Summary of Contents for Frontier GM1048E

- Page 1 O P E R A T O R ’ S M A N U A L GROOMING MOWERS GM1048E GM1060E GM1072E Manual 5BP960379B Date 11/11/2010...

-

Page 2: Signal Words

SAFETY Take note! This safety alert symbol found throughout this manual is used to call your attention to instructions involving your personal safety and the safety of others. Failure to follow these instructions can result in injury or death. This symbol means: ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! - Page 3 4.04 - Belt Tension 4.05 - Belt Replacement 4.06 - Driveline 5 - REPAIR PROCEDURES 5.01 - Gearbox 5.02 - Blade Spindle 5.03 - Suggested Spare Parts 5.04 - Storage 6 - TROUBLESHOOTING 7 - PRE-DELIVERY CHECKLIST PARTS MANUAL FRONTIER NDEX...

-

Page 4: General Information

Your Authorized Company Dealer has genuine parts in stock. Only these approved replacement parts should be used. FRONTIER ENERAL NFORMATION... -

Page 5: Model And Serial Number Id

Wheel spacer (#5BP0008528) Parts used to assemble wheel arm: Bolt HH M10-1.50x90 C8.8 Z P (#5BP0026185) Washer flat Ø11 W (#5BP0051776) Washer flat Ø10 W (#5BP0002034) Washer lock Ø10 Z (#5BP0001280) Nut HH M10-1.50 C6 TK Z (#5BP0001279) FRONTIER ENERAL NFORMATION... - Page 6 6” overlap in its longest working position. Refer to Section 4.06 of this manual, if it is determined that the driveline is too long See Section 4.06 - Driveline, for instructions on how to determine correct driveline length and FRONTIER ENERAL NFORMATION...

- Page 7 4. Attach the floating yokes of quick hitch adapter assembly to the linking plates of the mower. Note: Two ½” long bushings for the floating yokes are provided in the hardware bag of the quick hitch adapter kit. Ensure these spacers are installed onto the M16x60 bolt. procedures for shortening the driveline. FRONTIER ENERAL NFORMATION...

- Page 8 Ensure that the M16x60 bolt is approximately in the center of the slot on the floating yoke. Positioning the bolt in this location allows the mower to have maximum float both up and down. FRONTIER ENERAL NFORMATION...

- Page 9 CAUTION: If the three point hitch of the tractor is set in the lowest position, the driveline may bottom out against the quick hitch resulting in a bent driveline. If the mower is lifted after the driveline has been bent, it may also damage the gearbox, mounting plates and other hardware. FRONTIER ENERAL NFORMATION...

-

Page 10: Safety Precautions

6. Operate only in daylight or good artificial light. 7. Ensure mower is properly mounted, adjusted and in good operating condition. 8. Ensure that all safety shielding and safety signs are properly installed and in good condition. FRONTIER AFETY RECAUTIONS... -

Page 11: Starting And Stopping

6. Allow no riders on tractor or mower. 7. Allow moving parts to stop before repair. 8. Securely support mower before working underneath. Additional warning and operating decals are available at no extra charge. Please specify model and serial number when ordering. FRONTIER AFETY RECAUTIONS... - Page 12 ’ ROOMING OWERS PERATOR ANUAL Fig. 5 - Safety decals - implement; replace immediately if damaged. left side placed under belt shield right side Red reflective decal FRONTIER AFETY RECAUTIONS...

- Page 13 ’ ROOMING OWERS PERATOR ANUAL Safety decals - driveline; replace immediately if damaged. placed on outer shield placed on outer tube FRONTIER AFETY RECAUTIONS...

-

Page 14: Operational Safety

Accidents are most likely to occur with machines that are loaned or rented to someone who has not read the operator’s manual and is not familiar with a rotary mower. FRONTIER PERATION... - Page 15 . Look for loose fasteners, worn or broken parts, and leaky or loose fittings. 22. Use only the driveline supplied with the mower. Do not use it if it is missing any shield or safety protection. See Chapter 4 - Maintenance. FRONTIER PERATION...

- Page 16 He must also fill out the Pre-Delivery Checklist prior to delivering the mower. Fig. 6 Front mount mower. Fig. 7 Rear mount mower. See Chapter 7 - Pre-Delivery Checklist. FRONTIER PERATION...

-

Page 17: Cutting Height Adjustment

Be sure all wheel arms are adjusted equally. This is the only way to ensure a completely uniform cut. IMPORTANT: Very low cutting heights should be avoided. Damaging shock loads occur when the blades strike the ground repeatedly. This can cause damage to the mower. FRONTIER PERATION... -

Page 18: Pre-Operational Check

1 three point hitch . Never use this mower with tractors over 30 HP. CAUTION: Check the tractor PTO rpm to ensure it is set at 540 and turns clockwise. See Table 1, page 32. See Table 2, page 32. FRONTIER PERATION... - Page 19 CAUTION: Do not operate this mower at a PTO speed or direction of rotation other than that shown on the mower. Serious damage can occur to the machine and/or the operator. FRONTIER PERATION...

-

Page 20: Working Speed

This is particularly important when mowing around schools, public parks and golf courses. If you are using a mulching kit, you need to reduce your ground speed to under 2 mph (see fig. 9). See Section 4.03 - Blade Maintenance. See Section 4.03 - Blade Maintenance. FRONTIER PERATION... -

Page 21: Operating Techniques

540 rpm engine speed. The lower ground speed will permit the grass to at least partially rebound. Under some conditions grass will not rebound enough to be cut evenly, resulting in an uneven appearance. In general, lower cutting See Sharpening Blades in section 4.03 - Blade Maintenance. FRONTIER PERATION... -

Page 22: Uneven Terrain

4. Operate the implement up and down steep slopes, not across slopes, to prevent the tractor from tipping. Avoid sudden stops and starts, and slow down before changing directions on a slope. 5. Pass diagonally through sharp dips and avoid sharp drops to prevent hanging up the tractor and implement. FRONTIER PERATION... -

Page 23: Removing Mower From The Tractor

4. Always disengage PTO before raising the implement to transport position. 5. When raising the mower be sure the PTO driveline does not hit either the mower or the tractor. 6. During transport the mower should not be lifted over 14” to 16” from the ground. FRONTIER PERATION... -

Page 24: Maintenance Safety

12. Inflating or servicing tires can be dangerous. Whenever possible, trained personnel should be called to service and/or mount tires. 13. After servicing, be sure all tools, parts and service equipment are removed. FRONTIER AINTENANCE... - Page 25 1. Lubricate the driveline and the wheel yokes: Apply two or three shots of grease to the driveline cross and bearings and the telescoping shafts; apply the same Refer to Table 1 - Torque Specifications, page 32. See Section 4.03 - Blade Maintenance. FRONTIER AINTENANCE...

-

Page 26: Blade Maintenance

Blades must be kept sharp, at their original length and corners maintained. A blade must be replaced if, due to wear or damage, its original shape has been distorted. See Table 1 - Torque Specifications, page 32. See Section 4.04 - Belt Tension. FRONTIER AINTENANCE... - Page 27 WARNING: Do not substitute blades or any bolt for the blade retaining bolt. Company blades and blade retaining bolts are specially made for this application. Using non original parts can effect the quality of cut and may also cause damage to the mower. FRONTIER AINTENANCE...

-

Page 28: Belt Tension

4.04 - Belt Tension Belt tension control Check the belt tension by applying a force of 12-15 lb. pushing against the belt halfway between the pulleys. The belt deflection should be between ”- ”. FRONTIER AINTENANCE... -

Page 29: Belt Replacement

If the belt has been stretched or damaged to the point where the proper tension cannot be obtained it must be changed. Fig. 15 1. drive pulley 2. central pulley 3. side pulley 4. belt 5. belt tensioner 6. hitch plate 7. spring FRONTIER AINTENANCE... - Page 30 When the driveline is in the maximum extended position, the ideal minimum overlap of the two halves should be approximately 6” (see fig. 16). Fig. 16 min. 6" MAX. min. 2" MIN. FRONTIER AINTENANCE...

- Page 31 If determined that the driveline is too short for your tractor, contact your local dealer. CAUTION: Always work with the driveline as straight as possible. This will prolong its life and that of its components. It is advised, not to work at an angle greater than 15 degrees. FRONTIER AINTENANCE...

- Page 32 Blades tip Cutting # Belts # Wheels & Driveline width width rpm/min speed ft/min Blades height & type size ” GM1048E 16-30 48” 51” 3,037 13,188 1” - 4” 1 BX 4 - 8.4”x3.2” ASAE 2 GM1060E 16-30 60” 62”...

-

Page 33: Repair Procedures

It is suggested that the following spare parts be kept on hand for the mower at all times to prevent a minor problem from delaying work. See Section 4.05 - Belt Replacement. See Section 4.05 - Belt Replacement. See Section 4.03 - Blade Maintenance. FRONTIER EPAIR ROCEDURES... - Page 34 5. Loosen the belts if the mower is to be stored for an extended length of time. 6. Cover the mower from the elements in order to have it in perfect condition for the start of the next season. See Chapter 4 - Maintenance. FRONTIER EPAIR ROCEDURES...

-

Page 35: Troubleshooting

Dull blades. Sharpen blade. See Blades Maintenance section. Blades worn down, preventing Change blades. overlap. Cut grass windrows. Ground speed too low. Increase ground speed. Tractor rpm too slow. Increase tractor rpm, check engine and PTO speeds. FRONTIER ROUBLESHOOTING... -

Page 36: Pre-Delivery Checklist

Give customer the Operator’s Manual and encourage the customer to read the manual carefully. IMPORTANT: The dealer must complete the Warranty Registration, located on the Frontier website. Warranty claims will be denied if the Warranty Registration has not been completed. Model Number: __________... - Page 37 Note: Serial #’s with the XF prefix are subsequent to serial numbers with the BC prefix. For example: A reference to “serial # BC… 739197 & above” will also include all serial numbers with an XF prefix. Frontier ECO-R48, R60, R72 (US) Parts Manual 11/2010 Printed on January 12, 2011 ECO-R48, ECO-R60, ECO-R72 Ver.

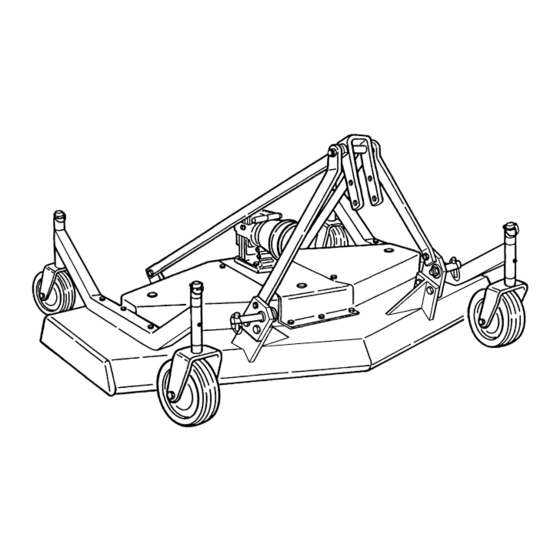

- Page 38 ’ ROOMING OWERS RAME PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 06/2007...

- Page 39 GM1048E, GM1060E, GM1072E Ref. Part # Description Qty. 5BP0151501P Frame 4’ rear discharge; GM1048E #BC…844971 & above 5BP0251501P Frame 5’ rear discharge; GM1060E #BC…844971 & above 5BP0351501P Frame 6’ rear discharge; GM1072E #BC…844971 & above 5BP0108817 Belt shield 4’ frame; GM1048E 5BP0208817 Belt shield 5’...

- Page 40 & W ’ ROOMING OWERS HREE OINT ITCH HEEL PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 07/2009...

- Page 41 Cotter pin 5BP0008528 Spacer 5BP0006615 Bolt HH M14-2.00x140 C8.8 Z P 5BP0030358 Nut PT M14-2.00 C6 Z TK 5BP0051772 Wheel arm 4’ frame; GM1048E 5BP0051781 Wheel arm 5’ frame; GM1060E 5BP0051783 Wheel arm 6’ frame; GM1072E 5BP0001065 Grease fitting M10-1.00 5BP0006586 Spacer, height adjustment 1”...

- Page 42 & S ’ ROOMING OWERS RANSMISSION PINDLE PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 07/2009...

- Page 43 5BP0051740 Spring 5BP0008623 Pulley SPB 250x1 5BP0008563 Support, belt tensioner; #BC…631791 & below 5BP0051741 Support, belt tensioner; GM1048E #BC…631792 & above 5BP0051745 Support, belt tensioner; GM1060E, GM1072E #BC…631792 & above 5BP0008571 Hitch plate; #BC…631791 & below 5BP0008571 Hitch plate; GM1048E #BC…631792 & above 5BP0051755 Hitch plate;...

- Page 44 & S ’ ROOMING OWERS RANSMISSION PINDLE PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 07/2009...

- Page 45 & S ’ ROOMING OWERS RANSMISSION PINDLE PERATOR ANUAL GM1048E, GM1060E, GM1072E Ref. Part # Description Qty. 5BP0008557 Spindle shaft 5BP0006639 Key 8x7x25 5BP0006636 Cover 5BP0006606 Shim Ø25x35x2 5BP0006626A Bearing 6205-ZZ 5BP0008538 Support, spindle shaft 5BP0008536 Spacer 5BP0006634A Bearing 6205-Z...

- Page 46 ’ ROOMING OWERS RONT OLLER AND ULCHING PTION PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 06/2010...

- Page 47 Nut PT M10-1.50 C6 TK Z 5BP0091281 Bolt HH M10-1.50x35 C8.8 Z F 5BP0030157 Washer fender Ø10 Z 5BP0008755 Baffling, front 4’ frame; GM1048E 5BP0115824 Baffling, front 5’ frame; GM1060E 5BP0008759 Baffling, front 6’ frame; GM1072E 5BP0008756 Baffling, rear 4’ frame; GM1048E 5BP0115825 Baffling, rear 5’...

- Page 48 ’ ROOMING OWERS ATCH UICK ITCH DAPTER PTION PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 06/2007...

- Page 49 The four (4) bolts (5BP0006578) and (4) nuts (5BP0005581) come with the mower and are not part of the quick hitch adapter kit. When ordering the quick hitch adapter together with the GM1060E or the GM1048E mower, the original driveline of the mower will be changed to part number 5BP0500404.

- Page 50 ’ ROOMING OWERS EARBOX PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 08/2010...

- Page 51 5BP0010196 Spacer 5BP0034196 Shim Ø35x45x2.5 5BP0042122 Snap ring, outer Ø35 5BP0002295 Oil seal 35.62.10 5BP0051581 Central plate 4’ frame; GM1048E 5BP0051583 Central plate 5’ frame; GM1060E 5BP0051585 Central plate 6’ frame; GM1072E 5BP0006688 Key 8x7x35 5BP0008623 Pulley SPB 250x1 5BP0006698 Nut SP M25-1.50 Z...

- Page 52 ’ ROOMING OWERS RIVELINE PERATOR ANUAL GM1048E, GM1060E, GM1072E; #XF…276188 & BELOW FRONTIER ARTS ANUAL 04/2009...

- Page 53 ’ ROOMING OWERS RIVELINE PERATOR ANUAL GM1048E, GM1060E, GM1072E; #XF…276188 & BELOW Ref. Part # Description Qty. 5BP1022010C PTO yoke 5BP1002020C Cross w/bearing 5BP1942045NC Outer tube w/yoke; GM1048E 5BP1942055NC Outer tube w/yoke; GM1060E 5BP1942070NC Outer tube w/yoke; GM1072E 5BP1952047NC Inner tube w/yoke; GM1048E 5BP1952057NC Inner tube w/yoke;...

- Page 54 ’ ROOMING OWERS RIVELINE PERATOR ANUAL GM1048E, GM1060E, GM1072E; #XF…276189 #XF...286013 FROM FRONTIER ARTS ANUAL 11/2010...

- Page 55 Standard cone (tractor end); from #XF…276189 to XF...286013 5BP1211735C Safety ring; from #XF…276189 to XF...286013 5BP1881709C Safety sleeve; from #XF…276189 to XF...286013 5BP1773043C Shield, outer tube; GM1048E #XF…286013 & below 5BP1773053C Shield, outer tube; GM1060E #XF…286013 & below 5BP1773068C Shield, outer tube; GM1072E #XF…286013 & below 5BP1872043C Shield, inner tube;...

- Page 56 ’ ROOMING OWERS RIVELINE PERATOR ANUAL GM1048E, GM1060E, GM1072E; #XF...286014 & ABOVE FRONTIER ARTS ANUAL 11/2010...

- Page 57 5BP6002010A Locking ring, outer tube; #XF...286014 & above 5BP6014010A Standard cone; tractor end; #XF...286014 & above 5BP5820452EA Shield, outer tube; GM1048E #XF...286014 & above 5BP5820552EA Shield, outer tube; GM1060E #XF...286014 & above 5BP5820702EA Shield, outer tube; GM1072E #XF...286014 & above 5BP5820452IA Shield, inner tube;...

- Page 58 ’ ROOMING OWERS ECALS PERATOR ANUAL GM1048E, GM1060E, GM1072E FRONTIER ARTS ANUAL 11/2010...

- Page 59 Decal, safety set, mower & operator’s manual in French 5BP960379B Operator’s & Parts Manual GM1048E, GM1060E, GM1072E Note: Serial #’s with the XF prefix are subsequent to serial numbers with the BC prefix. For example: A reference to “serial # BC… 739197 & above” will also include all serial numbers with an XF prefix.

- Page 60 Manual 5BP960379B Date 11/11/2010...

Need help?

Do you have a question about the GM1048E and is the answer not in the manual?

Questions and answers

Looking for wheels replacement