Table of Contents

Advertisement

Quick Links

MODEL NUMBERS:

ESC3100, ESC4100,

ESC4125, ESC4150,

ESC5175, ESC5200,

ESC6225, ESC7275

An ISO 9001-2008 Certified Company

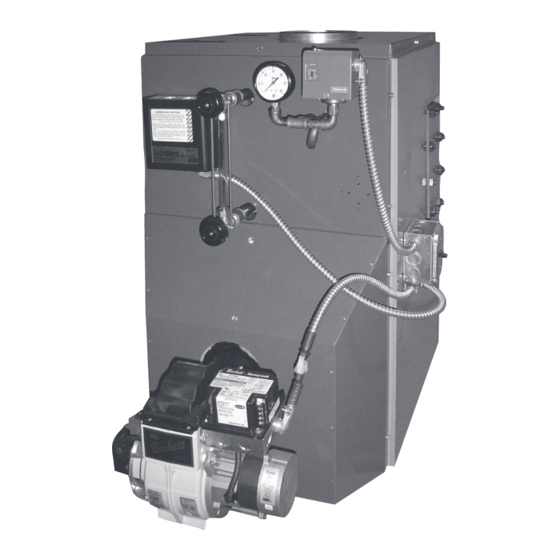

ESC STEAM

OIL-FIRED CAST IRON BOILER

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

PatENt 7,823,544

DUNKIRK BOILERS

2201 Dwyer Ave.

Utica, NY 13051

www.ecrinternational.com

P/N 240007514, Rev. F [03/2011]

Advertisement

Table of Contents

Summary of Contents for ECR DUNKIRK ESC3100

- Page 1 ESC STEAM OIL-FIRED CAST IRON BOILER INSTALLATION, OPERATION & MAINTENANCE MANUAL MODEL NUMBERS: ESC3100, ESC4100, ESC4125, ESC4150, ESC5175, ESC5200, ESC6225, ESC7275 PatENt 7,823,544 DUNKIRK BOILERS 2201 Dwyer Ave. Utica, NY 13051 www.ecrinternational.com An ISO 9001-2008 Certified Company P/N 240007514, Rev. F [03/2011]...

-

Page 2: Table Of Contents

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS TABLE OF CONTENTS IMPORtaNt: Read the following instructions Ratings, Data, And Dimensions ......3 COMPLEtELY before installing!! Installation Procedure ........4 WARNING Ventilation And Combustion Air ......5 1. Keep boiler area clear and free from Connecting Supply And Return Piping ..... -

Page 3: Ratings, Data, And Dimensions

RATINGS, DATA, AND DIMENSIONS I=B=R Oil Burner Min. Natural Draft Pump Nozzle (3)(4) I=B=R Net Ratings Chimney Size Output Input A.F.U.E. Pressure Furnished Boiler Model Steam Sq. Ft. Rating (4)(9) G.P.H. 140PSIG Square Number Round Steam 8x8x15 365S 0.65 .60 80B 8x8x15 3100S 1.00... -

Page 4: Installation Procedure

INSTALLATION PROCEDURE replacement of another appliance such as a water heater. WARNING The boiler shall be installed such that the oil ignition system Improper installation, adjustment, components are protected from water (dripping, spraying, alteration, service or maintenance can rain etc.) during appliance operation and service. cause injury or property damage. -

Page 5: Ventilation And Combustion Air

VENTILATION AND COMBUSTION AIR WARNING Air openings to combustion area must not be obstructed. By following the instructions below, adequate combustion air can be maintained. COMBUStION aIR REQUIREMENtS (Minimum Opening Requirement) Unconfined Area* Confined Area** Outside Inside Outside Combustion Air Combustion Air 1 Sq. - Page 6 VENTILATION AND COMBUSTION AIR When the boiler is installed in a confined space and Figure #6 all air is provided from the outdoors, the confined space shall be provided with two permanent openings, one commencing within 12 inches from the top and one commencing 12 inches from the bottom of the enclosure.

-

Page 7: Connecting Supply And Return Piping

CONNECTING SUPPLY AND RETURN PIPING Suggested piping for steam heating system can be Figure #8 for typical piping for domestic hot water seen in Figure #7. Actual piping may vary based on heater. system design and local conditions. Figures #9 and #10 for the suggested piping for a For further piping information refer to the I=B=R modular steam boiler. -

Page 8: Venting System Inspection & Installation

VENTING SYSTEM INSPECTION & INSTALLATION If oil fired water heater is vented into same flue as boiler, WARNING provide separate hole into chimney whenever possible. Boiler is to be vented by natural draft and When this isn’t possible, use “Y” connection in flue pipe, shall not be connected into any portion of using separate draft regulator for each unit. -

Page 9: Electrical Wiring

OIL TANk AND PIPING An oil line filter and shut-off valve should be installed in the Fuel pump connections and by-pass should be made suction line. Shut-off valves should be installed in both the according to instructions attached to the fuel pump. If suction and return lines at the burner for convenience in tank is more than 20' from the boiler, a two stage fuel servicing burner. - Page 10 STEAM WIRING W/BECkETT BURNER COMPONENT CODING Thermostat (Millivolt) Th-1 MR-PS Manual Reset Pressure Switch Circulator Thermostat (24 Volt) Control Terminal Th-2 Energy Cut-Off Thermostat (Line Voltage) Th-3 Relay Coil Pilot Safety Coil Transformer (120V/24V/40VA) TR-1 Relay Contacts Wire Connection Transformer (120V/24V/50VA) TR-2 Relay Contacts LWCO...

- Page 11 STEAM WIRING W/RIELLO BURNER WIRING CODE Line Voltage By Factory Low Voltage By Factory Line Voltage By Installer Low Voltage By Installer...

- Page 12 STEAM WIRING W/CARLIN BURNER WIRING CODE Line Voltage By Factory Low Voltage By Factory Line Voltage By Installer Low Voltage By Installer...

-

Page 13: Normal Sequence Of Operation

NORMAL SEqUENCE OF OPERATION boiler in operation, test the mechanical low water cut-off On a call for heat, the thermostat will actuate, completing device for proper operation. While burner is on, open the the circuit to the boiler. In turn, the ignition systems blow-off valve located in the lower portion of the cut-off are activated and ignition will begin. - Page 14 OPERATING INSTRUCTIONS Pressure Control - Remove cover and note pressure setting. With boiler operating, decrease the setting. out of position during transportation. Lubricate burner motor if necessary. When the setting is lower than boiler pressure, the Set room thermostat to call for heat, or jump thermo- control will open and turn off the boiler.

-

Page 15: Maintenance Procedures

OPERATING INSTRUCTIONS Refill boiler to its normal water line. It is recommended to replace the nozzle at the start of each C. Primary Control and Flame Sensor - heating season. Lubricate the burner motor and circulator motor - if required - with a few drops of a good grade of To Check: light motor oil. - Page 16 MAINTENANCE PROCEDURES Gradually raise hot water level to skimming hole (Figure #7) WARNING installed on the rear section of the boiler being careful not to Discharge will be boiling hot water and raise it above the opening of the hole. Skim until there are no steam.

-

Page 17: Service Checklist

MAINTENANCE PROCEDURES Periodic inspection and tightening of the tankless heater/cover WARNING plate bolts will reduce the risk of leaks. See parts 3 and 5 Water will be boiling hot. under "Coil and Cover Plate Replacement Parts." ELECtRONIC LOW WatER CUt-OFF It is suggested that a qualified service agency be employed to make an annual inspection of the boiler and heating Operation of the probe and control should be checked, with... -

Page 18: Replacement Parts

REPLACEMENT PARTS COIL aND COvER PLatE ItEM PaRt NO. DESCRIPtION QtY. ⁄ -14 x 1½ Bolt - hW-012.02 Square Head Gasket - B Tankless 252-2-2.00 Cover Plate - B Tank- 202-2-1.00 less Coil ⁄ - 14 Square hW-013.01 Nut 252-3-1.02 Tankless Coil L - 24 1635001 Well ¾... - Page 19 REPLACEMENT PARTS HaRDWaRE ItEM PaRt NO. DESCRIPtION Relief Valve #15 ¾ 1570001 Pipe Fit Coupling ¾" PF-019.02 PF-005.01 Pipe Fit Npl ¾ Close ⁄ -18 x 2 ⅜ hW06701 Stud 2252501 Support - Jacket Brkt ⁄ " x 18 x 1 ⅜" hW07001 Stud ⁄...

- Page 20 REPLACEMENT PARTS HEAT EXCHANGER ItEM PaRt NO. DESCRIPtION ItEM PaRt NO. DESCRIPtION #22 Push Nipple - 3 Sec. 100-5-10.01 Rear Section #22 Push Nipple - 4 Sec. #60 Push Nipple - 3 Sec. #22 Push Nipple - 5 Sec. #60 Push Nipple - 4 Sec. 100-1-5.01 #22 Push Nipple - 6 Sec.

- Page 21 REPLACEMENT PARTS SWING DOOR AND MOUNTING DOOR COMPONENTS ItEM PaRt NO. DESCRIPtION Mounting Door Insulation & 2552901 Plug Door Plug Replacement 2551901 Screw ¼ - 20 x ½ Self-Tap- hW-005.01 ping Observation Door 10011701 Obs. Door Gasket 25511101 ¼ x 1¾ Drive Lock Pin hW06801 10011501 Swing Door...

- Page 22 REPLACEMENT PARTS BURNER COMPONENtS ITEM PART NO. DESCRIPTION BRNR,BECK,AFG/UT2401,NOZ,.85,80B 240007286 BRNR,BECK,AFG/UT2402,NOZ,1.25,80B 240007288 BRNR,BECK,AFG/UT2403,NOZ,1.75,70B 240007289 BRNR,BECK,CF375/UT2601,NOZ,2.00,45B 240007290 BRNR,BECK,CF375/UT2602,NOZ,2.25,60B 240007291 BRNR,F5/40 SERIES,RIELLO,2 PCS 1050006 BRNR,F10/40 SER,RIELLO #3949071 BN07007 BRNR,OIL,EZ1,3100SE/STE,CARLIN BRNR,OIL,EZ1,4100SE/STE,CARLIN BRNR,OIL,EZ1,4125SE/STE,CARLIN BRNR,OIL,EZ1,4150SE/STE,CARLIN BRNR,OIL,EZ1,5200SE/STE,CARLIN BURNER OIL FLANGE GASKET #3616 BN08001 CAD CELL (FOR BOILERS W/ BECKETT BURNERS ONLY CD-001.01 CONTROL R7184B 1032 (7456U) (FOR BOILERS W/ BECKETT BURNERS ONLY) 240008816...

- Page 24 DUNKIRK BOILERS 2210 dwyer Avenue, Utica NY 13504-4729 Phone: (315) 797-1310 • Fax: (866) 432-7329 e-mail: info@ecrinternational.com web site: www.ecrinternational.com...

Need help?

Do you have a question about the DUNKIRK ESC3100 and is the answer not in the manual?

Questions and answers