Summary of Contents for Parker Zander BSP-MT 1-8/D3

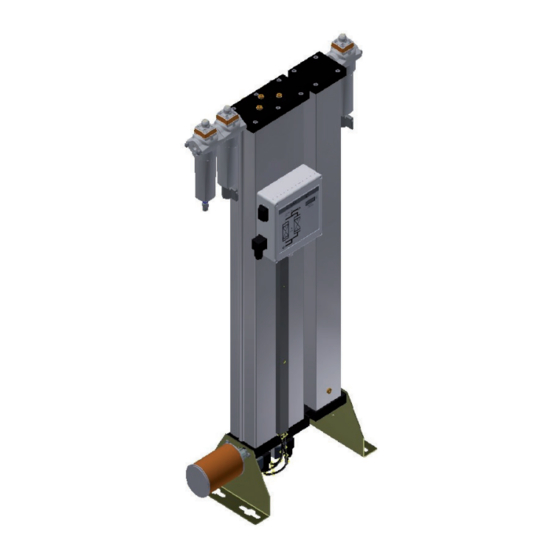

- Page 1 Dryer for Breathing air BSP-MT 1-8/D3 ( Generation - 3) Operating manual 28/01/2020 rev01 EN Cod: 398H272186...

-

Page 3: Table Of Contents

Maintenance work to be completed every 12 months ............36 Maintenance work to be completed every 24 months ............42 Maintenance work to be completed every 48 months ............42 Identify and eliminate faults Summary of faults ........................44 BSP-MT 1-8/D3... - Page 4 EN | User Manual Annex with technical documentation Technical data ......................... 48 Replacement and wear part list ....................49 Logic control diagram ......................51 Flow diagram .......................... 53 Installation on fl oor ......................... 54 BSP-MT 1-8/D3...

-

Page 5: Machine Passport

Further important data on the dryer such as the details on the permissible operating pressure and the electrical connection are found on the type plate (for position of the type plate see page 8 ) BSP-MT 1-8/D3... -

Page 6: General Information

Supplementary documents such as operating manuals for options or pertaining components must always be heeded. They contain additional information, e.g. regarding maintenance, and are therefore necessary for safe operation of the plant. Planned dryers may be equipped with special components. BSP-MT 1-8/D3... -

Page 7: About These Operating Instructions

These operating instructions must be continuously available at the site where the adsorber is used. We recommend to prepare a copy and to keep the same in a safe and freely accessible place next to the adsorber. Keep the original document in a safe place. BSP-MT 1-8/D3... -

Page 8: For Your Own Safety

◊ When fi lling drying agents, wear a dust mask and eye protection! ◊ If a spillage occurs, any spilt drying agent must be taken up immediately. There is a risk of skidding! BSP-MT 1-8/D3... -

Page 9: Intended Use Of The Dryer

Suspected misuse The dryer must not be misused as a climbing aid! Pipes, valves, and similar fi ttings have not been designed for such loads. They could fracture, tear off, or become damaged in another way. BSP-MT 1-8/D3... -

Page 10: Signs And Hazard Areas On The Dryer

Signs and hazard areas on the dryer Signs and labels Type plate of dryer Type plate of downstream fi lter Type plate of upstream fi lter Front view Please note these signs on the dryer. Keep them complete and always legible. BSP-MT 1-8/D3... - Page 11 When working at the oil indicator, always wear protective goggles. Skid risk When emptying and fi lling the vessels with drying agent, there is a risk of skidding caused by spilt drying agent. BSP-MT 1-8/D3...

-

Page 12: Transportation, Installation And Storage

Inform the haulier immediately in writing of any damages. Contact the manufacturer urgently in order to report the damage. Warning! A damaged dryer must not be taken into operation! Damaged components may lead to functional faults and possibly cause further damage. BSP-MT 1-8/D3... -

Page 13: Transporting And Installing The Dryer

The dryer should only be transported in an upright position. Note the weight of the dryer! Depending on its size, the dryer may weigh up to approx. 110 kg. Take this into account with regard to the following work steps! BSP-MT 1-8/D3... - Page 14 Retighten the screws securing the stand profi le and the muffl er. Use suitable attachment material of suffi cient carrying force to anchor the dryer to the wall. BSP-MT 1-8/D3...

-

Page 15: Storing The Dryer

If you wish to take the dryer back into service after an extended period of sto- rage, please proceed as described for its fi rst commissioning and start-up (see page 25). Store drying and purifying agents Do not store drying agents in the open air. Protect drying agents against humidity. BSP-MT 1-8/D3... -

Page 16: Technical Product Description

The stored humidity is then removed again from the drying agent and re-introduced into the ambient environment. To this end, the two chambers alternate between different operating modes. Whilst in one vessel, compressed air is de-humidifi ed (adsorption), in the other vessel the humid drying BSP-MT 1-8/D3... - Page 17 The humidity stored in the drying agent is taken up by the air fl ow and expelled into atmosphere via the muffl er. Regeneration in in the right drying agent chamber BSP-MT 1-8/D3...

- Page 18 When the drying agent in the adsorbing chamber has taken up a suffi cient level of humidity, then the switchover between the vessels will be effected between the vessels. Following switchover, the above-described process is repeated, with the adsorption and regeneration now taking place in the respective different vessel. BSP-MT 1-8/D3...

-

Page 19: Available Options

This replacement optimizes the regeneration air consumption and therefore restores the energy effi ciency of the dryer. To receive more information on this conversion, please contact the manufacturer. BSP-MT 1-8/D3... -

Page 20: Installation

The data required to meet these preconditions are contained in the technical documentation attached in the annex. Warning! If the above preconditions are not complied with, a safe operation of the dryer cannot be assured. Also, the functionality of the dryer may be detrimentally affected. BSP-MT 1-8/D3... -

Page 21: Connect Piping

The connection lines for the upstream fi lter (3) are to be installed at a slight incline in the direction of the upstream fi lter. One shutdown valve each (2, 6) is to be installed at the compressed air inlet and outlet ends of the dryer. BSP-MT 1-8/D3... -

Page 22: Installing The Electrical Connection

Fit terminal block into the connector and use bolt to remount the connector with seal on the switchbox. In all phases the dryer must be protected against short circuits by means of fuses. In order to relief cable strain, re-tighten the PG union. BSP-MT 1-8/D3... - Page 23 Connect the lines of the fault signalling system to relay K5 (see circuit diagram). Check bolt connections Before the initial start-up: Check all unions and bolt connections as well as the terminals in the control cabinet for secure seating; re-tighten if necessary. BSP-MT 1-8/D3...

-

Page 24: Start-Up

- of which: expansion time ~ 0,2 min ~ 0,2 min - of which: dehumidifi cation time ~ 4 min ~ 4 min - of which: pressure build-up ~ 1 min ~ 1 min Standby ~ 55 min, max. BSP-MT 1-8/D3... -

Page 25: Overview Of Operating And Control Elements

Switchbox with ON/OFF switch Display panel The display panel at the switchbox is equipped with LEDs (light emitting diodes) and a digital display, indicating the operating status of the dryer: Display panel at the switchbox BSP-MT 1-8/D3... - Page 26 With the optional dewpoint-sensing control, the following error messages might be dis- played: Display Cause ◊ Upper measuring range limit exceeded ◊ Dewpoint sensor defective. sens ◊ Dewpoint sensor not powered ◊ Cable defective or disconnected -999 ◊ Sensor defective BSP-MT 1-8/D3...

-

Page 27: Start Up Dryer

This causes the drying agent in each chamber to be regenerated repeatedly and thus to be prepared optimally for the take-up of humidity. BSP-MT 1-8/D3... - Page 28 (see also chapter , page 30). Then proceed as follows: Remedy fault: Look up possible cause of the fault, and how to remedy the same, in the table on page Remedy fault. Repeat the start-up procedure. BSP-MT 1-8/D3...

-

Page 29: Changing Cycle Mode (Optional)

How do I change cycle mode? Wait until the dryer has reached the pressure build-up phase (phase prior to switchover). One LED for Adsorption B1/B2 is on in the fl ow diagram. Set the ON/OFF switch to position The programme continues the cycle. BSP-MT 1-8/D3... -

Page 30: Monitoring Dryer Operation

The dewpoint at which a switchover is made is preset at the factory. After commissioning or extensive maintenance work, check the dewpoint display at the dryer. Under certain circumstances, the desired dewpoint is only reached after prolonged operation BSP-MT 1-8/D3... - Page 31 Display Cause ◊ Upper measuring range limit exceeded ◊ Dewpoint sensor defective sens ◊ Dewpoint sensor not powered ◊ Cable defective -999 ◊ Sensor defective For instructions on how to eliminate faults, see chapter Identify and eliminate faults BSP-MT 1-8/D3...

-

Page 32: Shutdown And Restart Dryer

Close the compressed air inlet valve (provided by the operator). Disconnect voltage supply Switch off the dryer by setting the ON/OFF switch to position 0. Disconnect dryer from compressed air system Close the compressed air outlet valve installed by the owner. BSP-MT 1-8/D3... -

Page 33: If Work Is To Be Carried Out On The Electrical System

Ensure that the manual drain on the downstream fi lter is closed. Pressurise and switch on the dryer as described in the section Open compressed air supply and switch on dryer on page 25. The dryer is now in operation again and operates fully automatically. BSP-MT 1-8/D3... - Page 34 Reassemble the fi lter and commission the dryer (see the operating manual of the fi lter for the reassembly). Switch on the dryer and pressurise as described in section Open compressed air supply and switch on dryer, page 22. Check that the vessel and the downstream fi lter are leak tight. BSP-MT 1-8/D3...

-

Page 35: Maintenance And Repair Of The Dryer

◊ Never leave tools, loose parts or cloths at or on the dryer. ◊ Only use replacement parts that are suitable for the relevant function and meet the techni- cal requirements stipulated by the manufacturer. This is always the case, if you use original replacement parts only. BSP-MT 1-8/D3... -

Page 36: Regular Maintenance Intervals

• valves coils. Check valves: Replace balls and springs. Upstream and Please see the enclosed operating instructions for the attached fi lters. downstream fi lter Maintenance work has to be carried out as specifi ed in this document. BSP-MT 1-8/D3... -

Page 37: Instructions For Use Of The Dongle

Contact the service department of the manufacturer. Clean dryer Remove any loose dust by means of a dry cloth, and, if required, also by means of a moist and well wrung cloth. Clean the surfaces with a moist well wrung cloth. BSP-MT 1-8/D3... -

Page 38: Maintenance Work To Be Completed Every 12 Months

— ..Blow out with compressed air for cleaning — ..or renew muffl er, if necessary. Undo muffl er BSP-MT 3-8 Muffl ers must be replaced annually and after each desiccant change. Screw sound absorber tight again. Restart dryer (see page 31 ). BSP-MT 1-8/D3... - Page 39 Hold the box of the dewpoint sensor ready. Release pressure from dryer and shut down the unit (see page 30 ) Loosen the screw at the adapter (1) and disconnect signal cable with the adapter and BSP-MT 1-8/D3...

- Page 40 Dispose of the used purifying agent in accordance with all applicable regulations. The different purifying agents fi ll layers (according to the technical data in appendix). Use a funnel, if necessary. Ensure that the agent is fi lled into the chamber with a high bulk density. BSP-MT 1-8/D3...

- Page 41 Before reassembling the check valve plate, you should replace the drying and the purifying agents. Removing the check valve plate Note: To replace the purifying agent, please refer to the instructions for 12-monthly maintenance tasks on page 42. BSP-MT 1-8/D3...

- Page 42 Before fi lling in new drying agent, we recommend that you replace the demister and the lower perforated plates. Replacing the lower perforated plate Loosen the screws on the solenoid valve plate. Remove and replace perforated plate and demisters. Removing solenoid valve plate BSP-MT 1-8/D3...

- Page 43 Restart the dryer (see page 31 ). Check that the connection is leak tight. Correctly affi xing the check valve plate Operate the dryer for two cycles, then shut it down again. Replace sound absorber as described on page 36 BSP-MT 1-8/D3...

-

Page 44: Maintenance Work To Be Completed Every 24 Months

Insert new balls and new springs and ensu- re that they are not jammed. Replace the seals at the securing screws and tighten the screws. If no other maintenance work is to be car- ried out: Restart the dryer (see page 31 ). Check valves BSP-MT 1-8/D3... - Page 45 (3). Position new solenoid (1) onto the armature and secure it to the spring bracket (5). Solenoid valve If no other maintenance work is to be carried out: Restart the dryer (see page 31 ). BSP-MT 1-8/D3...

-

Page 46: Identify And Eliminate Faults

• pressurised. Eliminate any faults in the compressed air system. Excessive compressed Leakage Check condensate trap at • • air consumption the upstream fi lter; clean, if necessary. BSP-MT 1-8/D3... - Page 47 Check spring and solenoid; • • (audible humming sound or replace, if necessary. Check valve fl apping). diaphragm; replace, if necessary. Dryer is excessively Solenoid valve Y1/Y2 can- Check solenoid and • • bled not be closed diaphragm; replace, if necessary. BSP-MT 1-8/D3...

- Page 48 The package includes a dongle with which you can reset the • • operating hours counter after maintenance has been carried out. For instructions on how to use the dongle see the enclosed information sheet (in the service kit). BSP-MT 1-8/D3...

-

Page 49: Annex With Technical Documentation

EN | User Manual Annex with technical documentation Annex with technical documentation This annex comprises the following information and technical documentation: ◊ Technical data ◊ Replacement and wear parts list ◊ Logic control diagram ◊ Flow diagram ◊ Dimensional drawing BSP-MT 1-8/D3... -

Page 50: Technical Data

65 – 86 dB(A) .. relative to free fi eld measurement, 1 m surr. fi eld Drying agent Chamber 1 100 % drying agent Chamber 2 100 % molecular sieve Chamber 3 Down Middle 33%activated carbon 33% catalyst 33%activated carbon BSP-MT 1-8/D3... -

Page 51: Replacement And Wear Part List

-45°C at 7 bare . .. All values refer to customary concentration levels present in the inlet air. Replacement and wear part list Note: When exchange or replacement parts are ordered, always state the dryer type and the build no. of the dryer. These data are found on the type plate. BSP-MT 1-8/D3... - Page 52 BPS-MT 1 to When Indicator tube for oil indicator P02/ZR BPS-MT 8 neccessary Dessicant and activated carbon packages Order-ID. 12 months – drying agent DESPAC2EF 12 months – purifying agent DESPAC3AK DESPAC1KTY DESPAC4KTY BSP-MT 1-8/D3...

-

Page 53: Logic Control Diagram

EN | User Manual Annex with technical documentation Logic control diagram Adsorption in B1 and regeneration in B2 BSP-MT 1-8/D3... - Page 54 EN | User Manual Annex with technical documentation Regeneration in B1 and adsorption in B2 BSP-MT 1-8/D3...

-

Page 55: Flow Diagram

Bottom plate 10.109 Left perforated plate 130.154 Seal 10.110 Conical pressure spring 130.155 Perforated plate 10.111 Right perforated plate Oil indicator Regeneration gas orifi ce plate Optional devices: Control unit Start-up device Control system Dewpoint-sensing unit Upstream fi lter BSP-MT 1-8/D3... -

Page 56: Installation On Fl Oor

[kg] Type BSP-MT 1 1/4" 16,5 BSP-MT 2 1/4" 21,5 BSP-MT 3 1/4" 29,0 BSP-MT 4 1/4" 1075 1051 36,0 BSP-MT 6 1/2" 1203 1097 75,0 BSP-MT 7 1/2" 1428 1322 85,0 BSP-MT 8 3/4" 1628 1522 97,0 BSP-MT 1-8/D3... - Page 58 A division of Parker Hannifin Corporation Parker Hannifin Manufacturing S.r.l. Sede Legale: Via Privata Archimede, 1- 2009 Corsico (MI) Italy Sede Operativa: Gas Separation and Filtration Division EMEA - Strada Zona Industriale, 4 35020 S.Angelo di Piove (PD) Italy tel +39 049 971 2111- fax +39 049 9701911 Web-site: www.

Need help?

Do you have a question about the BSP-MT 1-8/D3 and is the answer not in the manual?

Questions and answers