AVK 41 Series Operation And Maintenance Instructions

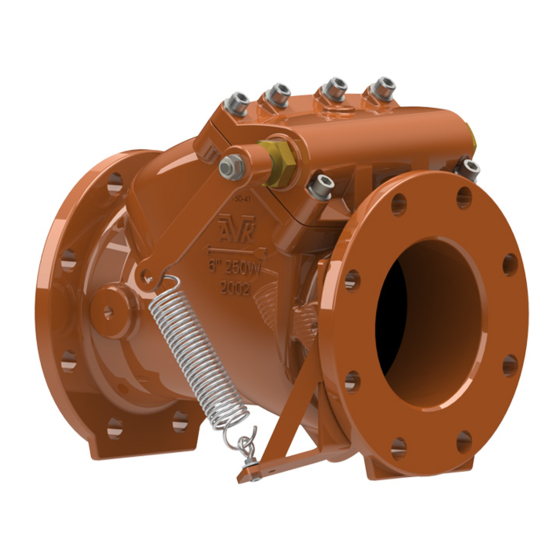

Swing check valve for water and waste water

Hide thumbs

Also See for 41 Series:

- Field maintenance and instruction manual (18 pages) ,

- Installation, operation and maintenance manual (18 pages) ,

- Installation, operation & maintenance manual (13 pages)

Table of Contents

Advertisement

Quick Links

TABLE OF CONTENTS

OPERATION AND MAINTENANCE INSTRUCTIONS

EXPLODED ASSEMBLY / PARTS LIST

AVK SERIES 41 SWING CHECK VALVE FOR WATER AND WASTE

INTRODUCTION / DESCRIPTION

WATER

HEALTH AND SAFETY AT WORK

SPARE PARTS

Series 41 DN350-600

DESIGN CONSTRAINTS

STORAGE AND HANDLING

1. INTRODUCTION

INSTALLATION

AVK Valves Swing Check Valves are primarily designed and manufactured for the prevention of flow reversal and

-

SWING

are suitable for potable water or sewage applications. The operation of the valve is fully automatic allowing liquid

-

LEVER AND WEIGHT

to flow in one direction only. The function of the external lever and weight, where fitted, is to provide additional

-

LEVER, WEIGHT AND GUARD

weight loading to the valve disk, thus giving mechanical assistance towards closure. The position of the weight is

adjustable and allows the closure rate to be varied to suit the actual working conditions.

MAINTENANCE

TROUBLESHOOTING

Swing check valve options covered by this manual

•

DISASSEMBLY FOR INSPECTION

•

RE-ASSEMBLY AFTER INSPECTION

•

The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development.

AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk

COPYRIGHT©AVK GROUP A/S 2018

Standard (without lever and weight)

Lever and weight (right hand as standard)

Lever, weight and guard

Maintenance Manual Series 41

*Subject to change without notice. (rev. 11/09 C)

www.avkuk.co.uk

1 of 13

O&M 020818

Advertisement

Table of Contents

Summary of Contents for AVK 41 Series

- Page 1 STORAGE AND HANDLING 1. INTRODUCTION INSTALLATION AVK Valves Swing Check Valves are primarily designed and manufactured for the prevention of flow reversal and SWING are suitable for potable water or sewage applications. The operation of the valve is fully automatic allowing liquid LEVER AND WEIGHT to flow in one direction only.

- Page 2 2 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818...

-

Page 3: Table Of Contents

3 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818... -

Page 4: Spare Parts

AVK Valves products are designed and manufactured to be for purpose, and to a high and reliable standard. This provides a safe product with minimum risk to health when used correctly for the purpose for which it was designed. -

Page 5: Installation

The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. page 4 AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818 Fig.1... - Page 6 6 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818...

- Page 7 7 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818...

-

Page 8: Swing

8 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818... -

Page 9: Maintenance

9 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818... -

Page 10: Disassembly For Inspection

10 of 13 The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development. AVK UK, 8 Rushmills, Northampton, England, UK, NN4 7YB, T: + 44 (0) 1604 601188. enquiries@avkuk.co.uk www.avkuk.co.uk O&M 020818...

Need help?

Do you have a question about the 41 Series and is the answer not in the manual?

Questions and answers