Summary of Contents for INGENIA Everest XCR

- Page 1 Everest XCR - Product manual Edition 10/01/2020 For the most up to date information visit the online manual. INGENIA-CAT S.L. AVILA 124 2-B 08018 BARCELONA...

-

Page 2: Table Of Contents

Common mating terminals and cables for all signal connectors..............29 Signalling LEDs 8.1. Start-up Sequence ............................32 8.2. Driver Status LEDs............................. 33 8.3. EtherCAT Status LEDs ............................33 8.4. CANopen Status LEDs ............................34 Wiring and Connections 9.1. Everest XCR Connection Diagram ........................36... - Page 3 9.2. Protective Earth ..............................38 9.3. Power Supply and Motor Power........................40 9.3.1. Single Power Supply ............................40 9.3.1.1 Power Supply Requirements..........................40 9.3.2. Dual Power Supply ............................41 9.3.2.1 Logic Supply Requirements..........................41 9.3.3. Power Supply EMI Filter............................ 41 9.3.4.

- Page 4 9.8.2.2 Ethernet over EtherCAT (EoE) Protocol - Used by Motion Lab 3..............78 Dimensions Installation 11.1. Unboxing ................................82 11.2. Installation Safety Requirements........................82 11.3. Mounting the Drive to a Heatsink or Cooling Plate ..................82 11.3.1. Back Installation ............................... 82 11.3.2.

-

Page 5: General Information

The information contained within this document contains proprietary information belonging to INGENIA-CAT S.L. Such information is supplied solely for the purpose of assisting users of the product in its installation. INGENIA-CAT S.L. rejects all liability for errors or omissions in the information or the product or in other documents mentioned in this document. ... -

Page 6: Safety Information

Everest XCR - Product manual | Safety Information 3. Safety Information 3.1. For your safety The instructions set out below must be read carefully prior to initial commissioning or installation in order to raise awareness of potential risks and hazards, and to prevent injury to personnel and/or damage to property. ... -

Page 7: Product Description

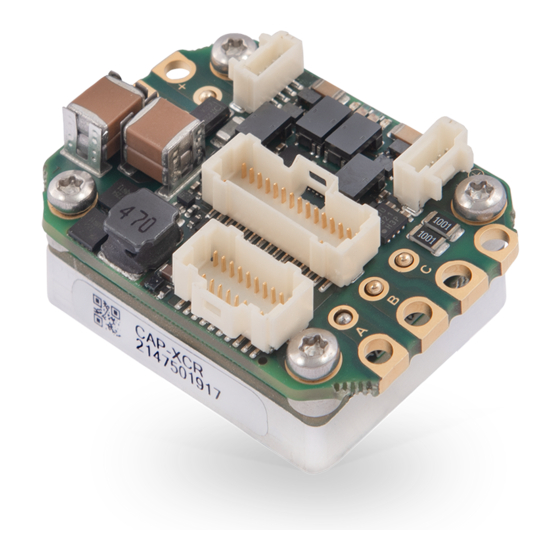

Everest XCR - Product manual | Product Description 4. Product Description Main features: • Ultra-small footprint • 80 V , 30 A continuous • Up to 99% efficiency • Up to 75 kHz current loop, 25 kHz servo loops • 10 kHz ~ 100 kHz PWM frequency •... - Page 8 Typically, 30 A(RMS) can be obtained with appropriate cooling and keeping heatsink at 50ºC. See ermal and Power Specifications below. For disambiguation on current definitions please see Disambiguation on current values and naming for Ingenia Drives . Maximum phase peak current 60 A @ 3 sec Active current limiting based on power stage and motor temperature. ...

- Page 9 Everest XCR - Product manual | Product Description Current sensing 3 phase, shunt based current sensing. 16 bit ADC resolution. Accuracy is ±2% full scale. Current sense resolution Current gain is configurable in 4 ranges: (configurable) • 2.475 mA/count • 1.352 mA/count •...

- Page 10 Everest XCR - Product manual | Product Description General purpose Inputs and 4 x non-isolated single-ended digital inputs - 5 V logic level & 3.3 V outputs compatible. Can be configured as: • General purpose • Positive or negative homing switch •...

- Page 11 Everest XCR - Product manual | Product Description Protections • Hardcoded / hardwired Drive protections: • Automatic current derating on voltage, current and temperature • Short-circuit Phase to DC bus • Short-circuit Phase to Phase • Short-circuit Phase to GND • Configurable protections: •...

- Page 12 Everest XCR - Product manual | Product Description Case temperature Operation: • -20 ºC to +60 ºC at full current (-40 °C on Extended version option) • +60 ºC to +85 ºC with derated current For further information, see Thermal Specifications below.

- Page 13 Everest XCR - Product manual | Product Description Certifications CE Marking • RoHS 3: Restriction of Hazardous Substances Directive (2011/65/UE + 2015/863/EU) • LVD: Low voltage directive (2014/35/EU) • EMC: Electromagnetic Compatibility Directive (2014/30/EU) Safe Torque Off (STO) • IEC 61800-5-2:2016 : SIL3 • IEC 61508:2010 : SIL3 •...

-

Page 14: Product Revisions

Everest XCR - Product manual | Product Description 4.3. Product Revisions Revision Date Notes 01 Jun 2018 Initial prototype 01 Oct 2018 Second prototype. Known issues or pending features: • Ethernet physical layer is affected by commutation noise 20 Dec 2018 ... -

Page 15: Thermal Model

Everest XCR - Product manual | Product Description Typical total standby power consumption with single supply Power savings by Power supply having dual Power Power stage enabled and switching at 0 current voltage supply and logic stage at 12 V* 10 kHz 20 kHz... -

Page 16: Current Derating

RMS values please refer to Disambiguation on current values and naming for Ingenia Drives. To ensure a proper performance of Everest XCR, the case temperature should be held always below 85 ºC (T = 85 ºC). 4.4.4. Heat dissipation and heatsink calculation Following figure show the total power losses at different operating points. - Page 17 Everest XCR - Product manual | Product Description Please, use the following procedure to determine the required heatsink: Based on the voltage & continuous (averaged) current required by your application and Current derating graph determine the Case temperature T . Remember that Case temperature must be always below 85 ºC (T <...

-

Page 18: Energy Efficiency

Everest XCR - Product manual | Product Description 4.4.5. Energy efficiency The following graph shows the electrical energy efficiency including logic for various operation points assuming 50 ºC case temperature and the drive delivering the maximum output power (i.e. maximum output voltage and motor speed). -

Page 19: Ethercat Specifications

Everest XCR - Product manual | EtherCAT Specifications 5. EtherCAT Specifications Ports available LED Signals Status LED Link/Act LED Supported Mailbox CoE, FoE, EoE SDO info Supported Segmented SDO Supported SDO complete access Supported Modes of Operation DS402 drive device profile Voltage mode... -

Page 20: Canopen Specifications

Everest XCR - Product manual | CANopen Specifications 6. CANopen Specifications 6.1. Specifications Ports available 1 CAN port LED Signals CANopen run LED (according to CiA-303) CANopen error LED (according to CiA-303) Modes of operation CiA-402 drive device profile • Voltage mode •... -

Page 21: Connectors Guide

Everest XCR - Product manual | Connectors Guide 7. Connectors Guide 7.1. Connector Overview 7.2. Supply P1 connector 2.6 mm diameter gold plated solder pads or flying leads option. Pad pitch is 5.08 mm. Signal Function Warning! Risk of electric shock! POW_SUP... -

Page 22: Motor

Everest XCR - Product manual | Connectors Guide Warning, power supply and motor terminals can have dangerous voltages in excess to 50 V and cause electric shock. Never touch them directly while in operation. The end installation must ensure that these terminals are not accessible. ... -

Page 23: Feedback Connector

Everest XCR - Product manual | Connectors Guide 7.4. Feedback Connector J1 connector 20 pins 2 row Pico-Clasp 1 mm pitch header. Molex 501190-2027 Signal Function +5V_OUT 5 V 200 mA total max. Pins 1, 9, 14 are internally connected. GND_D Digital signal ground... -

Page 24: Input / Outputs Connector

Everest XCR - Product manual | Connectors Guide ENC_Z+/CLK2+ Differential digital incremental encoder: Index+ input Single-ended digital incremental encoder: Index input Absolute encoder 2: Clock + ENC_Z-/CLK2- Differential digital incremental encoder: Index- input Single-ended digital incremental encoder: Leave unconnected Absolute encoder 2: Clock - +5V_OUT 5 V 200 mA total max. - Page 25 Everest XCR - Product manual | Connectors Guide J2 connector 30 pins 2 row Pico-Clasp 1 mm pitch header. Molex 501190-3017 Signal Function STO_1 Safe Torque Off input 1 (positive, active from 5 V to 30 V, ISOLATED) Protective earth connection, internally connected to standoffs and drive cold plate. Can be used to connect cable shield.

-

Page 26: Ethercat Connectors

Everest XCR - Product manual | Connectors Guide Digital input 3 (5V levels) Digital input 4 (5V levels) OUT1 Digital output 1 (5V levels) OUT2 Digital output 2 (5V levels) OUT3 Digital output 3 (5V levels) OUT4 Digital output 4 (5V levels) AN1+ Analog input 1 positive (±10V range) -

Page 27: Mating Connectors

Everest XCR - Product manual | Connectors Guide J3 & J4 connectors 5 pins 1 row Pico-Clasp 1 mm pitch header. Molex 501940-0507 Signal Function Suggested pinout Suggested pinout RJ45 M12-4 D-coded TX_D+ Transmit Data+ line. Colour typ.: White - Orange TX_D- Transmit Data- line. Colour typ.: Or... - Page 28 Everest XCR - Product manual | Connectors Guide J1 mating connector Image Part number Molex 501189-2010 J2 mating connector Description Molex Pico-Clasp™ 1.0 mm pitch 30 positions dual row receptacle with locking ramp Image Part number Molex 501189-3010 J3 & J4 mating connectors with latch holder Description Molex Pico-Clasp™...

-

Page 29: Common Mating Terminals And Cables For All Signal Connectors

Everest XCR - Product manual | Connectors Guide Description Molex Pico-Clasp™ 1.0 mm pitch 5 positions single row receptacle with locking ramp. Provides less strong locking compared to the latch holder but will avoid breaking the PCB connector in case of strong pull. - Page 30 Everest XCR - Product manual | Connectors Guide J1, J2, J3, J4 Crimped wires 150 mm Description Molex Pico-Clasp™ 28 AWG black jumper lead socket to socket 150 mm length. Gold plated. Image Part number Molex 079758-1016 J1, J2, J3, J4 Crimped wires 300 mm Description Molex Pico-Clasp™...

- Page 31 Everest XCR - Product manual | Connectors Guide Image B-155-9001 INGENIA | 2020-10-01 00:04:38...

-

Page 32: Signalling Leds

Everest XCR - Product manual | Signalling LEDs 8. Signalling LEDs The drive provides information through 6 signalling LEDs: • EtherCAT 0 link: LED 6 green • EtherCAT 1 link: LED 1 green • Driver Status: LED2 & LED3 (one bi-color). •... -

Page 33: Driver Status Leds

Everest XCR - Product manual | Signalling LEDs Protocol EtherCAT 0 Link EtherCAT 1 Link Drive Status EtherCAT Status FTP boot mode See below See below Reserved Switch off during initialization ORANGE blink (~500 ms) when initialization is done 8.2. Driver Status LEDs Two LEDs indicate driver status. Note that both LEDs are grouped into a single red/green package. -

Page 34: Canopen Status Leds

Everest XCR - Product manual | Signalling LEDs 8.4. CANopen Status LEDs One Bi-color LED (shared with EtherCAT communication) provides information about the CANopen communication status, according to CiA 303-3 recommendations. The green LED is the RUN LED, and the red LED is the ERROR LED. - Page 35 Everest XCR - Product manual | Signalling LEDs LINK LED state Slave State Port opened (no activity on port) INGENIA | 2020-10-01 00:04:38...

-

Page 36: Wiring And Connections

Everest XCR - Product manual | Wiring and Connections 9. Wiring and Connections 9.1. Everest XCR Connection Diagram Detailed wiring diagram for each module: INGENIA | 2020-10-01 00:04:38... - Page 37 Everest XCR - Product manual | Wiring and Connections • Protective Earth • Power Supply and Motor Power • Safe Torque Off (STO) • Brake and Motor Temperature • Feedbacks • Inputs and Outputs • Communications INGENIA | 2020-10-01 00:04:38...

-

Page 38: Protective Earth

Everest XCR - Product manual | Wiring and Connections 9.2. Protective Earth Connection of Everest XCR Servo Drive and motor housing to Protective Earth (PE) is required for safety and Electromagnetic Compatibility (EMC) reasons. Electrical faults can electrically charge the housing of the motor or cabinet, increasing the risk of electrical shocks. - Page 39 Always minimize PE connection length. • For best EMC performance Everest XCR should be mounted physically close to the actuator or inside the enclosure. In case the Everest XCR is not integrated on the motor or actuator, use shielded cables with isolating jacket, connecting the shield to PE with a cable clamp to the PE plane.

-

Page 40: Power Supply And Motor Power

9.3.1. Single Power Supply The Everest XCR can be powered from a single power supply as shown in the following figure. Since the power cables are soldered to the board it is essential to provide mechanical fastening to avoid ripping them off. -

Page 41: Dual Power Supply

The connections are shown next, a good PE plane is strongly recommended. Please follow grounding recommendations. Note that the Everest XCR includes 2 x 1 nF 2 kV capacitors between GND_P and PE (the drive aluminum enclosure). INGENIA | 2020-10-01 00:04:38... -

Page 42: Shunt Braking Resistor Connection

For the lowest EMC, it is recommended to use a 2 stage filter like TE Connectivity 30EMC6. 9.3.4. Shunt Braking Resistor Connection A shunt braking resistor can be activated from Everest XCR by using an external transistor. Any of the 4 general- purpose outputs can be configured to turn-on when the dc bus exceeds a certain threshold: Shunt braking... -

Page 43: Motor Connections

Everest XCR - Product manual | Wiring and Connections Shunt resistor calculation tool Additional information on shunt braking resistor sizing and a calculation tool can be found here. 9.3.5. Motor Connections 9.3.5.1 3 Phase Brushless INGENIA | 2020-10-01 00:04:38... -

Page 44: Dc Motor

• PE conductor should never pass through the choke. • Avoid contact of the toroid core with a grounding point. The next table shows recommended chokes for the Everest XCR. Type Manufacturer Part number Remarks Wide frequency oval ferrite cable... -

Page 45: Power Wiring Recommendations

Everest XCR - Product manual | Wiring and Connections 9.3.6. Power Wiring Recommendations 9.3.6.1 Cable Selection Power cables for the Everest XCR must be designed according to the averaged RMS current of the application. Please follow the next recommendations: • The cable insulator must tolerate ≥ 180 ºC. Silicone or Teflon insulation are suggested. PVC or thermoplastic cables are not recommended due to their low operating temperature. ... - Page 46 Everest XCR - Product manual | Wiring and Connections Cut and peel the power cables in advance with the appropriate length. The peeled length can be around 3 mm. Do not cut them after soldering as it will cause permanent tensions. Pre-tin the stranded wires by applying the solder with flux to the wire using a heated soldering iron tip. This can be done with a solder bath method.

-

Page 47: Safe Torque Off (Sto)

In order to ensure redundancy and safety, the Everest XCR includes 2 separate STO inputs that must be activated or deactivated simultaneously (maximum 1.4 s mismatch). A difference of state between STO1 and STO2 inputs will be interpreted as an abnormal situation after 1.4 s the drive will be latched in a fault state. -

Page 48: Integration Requirements

Everest XCR - Product manual | Wiring and Connections Safety Function Value Specification High-demand The EUC (Equipment Under Control) is considered as a high-demand or continuous demand mode mode system. Mission Time The mission time of the EUC is of 20 years. - Page 49 Everest XCR - Product manual | Wiring and Connections Minimum, non- t < 400 µs detected STO short The Safety controller can transmit short pulses to STOx inputs for pulse diagnostics purposes. These pulses will be ignored by the safety circuit and will not stop the power stage but can be read from...

-

Page 50: Sto External Diagnostic Test

The procedure requires the Everest XCR to be connected to a brushless motor. Procedure... - Page 51 Shut-down Everest XCR supply and remain in this state for more than 10 seconds. Power on the Everest XCR with STO1= low, STO2 = high. Remain in this state more than 3.4 seconds. Try to perform a "Motor Enable" (using Power stage is not enabled.

-

Page 52: Sto Operation States

Everest XCR - Product manual | Wiring and Connections Procedure Action Expected Result Step Power on the Everest XCR with STO1= high, STO2 = high. Try to perform a "Motor Enable" (using Power stage can be enabled, allowing motor Motionlab 3 or network commands). -

Page 53: Interface And Connections

Everest XCR - Product manual | Wiring and Connections Mode State STO1 STO2 Power State description status / status / stage report abnorm level level status al fault status Abnor < 1.1 V > 3.6 If any issue is detected on the... - Page 54 Everest XCR - Product manual | Wiring and Connections STO1 and STO2 signals should always change at the same time with a maximum of 1.4 s mismatch. This is necessary to have 2 channel redundancy and allow diagnostics, as a mismatch will cause an abnormal fault.

-

Page 55: Sto Bypass (Needed When No Sto Functionality Is Implemented)

Everest XCR - Product manual | Wiring and Connections 9.4.6. STO bypass (needed when no STO functionality is implemented) If STO is not be used, it must be overridden with 3 wire jumpers on the I/O connector, otherwise, it will not be possible to enable the drive. -

Page 56: Brake And Motor Temperature

Electromechanical brakes are needed in critical applications where the disconnection of the motor or a lack of electric braking could be dangerous or harmful (i.e. falling suspended loads). Everest XCR Servo Drive includes a brake output on the I/O connector J2. The brake output is an N-Channel MOSFET that can be PWM modulated to reduce effective brake voltage and thus power consumption when energized. ... -

Page 57: External Temperature Sensor

Everest XCR - Product manual | Wiring and Connections 9.5.2. External temperature sensor The Everest XCR motor safety system connector allows the connection of an external temperature sensor based on changes of resistance (PTC thermistor, bimetal, NTC, PT100, silicon temperature sensors) to measure the motor temperature. - Page 58 Everest XCR - Product manual | Wiring and Connections CAUTION, motor overload. The Everest XCR may allow currents that can damage or cause a fire to the motor. Always ensure that the continuous and peak current ratings of the motor are respected by adjusting during the drive configuration. ...

-

Page 59: Feedbacks

Everest XCR - Product manual | Wiring and Connections 9.6. Feedbacks The Everest XCR can be connected to a maximum of 3 feedback devices at the same time that might be used for commutation and/or velocity/position control purposes. These devices are connected in the J1 connector of the... - Page 60 Open collector Logic output Push-pull output Pull-up resistor value 1 kΩ Next figures show the typical waveforms of the digital Halls signals. Next figure illustrates how to connect the digital Halls to Everest XCR and a simplified input schematic. INGENIA | 2020-10-01 00:04:38...

-

Page 61: Absolute Encoder 1

Fail safe bias resistors ENC_x+ (positive input) 500 Ω to 5 V ENC_x- (negative input) 500 Ω to 2.5 V (equivalent) Next Figure shows how to connect a single SSI or BISS-C absolute encoder to the Everest XCR servo drive. INGENIA | 2020-10-01 00:04:38... - Page 62 In the case that the encoder has a current consumption higher than 200 mA (maximum current output of the +5V_OUT pin of the Everest XCR) or that the encoder has an input supply > 5V, an external power supply will need to...

-

Page 63: Absolute Encoder 2

Fail safe bias resistors ENC_x+ (positive input) 1 kΩ to 5 V ENC_x- (negative input) 1 kΩ to 2.5 V (equivalent) The next figure shows how to connect a secondary SSI absolute encoder to the Everest XCR servo drive. INGENIA | 2020-10-01 00:04:38... -

Page 64: Incremental Encoder

Everest XCR - Product manual | Wiring and Connections 9.6.4. Incremental Encoder Everest XCR can use single-ended or differential digital incremental encoder inputs (also known as quadrature incremental encoders) for velocity and/or position control, as well as for commutation purposes. The encoder provides incremental position feedback that can be extrapolated into precise velocity or position information. - Page 65 220 Ω (between ENC_x+ and ENC_x-). Fail safe bias resistors ENC_x+ (positive input) 1 kΩ to 5 V ENC_x- (negative input) 1 kΩ to 2.5 V (equivalent) The wiring of a single-ended encoder to the Everest XCR is shown next: INGENIA | 2020-10-01 00:04:38...

-

Page 66: Feedback Wiring Recommendations

Everest XCR - Product manual | Wiring and Connections Sometimes encoders require different supply voltages than 5 V or need more than the 200 mA provided by the drive. In those cases, the connection from the external power source should be as shown next: ... - Page 67 Everest XCR - Product manual | Wiring and Connections • Connect the Everest XCR and encoder GND signals even if the encoder supply is not provided by the drive. • The connection between Everest XCR PE and the motor metallic housing is essential to provide a low impedance path and minimize noise coupling to the feedback.

-

Page 68: Inputs And Outputs

Non-isolated I/O Everest XCR inputs and outputs are not isolated. The reference voltage of the drive (GND_D) and the ground of the devices connected to I/Os must be the same. Otherwise, inputs or outputs may be damaged. For electromagnetically noisy environments and for signals that could be user-accessible and cause electric shock, reinforced isolation is necessary. - Page 69 Everest XCR - Product manual | Wiring and Connections The interface for 3 wire NPN and PNP sensors is shown next. INGENIA | 2020-10-01 00:04:38...

-

Page 70: Analog Input Interface

Everest XCR - Product manual | Wiring and Connections 9.7.2. Analog Input Interface The Everest XCR has a high accuracy fully differential 16-bit analog input AN1. See the specifications next: Specification Value Type of input Differential ESD protected ESD capability IEC 61000-4-2 (ESD) ± 15 kV (air), ± 8 kV (contact) Input voltage range ±10 V differential (AN1+ - AN1-) -

Page 71: Digital Outputs Interface

Everest XCR - Product manual | Wiring and Connections 9.7.3. Digital Outputs Interface Everest XCR Servo Drive has 4 non-isolated digital outputs. These outputs can be used to drive optocouplers, LEDs or other digital circuits. Specification Value Number of outputs Type of output Push-pull output at 5 V ESD protected. - Page 72 Everest XCR - Product manual | Wiring and Connections INGENIA | 2020-10-01 00:04:38...

-

Page 73: Communications

(Controller Area Network) bus. When the drive is configured with the CANopen interface the J4 connector ETH Port 0 should be used with a standard Ethernet port for configuration and firmware loading. The Everest XCR CAN interface is not isolated. If your computer has no Ethernet port, you can use an Ethernet - USB adapter, like TeckNet HU043. -

Page 74: Can Wiring Recommendations

Everest XCR - Product manual | Wiring and Connections 9.8.1.1 CAN wiring recommendations • Build CAN network using cables with 2-pairs of twisted wires (2 wires/pair) as follows: one pair for CAN_H with CAN_L and the other pair for GND. • Do not make a 2 wire only interface. Not connecting the CAN GND may result in loss of data and poor EMC performance. ... -

Page 75: Ethercat Interface

Motion Lab 3. The next figure shows how to connect the Everest XCR in an EtherCAT bus. It is recommended to follow the standard IEC 61918-2013 for best practices. INGENIA | 2020-10-01 00:04:38... -

Page 76: Recommended Ethercat Cables And Connectors

Everest XCR - Product manual | Wiring and Connections 9.8.2.1 Recommended EtherCAT cables and connectors The following table shows the recommended connectors and cable colors for EtherCAT according to IEC 61918 Appendix H. INGENIA | 2020-10-01 00:04:38... - Page 77 Everest XCR - Product manual | Wiring and Connections Signal Function Pin for RJ45 M12-4 M8-4 Cable colour as Cable colour Correspondi per TIA-568B as per ng pin on D coded D coded EN61918 Everest XCR TX_D+ Transmit White Orange Yellow data +...

-

Page 78: Ethernet Over Ethercat (Eoe) Protocol - Used By Motion Lab 3

EtherCAT packets allowing to establish a communication between standard Ethernet clients and EtherCAT devices over an EtherCAT network in a transparent way. Thanks to this protocol is possible to configure a specific Everest XCR of the network using Motion Lab without requiring to modify the wiring of the installation. ... - Page 79 Everest XCR - Product manual | Wiring and Connections EoE and TwinCAT You can find more information on how to configure EoE on Beckhoff TwinCAT in the following link: http:// doc.ingeniamc.com/summit/manuals/reference-manual/tricks-and-tips/setting-up-ethernet-over- ethercat-eoe INGENIA | 2020-10-01 00:04:38...

-

Page 80: Dimensions

Everest XCR - Product manual | Dimensions 10. Dimensions All dimensions are in mm. All tolerances ≤ ±0.2 mm. Assembly instructions are indicated here: Installation. INGENIA | 2020-10-01 00:04:38... - Page 81 Everest XCR - Product manual | Dimensions 3D Model For further detail, download the STEP model. http://distext.ingeniamc.com/products/EVE-XCR/steps/ INGENIA | 2020-10-01 00:04:38...

-

Page 82: Installation

Voltage (ELV), ≤ 50 V. 11.3. Mounting the Drive to a Heatsink or Cooling Plate The drive has 4x M2.5 threaded holes with a max. thread depth of 6.4 mm for assembling the Everest XCR to a cooling plate or heatsink. See Dimensions section for further details. - Page 83 Everest XCR - Product manual | Installation sink. There are several thermal interface alternatives, some suggested part numbers are T-Global Technology LI98-1140-27-0.25, Berquist Bond-Ply 100 series, t-Global Technology GT30S, or copper conductive tape CCH-18-101-0100. To install the drive, follow these steps: Ensure the bottom surface of the drive and the heatsink are clean and dry. Isopropyl alcohol (isopropanol) applied with a lint-free wipe or swab should be adequate for removing surface contamination such as dust or fingerprints.

-

Page 84: Front Installation

Everest XCR - Product manual | Installation For best power and thermal performance (high current and voltage application), thermal grease, pastes, or silicone are recommended. The best thermal material tested is ARCTIC MX-4. Chemtronics CW7250 (white paste non-conductive) and Chemtronics CW7100 (silver-based, conductive) also offer good results. - Page 85 Everest XCR - Product manual | Installation INGENIA | 2020-10-01 00:04:38...

-

Page 86: Commissioning

Everest XCR - Product manual | Commissioning 12. Commissioning 12.1. Safety first Always keep the recommendations of Safety Information in mind. Spending some extra minutes on safety, keeping the workspace clean and ordered can save several days or weeks in case of malfunction or damage! ... -

Page 87: Decommissioning

Everest XCR - Product manual | Commissioning Initial Commissioning Once the Everest has been installed as described in Installation, wired according to the Wiring and Connections and Pinout, the initial commissioning can be performed following the Quick Start guide: • Wire the drive • Switch on the power supply •... -

Page 88: Emc And Environmental Testing Details

Everest XCR - Product manual | EMC and Environmental Testing Details 13. EMC and Environmental Testing Details Testing Type Compliance Details EMC Compliance IEC 61800-3:2017: Adjustable speed electrical power drive systems. Part 3: EMC requirements and specific test methods • CISPR 16-1-2:2014 + CISPR 11:2015 + A1:2016: Conducted emissions: EN 61800-3 Category C2 •... - Page 89 Everest XCR - Product manual | EMC and Environmental Testing Details Testing Type Compliance Details Environmental Testing Compliance IEC 60068-2-1:2007: Test Ad, Cold IEC 60068-2-2:2007: Test Be, Dry Heat IEC 60068-2-38:2009: Test Z/AD, Composite temperature / humidity cyclic IEC 60068-2-78:2012: Test Cab, Damp heat, steady state...

-

Page 90: Service

We are committed to quality customer service. In order to serve in the most effective way, please open a ticket on our service desk at www.ingeniamc.com/support or contact your local sales representative for assistance. INGENIA-CAT S.L. AVILA 124, 2-B 08018 BARCELONA...

Need help?

Do you have a question about the Everest XCR and is the answer not in the manual?

Questions and answers