Table of Contents

Advertisement

Quick Links

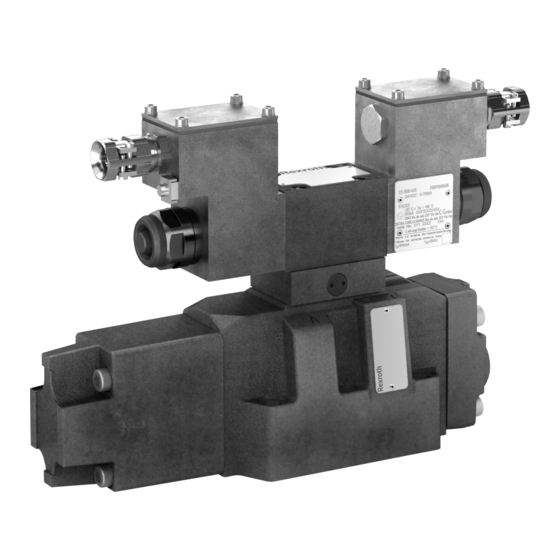

Proportional directional valves,

pilot-operated,

without electric position feedback

(area of application according to the explosion protection directive 2014/34/EU: II 2G)

Type 4WRZ..7X/...XE...

(IECEx certificate of conformity

of the valve solenoid)

Operating instructions

RE29115-XE-B/09.19

Replaces: 04.16

Document no. RA78494073_AA

English

Advertisement

Table of Contents

Summary of Contents for Bosch REXROTH 4WRZ 7X/XE Series

- Page 1 Proportional directional valves, pilot-operated, without electric position feedback (area of application according to the explosion protection directive 2014/34/EU: II 2G) Type 4WRZ..7X/...XE... Replaces: 04.16 Operating instructions Document no. RA78494073_AA (IECEx certificate of conformity RE29115-XE-B/09.19 English of the valve solenoid)

- Page 2 IT: La messa in servizio di questo prodotto può essere eseguita solo se si dispone del presente manuale d‘uso in una lingua ufficiale della UE conosciuta e se ne è stato compreso il contenuto. In caso contrario rivolgersi al referente Bosch Rexroth o al punto di assistenza competente.

- Page 3 NL: U mag het product pas in bedrijf stellen, als deze bedieningshandleiding voor u beschikbaar is in een voor u begrijpelijke, officiële taal van de EU en als u de inhoud daarvan begrepen heeft. Is dit niet het geval, neem dan a.u.b. contact op met uw Bosch Rexroth contactpersoon of de servicepartner.

- Page 4 Our products are subject to a natural process of wear and aging. © All rights with Bosch Rexroth AG, also in case of applications for industrial property protection. It may not be reproduced or given to third parties without consent of Bosch Rexroth AG.

-

Page 5: Table Of Contents

10.1 Cleaning and care 10.2 Inspection and maintenance 10.3 Maintenance schedule 10.4 Repair 10.5 Rectifying external leakages 10.6 Spare parts Disassembly and removal Disposal 12.1 Environmental protection 12.2 Return to Bosch Rexroth AG 12.3 Packaging 12.4 Materials used 12.5 Recycling RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... - Page 6 6/48 Extension and modification Troubleshooting and fault correction 14.1 How to proceed for troubleshooting Technical data Appendix 16.1 List of addresses Declaration of conformity Index Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

-

Page 7: About This Documentation

In this documentation, safety instructions are included in chapter 2.6 “Product-specific safety instructions” and in chapter 3 “General information on damage to property and damage to product” and whenever a sequence of actions or instructions is explained which bear the danger of personal injury or damage to property. The hazard avoidance measures described must be observed. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... - Page 8 The following abbreviations are used in this documentation: Table 4: Abbreviations Abbreviation Meaning ATEX EU Directive for Explosion Protection (Atmosphère explosible) European Standard International Organization for Standardization International Electrotechnical Commission Rexroth document in English language Ingress protection class of electric operating equipment Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

-

Page 9: Safety Instructions

The valve may only be operated in a technically perfect condition and used as described in these operating instructions. The connection conditions, application conditions and performance data defined in these operating instructions must not be changed. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... -

Page 10: Improper Use

• Non-compliance with the specified performance limits Changes and/or modifications to the valve are not admissible, refer to chapter 13 “Extension and modification”. Bosch Rexroth AG does not assume any liability for damage caused by improper use. The user assumes all risks involved with improper use. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... -

Page 11: Qualification Of Personnel

Understanding of the additional importance of work permit systems and safe electrical separation regarding explosion protection Bosch Rexroth offers measures supporting training in specific fields. Please find an overview of the training contents on the Internet at: http://www. boschrexroth.de/didactic... -

Page 12: General Safety Instructions

• Only use original Bosch Rexroth accessories and spare parts in order to prevent any hazard to persons due to unsuitable spare parts. • Comply with the technical data and environmental conditions specified in the product documentation. -

Page 13: Product-Specific Safety Instructions

The valve controls movements in machines or systems. In case of mechanical and electric faults, e.g. failure of the energy supply, persons may be caught by the system, kicked away or bruised. ▶ During set-up of your circuit, observe functional safety e.g. according to EN ISO 13849. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... - Page 14 Check the surface protection on the valve and the valve mounting screws at regular intervals. Contact with salt water leads to increased corrosion on the valve. This may chemically corrode and damage individual components of the valve. Therefore take suitable corrosion protection measures. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

-

Page 15: Notices On The Valve Use

The machine end-user is obligated to check in the order confirmation whether the delivered valve corresponds to the required category and associated zone or equipment protection level. The machine end-user of the Bosch Rexroth valve is responsible that • the valve is only being used according to the intended use as defined in these operating instructions. -

Page 16: General Information On Damage To Property And Damage To Product

Ensure that no cleaning agents are able to penetrate the hydraulic system. Environmentally harmful hydraulic fluid Leaking hydraulic fluid leads to environmental pollution. ▶ Immediately remedy possible leakage. ▶ Dispose of the hydraulic fluid in accordance with the currently applicable national regulations in your country. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... -

Page 17: Scope Of Delivery

▶ Check the scope of delivery for possible transport damage, see chapter 6 “Transport and storage”. In case of complaints, please contact Bosch Rexroth AG, see chapter 16.1 "List of addresses". Accessories such as valve subplates and valve mounting screws are not included in the scope of delivery and must be ordered separately. See chapter 7.6 “Required accessories”. -

Page 18: Product Identification

Table 5: Information on the name plate of the main valve Type of information Manufacturer's logo Material no. of the valve Type designation complete valve Serial number of the valve Manufacturer's factory number Date of manufacture (year and week) Maximum operating pressure Ambient temperature range Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... - Page 19 Hydraulic symbol according to ISO 1219 Designation of origin Name and address of the manufacturer Production order number CE mark Explosion protection mark Mark according to ATEX directive 2014/34/EU Mark for the type of protection of the mechanical part according to EN 80079-36 95/230 Bosch Rexroth QR code RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 20 Rated current for external miniature fuse Rated voltage for external miniature fuse Data matrix code of the valve solenoid manufacturer 1) Depending on valve sizes and configuration of the solenoid coils, higher ambient temperatures are admissible; see “Data sheet 29115-XE". Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 21 Corresponds to zone 21 according to directive 1999/92/EC. High safety level. Potentially explosive areas where an explosive atmosphere due to stirred dust (= device group II) is normally not present or occurs only rarely or short-time. Corresponds to zone 22 according to directive 1999/92/EC. Normal safety level. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

-

Page 22: Transport And Storage

Danger of cut injuries! ▶ Wear suitable protective equipment for the transport of the safety valve. Further information regarding transport is available from Bosch Rexroth, see chapter 16.1 "List of addresses". Notify your responsible sales contact person any transport damage within one week. The addresses of the sales subsidiaries can be found on the Internet at: http:/www.boschrexroth.com/adressen... - Page 23 After expiry of the maximum storage time, we recommend having the valve checked by your competent Bosch Rexroth service. In case of questions regarding spare parts, please contact the Bosch Rexroth service responsible for your valve, see chapter 10.6 “Spare parts”. Following disassembly If a dismounted valve is to be stored, it has to be preserved for protection against corrosion for the duration of storage.

-

Page 24: Assembly

▶ It is imperative to provide for absolute cleanliness. The valve must be protected from dirt during installation. Contamination of the hydraulic fluid may considerably reduce the life cycle of the valve. ▶ Observe the installation position specified in “Data sheet 29115-XE”. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... -

Page 25: Prior To Assembly

For subplates with dimensions for valves with porting pattern according to ISO 4401, refer to “Data sheet 45100”. Ordering address The addresses of our responsible sales organizations can be found online under for accessories www.boschrexroth.com and valves and in appendix 16.1 “List of addresses”. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... -

Page 26: Assembling The Valve

▶ Do not remove the protective caps of the valve until assembly. ▶ After disassembly, seal the hydraulic fluid bores with suitable cap elements. ▶ Immediately remove hydraulic fluid that has leaked out. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... - Page 27 M10 x 60 - 10.9 58.0 Nm ±20% M6 x 60 - 10.9 12.2 Nm ±10% Size 25 M12 x 60 - 10.9 100.0 Nm ±20% Size 32 M20 x 80 - 10.9 340.0 Nm ±20% RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 28 Mark all checked fittings, e.g. using a permanent marker. Make sure that all pipes and hose lines and every combination of connection pieces, couplings or connection points with hoses or pipes are checked for their operational safety by a person with appropriate knowledge and experience. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 29 The use of connection lines with shielding or sheathing can lead to potential backfeeding and is thus an explosion hazard! ▶ Only use connection lines without shielding or sheathing. For information on the prescribed pre-fuse, refer to “Data sheet 29115-XE”. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 30 During the assembly, ensure leak-tightness between cable and line entry and terminal box. Route the connection line in a strain-relieved form. The first mounting point must be within 15 cm of the cable and line entry. Connection of the valve solenoid is polarity-independent. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 31 Remove the outer sheath of the connection line and the insulation of the individual conductors. Press the wire end ferrules to the individual conductors. For the stripping lengths, refer to Fig. 5 and Table 9. Fig. 5: Stripping lengths RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 32 Connection for potential equalization 2.0...2.4 Nm conductor Assemble the cover with the sealing device underneath. Tighten the mounting screws with their spring washers diagonally, one after the other. Tightening torque of the cover screws: 1...1.1 Nm. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 33 Re-attach the solenoid coil in the desired position. Assemble the O-ring onto the pole tube and slide it forward up to the solenoid coil. Re-tighten the mounting nut of the valve solenoid (hexagon nut, wrench size 32, tightening torque 4 + 1 Nm). RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

-

Page 34: Commissioning

Condensed water can build up in the terminal box and cause a short-circuit! ▶ Allow the valve to acclimatize for some hours prior to commissioning as the electric connections in the terminal box might be damaged by the generation of condensed water. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... - Page 35 ▶ Check whether there is an internal leakage. The check must be carried out according to the possibilities present at the hydraulic system. An internal leakage can be valve-specific but does not necessarily affect the functionality of the valve. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

-

Page 36: Operation

Changing the settings at the valve is not admissible. For information on the operation, please refer to the operating instructions for the hydraulic system into which the valve is installed. If errors occur, refer to chapter 14 “Troubleshooting”. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... -

Page 37: Maintenance And Repair

The check must, however, at least be carried out every three years from the date of manufacture of the valve. The date of manufacture of the valve can be found on the name plate, see chapter 5.1.1 “Information on the name plate of the main valve”. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... - Page 38 The sealing elements are only intended for single use. Re-assemble the cover of the terminal box with the seal beneath it. Tighten the mounting screws with the spring washers diagonally, one after the other. Tightening torque of the cover screws: 1...1.1 Nm. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

-

Page 39: Maintenance Schedule

39/48 10.3 Maintenance schedule Valves require low maintenance if used as intended. For a long and reliable operation of the valve, Bosch Rexroth recommends regularly checking the hydraulic system and the valve. 10.3.1 Checking for leakage Check the valve for leakage. An early detection of hydraulic fluid loss may help you to identify and remedy errors. -

Page 40: Spare Parts

In case of questions about spare parts, please contact your responsible Bosch Rexroth Service: Bosch Rexroth AG Service Hydraulics Bürgermeister-Dr.-Nebel-Str. 8 97816 Lohr am Main Tel: +49 (0) 9352/40 50 60 service@boschrexroth.de For the addresses of our sales and service network please refer to: www.boschrexroth.com/adressen Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19... -

Page 41: Disassembly And Removal

Close the hydraulic channels of the subplate (on the customer side) to avoid contamination. If the valve is exchanged, all further steps are analogous to mounting, see chapter 7 “Assembly”. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... -

Page 42: Disposal

They can be recycled without any problems. For environmental reasons, disposable packaging should not be used for returning products to Bosch Rexroth. 12.4 Materials used Hydraulic components from Bosch Rexroth do not contain any hazardous materials that could be released during intended use. Normally, no unfavorable effects on human beings and on the environment have to be expected. -

Page 43: Recycling

(machine/system, electrical systems, control) or at the valve? If so: What were they? – Was the valve and/or the machine used as intended? – How did the fault become apparent? ▶ Try to get a clear idea of the cause of error. Ask the direct (machine) operator. RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG... - Page 44 Following faults due to contamination, in addition to the repair, it is essential to check the oil quality and improve it, if necessary, by suitable measures such as flushing or the additional installation of filters. 15 Technical data For the technical data of your valve please refer to “Data sheet 29115-XE”. Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 45 +49 (0) 9352/40 50 60 Email service@boschrexroth.de Headquarters Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Phone +49 (0) 9352/40 30 20 Email my.support@boschrexroth.de The addresses of our sales and service network and sales organizations can be found at www.boschrexroth.com/adressen RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 46 46/48 Declaration of conformity 17 Declaration of conformity Bosch Rexroth AG, 4WRZ..7X/...XE..., RE 29115-XE-B/09.19...

- Page 47 ▶ I Improper use Inspection and maintenance Intended use ▶ L List of addresses ▶ M Maintenance Maintenance schedule Modification ▶ N Name plate Notices on the valve use ▶ O Obligations of the machine end-user Operation RE 29115-XE-B/09.19, 4WRZ..7X/...XE..., Bosch Rexroth AG...

- Page 48 Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Tel: +49 (0) 9352/40 30 20 my.support@boschrexroth.de www.boschrexroth.com Subject to change without notice Printed in Germany RE 29115-XE-B/09.19...

Need help?

Do you have a question about the REXROTH 4WRZ 7X/XE Series and is the answer not in the manual?

Questions and answers