Seawater Pump DC Alternator DC Circuit Breaker Fuel Manifold Fuel Injector Heat Exchanger End Cap AC Circuit Breaker for...

-

Page 14: Control Panels

Updated 10-3-19 Control Panels 1. SHUTDOWN BYPASS-PREHEAT SWITCH There are two functions built into this switch: 1. Preheats the fuel before beginning the starting process. Press switch 10 seconds before attempting start-up. 2. Bypasses the safety shutdown feature during starting process. Keep switch engaged while starting engine and for up to five seconds afterwards, allowing oil pressure to build beyond shutdown set point. -

Page 15: Operating Procedures

Updated 10-3-19 Operating Procedures BREAK-IN PERIOD STARTING 1. The first 100 hours on a new or reconditioned 1. Hold the Shutdown Bypass-Preheat switch in the engine are critical to its life and performance. ON position for 10 seconds before starting a cold 2. Operate the engine under various conditions, engine. Holding the switch too long can burn out the particularly heavy loads to help seat engine glow plugs. -

Page 16: Shutdowns And Alarms

Watch the oil pressure gauge carefully and shut off the engine if it does *- For use with M843NW3 and M843NW3G generator sets with heat not show a normal reading (20-60 PSI) after a exchangers. Consult your Northern Lights dealer for your unit’s specific spare parts requirements. few seconds of operation. d. If the oil level is normal, DO NOT restart the engine. Call your dealer for assistance. -

Page 17: Servicing Schedule Chart

Updated 10-3-19 Servicing Schedule Chart The Servicing Schedule Chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each Service Point (SP) is listed on the page noted in the ‘page’ column. DAILY: EVERY 500 HOURS: Check oil level in engine Change primary fuel filter element Check primary fuel filter Change secondary fuel filter SP10 Check cooling water level SP15 Change impeller in raw water pump SP16 Check exhaust elbow AFTER FIRST 50 HOURS: EVERY 1000 HOURS:... -

Page 18: Servicing

Never allow the level to go below this 2. Use the most current API service category diesel rated area. Follow the lubrication recommendations on this oil. Northern Lights recommends the use of multi- page (Fig. 4). viscosity oil. 3. Use the proper weight oil for your average SP-2. -

Page 19: Air Cleaner

Updated 10-3-19 Servicing SP-4. AIR CLEANER 1. Inspect air cleaner every 200 hours. In dusty conditions, check more often. 2. Marine sets: if dirty, wash element in soapy water. Rinse and dry thoroughly before re-installing. Replace if necessary. Part number for the element is: M843N – #24-22009 NOTE: Failure to change air cleaner at recom- mended times can cause severe engine damage. -

Page 20: Valve Clearances

Updated 10-3-19 Servicing SP-6. VALVE CLEARANCES Cylinder No. Valve Arrangement Int. Exh. Int. Exh. Int. Exh. 1. Adjust valve clearance after 1000 hours or as needed. 2. To bring the No. 1 cylinder to top dead center in the When No.1 cylinder compression stroke, align the timing mark; the top is at Top Dead Center in the compression mark of the crank pulley with that of the timing gear... -

Page 21: Fuels - General

Updated 10-3-19 Servicing FUELS - GENERAL Primary Fuel Filter 1. Use only clean, high quality fuels of the following specifications, as defined by ASTM designation D975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures Part Numbers above freezing 32°F (0°C). b. Use grade no. 1 at ambient temperatures below Complete Unit: freezing and for all temperatures at an altitude of 24-50002... -

Page 22: Injector Service

1. Since operating conditions may vary considerably, it whenever necessary. Check should be made by a is difficult to give a definite interval for checking the Northern Lights dealer or local injection repair injection pump. But as a rule, pump settings, station. maximum speed, idle speed and exhaust smoke should... - Page 23 Updated 10-3-19 Servicing For illustrative purposes only, may not be your exact model. Figure 10: Remove delivery line flare nuts. Figure 14: Remove return line. Figure 11: Remove delivery lines. Figure 15: Unscrew injector. Figure 12: Cover lines, inlets and injection pump outlets. Figure 16: Remove and replace copper sealing washer.

-

Page 24: Cooling System - General

Updated 10-3-19 Servicing COOLING SYSTEM - GENERAL SP-12. CHECKING COOLANT LEVEL NOTE: Be sure to close the sea-cock before working 1. Check the coolant level each day before starting on the engine cooling system. the engine. Check the water level by removing the pressure cap from the expansion tank. -

Page 25: Heat Exchanger

OPX300K-2, included with your manual kit. Contact 2. Drain expansion tank and heat exchanger. 3. Remove heat exchanger end covers and remove your Authorized Northern Lights dealer or factory representative for additional copies. core. 4. Clean the inside of exchanger core tubes using ELECTRICAL SYSTEM - GENERAL a metal rod. -

Page 26: Booster Batteries

Servicing SP-19. WINTERIZING / OUT-OF-SERVICE BOOSTER BATTERIES If the generator set will not be used for more than 3 CAUTION: Battery gas can explode. months the following preparations should be taken for Keep all flames and sparks away from batteries. long term storage. -

Page 27: Troubleshooting

• If breaker is tripped, reset it. Does Not Function Faulty connection • Clean and tighten battery and harness plug connections. Sulfated or worn out batteries • Check specific gravity and electrolyte level of each battery. If you cannot correct problems with these procedures, see your Northern Lights dealer. OM843NW3 5/21... -

Page 28: Engine

Updated 2-10-20 Troubleshooting ENGINE PROBLEM POSSIBLE CAUSE RECOMMENDATION(S) Engine Hard to Start Improper starting procedure • See starting section of this manual. Take or Will Not Start special note of Bypass Switch operation. No fuel • Check level of fuel in fuel tank. Low battery output •... - Page 29 • Service air cleaner. Improper valve clearance • See your dealer. Injection nozzles dirty • See your dealer. Injection pump out of time • See your dealer. If you cannot correct problems with these procedures, see your Northern Lights dealer. OM843NW3 5/21...

- Page 30 • Use correct fuel for temperature. White Smoke Cold engine • Warm up engine to normal operating temperature. Defective thermostat • Remove and check thermostat. Engine timing off • See your dealer. If you cannot correct problems with these procedures, see your Northern Lights dealer. OM843NW3 5/21...

-

Page 31: Ac Wiring

Updated 4-23-20 AC Wiring Diagrams OM843NW3 5/21... - Page 32 Updated 4-23-20 AC Wiring Diagrams OM843NW3 5/21...

- Page 33 Updated 10-13-20 AC Wiring Diagrams OM843NW3 5/21...

- Page 34 Updated 4-23-20 AC Wiring Diagrams OM843NW3 5/21...

-

Page 35: Dc Wiring

Updated 4-23-20 DC Wiring Diagrams OM843NW3 5/21... - Page 36 Updated 4-23-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 37 Updated 4-23-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 38 Updated 10-13-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 39 Updated 10-13-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 40 Updated 10-13-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 41 Updated 10-13-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 42 Updated 4-23-20 DC Wiring Diagrams OM843NW3 5/21...

- Page 43 Updated 10-13-20 DC Wiring Diagrams OM843NW3 5/21...

-

Page 44: Panel Wiring

Updated 6-5-17 Panel Wiring Diagrams OM843NW3 5/21... - Page 45 Updated 6-5-17 Panel Wiring Diagrams OM843NW3 5/21...

- Page 46 Updated 10-13-20 Panel Wiring Diagrams OM843NW3 5/21...

-

Page 47: Appendix (Non-Current Production Diagrams) Dc Electrical

Updated 3-13-12 DC Wiring Diagrams OM843NW3 5/21... - Page 48 Updated 3-13-12 DC Wiring Diagrams OM843NW3 5/21...

- Page 49 DC Wiring Diagrams OM843NW3 5/21...

- Page 50 Updated 9-12-13 DC Wiring Diagrams OM843NW3 5/21...

-

Page 51: Panel Diagrams

Updated 3-13-12 Panel Wiring Diagrams OM843NW3 5/21... - Page 52 Updated 3-13-12 Panel Wiring Diagrams OM843NW3 5/21...

- Page 53 Updated 3-13-12 Panel Wiring Diagrams OM843NW3 5/21...

- Page 54 Updated 3-13-12 Panel Wiring Diagrams OM843NW3 5/21...

- Page 56 4420 14th Ave. NW., Seattle WA 98107 Tel: (206) 789-3880 • 1-800-762-0165 • www.northern-lights.com Northern Lights and Lugger are registered trademarks of Northern Lights, Inc. © 2020 All rights reserved. Litho USA.

Need help?

Do you have a question about the M843NW3G and is the answer not in the manual?

Questions and answers