Table of Contents

Advertisement

Ridder Drive Systems B.V.

Lorentzstraat 32

3846 AX Harderwijk

PO Box 360

3840 AJ Harderwijk

the Netherlands

T +31 (0)341 416 854

F +31 (0)341 416 611

I ridder.com

E info@ridder.com

Maintenance Instruction

Horticulture, Intensive Livestock and Crop Storage

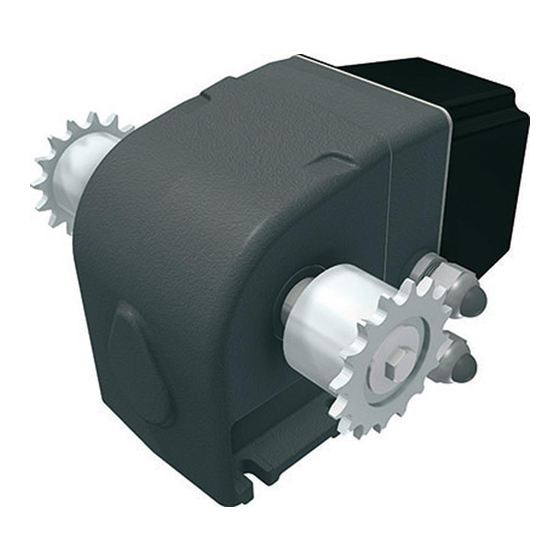

RLD MotorGearbox

RW MotorGearbox

RB TubeMotor

RPR DriveUnit

RPD MotorGearbox

W WormGearbox

RMD ManualDrive

TRN RackDrive

RRD RackDrive

TU RackDrive

Original instruction

RI0001EN - 2021.03 - V01

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ridder RLD

- Page 1 Ridder Drive Systems B.V. Lorentzstraat 32 3846 AX Harderwijk T +31 (0)341 416 854 PO Box 360 F +31 (0)341 416 611 3840 AJ Harderwijk I ridder.com the Netherlands E info@ridder.com Maintenance Instruction Horticulture, Intensive Livestock and Crop Storage RLD MotorGearbox...

-

Page 2: Table Of Contents

Table of contents General General information About this document......................Technical information Maintenance Maintenance RLD motor gearboxes..................Maintenance RW motor-gearboxes ..................Maintenance RB tube motors ....................Maintenance RPR drive-units....................Maintenance RPD motor gearboxes ..................Maintenance W240/400/600 worm gearboxes..............Maintenance RMD manual-drive units ................ -

Page 3: General

● Replacement of parts is necessary ● A problem is found with no solution. Refer to “Troubleshooting” (manual) first. Refer to the Ridder catalogue or the website at ridder.com for more information about spare parts (or accessories) that are available. - Page 4 General General information Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com...

-

Page 5: Technical Information

Inspection and maintenance work is only permitted to approved personnel. Maintenance RLD80/200 [0-10 V/Modbus] Maintenance on the RLD motor gearbox is usually not necessary ("maintenance-free"). It is recommended to do the checks that follow every 6 months: ● Of the correct operation of the drive unit and the system ●... -

Page 6: Maintenance Rb Tube Motors

Inspection and maintenance work is only permitted to approved personnel. Maintenance RB For the Ridder RB tube motor and accessories not much maintenance is necessary. It is recommended to do the checks that follow every 6 months. ● Do a check of the set end positions of the limit-switch system. -

Page 7: Maintenance Rpd Motor Gearboxes

● For oil leakage. Tell your installer if there is a leakage ● Of the mechanical condition (wear and tear, hand crank, output-shaft connections to the operated system, fasteners and such). Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com... -

Page 8: Maintenance Trn Rack Drives

● Lubricate rack (all around) with brush (teeth, sides, bottom). ● Lubricate bearing (opposite system) all around (fully: between surfaces tube/bearing) with brush. Lubricant TRN Grease: CASTROL OPTILEB-GR 823-2 (item number: 182029) Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com... -

Page 9: Maintenance Rrd700 Rack Drives

● Lubricate rack (all around) with brush (teeth, sides, bottom). ● Lubricate plastic bearing (opposite system) all around (fully: between surfaces tube/bearing) with brush. Lubricant RRD700 Grease: CASTROL OPTILEB-GR 823-2 (item number: 182029) Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com... -

Page 10: Maintenance Rrd800 Rack Drives

● Lubricate pinion-house unit with grease gun (approximately 5 strokes per grease nipple). ● Lubricate rack (all around) with brush (teeth, sides, bottom). Lubricant RRD800 Grease: CASTROL OPTILEB-GR 823-2 (item number: 182029) Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com... -

Page 11: Maintenance Tu Rack Drives

● Lubrication of sheet-steel racks is not permitted. Lubricant TU and slide-bearing plates Grease: DIVINOL LITHOGREASE 7000 (DLG7) (item number: 182051/ 182056/ 182058) Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com... - Page 12 Technical information Maintenance Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com...

-

Page 13: Accessories

Grease: Divinol Lithogrease 7000 (DLG7) - TU rack drives High quality lithium complex grease with Teflon for lubrication of slide bearings and Ridder TU rack drives. Suitable for use from -20 °C up to +150 °C operating-temperature ranges. Divinol Lithogrease 7000 (DLG7) grease is water resistant. - Page 14 ............................. Ridder Drive Systems B.V.

- Page 15 ............................. Ridder Drive Systems B.V.

Need help?

Do you have a question about the RLD and is the answer not in the manual?

Questions and answers