Subscribe to Our Youtube Channel

Summary of Contents for Ridder LogicDrive RLD80

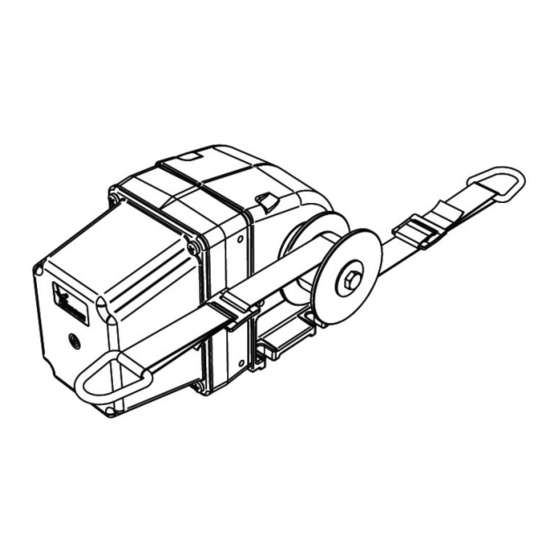

- Page 1 Product Manual Ridder LogicDrive RLD80 265100EN - 2017.07 - V04 Ridder Drive Systems Lorentzstraat 36-38 3846 AX Harderwijk P.O. Box 360 3840 AJ Harderwijk The Netherlands T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com E info@ridder.com...

- Page 2 Table of contents 1.1 LogicDrive RLD80 product manual Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 3 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 4 Mechanical Electrical Control Environment 2.4 LogicDrive RLD80 dimensions Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 5 Winch belt forces depend on: Graph lines: Belt forces only applicable for opening and closing air inlets and Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 6 2.6 LogicDrive RLD80 packaging contents 45° ≤ α ≤ 315° 315° < α < 45° 45° ≤ α ≤ 315° 315° < α < 45° 90° 90° 45° 45° α=0° α=0° 180° 180° 315° 315° 270° 270° Ridder Drive Systems...

- Page 7 Please ensure that the RLD80 is mounted securely, so forces applied. cover remains accessible so you will have no problems Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 8 3.4 Pre-winding the winch belt onto the belt drum Belt drum with a single belt: Belt drum with a double belt: Not pre-winding the winch belt may result Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 9 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 10 Max. cable length at 24 V DC mm² Please use only suitable control components and switch materials. The LogicDrive requires a supply voltage of 24 V DC ± 10 %. Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 11 Always use separate cables for the 24 V DC supply voltage and 0-10 V DC control signal. Connect the shield in the control box and NOT in the RLD80! Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611...

- Page 12 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 13 Control signal Teach-in sequence Minimum movement Teach-in mode mode Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 14 Hold to run DIR A Hold to run DIR B Pulse DIR A Pulse DIR B Stop pulse Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 15 5.3 LogicDrive RLD80 status LEDs Control Emergency signal 0-10 V 1-10 V 2-10 V V DC. of the control signal range must be greater than 1 V DC. Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611...

- Page 16 Picture Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 17 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 18 Picture Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 19 Picture Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 20 Picture Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 21 7.1 LogicDrive RLD80 alarm contact Connect the alarm contact of the RLD80 to an alarm unit or an alarm input of a control box! 8.1 LogicDrive RLD80 blink codes of status LEDs Blink code / Meaning Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 22 Blink code / Meaning Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 23 Blink code / Meaning Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 24 9.1 LogicDrive RLD80 maintenance Problem 1 The LogicDrive RLD80 does not respond to the control signal. Cause 1 Cause 2 Cause 3 Cause 4 Cause 5 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 25 Problem 2 signal. Cause 1 Cause 2 Cause 3 10.2 Technical Support www.ridder.com 10.3 Environment Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 26 11.1 LogicDrive RLD80 accessories Item no. 587101 587102 587200 507220 590023 590008 Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 27 12.1 Meaning of warnings in this product manual is performed incorrectly. Ridder Drive Systems T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com...

- Page 28 www.ridder.com...

Need help?

Do you have a question about the LogicDrive RLD80 and is the answer not in the manual?

Questions and answers