Table of Contents

Advertisement

Quick Links

Crane Electronics Ltd

The force in torque management

Operators Manual

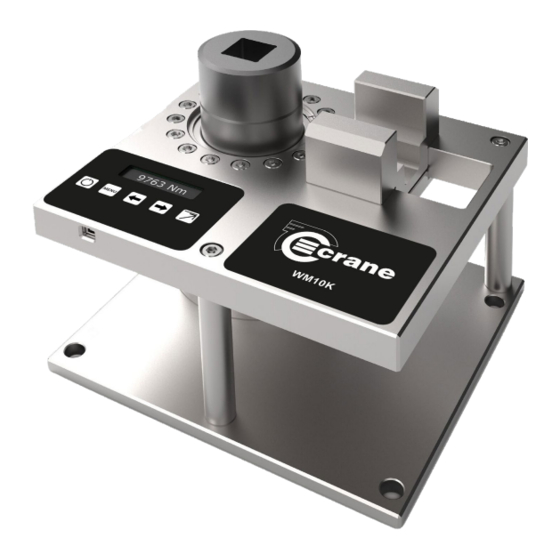

WM10K Torque Tester

Manual Issue 1

Crane Electronics Ltd

Notice

ALL RIGHTS RESERVED. Reproduction of any part of this manual in any form whatsoever,

without the prior permission in writing from Crane Electronics Ltd is forbidden.

Copyright © September 2021 by Crane Electronics Ltd.

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

1

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane-electronics.com

Advertisement

Table of Contents

Summary of Contents for Crane Electronics WM10K

- Page 1 Crane Electronics Ltd Notice ALL RIGHTS RESERVED. Reproduction of any part of this manual in any form whatsoever, without the prior permission in writing from Crane Electronics Ltd is forbidden. Copyright © September 2021 by Crane Electronics Ltd. Crane Electronics Ltd...

-

Page 2: Table Of Contents

Crane Electronics Ltd The force in torque management CONTENTS Contents UKCA Marking, CE Marking & Compliance Product Disposal & About this Manual Packing list Features & Dimensions Specifications Technical Features Icons Start Up Operation Fixed Icons Measurement Units Filters Maintenance... -

Page 3: Ukca Marking, Ce Marking & Compliance

Tel: +44 (0)1455 25 14 88 UKCA MARKING Crane Electronics Limited declares that the WM10K has been assessed and complies with the UK regulatory requirements. CE MARKING Crane Electronics Limited declares that the WM10K has been assessed and complies with the requirements of the relevant CE Directives. -

Page 4: Product Disposal & About This Manual

To enable this product to be disposed of properly i.e. cradle to grave, Crane Electronics is willing to accept the return of your product (at your cost) for recycling or alternatively, for more detailed information about recycling of this product please contact your local authority or the Distributor / Company where you have purchased the product. -

Page 5: Packing List

- 1 x standard reaction stop - 1 x secondary reaction post - Can be supplied with or without a protective carry case Please ensure all items are present and notify Crane Electronics Ltd immediately of any shortages. Crane Electronics Ltd Watling Drive... -

Page 6: Features & Dimensions

Crane Electronics Ltd The force in torque management FEATURES AND DIMENSIONS – WM10K Weight: 50 Lbs [23 kg]. Crane Electronics Ltd Watling Drive Sketchley Meadows Hinckley LE10 3EY Tel: +44(0) 1455 25 14 88 www.crane-electronics.com... -

Page 7: Specifications

Not Suitable for use with hydraulic or impact tools The accuracy of the WM10K is calibrated to meet or exceed: 1% of Full Scale Deflection (FSD) from 2% to 8% of torque range and 1% of reading from 8% to 100% of torque range. - Page 8 The digital display module includes a USB/battery charger port as shown below: DC Interface - The interface for the 5V DC USB AC adapter is supplied with the WM10K. Use the adapter if you plan on using the main power source.

-

Page 9: Technical Features

Operating Temperature: 32°F [0°C] to 122°F [50°C]. Accuracy: The accuracy of the WM10K is calibrated to meet or exceed: 1% of FSD from 2% to 8% of torque range and 1% of reading from 8% to 100% of torque range. -

Page 10: Start Up

START UP Mount the tool: Remove the WM10K components from the packaging and place on a flat surface. Ensure that the digital display module is plugged in or sufficiently charged to operate. Select and position an appropriate adaptor onto the run down fixture to allow the proper mounting of the tool. - Page 11 Slide the reaction stop to the desired position. Lock into place by rotating the lock handle located directly under the reaction stop. Once the WM10K unit has been appropriately adjusted, complete the mounting of the tool. Handle Crane Electronics Ltd...

-

Page 12: Operation

Crane Electronics Ltd The force in torque management OPERATION Check torque with digital display: Activate the tool, ensure that all safety precautions are being followed. Take note of potential pinch points when handling the tool during calibration testing. After the tool stalls, the peak reading will momentarily appear on the display module, and then is saved. For the next cycle it is important to reverse the tool and loosen the run down fixture. -

Page 13: Measurement Units

The peak mode is recommended for rotary tools and wrenches. Track Mode The track mode displays the torque as it is being applied to the transducer. This mode is used primarily for verifying the calibration of the WM10K unit. MEASUREMENT UNITS Press the Menu button and then press... -

Page 14: Maintenance

The force in torque management MAINTENANCE The WM10K Calibration System requires very little maintenance, but periodic lubrication of the run down fixture is critical to the longevity of the tool. The run down bolt and disc spring should be periodically removed and inspected, and if necessary, coated with a high pressure anti-seize lubricant. -

Page 15: Troubleshooting

Service, Repair and Calibration All service, repair or calibration requirements for the WM10K can be handled by Crane Authorized Service Centers. For more information, contact Crane Electronics on +44(0)1455251488, email service@crane-electronics.com or visit www.crane-electronics.com...

Need help?

Do you have a question about the WM10K and is the answer not in the manual?

Questions and answers