Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Frontier DM1160

- Page 1 OPERATOR'S MANUAL DISK MOWER DM1160 9N004AUS F - English (USA) - 12-2012...

-

Page 3: Dear Owner

Designated use of the machine The DM1160 mower must only be used for the purpose for which it was manufactured: mowing on the ground of hay fields, grass silage fields and improved pastures for the purpose of harvesting fodder for feeding livestock. -

Page 4: Table Of Contents

DM1160 $CONTENTS Dear Owner........................1 Contents ......................... 2 Identification of the machine ..................4 Front view ............................4 Rear view ............................4 Model identification plate.........................5 Optional equipment ..........................5 Safety ..........................6 Description of symbols used in this document ................6 Safety instructions..........................7... - Page 5 DM1160 Instructions for work....................37 Putting the machine into work position ..................37 Adjustments in working position ....................39 Machine use ............................42 Optional equipment......................43 Reinforced PTO shaft ........................43 "HD" disks ............................43 Raised skid shoes ..........................48 2 swath shields ..........................48 Inner swath shield ..........................49 ...

-

Page 6: Identification Of The Machine

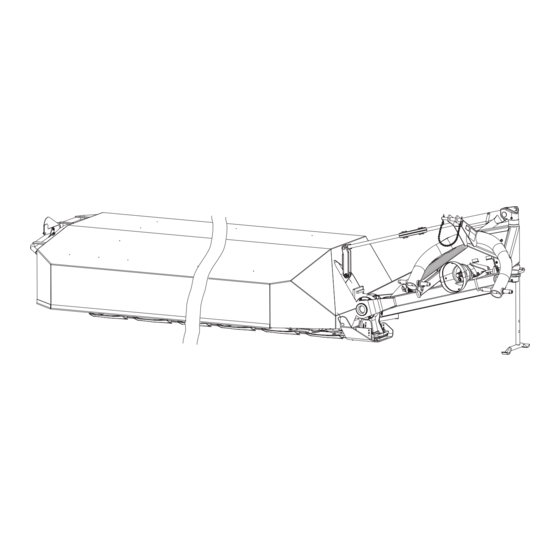

DM1160 $IDENTIFICATION OF THE MACHINE 1. Front view 2. Rear view Identification of the machine... -

Page 7: Model Identification Plate

DM1160 3. Model identification plate Please write below the type and serial number of the machine. This information is to be given to your John Deere dealer for all parts order or warranty claim. DM1160 Type: Serial no.: MADE IN FRANCE DEERE &... -

Page 8: Safety

DM1160 $SAFETY 1. Description of symbols used in this document This symbol indicates a potentially hazardous situation that if not avoided, could result in serious bodily injury. This symbol is used to identify special instructions or procedures which, if not followed strictly, could result in machinery damage. -

Page 9: Safety Instructions

DM1160 2. Safety instructions Introduction The machine must only be operated, maintained and repaired by qualified persons who are familiar with the machines' operation and understand safety regulations and procedures for preventing accidents. The operator must follow the safety instructions in this manual and in the warnings posted on the machine. The operator is also obliged to respect current legislation concerning accident prevention, work safety and public traffic circulation. - Page 10 DM1160 Precautions to take before using the machine Do not wear loose clothing which could become caught up in moving parts. Wear appropriate protective clothing (gloves, shoes, goggles, helmet, ear defenders, etc.). Ensure that all operating controls (ropes, cables, rods, etc) are placed so as they cannot be operated unintentionally and cause damage or injury.

- Page 11 DM1160 Precautions when driving on public roads Dimensions Depending on the dimensions of the machine, contact the relevant authorities to ensure that it can be legally transported on public roads. If the machine is over the maximum legal size, follow the local regulations for special transportation of oversize equipment.

-

Page 12: Hydraulic Circuit

DM1160 Precautions when coupling Before attaching the machine, make sure that it cannot accidentally start moving (chock the wheels) and that the parking stand is in the right position. The machine must only be attached to the hitch points provided for this purpose. -

Page 13: Pto Shaft

DM1160 PTO shaft Use only PTO shafts supplied with the machine or recommended by the machine manufacturer. The protective shield of the tractor PTO stub, the PTO shaft guards and the protective shield of the machine input shaft must always be in place and in good condition. -

Page 14: Safety Decals

DM1160 Precautions during maneuvers When moving the machine from the transport position to the working position and vice versa, make sure that nobody is within the machine pivoting area. Remote controlled components Danger of crushing and shearing can exist when components are operated by hydraulic or pneumatic controls. - Page 15 DM1160 Precautions for maintenance and repair work Before leaving tractor before adjusting, maintaining or repairing the machine, disengage the PTO drive, turn off the engine, remove ignition key and wait until all moving parts have come to a complete stop and apply park brake.

- Page 16 DM1160 Projection of stones and foreign objects For driver safety, always use a tractor equipped with a cab. Keep the ground to mow free of foreign bodies. Avoid mowing on stony or rocky grounds. If this is not possible, take extra safety precautions, such as:...

- Page 17 DM1160 Precautions for machine use After each use, check the cutting tools (disks, knives) and their attachment hardware in accordance with the instructions given in the present manual. Immediately replace any worn, damaged or missing cutting tool or element. To do this, use the tool outfit supplied with the machine.

-

Page 18: Location And Description Of Safety Decals On The Machine

DM1160 3. Location and description of safety decals on the machine Location of safety decals DANGER CAUTION CAUTION Entanglement in rotating Avoid serious injury from injection of driveline can cause serious pressurized hydraulic fluid. Operate only with injury or death... - Page 19 DM1160 Description of safety decals Operating instructions (1) CAUTION The operators' manual contains all the information necessary for using the machine safely. It is imperative to read and comply with all instructions. BEFORE STARTING THE MACHINE READ OPERATOR’S MANUAL AND SAFETY INSTRUCTIONS.

- Page 20 DM1160 Rotating cutting tools (4) Keep away from the mower knives all the time the engine is running, the PTO drive engaged and the moving parts have not come to a complete stop. Body crushing (5) Stay a safe distance from the machine.

- Page 21 DM1160 Precautions for machine use and CAUTION maintenance (8) With the guards in position, disengage the PTO drive 1. Keep all shields in place and turn off the engine before adjusting, maintaining or 2. Disengage and shut off al repairing the machine, keep at a safe distance from all...

- Page 22 DM1160 Hydraulic circuit under pressure (11) CAUTION Any liquid under pressure (particularly oil from hydraulics) can penetrate the skin and cause severe Avoid serious injury from injection of injury. pressurized hydraulic fluid. Before any adjustments, maintenance or repairs are Always relieve pressure before...

-

Page 23: Machine Specifications

DM1160 $MACHINE SPECIFICATIONS 1. Description and glossary Check chain Three-point hitch coupler Safety breakback Parking stand Work/transport cylinder Compensating spring Belt guard Front guard Cutterbar 10 : Swath shield Machine specifications... -

Page 24: Technical Specifications

DM1160 2. Technical specifications Attachment type 3 point linkage category 1 and 2 Number of disks Working width 2.40 m (7’10’’) Width in working position 4.30 m (14’1’’) Height in working position 1.15 m (3’9’’) Length in working position 2.35 m (7’9’’) Width in transport position 1.72 m (5’8’’) -

Page 25: Putting Into Service

DM1160 $PUTTING INTO SERVICE 1. Description of control elements The machine is supplied with an 16 mm box wrench (1) to carry out certain adjustment and maintenance tasks. 2. Coupling and uncoupling The machine adapts to tractors fitted with a 3-point hitch coupler category 1 or 2. - Page 26 DM1160 Preparing the tractor Check that the tractor's authorized gross weight as well as its lift capacity and maximum weight per axle are not exceeded. The front axle load (1) must never, under any circumstances, be less than 20% of the tractor's unladen weight.

-

Page 27: Preparing The Machine

DM1160 Preparing the machine Linkage adjustment The machine adapts to tractors fitted with a 3-point hitch coupler category 1 or 2. 3 point, Category 1: - Place lower links in position (a): 3 point, Category 2: - Place lower links in position (b):... - Page 28 DM1160 Coupling the machine - Lower the tractor three-point linkage. - Attach lower links to the hitch pins on either sides of the machine (a). - Secure each hitch pin with lynch pin (b). - Attach top link. - Lift the machine using the tractor lift linkage until the parking stand no longer rests on the ground.

-

Page 29: Hydraulic Connections

DM1160 Hydraulic connections - Connect the mowing unit lift cylinder to a single acting valve. Check chain - Fit check chains See section "Frame height adjustment" to position the check chains. Putting into service... - Page 30 DM1160 Primary PTO shaft Make sure that the PTO shaft is correctly adjusted, to avoid premature wear and tear. The tractor PTO stub must rotate at a speed of 540 min Separate the two half PTO shafts and connect them to the machine's input shaft and to the tractor PTO stub.

- Page 31 DM1160 - Attach PTO shaft guard using chain provided in order to prevent it from rotating. Immediately replace any worn or damaged guard. Adjusting the machine Positioning of lower links - Measure dimension A. - Adjust tractor lower link stabilizers to measure A = 50 mm (2’’).

- Page 32 DM1160 Frame height and check chains. - Tractor fitted with a hydraulic position control function: • Lower the tractor lift linkage so that hitch pins are at a distance H = 400 mm (1’4’’) from the ground. • Note the corresponding lever position in the tractor cab.

- Page 33 DM1160 Safety breakback On hitting an obstacle, the safety breakback causes the cutterbar to pivot rearwards. If the machine hits an obstacle, disengage the PTO drive, stop the tractor engine, remove the ignition key and wait for all moving parts to come to a complete standstill.

- Page 34 DM1160 Uncoupling the machine For tractors not fitted with a hydraulic position control function, unhook check chain. The machine must be uncoupled in working position. From the transport position: - Remove lynch pin (1) and pin (2). - Put compensation system in working position using pin (2) and lynch pin (1).

- Page 35 DM1160 - Activate the transport/work cylinder control valve in the "pivot into work" position. - Lift the machine with the tractor's three point linkage. - Press push-button (1) and lower parking stand (2) until push-button engages in position (3). - Lower the tractor three-point linkage to rest the machine on the ground.

-

Page 36: Instructions For Transport

DM1160 $INSTRUCTIONS FOR TRANSPORT Before placing the machine into transport position: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. 1. Putting the machine into transport position From the working position: - Lift the machine with the tractor's three point linkage. - Page 37 DM1160 - Activate the transport/work cylinder to bring the mowing unit in transport position. - Remove R-clip (2). - Remove transport lock (1). - Install transport lock (1). - Secure using R-clip (2). The machine is in transport position. Never engage the tractor PTO drive when the machine is in transport position.

-

Page 38: Conformity With The Road Regulations

DM1160 2. Conformity with the road regulations Before driving the machine on public roads, ensure that the machine complies with current highway code regulations. Check that the retroreflective signalling equipment is clean before going on public roads. Replace worn or damaged reflectors. -

Page 39: Instructions For Work

DM1160 $INSTRUCTIONS FOR WORK Before placing the machine in working position: - Check that nobody is within the machine pivoting area. - If there is someone, make sure the person moves away. 1. Putting the machine into work position From the transport position: - Lift the machine with the tractor's three point linkage. - Page 40 DM1160 - Install lock (1) on frame. - Secure using R-clip (2). - Activate the transport/work cylinder control valve in the "pivot into work" position. - Press lock (1) and lower front guard (2). - The guard locks automatically. The machine is in working position.

-

Page 41: Adjustments In Working Position

DM1160 2. Adjustments in working position Cutting height The desired cutting height is obtained directly by adjusting the top link length. The height can be adjusted between 30 and 80 mm (1.1’’ - 3.1’’) depending on the tractors. To obtain a different cutting height: - Place the machine in working position. - Page 42 DM1160 Swathing system The swathing system comprises: - A swath shield. - A swath stick. The swath stick fitted on the swath shield can be adjusted in 6 positions according to the working conditions: Adjust stick angle according to the crop density and length.

- Page 43 DM1160 On slopes For mowing on slopes exceeding 10° below horizontal, lengthen cylinder rod. Coupling device (a):Work on flat grounds. Coupling device (b):On slopes (X). To switch from configuration (a) to configuration (b): - Remove bolts (1) and nuts (2).

-

Page 44: Machine Use

DM1160 3. Machine use Before mowing and to reduce risks of projections, lower the front guard. Keep all persons and animals away from the machine danger zone. Never lean or step on the protection cover. Before the machine engages the crop:... -

Page 45: Optional Equipment

DM1160 $OPTIONAL EQUIPMENT 1. Reinforced PTO shaft Part no. KN1086060 In the following cases, the machine can be fitted with a longer, reinforced PTO shaft with a free wheel - Too short standard PTO shaft. - Tractor fitted with a hydraulic PTO. - Page 46 DM1160 Inspection of knives and securing elements Immediately replace worn or damaged parts with original manufacturer parts. Knives Inspect systematically all knives before the machine is operated to: • guarantee the cutting quality. • guarantee safety in use. • Prevent cutterbar damage risks.

- Page 47 DM1160 Fixing elements Check the fixing elements: - After hitting an obstacle. - When replacing knives. - At the beginning of each season. The fixing bolts should be changed in the following cases: - When there is visible distortion. - When the locking compound is worn or inoperational.

- Page 48 DM1160 Knife replacement Replace knife lock-nuts and bolts when they have been removed 5 times. Replace immediately all worn or distorted knives. Never straighten a bent knife. Always replace both knives per disk. Clean the nut case. Place a wooden wedge between two disks to stop them from rotating.

- Page 49 DM1160 When remounting: Position conical center of dust seal (3) at the bottom. Position their largest diameters at right angles to each other. Position conical center of spring washer at the top. Place a wooden wegde (2) between two disks to stop them from moving.

-

Page 50: Raised Skid Shoes

DM1160 When replacing the outer cone, make sure to reinstall the cap. 3. Raised skid shoes Kit no. KN1016400 The raised skid shoes enable mowing higher, between 60 and 120 mm (2.4’’ - 4.8’’). Replace the end disk skids by the 2 raised skid shoes. -

Page 51: Inner Swath Shield

DM1160 5. Inner swath shield Kit no. KN1036000 The inner swath shield enables reducing the swath width by approximately 300 mm (1’) depending on the crop density. Optional equipment... -

Page 52: Maintenance And Storage

DM1160 $MAINTENANCE AND STORAGE Before adjusting, maintaining or repairing the machine, turn off ignition key and wait until all moving parts have come to a BEFORE ADJUSTING complete stop. MAINTAINING OR REPAIRING THE MACHINE, TURN OFF THE ENGINE, REMOVE IGNITION... -

Page 53: Lubrication

DM1160 2. Lubrication Clean grease zerks before greasing. Lubricate with multi-purpose grease grade NLGI 2. PTO shaft Primary PTO shaft - Every 8 hours: • universal joints (1). - Every 20 hours: • transmission tube (2). - Every 40 hours: •... - Page 54 DM1160 Cutterbar draining and refilling Before draining oil, operate the machine for a few minutes so that the oil warms up. The cutterbar is lubricated with 2.25 L (0.59 US gal) of extreme-pressure gear oil with viscosity grade SAE 80W90 and API grade GL5.

- Page 55 DM1160 Lateral gearbox draining Before draining oil, operate the machine for a few minutes so that the oil warms up. The lateral gearbox is lubricated with 0.25 L (0.5 US pints) of extreme-pressure oil for mechanical transmissions with viscosity grade SAE 80W90 and API grade GL5.

-

Page 56: Maintenance

DM1160 3. Maintenance Before adjusting, maintaining or repairing the machine, turn off ignition key and wait until all moving parts have come to a BEFORE ADJUSTING complete stop. MAINTAINING OR REPAIRING THE MACHINE, TURN OFF THE ENGINE, REMOVE IGNITION KEY AND WAIT UNTIL ALL ... - Page 57 DM1160 Adjusting the tension: - Unscrew the 2 nuts (1). - Tighten screw (2) to tension belts. - Check belt tension. - Tighten the 2 nuts (1). - Torque: 13 daN m (96 lbf ft). Breather plug checking and cleaning From the working position: Remove breather plug (1).

- Page 58 DM1160 Checking cutterbar oil level Regularly check the cutterbar oil level: From the transport position: • Remove filler plug (1). • The oil must reach the lower edge of the filling hole. • Top up if necessary. • Clean...

- Page 59 DM1160 Inspection of knives and securing elements Immediately replace worn or damaged parts with original manufacturer parts. Knives Inspect systematically all knives before the machine is operated to: • guarantee the cutting quality. • guarantee safety in use. • Prevent cutterbar damage risks.

- Page 60 DM1160 Fixing elements Check the fixing elements: - After hitting an obstacle. - When replacing knives. - At the beginning of each season. The fixing bolts should be changed in the following cases: - When there is visible distortion. - When the locking compound is worn or inoperational.

- Page 61 DM1160 Knife replacement Replace knife lock-nuts and bolts when they have been removed 5 times. Replace immediately all worn or distorted knives. Never straighten a bent knife. Always replace both knives per disk. Clean the nut case. Place a wooden wedge between two disks to stop them from rotating.

- Page 62 DM1160 When remounting: Position conical center of dust seal (3) at the bottom. Position their largest diameters at right angles to each other. Position conical center of spring washer at the top. Place a wooden wegde (2) between two disks to stop them from moving.

-

Page 63: Storage

DM1160 When replacing the outer cone, make sure to reinstall the cap. 4. Storage At the end of each season - Clean the machine thoroughly. - Drain all gearboxes and cutterbar and refill with new oil (see "Lubrication" chapter). -

Page 64: Troubleshooting Guide

DM1160 $TROUBLESHOOTING GUIDE Problem Cause Remedy Uneven stubble. Dull or broken knives. Replace knives. Knives not installed correctly. Make sure the arrow on the knife upper face is pointing in the disk's direction of rotation. Too low PTO speed (rotational Increase speed to 540 min frequency). - Page 68 Imprimé en France par KUHN Printed in France by KUHN...

Need help?

Do you have a question about the DM1160 and is the answer not in the manual?

Questions and answers