Advertisement

Quick Links

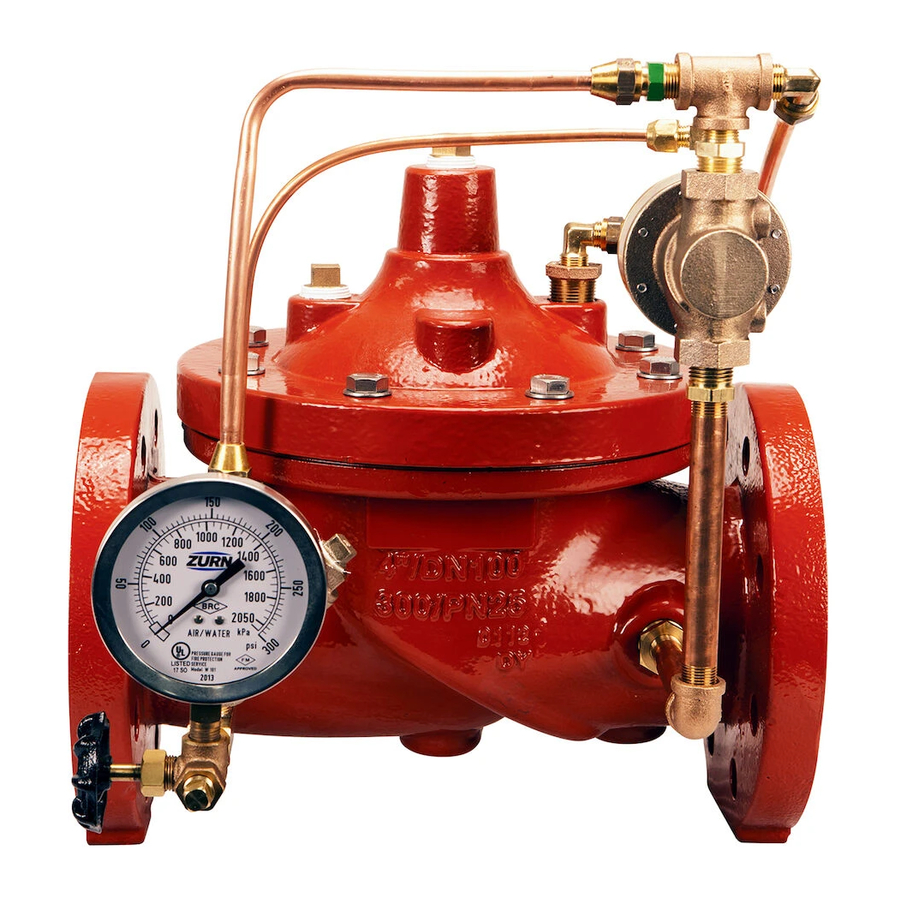

Model ZW205FP

Fire Pump Relief Valve

Globe and Angle Pattern Bodies

2", 2-1/2", 3", 4", 6", 8", & 10"

Installation

DESCRIPTION

The Zurn Wilkins Model ZW205FP Fire Pump Pressure Relief Valve

is designed specifically for Fire Suppression Systems to relieve high

system pressures. The pilot assembly reacts quickly to increases

of upstream pressure to prevent damage to system piping, valves,

and sprinklers while maintaining positive pressure on fire pumps. As

the water demand increases in the fire suppression system the relief

valve will start to close, directing more water to suppress fires. The

relief valve will maintain the upstream pressure at the set pressure as

long as maximum flow rates of the valve are not exceeded. The Zurn

Wilkins Model ZW205FP is design to open quickly and close slowly to

prevent upstream pressure surges. In addition the Model ZW205FP

comes standard with red epoxy coating internally and externally for

corrosion protection, as well an inlet pressure gauge for quick and easy

maintenance or repair. The ZW205FP is available in both globe and

angle pattern bodies.

Installation / Start-up

INSTALLATION

NOTE: Prior to installation of the ZW205FP, ensure that all debris is

flushed out the piping system before installed.

1.

During the installation of a ZW205FP in a sprinkler system, Underwriter

Laboratories (UL) requires NFPA 13 "Standard for Installation of Sprinkler

Systems" and NFPA 20 "Standard for the Installation of Stationary Pumps

for Fire Protection" be followed.

2.

Upon installation UL also requires that the ZW205FP be tested in

accordance with NFPA 13 or NFPA 20. Thereafter the valve shall be in-

spected, tested, and maintained in accordance to NFPA 25 "Standard for

the Inspection, Testing, and Maintenance of Water-Based Fire Protection

Systems".

3.

For making adjustments and servicing allow for adequate space

around the valve.

4.

Position the ZW205FP in line matching the direction of flow as indi-

cated on the valve model tag with the proper direction of flow in the system.

Once attached to line, double check all fasteners/bolts in the pilot system

and on main valve are tight and there is no damage prior to pressurizing

system.

NOTE: Pressure in some applications can be very high so be thor-

ough in checking and inspecting for proper installation and makeup.

6.

Zurn Wilkins valves are designed to operate in both the vertical and

horizontal positions. However, it is recommended that ZW205FP's 6" and

larger, be installation in the horizontal position.

The horizontal positioning of the larger valves avoids premature wear due to

mass of plunger assemblies as well as allows for greater accessibility during

annual inspections, and maintenance.

!

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

!

ADVERTENCIA: Cáncer y daño reproductivo - www.P65Warnings.ca.gov

!

AVERTISSEMENT: Cancer et néfastes sur la reproduction - www.P65Warnings.ca.gov

®

Start-up

Maintenance Instructions

START-UP

CAUTION: To prevent personnel injury and damage to equipment

check that downstream venting is adequate prior to start-up and

test procedures. All adjustments under

pressure should be made slowly. If the main valve opens or closes

too fast it may cause surging in upstream piping.

1.

a ZPI valve position indicator be installed to aid in verifying proper valve

movement. Pressurize the upstream side of the ZW205FP.

2.

valve and pilot system of air. To vent air, partially open or loosen the high-

est plugs or fittings in the system. The ZPI valve position indicator is a

great location, as it has a test cock at the top to vent air pressure. It may

be necessary to bleed system more than once. After removal of air in the

system tighten all loose fittings. NOTE: If valve is installed vertically, it

will be necessary to loosen some upper cover bolts until you have

vented all the air from the cover chamber.

3.

different procedures. Choose one based on the capabilities of the fire

protection system

a. Close all discharge lines from the fire pump so all flow goes

through the ZW205FP. Loosen the pilot adjustment screw all the way

to lower the set relief pressure. Turn on the fire pump to pressurize the

upstream side of the ZW205FP. Note: The control valve should open

and allow a lot of water to flow. If there is no flow, continue turning

the pilot adjustment screw counterclockwise. Once water is flowing

through the control valve, slowly turn the pilot valve adjustment screw

clockwise. As the screw is tightened the control valve will slowly start to

close causing upstream pressure to increase. Continue turning adjust-

ment screw clockwise until upstream pressure is stable at the desired

relief set pressure.

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

ZW205FP

ZW205FPG

Class 150 Flanged

Grooved

Max 250 psi Inlet

Max 300 psi Inlet

LISTED

FM

APPROVED

Prior to pressurizing the valve assembly, it is also recommended that

As the valve is filling with water, it is necessary to bleed the main

One can adjust the set pressure of the control valve by one of three

®

ZW205FPY

Class 300 Flanged

Max 300 psi Inlet

ZW205FPTH

Threaded

t

Max 300 psi Inle

ZURN WILKINS

1

www.zurn.com

Advertisement

Summary of Contents for Zurn Wilkins ZW205FP

- Page 1 Class 300 Flanged long as maximum flow rates of the valve are not exceeded. The Zurn Max 250 psi Inlet Max 300 psi Inlet Max 300 psi Inlet Wilkins Model ZW205FP is design to open quickly and close slowly to ZW205FPTH prevent upstream pressure surges. In addition the Model ZW205FP Threaded LISTED...

- Page 2 Operation The Zurn Wilkins ZW205FP utilizes a pressure relief pilot valve that installs on the discharge side of the control circuitry. The pilot Model PV-RLF is a direct acting, normally closed, spring loaded, diaphragm actuated valve. The operation of the ZW205FP begins with accurately sizing the valve, then fine tuning the control circuitry by adjusting the PV-RLF to open at the desired upstream pressure.

- Page 3 Replace any damaged uled preventative maintenance and inspection is highly recom- components as necessary. mended. ZURN WILKINS recommends annual inspection of valves for leaks and proper operation. It is also recommended Next, clean and inspect the seat inside the main valve that a repair kit with a new diaphragm, disc, and o-rings be on body. If excessive water deposits are present, fine grit sand pa-...

- Page 4 5. On the other side of the stem place the small washer, 3x8-16 Jam Hex Nut Relief Pilot Seat o-ring, plunger (with the rubber facing away from the spacer), and nut. ZURN WILKINS 1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766 ISZW205FP-2-10 (REV. C 6/17) www.zurn.com...

Need help?

Do you have a question about the ZW205FP and is the answer not in the manual?

Questions and answers