Summary of Contents for KSB Compacta UZ10.450D

- Page 1 Floodable Sewage Lifting Unit Compacta - Amarex N/KRT from series S-V/1 Installation/Operating Manual...

- Page 2 All rights reserved. Contents provided herein must neither be distributed, copied, reproduced, edited or processed for any other purpose, nor otherwise transmitted, published or made available to a third party without KSB´s express written consent. Subject to technical modification without prior notice.

-

Page 3: Table Of Contents

Contents Contents Glossary ....................5 General ....................7 Principles ......................7 Installation of partly completed machinery ..........7 Target group ....................7 Other applicable documents ................7 Symbols ......................7 Safety ....................8 Key to safety symbols/markings ..............8 General ......................8 Intended use .................... - Page 4 Contents Installation at Site ................21 Safety regulations ..................21 Checking the site before installation ............21 Installing the lifting unit ................21 Connecting the piping .................. 22 Cellar drainage ....................24 Connection to power supply ................ 24 Checking the direction of rotation .............. 24 Commissioning/Start-up/Shutdown ..........

-

Page 5: Glossary

Glossary Glossary Backflow water produced below the flood level. It defines general requirements as well as Waste water flowing back from the sewer into principles of construction and testing. the connected drainage piping EN 12 056-4 Backflow loop European standard governing the selection, The section of the discharge pipe of a waste operation and maintenance of sewage lifting water lifting unit that is located above the... - Page 6 Glossary Working space The space required for performing work on the unit Compacta - Amarex N/KRT 6 of 56...

-

Page 7: General

The series/serial number uniquely identifies the lifting unit and serves as identification for all further business processes. In the event of damage, immediately contact your nearest KSB service centre to maintain the right to claim under warranty. Noise characteristics (⇨ Section 4.9 Page 19) 1.2 Installation of partly completed machinery... -

Page 8: Safety

2 Safety 2 Safety All the information contained in this section refers to hazardous situations. DANGER 2.1 Key to safety symbols/markings Table 3: Definition of safety symbols/markings Symbol Description DANGER DANGER indicates a high-risk situation which, if not avoided, will result in death or serious injury. -

Page 9: Personnel Qualification And Training

2 Safety ▪ The lifting unit must only handle the fluids described in the product literature of the respective design variant. ▪ Never operate the lifting unit without the fluid to be handled. ▪ Observe the information on minimum flow rates specified in the product literature (to prevent overheating, bearing damage, etc). -

Page 10: Safety Instructions For The Operator/User

2 Safety 2.7 Safety instructions for the operator/user ▪ The operator shall fit contact guards for hot, cold and moving parts and check that the guards function properly. ▪ Do not remove any contact guards while the pump is running. ▪... -

Page 11: Transport/Temporary Storage/Disposal

1. On transfer of goods, check each packaging unit for damage. 2. In the event of in-transit damage, assess the exact damage, document it and notify KSB or the supplying dealer (as applicable) and the insurer about the damage in writing immediately. -

Page 12: Storage/Preservation

(set). Always indicate any safety and decontamination measures taken. (⇨ Section 11 Page 53) NOTE If required, a blank certificate of decontamination can be downloaded from the KSB web site at: www.ksb.com/certificate_of_decontamination Compacta - Amarex N/KRT 12 of 56... -

Page 13: Disposal

3 Transport/Temporary Storage/Disposal 3.5 Disposal WARNING Fluids posing a health hazard and/or hot fluids Hazard to persons and the environment! ▷ Collect and properly dispose of flushing liquid and any residues of the fluid handled. ▷ Wear safety clothing and a protective mask, if required. ▷... -

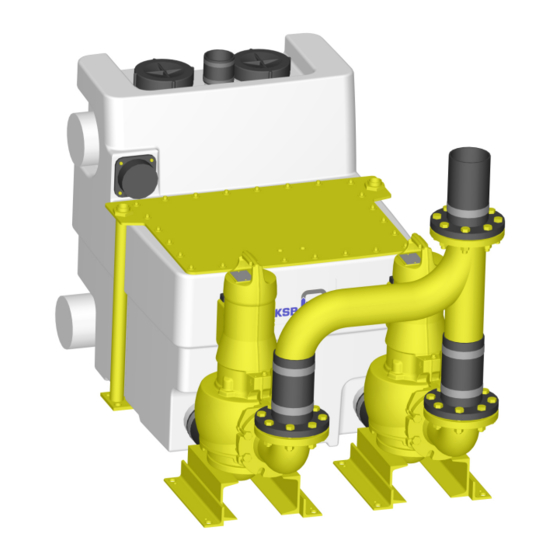

Page 14: Description

4 Description 4 Description 4.1 General description Sewage lifting units for the collection and automatic lifting of unpressurised waste water with or without faeces to a level above the flood level. ▪ The sewage lifting unit consists of either one or two collecting tanks, two pump sets and the unit control system. -

Page 15: Name Plates

D-67227 Frankenthal Compacta UZ12.450 D No.: 120 m /h • H 14,5 m • IP 68 EN 12050 - 1 Made by KSB Size Serial No. Maximum flow rate Mode of operation European standard Series code Maximum head Enclosure K e y t o t h e s e r i e s c o d e... - Page 16 4 Description DANGER Flooding of control unit Danger of death from electric shock! ▷ Operate the control unit in flood-proof rooms only. L e v e l C o n t r o l B a s i c 2 T y p e B a s i c C o m p a c t ( B C ) ▪...

-

Page 17: Configuration And Function

4 Description Master switch Control panel Manual-0-automatic switch NOTE The control units are not explosion-proof, and therefore must only be operated outside potentially explosive atmospheres. The control unit is always located outside the potentially explosive atmosphere and may only be installed in a flood-proof room. 4.5 Configuration and function Fig. -

Page 18: Fluids Handled

4 Description Table 7: Control unit power data, LevelControl Basic 2 Characteristic Value Rated operating voltage 3 ~ 400 V AC +10 % -15 % 1 ~ 230 V AC +10 % -15 % Mains frequency 50 Hz ± 2 % Enclosure 400 V: IP 54... -

Page 19: Collecting Tank

4 Description ‒ animal faeces together with the necessary flushing water as well as stormwater in case no other way of disposal is possible. Impermissible Substances / water which must not be discharged into the sewer system are, amongst fluids others: Solid matter, fibres, tar, sand, cement, ash, coarse paper, paper towels, cardboard, debris, garbage, offal, grease, oil. - Page 20 4 Description Max. current Size HxWxD [mm] [kg] 760 x 600 x 210 Type BS2 400 x 300 x 155 760 x 600 x 210 760 x 600 x 210 760 x 600 x 210 760 x 600 x 210 760 x 600 x 210 760 x 600 x 210 Compacta - Amarex N/KRT...

-

Page 21: Installation At Site

5 Installation at Site 5 Installation at Site The section Installation at Site describes the conditions which must be fulfilled to assemble the individual components to form a completed sewage lifting unit in accordance with the instructions and without compromising the safety and health of persons. -

Page 22: Connecting The Piping

5 Installation at Site ✓ The installation room is of sufficient size - see connection example. (⇨ Section 10.2 Page 48) ✓ The installation room is adequately lit. ✓ Alerts are always recognised in due time by the operator (external alarm transmitters are used, if required). - Page 23 5 Installation at Site D i s c h a r g e l i n e CAUTION Incorrect installation of discharge line Leaks and flooding of installation room! ▷ Run the discharge line above the flood level before leading it into the sewer. ▷...

-

Page 24: Cellar Drainage

5 Installation at Site D r a i n a g e n o z z l e f o r h a n d d i a p h r a g m p u m p NOTE We recommend to connect a hand diaphragm pump (available as accessory) to allow complete drainage of the tank for servicing work. - Page 25 5 Installation at Site CAUTION Wrong direction of rotation The lifting unit does not reach its duty point! ▷ Check the direction of rotation. The direction of rotation must be checked during commissioning or when the unit is returned to service. For checking the direction of rotation of the pump refer to the installation/operating manual of the submersible motor pump.

-

Page 26: Commissioning/Start-Up/Shutdown

6 Commissioning/Start-up/Shutdown 6 Commissioning/Start-up/Shutdown 6.1 Commissioning/start-up 6.1.1 Prerequisites for commissioning/start-up Before commissioning/start-up of the lifting unit make sure that the following requirements are met: ▪ The lifting unit has been properly connected to the electric power supply and is equipped with all protection devices. ▪... -

Page 27: Commissioning/Start-Up Of Control Unit

6 Commissioning/Start-up/Shutdown Sizes UZ13.450/13.900 UZ14.450/14.900 UZ15.450/15.900 6.2.2 Switching frequency To prevent high temperature increases in the motor and excessive loads on the motor, seal elements and bearings, the switching frequency shall not exceed the maximum number of start-ups per hour as indicated in the table below. Table 10: Max. - Page 28 6 Commissioning/Start-up/Shutdown 6.3.1 Lifting unit with LevelControl Basic 2 Type BS Type BC S t e p s r e q u i r e d f o r c o m m i s s i o n i n g : Setting the motor Set the motor protection switch to the rated motor current indicated on the pump protection switch...

-

Page 29: Shutdown

6 Commissioning/Start-up/Shutdown Fig. 8: Battery of LevelControl Basic BS F u n c t i o n a n d l e a k t e s t i n g NOTE A sensor fault may be displayed when the lifting unit has not been filled yet. It will disappear after the lifting unit has been filled. - Page 30 6 Commissioning/Start-up/Shutdown DANGER Failure to interrupt power supply Danger to life! ▷ Disconnect all electrical connections from the power supply and secure against unintentional start-up. 4. Drain the tank completely (e.g. by means of the hand diaphragm pump). 5. After long idle periods: Remove and clean the submersible motor pump.

-

Page 31: Operation

7 Operation 7 Operation DANGER Unintentional starting of pumps Risk of injury: Limbs can be pulled into or crushed by machinery! ▷ Make sure that nobody is within the immediate, hazardous vicinity of the pumps. ▷ Make sure that all piping is properly installed and that no pumped fluid can escape. - Page 32 7 Operation Table 11: Traffic light LEDs Description Green Readiness for operation Yellow Warning (one or more warnings) Alert (one or more alerts) L E D f o r p u m p o p e r a t i n g s t a t u s This LED indicates the operating status of the pumps: Table 12: LED for pump operating status Description...

-

Page 33: Manual-0-Automatic Selector Switch

7 Operation 7.2 Manual-0-automatic selector switch Each pump can be operated as follows by means of a manual-0-automatic selector switch: Table 14: Switch positions of manual-0-automatic selector switch Switch position Function Function allowing the pump to be operated manually for a short period. - Page 34 7 Operation 7.3.2 Setting parameters NOTE The parameters that you can call up depend on the operating mode and measurement method. Only parameters that are relevant to the current operating mode and measurement method are displayed. Fig. 12: Setting parameters 1.

- Page 35 7 Operation Parameter Description 3.3.4.2 Base Load ON Level Base Load ON [mm] 3.3.4.3 Peak Load ON Level Peak Load ON [mm] 3.3.4.4 High Water Level High Water [mm] 3.3.5.3 Stop Delay Setting the stop delay [ 4.1.1 Firmware Version Firmware version 7.3.3 Acknowledging alerts and warnings NOTE...

- Page 36 NOTE The rechargeable batteries must be replaced every five years to ensure that the device operates reliably in battery mode. Use original KSB spare parts only. 1. Switch off the power supply. 2. Open the control unit. 3. Disconnect the battery.

- Page 37 7 Operation 9. Reconnect the power supply. Compacta - Amarex N/KRT 37 of 56...

-

Page 38: Servicing/Maintenance

8 Servicing/Maintenance 8 Servicing/Maintenance 8.1 General information/Safety regulations WARNING Improper lifting/moving of heavy assemblies or components Personal injury and damage to property! ▷ Use suitable transport devices, hoisting equipment and lifting tackle to move heavy assemblies or components. WARNING Work on the lifting unit by unqualified personnel Risk of personal injury! ▷... - Page 39 8.2.1 Inspection contract For all inspection and servicing work to be carried out at regular intervals we recommend taking out the inspection contract offered by KSB. Contact your Service Partner for details. Checklist for commissioning, inspection and maintenance (⇨ Section 8.7 Page 41) 8.2.2 Measuring the insulation resistance of the motor...

-

Page 40: Dismantling The Pump

8 Servicing/Maintenance R e m o v i n g t h e p u m p f r o m C o m p a c t a U Z 1 2 . 4 5 0 t o U Z 1 5 . 9 0 0 NOTE The discharge line does not need to be dismantled. -

Page 41: Tightening Torques

8 Servicing/Maintenance 8.5 Tightening torques Component Max. tightening torque Plate 185 on tank 6 Nm 8.6 Disposal/recycling of the lifting unit Lifting units consist of materials that can be separately recycled. Plastic components are marked in accordance with ISO 11 469. 8.7 Check list for commissioning/inspection ➀... - Page 42 8 Servicing/Maintenance Actions Required during ➁ Replace rechargeable batteries every 5 years of operation. (⇨ Section 7.3.5 Page 36) ➀ ➁ If applicable: reset service alert (LevelControl Advanced only). ➀ ➁ Determine the spare parts requirements, if any. ➀ ➁ Advise and/or train operating staff.

-

Page 43: Trouble-Shooting

✘ Manual-0-automatic switch set to "0" Set manual-0-automatic selector switch to "Automatic". ✘ ✘ Motor winding or electrical cable are Replace with original KSB parts or contact defective. KSB. ✘ Water level in the tank too low during Check level sensor. - Page 44 9 Trouble-shooting A B C D E F Possible cause Remedy Release the pump pressure before attempting to remedy faults on pressure-retaining parts. Disconnect the pump from the power supply! ✘ Check valve does not shut off tightly. Clean the check valve, screw the lifting screw back as far as it will go.

-

Page 45: Related Documents

10 Related Documents 10 Related Documents 10.1 General assembly drawing/exploded view and list of components 10.1.1 General assembly drawing of the lifting unit Part No. Description 160.1/.2 Cover 17-5 Baffle, cpl. Foot Plate 400.03 Gasket 412.08/.31/.41 O-ring 550.04/.21 Disc Strip Tank Pump 70-1... - Page 46 10 Related Documents Part No. Description 99-3.1 Mounting accessories 99-3.2 Set of accessories (pads) 5B.1 Vent connection Compacta - Amarex N/KRT 46 of 56...

- Page 47 10 Related Documents 10.1.2 Exploded view of collecting tank Part No. Description 160.1 Cover Plate 412.08/.31/.41 O-ring Strip Tank 710.1/.2 Pipe 719.1/.2/.5/.6 Flexible tube 733.1/.21/.55/.5 Hose clip 81-45 Level sensor 90-3 Set of mounting elements 920.4 99-3.2 Set of accessories (pads) 5B.2 Vent connection Compacta - Amarex N/KRT...

-

Page 48: Connection Examples

10 Related Documents 10.2 Connection examples 10.2.1 Compacta UZ10.450 - UZ15.900 NOTE Rooms containing lifting units shall be of sufficient size to give a working space of at least 60 cm around and above all parts to be operated or serviced. Flood level Compacta - Amarex N/KRT 48 of 56... -

Page 49: Dimensions

10 Related Documents 10.3 Dimensions Alert Peak load Pump ON Pump OFF Compacta - Amarex N/KRT 49 of 56... -

Page 50: Wiring Diagrams

10 Related Documents 10.4 Wiring diagrams 10.4.1 LevelControl Basic 2 Type BC - dual-pump unit - DOL starting - up to 4 kW - with motor protection switch Compacta - Amarex N/KRT 50 of 56... - Page 51 10 Related Documents 10.4.2 LevelControl Basic 2 Type BS - dual-pump unit - DOL starting - 5.5 kW and above, with motor protection switch Compacta - Amarex N/KRT 51 of 56...

- Page 52 10 Related Documents 10.4.3 LevelControl Basic 2 Type BS - dual-pump unit - star/delta starting - 5.5 kW and above - with motor protection switch Compacta - Amarex N/KRT 52 of 56...

-

Page 53: Certificate Of Decontamination

11 Certificate of Decontamination 11 Certificate of Decontamination Type ..........................Order number/ Certificate of decontamination ..........................Order item number Delivery date ..........................Field of application: ....................................................Fluid handled Please tick where applicable ⃞ ⃞ ⃞ ⃞ radioactive explosive corrosive toxic ⃞... -

Page 54: Draft Ec Declaration Of Conformity

12 Draft EC Declaration of Conformity 12 Draft EC Declaration of Conformity Manufacturer: KSB Aktiengesellschaft Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the floodable sewage lifting unit: Compacta-Amarex N/KRT Series code: S-W - S-D ▪ is in conformity with the provisions of the following Directives as amended from time to time: –... -

Page 55: Index

Index Index Alerts and warnings Maintenance 38 Acknowledging 36 Manual-0-automatic selector switch 33 Alerts list Displaying 36 Navigation keys 32 Cellar drainage 24 Certificate of decontamination 53 Commissioning/start-up 26 Operating limits 8 Control panel 31 Other applicable documents 7 Dimensions 19 Parameters Display 32 Setting 34... - Page 56 KSB Aktiengesellschaft P.O. Box 1361 • 91253 Pegnitz • Bahnhofplatz 1, 91257 Pegnitz (Germany) Tel. +49 9241 71-0 • Fax +49 9241 71-1793 www.ksb.com...

Need help?

Do you have a question about the Compacta UZ10.450D and is the answer not in the manual?

Questions and answers