Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for LEGRAND bticino RCP

- Page 1 Installation for RCP busbar systems. Rev. 02 - 04/2017...

-

Page 2: Table Of Contents

RCP INSTALLATION MANUAL INDEX Warnings ............Handling . -

Page 3: Warnings

RCP INSTALLATION MANUAL WARNINGS These instructions are provided to ensure appropriate storage, correct installation, and efficient use of the system. Note: carefully read these instructions upon receipt of the material and before installing the system, and putting it into operation. The installation must be completed by competent and suitably trained personnel, as prescribed by IEC 11-27 and 50110-1:2004-11 (IEC 11-48) standards, corresponding international standards, or specific applicable... -

Page 4: Handling

RCP INSTALLATION MANUAL HANDLING When handling the material, comply with the regulations for safety in the workplace pursuant Leg. Decree No. 81 dated 09/04/2008 (Consolidated act on safety in the workplace). Follow the indications supplied to prevent damage to materials, or risks to personnel. - Page 5 RCP INSTALLATION MANUAL NOT OK Do not use belts or other system to lift the busbar in unbalanced position. NOT OK Do not lift the busbars from their ends Rev. 02 - 4/2017...

- Page 6 RCP INSTALLATION MANUAL Correct way to lift the busbar, equal distance on each side Rev. 02 - 4/2017...

-

Page 7: Good Reception

RCP INSTALLATION MANUAL GOOD RECEPTION Upon receipt of the goods check the following: integrity of the packaging, and the goods, if delivered in a see-through package consistency of the material with the Delivery Note and the packing list, if supplied consistency of the material with the order acknowledgement details In case of any disclaims, please inform us in writing following the instructions found in the notifications section. -

Page 8: Storage Of Hardware And Chemical Components

RCP INSTALLATION MANUAL We recommend that upon receiving the goods, the integrity of the packaging is checked WITH THE FREIGHT FORWARDER PRESENT. If you find that the packaging has suffered damage and/or collisions of varying degree, please write MATERIAL RECEIVED DAMAGED on the Delivery Note, to enable us to initiate a complaint procedure against the freight forwarder. -

Page 9: Installation Instructions

RCP INSTALLATION MANUAL PRELIMINARY INSTALLATION INSTRUCTIONS Before the installation, all material should be inspected for damage. When installing the busbars comply with the following: For the installation only use bracketing systems supplied by BTicino, and follow the instructions found in the catalogue or enclosed with the item. Only use accessories supplied by BTicino. -

Page 10: Distance And Dimensions

RCP INSTALLATION MANUAL Distances and dimensions During the placement of the busbar elements pay attention to distance from the ceiling, wall and floor. Below the minimum distance: 100mm *400mm **100mm 40mm **100mm Ceiling distance. Wall distance , horizontal Wall distance, vertical installation. - Page 11 RCP INSTALLATION MANUAL If you do not use supports supplied by Bticino to fix the busbar, you must verify the support capacity load of your supports. You can use the following technical data: RCP – 4 CONDUCTROS – ALUMINIUM* 2 x 2500 SINGLE BARS DOUBLE BARS DOUBLE BARS...

- Page 12 RCP INSTALLATION MANUAL RCP – 5 CONDUCTROS – ALUMINIUM* 2 x 2500 SINGLE BARS DOUBLE BARS DOUBLE BARS 1000 1250 1600 2000 2500 3200 4000 5000 Rating Weight (RCP Kg/m 48.2 48.2 52.4 67.1 83.1 160.5 Standard 5C) Weight Kg/m 39.8 49.1 49.1...

-

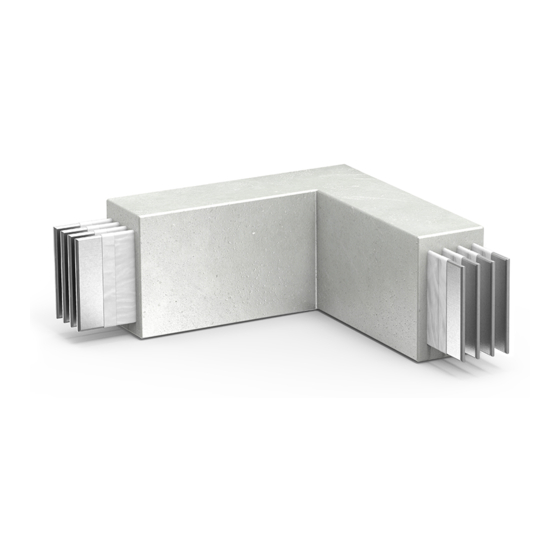

Page 13: Type Of Supports

RCP INSTALLATION MANUAL Types of supports There are brackets for vertical and for horizontal suspension, on request we have brackets solution for aggressive environments. HORIZONTAL SUSPENSION BRACKET The brackets enable sturdy installation of the busbar to the system support structures. The recommended installation distance between brackets is 1.5 meters Rev. - Page 14 RCP INSTALLATION MANUAL ASSEMBLY Tie rod NOTICE Tighten the nuts to 50 Nm. Rev. 02 - 4/2017...

- Page 15 RCP INSTALLATION MANUAL VERTICAL SUSPENSION BRACKET In case of rising mains, thanks to pre-load springs ( see page 18 ), these brackets absorb the forces pressing on the busbar and direct any expansion in a precise direction. They therefore operate as a limitation, and support the traction and compression forces of the busbar trunking system.

-

Page 16: Rules For Support Installation

RCP INSTALLATION MANUAL Rules for supports installation A support shall never coincide with a junction For easier leveling, always use two supports for each element. Always maintain a distance of at least 530 mm between the center of junction and the support on one side of the junction to be able to assemble the junction kit. The minimum distances between the installed elements, walls, and ceilings must be taken into account while installing the supports, as shown before ( distance and dimension Paragraph ). - Page 17 RCP INSTALLATION MANUAL NOTICE For the case of 5000 A (Al) and 6300 A (Cu), please, consider the following indications. - Vertical solution (only one): in the picture it is shown how to install a rising main for these two ranges 5000 A (Al) and 6300 A (Cu);...

- Page 18 RCP INSTALLATION MANUAL There are two different configurations: Standard brackets vertical brackets 1.Without springs 2.With springs Configuration 1 : use this configuration if the section line is between 2 an 4 meters. The vertical bracket must be secured to the wall; the standard bracket must be secured to shelves which can guarantee the load.

- Page 19 RCP INSTALLATION MANUAL ASSEMBLY collar Tie rod Support NOTICE All 3 types of brackets for the vertical solution will be installed as shown in the previous picture. ( with shelf and springs / with springs / bracket only ) If you use vertical brackets without springs you must fix at first the tie rods and the collar on the busbar and then fix the collar on the support.

-

Page 20: Junction Installation

RCP INSTALLATION MANUAL Junction installation WARNINGS Read all the instruction sheet ( attached with mould kit ) before starting the installation Ensure that all contact surfaces are clean and free of impurities. Ensure that the monoblock is exactly in-between two elements to be joined. Do not knock or hit the junction block hard when you insert it. - Page 21 RCP INSTALLATION MANUAL PROCEDURE Before starting ensure to have all the materials: Resin and hardener ( ZU-65200002R ). Filler mix and bucket ( ZU-65200001R ). Mould kit with release agent. Rubber hammer Industrial mixer (rated 750 W or above) Clamping tools ( only for vertical junction) Metallic rasp or grinding stone Silicone/silicone gun For junction casting in environment temperature between 5°C to 18°C you need to...

- Page 22 RCP INSTALLATION MANUAL RCP 3 CONDUCTORS JUNCTION Number of Number of Material Rating (A) junction per Material Rating (A) junction per 3,00 3,00 3,00 1000 3,00 1000 3,00 1250 3,00 1250 3,00 1600 2,60 1600 2,60 2000 2,60 2000 2,15 2500 2,15 2500...

- Page 23 RCP INSTALLATION MANUAL Ensure the junction kit and the mould kit are not damaged: Apply the sealant and the release agent: Rev. 02 - 4/2017...

- Page 24 RCP INSTALLATION MANUAL Ensure the correct position of the RCP elements, the distance between bars must be 40mm. Clean the bar’s surface, do not remove the surface treatment ( if applied). Fit the monoblock between the copper or aluminum conductors from above or below.

- Page 25 RCP INSTALLATION MANUAL Place the mould on the mechanical connection and secure it with the two C- profiles. Rev. 02 - 4/2017...

- Page 26 RCP INSTALLATION MANUAL In vertical junction use a bracket to keep the mould in the correct position ( horizontal suspension bracket - edgewise installation Rev. 02 - 4/2017...

- Page 27 RCP INSTALLATION MANUAL If you do not have a bracket or you prefer it, you can use two blocks and one clamping tool to keep the mould in the correct position (in the second case make sure that the blocks do not damage the busbar's surface. We recommend using wooden blocks for this solution.): Rev.

- Page 28 RCP INSTALLATION MANUAL Mix all the component, checks the correct sequences in the following pictures. If the temperature is below 18°C you must add an additive ( ZU-65200003R ) to the resin during the operation 1. During this process use mask with protection grade FFP1. Pour the mix into the mould carefully.

- Page 29 RCP INSTALLATION MANUAL Allow the cast resin mix to harden then, remove the mould and use a metallic rasp to clean the edges. Rev. 02 - 4/2017...

-

Page 30: Junction Ip 68-55

RCP INSTALLATION MANUAL Junction IP68-IP55 The RCP busbar system is compatible with SCP busbar system. When you connect RCP with SCP the protection grade becomes IP55. The junction is very easy to install: Check the correct position of RCP and SCP ( see the picture below ). -

Page 31: Fire Barrier

RCP INSTALLATION MANUAL Fire barrier One fire barrier kit is composed of two parts, one for each face of the wall. The length of one part is 200 mm. In the fire barrier kit there are 24 panels of fire resistant material, screw and mastic to fix the fire resistant sheet to the wall and to the RCP. - Page 32 RCP INSTALLATION MANUAL Once the barriers are assembled with screws, fill all the joints between panels with the promaseal paste and then work it with a putty knife to obtain a smooth and homogeneous aspect. check the RCP catalog for L and H dimensions Rev.

-

Page 33: Switchboard Connection

RCP INSTALLATION MANUAL Switchboard connection On switchboard connections verify that: the air distances between bars with different potentials are over 40 mm wide. If it is not the case, contact Eng. Dept. Zucchini Brand to evaluate the employment of correct insulating material. the torque moment of connecting screws is correct (required values: 85 Nm for M12, 100 Nm for M14, 120 Nm for M16, 170 Nm for M18, 25 Nm for M8 and 50 Nm for M10). -

Page 34: Final Test And Periodic Inspections

RCP INSTALLATION MANUAL Final test and periodic inspections FINAL TEST Insulation test at 1000V, with minimum value of 1 MOhm, for the line. The insulation test has to be carried out between phases, between phases and neutral, and between every single phase and the earth ( when required ). After having run the plant at the maximum working current, and let it work for at least 6 hours, carry out a thermal test. - Page 35 RCP INSTALLATION MANUAL Temperature form PERSON IN CHARGE OF INSPECTION COMPANY ( if different from installing company ) INSPECTION DATE SIGNATURE Check point n. Measured T Ambient T Dt = Measured T - Ambient T Ib = Working current Rev. 02 - 4/2017...

-

Page 36: Contact Us

RCP INSTALLATION MANUAL For further information or explanation please get in contact with Customer CareZucchini. Tel: 0365 332811 Fax: 0365 31934 E-mail: IT-PostVenditaZucchini@bticino.it Rev. 02 - 4/2017...

Need help?

Do you have a question about the bticino RCP and is the answer not in the manual?

Questions and answers