Summary of Contents for Delfin TP.CV-070

- Page 1 Industrial vacuum TP.CV-070 Operator’s and maintenance manual Original and official manual Read this manual carefully before using the vacuum cleaner...

- Page 2 This manual should be considered an integral part of the vacuum cleaner and must be kept together with the unit until this is scrapped. In case of loss of or damage to the manual, ask DELFIN for a new copy.

- Page 3 Introduction 2018...

-

Page 4: Table Of Contents

Information section Identification of main parts Accessories provided Identification details of manufacturer Marking plate Intended uses Allowed environmental conditions Noise level Storage Scrapping 1.10 Technical details 1.11 Warranty Safety section Safety details Safety warnings Safety plates and symbols Outstanding risks Applied directives Installation section Handling... -

Page 5: Information Section

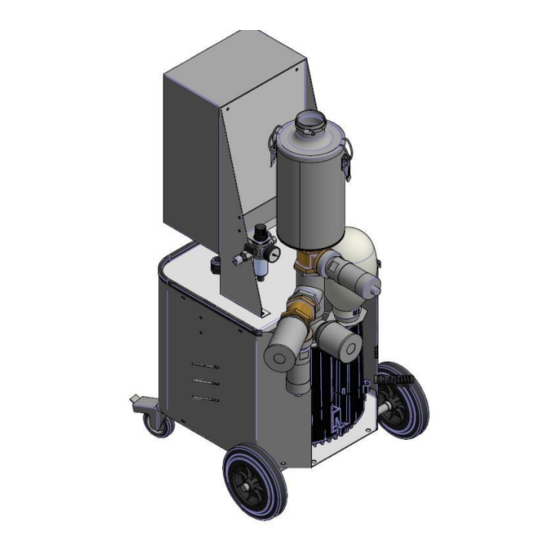

Information Section Identification of main parts Switchboard Castors Wheels Suction unit Inlet for TP.CV connection... -

Page 6: Accessories Provided

Information Section Accessories provided FI.0164.0000: HEPA SAFETY FILTER (ONLY SPARE PART) -

Page 7: Identification Details Of Manufacturer

Information Section Identification details of manufacturer Delfin U.R.L. Strada Della Merle, 49/a 10036 SiTime Tories (TO) - Italy Tel. 0039.011.800.55.00 Fax. 0039.011.800.55.06 www.delfinvacuums.it delfin@delfinvacuums.it Marking plate In compliance with the Machine Directive 2006/42/CE on vacuum cleaners, the machine is fitted with CE plates. -

Page 8: Intended Uses

Information Section Intended uses These specific vacuum cleaner models have been designed, built and protected for vacuuming dusts and solid materials only, using special filters. Warning! Always use specific filters for the type of dust or materials to be vacuumed. Any other use is considered IMPROPER. -

Page 9: Technical Details

Information Section 1.10 Technical details TP.CV-070 Power Voltage Volts Max. vacuums rate mm H 2.700 Max. air flow rate Noise level dB(A) Filter type Absolute filter H Capacity Suction inlet Ø Dimensions 67 X 58 X 110... -

Page 10: Warranty

The warranty shall be invalidated in the event of the vacuum cleaner having been repaired by unauthorized third parties or of equipment or accessories being used that have not been supplied by Delfin or which have not been recommended or approved by Delfin or whose serial number has been removed or altered during the warranty period. -

Page 11: Safety Section

They should also have the tools necessary to perform these duties properly. Delfin shall under no circumstances be deemed liable for accidents or damage caused by use of the vacuum cleaner by personnel not properly trained or who use it in an improper manner, as well as by even partial failure to comply with the safety regulations and intervention procedures indicated in this manual. -

Page 12: Safety Warnings

Safety Section Safety warnings Attention! The following indications are, by themselves, not enough to fully protect against all the hazards that could arise during vacuum cleaner operation. These will have to be integrated with common sense and the experience of the operator, both of which are crucial factors for preventing accidents. Each section of this manual lists further specific safety warnings for the various operations. - Page 13 The machine is supplied with: instruction manual, Exploded Spare Parts drawing, Test Sheet, Warranty Slip, Approval Certificate. In the event of Customers fitting a tool to the machine not supplied by DELFIN, make sure the safety conditions required by Machine Directive 2006/42/CE are complied with and in any event, DELFIN is unable to accept liability for any problems arising from use of such tool.

- Page 14 The manual should always be kept handy for reference so the operating cycle can be checked every time there are doubts. In the event of this manual being lost or damaged, ask DELFIN for a new copy. Structural damage and improper alterations or repairs could change the protection capacity of the vacuum cleaner and therefore cancel this certification.

-

Page 15: Safety Plates And Symbols

Clean these with a cloth, soap and water. Do not use solvents, diesel fuel or petrol. Replace the damaged plates with new ones supplied by Delfin. If a plate is affixed to a replaced part, make sure a new plate is affixed to the new part. -

Page 16: Outstanding Risks

Safety Section Outstanding risks Careful analysis of risks performed by the manufacturer and stored in the technical file has made it possible to eliminate most of the risks associated with vacuum cleaner operation. The manufacturer advises carefully following the instructions, procedures and advice contained in this manual as well as applicable safety regulations, including the use of the envisaged protection devices, both those integrated in the cleaner and individual. -

Page 17: Installation Section

Installation Section Handling The machine is supplied in a strong cardboard box secured with straps. Transport the package using a fork-lift truck of adequate lifting capacity and make sure it is stable and that weight is properly distributed on the forks. Before starting to move, make sure the transit area is free and that there are no moving objects on the packaging. -

Page 18: Installation

Installation Section Installation Warning! Before installing the vacuum cleaner, carefully make a sight check to pinpoint any damage suffered during transport. In the event of any component parts being damaged, do not proceed with installation. Notify the manufacturer and reach an agreement on how to proceed. The vacuum cleaner already features a suction filter. - Page 19 Installation Section Make sure the power supply corresponds to the voltage and frequency indicated on the vacuum cleaner plate TP.CV-070 190308274 2019 Warning! Do not fit the plug in the power socket with wet hands. In the event of an extension being used, make sure this is in perfect condition, in compliance with CE...

-

Page 20: Operation Section

Operation Section Description of controls 1. REMOTE SOCKET 2. POWER ON- WHITE LIGHT 3. THERMAL RELEASE – YELLOW LIGHT 4. FILTER CLEANING – GREEN LIGHT 5. FILTER CLEANING MODE AUTO/MAN (SEP) 6. SUCTION START MODE 7. START SUCTION (CV) / FILTER CLEANING (SEP) MANUAL MODE – GREEN BUTTON 8. -

Page 21: Work Cycle

Operation Section Work cycle Warning! Before fitting the plug, make sure the power voltage corresponds to that on the CE marking plate. Make sure the power plug is correctly fitted in the power socket. Make sure the flexible hose is properly fitted and locked in the vacuum pipe union. Make sure the power cable and any extension used are integral and in perfect condition. - Page 22 Operation Section Mode of operation: Abbreviations: - EV1: solenoid valve 1, gate valve for discharging cycle --EV2: solenoid valve 2, gate valve for discharging cycle When the engine starts, on both local and remote start mode, the T1 starts. When T1 ends then EV1 and EV2 are excited for a T2 period. When T2 ends both solenoid valves release and the discharging flap closes (due to the presence of vacuum) and T1 starts again.

-

Page 23: Maintenance Section

Maintenance Section Informative notes This section describes the control and special maintenance operations crucial for keeping the vacuum cleaner in perfect working condition. Any other jobs which might be necessary to eliminate operating faults must be expressly authorized by the manufacturer. -

Page 24: Maintenance Operations

A qualified operator must periodically verify the cables’ tightening in the electric components of the electric board: with prolonged use of the vacuum, the vibrations can loosen the tightening and cause important damages to components. Warning! All maintenance and repair jobs must be performed directly by DELFIN or its authorized dealers. -

Page 25: Troubleshooting

Check the seals and, if necessary, replace it Check for any air leaks out of Air leak closing fasteners, tightening screws, container or filter chamber Motor very noisy. Contact Delfin after-sales Warning! For any other problems, contact the DELFIN after-sales service. -

Page 26: Spare Parts Section

Spare Parts Section Recommended spare parts Code Description FI.0164.0000 HEPA SAFETY FILTER... - Page 27 Spare Parts Section Delfin Syl Strada Della Merle, 49/a 10036 SiTime Tories (TO) – Italy Tel. 0039.011.8005500 Fax 0039.011.8005506...

Need help?

Do you have a question about the TP.CV-070 and is the answer not in the manual?

Questions and answers