Table of Contents

Advertisement

Quick Links

Operator's/Installation/Service Manual

Braun

Braun

Commercial

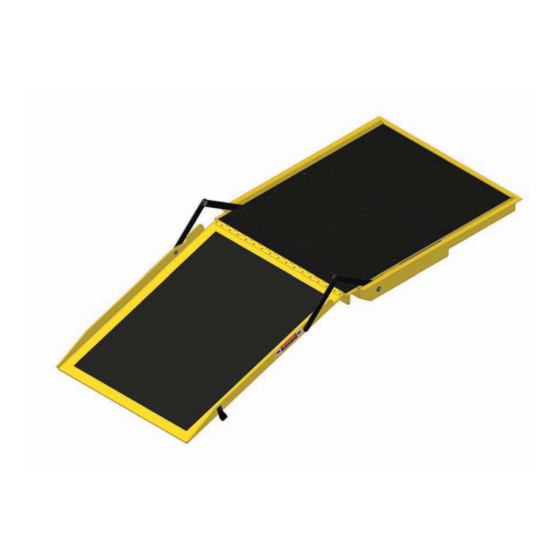

RA400 Transit Ramp

RA400 Transit Ramp

for Low-Floor Transit Vehicles

Model FF3248Y-24V

Model FF3248Y-24V

"Providing Access to the World"

International Corporate Hdqrs: P .O. Box 310

1-800-THE LIFT

®

(574) 946-6153

35168

November 2008

®

®

Winamac, IN 46996 USA

FAX: (574) 946-4670

W ARNING

Read manual

before operating,

installing or

servicing ramp.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Advertisement

Table of Contents

Summary of Contents for Braun RA400

- Page 1 Operator's/Installation/Service Manual Braun Braun W ARNING Commercial RA400 Transit Ramp RA400 Transit Ramp for Low-Floor Transit Vehicles Model FF3248Y-24V Model FF3248Y-24V Read manual ® before operating, "Providing Access to the World" ® installing or International Corporate Hdqrs: P .O. Box 310...

- Page 2 This manual includes operating instructions, installation instructions, servicing instructions and instructions for troubleshooting, if needed. Braun ramps are built for dependability and will provide years of service and mobility independence, as long as the ramp is installed and maintained as specified, and the ramp is operated by an instructed person.

-

Page 3: Table Of Contents

Ramp Power Operation..........10 Power Ramp Safety ..........10 Repair Parts Gravity Drift Down ............ 10 Ramp Manual Operation ...........11 RA400 Ramp Exploded View Ramp Passenger Safety ........11, 12 Repair Parts List ............32 Exploded View (Fold Out) ......33A, 34A Ramp Installation Specifications and Dimensions ....33B, 34B... -

Page 4: Ramp Terminology

RAMP TERMINOLOGY Ramp Terminology Illustration - FF3248Y-24V Refer to the illustration below and the illustrations on page 3 for identification of components and clarifica- tion of direction terminology. Sub floor (Fixed) Drive Arm Linkage Weldment Drive Ramp Vertical Side Plate (Barrier) Right Left... -

Page 5: Ramp Component Terminology Illustrations

RAMP TERMINOLOGY Ramp Component Terminology Illustrations - FF3248Y-24V Relays Cylinder Right Cam/Microswitch Assembly Pump Left Ramp Drive Arm As viewed from outside the vehicle Pump Cylinder Drive Drive Arm Linkage Cam/Hydraulic Counter Assembly Pan Weldment Left Note: The sub floor, pan sup- port structures and the ramp have been removed from these Right... -

Page 6: Introduction

RAMP TERMINOLOGY Introduction Braun RA400 Series Transit The RA400 provides fully auto- Read and become familiar with Ramps (to be referred to as matic operation of ramp functions. all operation safety precautions, RA400 throughout this manual) The electric/hydraulic system is operation notes and details, are designed for use in low-floor... -

Page 7: Ramp Components

The floor system which contains the RA400 stows (folds) onto the sub Drive Arm Assembly: The hydraulic pump and electrical floor providing an unobstructed cylinder driven drive arm assem-... -

Page 8: Ramp Operation

W ARNING Load and unload on level surface only. contact The Braun Corporation immedi- W ARNING Engage vehicle parking brake before operating ramp. ately. Failure to do so... - Page 9 W ARNING Do not remove any guards or covers. W ARNING If the information contained in this manual is not fully understood, contact The Braun Corporation immediately. W ARNING Failure to follow these safety precautions may result in serious bodily injury and/or prop- erty damage.

-

Page 10: Operation Notes And Details

The commercial As stated in the Ramp Operation manual operating instructions oriented RA400 Ramp is operated Safety section, all information in before attempting ramp opera- by the transit vehicle driver/atten- this manual is provided for the tion procedures or assisting ramp dant. -

Page 11: Operation Procedure Review

RAMP OPERATION Operation Procedure Review The Braun Corporation recom- Transit agency supervisors W ARNING mends that transit agency su- should train and educate all pervisors and driver/attendants driver/attendants on the proper Read and become review the safety precautions and use and operation of the vehicle,... -

Page 12: Ramp Power Operation

RAMP OPERATION Ramp Power Operation The power ramp is attendant operated and activated Before operating the ramp, park the vehicle on by the control switch provided by the vehicle con- a level area, away from vehicular traffic. Place verter (ramp installer). A momentary contact ramp the vehicle transmission in “Park”... -

Page 13: Ramp Manual Operation

Ramp Manual Operation If you experience power or equipment failure, Figure A the ramp can be manually stowed and de- ployed. The RA400 ramp must be manually operated by an attendant. Manual Strap A manual strap is provided on the right side of the ramp (see Figure A). - Page 14 RAMP OPERATION Ramp Passenger Safety (Continued) W ARNING W ARNING Position and fasten Be aware of the wheelchair- ramp slope. equipped occupant seat belt before loading onto the wheelchair ramp. 52217 Failure to do so may result in serious Stabilizing Wheelchairs: Pow- Wheelchair passengers who bodily injury and/or ered and manual wheelchairs...

-

Page 15: Ramp Installation

Do not operate ramp prior to positive securement of the pan. instructions are not fully understood, W ARNING Check for obstructions such as gas lines, wires, exhaust, etc. contact The Braun before drilling or cutting during installation procedures. Corporation immedi- ately. Failure to do W ARNING... -

Page 16: Installation Instructions

Braun Mobility Products. bodily injury and/or property damage. Chassis Requirements The RA400 is designed for use in Outboard Support Tube: An The ramp pan horizontal bor- low-floor transit vehicles. A “floor outboard support tube must be der (lip) sets on the floor pocket... -

Page 17: Obstructions

RAMP INSTALLATION Door(s) must open outward. Obstructions: Any intrusive ob- There must be a minimum 1/8” When closed, the door(s) should structions within the door opening clearance between the de- align with and conform to the or the ramp mounting/operating ployed ramp assembly and the outboard edge of the ramp pan area (such as seats, molding,... - Page 18 RAMP INSTALLATION "Floor Pocket" Clear Opening Dimensions Figure C Right Left As viewed from outside the vehicle Clear Door Opening Width Dimension Figure D Door(s) must open outward. Right Vehicle chassis “floor pocket” configuration Left must be aligned cen- ter with door opening. As viewed from outside the vehicle Page 16...

- Page 19 RAMP INSTALLATION Installed Ramp -Stowed Figure E Stowed RA400 Right Ramp positioned in the “floor pocket.” Left As viewed from outside the vehicle Installed Ramp - Deployed Figure F Right There must be a minimum 1/8” clearance between the deployed ramp assembly and the vehicle floor or any obstruction on the...

-

Page 20: Electrical Connections

(center off) W ARNING is mounted at the back of the will typically be mounted near the RA400 ramp. A mating connec- driver. The control switch may Route cables clear tor (male plug) is supplied with be part of a panel providing other of exhaust system, the ramp. -

Page 21: Electrical Connection Illustration

RAMP INSTALLATION Electrical Connection Illustration An 8-pin Deutsch connector (male Terminate the power supply, ground, W ARNING plug) is supplied with the ramp. ramp OUT signal and ramp IN signal as specified in legend. The ramp installer provides an ap- Positive (+) battery propriate momentary contact control The Positive (+) “battery”... -

Page 22: Maintenance And Lubrication

Drive Arms and Cam Gear Pivot Shafts (2 Places) LO Ramp Hinge Note: Gears and gear racks are at drive arm gear positions. Specified (recommended) Available Braun Lubricant Type Lubricant Amount Part No. Light Penetrating Oil LPS2, General Purpose 11 oz. -

Page 23: Maintenance And Lubrication Introduction

The maintenance and lubrication procedures speci- When servicing the bodily injury and/or fied in this schedule must be performed by a Braun ramp at the consecu- property damage. authorized service representative at the scheduled tive recommended in-... - Page 24 MAINTENANCE and LUBRICATION continued Inspect drive arm pivot points (mounting Tighten, replace or correct as needed. screws, nuts and bearings) for positive secure- ment, wear or damage Clean ramp and ramp mounting area (ensure Clean and remove debris or obstructions no debris in area to obstruct stowing/stacking) 8 Weeks or 200...

- Page 25 MAINTENANCE and LUBRICATION continued Hydraulic Fluid (Pump) - Check level. Note: Use Braun 32840-QT (Exxon ® Univis HVI 26) Fluid should be changed if there is visible hydraulic fluid (do not mix with Dextron III or contamination. Inspect the hydraulic system other hydraulic fluids).

-

Page 26: Troubleshooting

W ARNING ramp, discontinue operation remedy can then be determined immediately! Contact your sales by process of elimination. Wiring Troubleshooting and representative or call The Braun Diagrams, Electrical Schematics, repair procedures Corporation at 1-800-THE LIFT ® Hydraulic Diagrams and Hydrau-... - Page 27 2.13 Drift Out Microswitch harness dis- Connect, repair or replace Operation connected, damaged or otherwise damaged 2.14 Pump motor brushes worn Contact Braun Product Support - replace pump 2.20 Locked in 2.21 Ramp was stopped within the Activate Stow function until ramp is out Intermediate of the Deploy “Drift Out”...

- Page 28 3.42 Stow pressure relief valve setting Adjust relief valve setting. 3.00 too low STOW Doesn’t 3.43 Stow pressure relief valve stuck Contact Braun Product Support - re- (In) Stow open due to contamination or other- place pump wise damaged 3.50 Faulty or 4.51 See 2.40...

- Page 29 BLANK for LAYOUT Page 27...

-

Page 30: Electrical Schematic - Ff3248Y-24V

CIRCUIT PROTECTION BATTERY GROUND DEVICE MOTOR (25 AMP.) * RECOMMENDED WIRE GUAGE COUNTER RA400 TRANSIT RAMP ASSEMBLY DRAWING SHOWN WITH RAMP IN STOWED POSITION 12 GA. RD 12 GA. BK "DRIFT IN" MICROSWITCH STOW RELAY 14 GA. BL/BK 14 GA. BL/BK 12 GA. -

Page 31: Wiring Diagram - Ff3248Y-24V

TROUBLESHOOTING Wiring Diagram - FF3248Y-24V Page 29... -

Page 32: Hydraulics

HYDRAULICS Hydraulic Schematic - FF3248Y-24V Cylinder, Double Description Symbol Acting Pump, Bidirectional Relief Valve Displacement Pump Motor, Check Valve Bidirectional Flow Control Hydraulic Port Valve Fixed Orifice Filter Screen Reservoir, 3 Way 2 Position Vented Shuttle Valve "A" "A" "B" "B"... -

Page 33: Hydraulic Diagram And Parts List - Ff3248Y-24V

HYDRAULICS Hydraulic Diagram and Parts List - FF3248Y-24V Item Qty. Description FF3248Y-24V CYLINDER - 1514.3 - COMPACT C1514.3-9800 CYLINDER - 1514.3 - COMPACT C1514.3-9900 PUMP - POWER UNIT - 24V HYDRAULIC - COMPACT 30775-24V HOSE ASSEMBLY - 5.5" - 1/8" DIA - SW/SW 16004A-005.5 HOSE ASSEMBLY - 9"... -

Page 34: Repair Parts

REPAIR PARTS Item Qty. Description FF3248Y-24V RA400 MAIN PAN WMT. RA40444WY-48 GEAR RACK WELDMENT RA40402WBKN BEARING STRIP RA40105 MAIN DRIVE ARM WELDMENT RA40401LWBKN WMT-MAIN DRIVE ARM/RIGHT RA40401RWBKN FOLD LINK WELDMENT RA40050WBKN CYLINDER-1514.3-COMPACT CYL. C1514.3-9800 CYLINDER-1514.3-COMPACT CYL. C1514.3-9900 PUMP-POWER UNIT-24V HYDRAULIC/ COMPACT... -

Page 35: Exploded View (Fold Out)

EXPLODED VIEW Page 33A Page 34A... - Page 36 SPECIFICATION AND DIMENSIONS Power Unit: Hydraulic Pump Module Deployed View Voltage: 24 VDC Notes: Mounting holes/brackets per application 35.500" 49.318 Stowed View 97.643" 32.50" 48.325 49.318" 32.500" 31.994" 35.50" 49.318" 2.438" 2.626" 2.62 4.125" 2.25" 2.485" 22.281" 23.597" 33.50" 48.325" 22.281"...

-

Page 37: Braun Limited Warranty

first retail purchaser by an independent, authorized dealer of Braun, or, if the dealer places the product into any type of service prior to retail sale, on the date the dealer first places the product in such service. - Page 38 You must inspect the product for this type of damage when you take delivery. If you find any such defect or damage you must notify the selling dealer, or Braun, at the time of delivery to have these items covered by this limited warranty and to have work performed on the items at no cost to you as provided by this limited warranty.

- Page 39 Braun will do and does not guarantee anything about the product for any time period. Nothing in this warranty, or any action of Braun, or any agent of Braun, shall be interpreted as an extension of any warranty period or the filing limitation period in this paragraph. Some states do not allow a reduction in the statute of limitations, so this reduction may not apply to you.

- Page 40 "Providing Access to the World" ® Over 300 Braun Dealers Worldwide ® "Providing Access to the World" International Corporate Hdqrs: P .O. Box 310 Winamac, IN 46996 USA ® 1-800-THE LIFT (574) 946-6153 FAX: (574) 946-4670...

- Page 41 All illustrations, descriptions and specifications in this manual are based on the latest product information available at the time of publication. The Braun Corporation reserves the right to make changes at any time without notice. time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

Need help?

Do you have a question about the RA400 and is the answer not in the manual?

Questions and answers