Summary of Contents for Northern Lights OL1276

- Page 1 OL1276 For Models: L1276A and L1276A2 OPERATOR’S MANUAL Marine Generators | Marine Diesel Engines | Land-Based Generators...

- Page 2 4420 14th Avenue N.W. Seattle, WA 98107 Tel: (206) 789-3880 Fax: (206) 782-5455 Copyright ©2010 Northern Lights, Inc. All rights reserved. Northern Lights™, and the Northern Lights logo are trademarks of Northern Lights, Inc. Printed in U.S.A. PART NO.: L1276 03/10...

-

Page 3: Table Of Contents

This publication is the property of Northern Lights, Inc. It may not be reproduced in whole or in part without the written permission of Northern Lights, Inc. © Northern Lights, Inc. All rights reserved. Litho U.S.A. Publication number OL1276 03/10... -

Page 4: Introduction

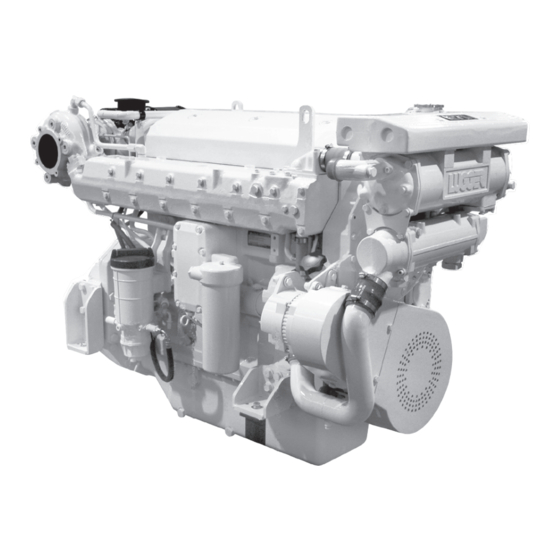

® turbocharged propulsion engine with a L1276A2 John Deere engine block, aftercooled, Tier II. Serial Numbers When referencing Northern Lights, Inc. equipment by serial number, please refer only to the number stamped on the Northern Lights ® or Lugger ®... -

Page 5: Warranty

Diesel engine exhaust and some of its constitu- Please take special notice of these sections. ents are known to the State of California to cause cancer, birth defects, and other reproductive harm. OL1276 03/10... -

Page 6: L1276A

11. Lube Oil Drain 18. Lube Oil Filter 5. Heat Exchanger Zinc (2) 12. Raw Water Pump 19. Dipstick 6. Crankcase Vent 13. Lube Oil Fill 20. Oil Cooler 7. Air Cleaner 14. Turbocharger 21. Secondary Fuel Filter OL1276 03/10... - Page 7 Notes OL1276 03/10...

-

Page 8: Operating Procedures

If the engne fails to start with the fi rst attempt, be sure that the starter has stopped com- pletely before re-engaging. NOTE: Never race a cold engine. Operate at 1000 RPM for a 3 to 5 minute warm-up period. OL1276 03/10... -

Page 9: Break-In Period

If the oil level is normal, DO NOT restart the engine. Call your Northern Lights or Lugger dealer for assistance. BREAK-IN PERIOD 1. -

Page 10: Servicing Schedule Chart

5) At 2500 hrs. an electronic injector preload adjusment must be made. 2) Consult manufacturer's maintenance schedule, note on chart. 6) Check at 5000 hours. 3) Whenever necessary. 4) Replace crankshaft damper @ 4500 hrs. or 60 mos., which ever occurs fi rst. OL1276 03/10... -

Page 11: Service Record

Check and fl ush cooling system SP19 Change impeller in raw water pump SP21 Check state of charge of batteries 2500 HOURS Check valve clearances SP16 Check and clean heat exchanger SP17 Check and clean reverse gear oil cooler SP23 Check crankshaft damper OL1276 03/10... -

Page 12: Servicing

2. The oil level must be between the “Waffl ed area” engine with the air cleaner removed. and the “Add”. Never allow the level to go below the “Add”. 3. Always add the same viscosity of oil as is already in the crankcase. OL1276 03/10... -

Page 13: Valve Clearances

5. Storing fuel: a. Keep dirt, scale, water and other foreign matter out of fuel. b. Avoid storing fuel for long periods of time. c. Fill the fuel tank at the end of each day's operation. This will reduce condensation. OL1276 03/10... -

Page 14: Fuel Filters

Pump primer until fi rm. C- Water Drain Valve g. Crank the engine until it starts (15 seconds maximum, 60 seconds rest). h. Open return line. Reproduced with permission from John Deere & Company, c.2003. All rights reserved. RG12829 Figure 2.1 OL1276 03/10... -

Page 15: Turbocharger

(Figure 3-B) Maximum Dissolved Solids 20.0 pitted unless the proper concentration and type of Maximum Total Hardness 10.0 SCA's are present in the coolant. Water pump impel- lers are also susceptible to pitting. PH Level 5.5 to 9.0 OL1276 03/10... -

Page 16: Cooling System - General

Run the engine for 2 hours and retest the coolant. Continue process until SCA -24°C +106°C Minimum -12°F +222°F concentration meets recommended levels. 3. SCA is available from your Northern Lights dealer -52°C +111°C Maximum in the following sizes. -62°F +232°F Pint - Part Number....20-00002 1/2 gallon - Part Number..20-00003... -

Page 17: Cooling System Flushing

If applicable, open the cooling system amount of EGC (antifreeze). air vent on top of turbocharger. 3. Test kits are available through your Northern Lights 4. Open the drains on the exhaust manifold and engine or Lugger Dealer. -

Page 18: Raw Water Pump

1. Remove the ground connection for the engine control system-to-vessel frame. 2. Disconnect the connectors from the ECU. 3. Connect the welder ground close to the welding point and be sure that the ECU or other electronic components are not in the ground path. OL1276 03/10... -

Page 19: Booster Batteries

100 hours. Clean corro- sion with a water and baking soda solution. Flush with clean water. Tighten terminals and grease them to inhibit corrosion. 3. Check the battery condition with a hydrometer every 750 hours. OL1276 03/10... -

Page 20: Troubleshooting

Troubleshooting If you cannot correct problems with these procedures, see your Lugger or Northern Lights dealer. valve. See your dealer. Engine Will Not Crank Broken piston spray jet: Weak battery: • Replace piston spray jet. See your dealer. • Replace battery. - Page 21 Troubleshooting If you cannot correct problems with these procedures, see your Lugger or Northern Lights dealer. Excessive Fuel Consumption (continued) Engine Emits White Smoke Engine overloaded : Water-to-air aftercooler fails: • Reduce load on engine. • Remove and inspect water-to-air aftercooler.

-

Page 22: Engine

Fuel Temperature Input Voltage Low Injector Wiring Shorted to Power Source Injector Wiring Shorted to Ground Injector Supply Voltage Problem ECU Error Cam Position Input Noise Cam Position Input Missing Cam Position Input Pattern Error Crank Position Input Noise OL1276 03/10... -

Page 23: Diagnostic Trouble Codes

ECU. Contact your dealer for help in correcting these codes. EE - Error XXXXX - EP ACP - Err No Data No Addr XXXXX - BO ACP - Err XXXXX - BR No Data No Data BUS - EP OL1276 03/10... -

Page 24: Data Sheets Unit Specifi Cations

3255 lbs (1477 kg) 3255 lbs (1477 kg) 3255 lbs (1477 kg) 1. Based on SAE J816b. 2. Specifi cation subject to change without notice. Contact Alaska Diesel Electric for updates. 3. Based on EN ISO 8665: 2006 OL1276 03/10... -

Page 25: On-Board Spare Parts

Northern Lights DC Wiring Diagram L1276 12 Volt Standard Ground Drawing D-4264 OL1276 11-03... - Page 26 Northern Lights DC Wiring Diagram L1276 12 Volt Isolated Ground Drawing D-4251A OL1276 11-03...

-

Page 27: Wiring Diagrams

Northern Lights DC Wiring Diagram L1276 24 Volt Standard Ground Drawing D-4030G OL1276 11-03... - Page 28 Northern Lights DC Wiring Diagram L1276 24 Volt Isolated Ground Drawing D-4026B OL1276 11-03...

- Page 29 Thermostat Thermostat Cover Gasket Speed Sensor Rocker Arm Cover Gasket Gasket Kit, Engine Overhaul Bearing Zinc Anode* Raw Water Pump Impeller w/Gasket* Raw Water Pump* Coolant Pump Repair Kit Workshop Manual Drive Belts *Heat exchanger cooled engines only OL1276 03/10...

- Page 30 4420 14th Ave. NW., Seattle WA 98107 Tel: (206) 789-3880 • 1-800-762-0165 • Fax: (206) 782-5455 Northern Lights and Lugger are registered trademarks of Northern Lights, Inc. www.northern-lights.com © 2010 All rights reserved. Litho USA.

Need help?

Do you have a question about the OL1276 and is the answer not in the manual?

Questions and answers