Subscribe to Our Youtube Channel

Summary of Contents for Alfa Laval GJ PF

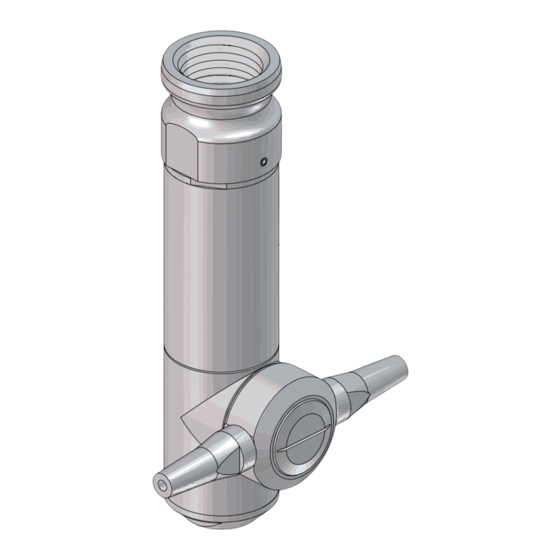

- Page 1 Instruction Manual Alfa Laval GJ PF 4125-0000 Covering: Standard machines First published: 2015-07 100002784-EN2 2020-08 Original manual...

-

Page 3: Table Of Contents

Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 1. EC Declaration of Conformity ............... 2. Safety ....................2.1. Important information ................2.2. Warning signs ..................2.3. Safety precautions ................3. -

Page 4: Ec Declaration Of Conformity

+45 79 32 22 00 Phone No. hereby declare that Tank Cleaning Machine Designation Alfa Laval GJ PF Type From serial numbers from P-100 to P-9999 is in conformity with the following directive with amendments: Machinery Directive 2006/42/EC - DS/EN ISO 12100:2010... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. Always read the manual before using the tank cleaning machine! 2.1 Important information WARNING Indicates that special procedures must be followed to avoid serious personal injury. CAUTION Indicates that special procedures must be followed to avoid damage to the tank cleaning machine. -

Page 6: Safety Precautions

Alfa Laval GJ PF properly grounded. While grounding the unit is important, there is no provided location for grounding on the Alfa Laval GJ PF. -

Page 7: Introduction

The Alfa Laval GJ PF is designed for both portable and CIP (Clean In Place) applications. If the Alfa Laval GJ PF is permanently mounted inside a tank, we strongly recommend inspecting the unit every few hundred hours of operation, see section6 Maintenance for more information. -

Page 8: Patents And Trademarks

The Alfa Laval logotype is a trademark or a registered trademark of Alfa Laval Corporate AB. "Gamajet" is a trademark or registered trademark of Alfa Laval. The Alfa Laval GJ PF product has patent in the US (US 6.123.271 & US 6.561.199). Other products or company names mentioned herein may be the trademarks of their respective owners. -

Page 9: Installation

Every Alfa Laval GJ is operationally tested before shipment and is ready to run after unpacking. No assembly is required prior to use. The Alfa Laval GJ has been configured to meet the operating conditions (at the Alfa Laval GJ, not at the pump) given to us, e.g. - Page 10 Entry openings Depending on the configuration, an Alfa Laval GJ PF can fit through a range of tank inlet sizes. For a pin drive machine with long nozzles, the minimum opening size is 174.7 mm (6.875 inches), while a clutch machine with long nozzles can fit through a 98.5 mm (3.875 inch) opening with the nozzles oriented vertically.

- Page 11 Do not confuse the maximum operating pressure of a PD pump with the actual operating pressure, the actual operating pressure is dictated by the fixed flow rate of the pump and the Alfa Laval GJ PF / plumbing system. If a PD pump is used, the Alfa Laval GJ PF should be sized to, first, match the flow capability of the pump and, second, not exceed the PowerFlex’s or...

-

Page 12: Recycling Information

- At end of use, the equipment must be recycled according to relevant, local regulations. Beside the equipment itself, any hazardous residues from the process liquid must be considered and dealt with in a proper manner. When in doubt, or in the absence of local regulations, please contact your local Alfa Laval sales company. -

Page 13: Operation

Every PowerFlex that ships is accompanied by a birth certificate. This document indicates how the PowerFlex performed in our testing tank before it shipped based on the operating conditions supplied to Alfa Laval GJ. To ensure the longest possible life of the PowerFlex, please verify the operating conditions and, most importantly, the machine’s cycle time. -

Page 14: Trouble Shooting

5 Operation Pay attention to possible faults Read the instructions carefully 5.2 Trouble shooting Does rotor (32.1) - Cracked input pinion (33.3) - section 6.4 Inspection and service of components turn freely by - Damaged planetary gearhead (14) - section 6.4 Inspection and service of components hand? Do nozzle - Cracked/loose input pinions (33.3) - section 6.4 Inspection and service of components... - Page 15 INSUFFICIENT FLOW The Alfa Laval GJ was configured to meet certain operating conditions outlined at the time of the initial sale, such as flow rate /h)(GPM), pressure (bar)(PSI), temperature, chemical content of the wash fluid, cycle time, etc. If the nozzle size is too small and/or the opening at the bottom of the stator is too large, the tee housing will not turn.

- Page 16 5 Operation Pay attention to possible faults Read the instructions carefully Step 3 DEBRIS INSIDE Loosen the collar set screw (30), remove the collar (11), and then lift out the stator (12). Look for and remove any debris caught in the stator and the vanes of the rotor (32.1).

-

Page 17: Cleaning Solution Leakage

Read the instructions carefully 5.3 Cleaning solution leakage Cleaning solution leakage The Alfa Laval GJ PF is a self-flushing machine and thus has 5% leakage designed into the machine. Excessive leakage may indicate a larger issue. Worn bearings & seals Excessive leakage from the tee housing or nozzle housing usually indicates worn housing bearings and seals. - Page 18 5 Operation Pay attention to possible faults Read the instructions carefully Worn clutch O-ring Severe leakage above the tee housing may be the result of excess wear on the clutch O-ring (29). There will be leakage through this point regardless due to the normal clutch operation, but severe leakage is not ordinary.

-

Page 19: Poor Cleaning Performance

- Inadequate drainage Ensure that the vessel drains the effluent (used wash fluid) as fast as it’s being sprayed in through the Alfa Laval GJ. The floor of the vessel should be sloped or pitched toward the drain and the drainage opening should be large enough to gravity-drain the effluent from the vessel. -

Page 20: Recommended Cleaning

5 Operation The Tank Cleaning machine is designed for cleaning in place (CIP). CIP = Cleaning In Place. Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. HNO3 = Nitric acid. 5.5 Recommended cleaning Step 1 Caustic danger! Always handle lye and acid with great care. -

Page 21: Maintenance

6.2 General dismantling set up NOTE A rigorously implemented preventative maintenance program will significantly reduce repair costs over the life of the Alfa Laval GJ.The foundation of such a program is regularly scheduled inspections to discover and replace worn or damaged parts before they can cause the failure of other, more costly, components. - Page 22 An interval of 100 hours is recommended initially. If all of the components are found to be in acceptable condition after the first 100 hours, the Alfa Laval GJ may then be inspected and routine preventive maintenance should be performed every 500 to 700 hours of operation, depending on the severity of use.

-

Page 23: General Dismantling

6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. 6.3 General dismantling Step 1 Inlet collar 1. Loosen the collar set screw (30) with a 3/32” hex key, minimum 2 turns. 2. Remove the inlet collar (11) and stator (12). 4125-0013 WARNING Hold or turn on stem. - Page 24 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 2 Nozzle housing 1. Unscrew the nose plate (10.1) with a screwdriver. 2. Pull the nozzle housing assembly from the nose of the tee housing with the outer nozzle housing bearing (24) and nozzle housing seal (27) included.

- Page 25 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 4 Body assembly 1. Unthread the tee housing cap (15) from the tee housing (8). Note: This is a left hand thread. 2.

-

Page 26: Inspection And Service Of Components

6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. 6.4 Inspection and service of components Step 1 Stator 1. Inspect the through holes of the stator (12) to be sure that they are clear. - Page 27 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 2 1. Pull and twist the gearhead lower bearing housing (21.1) and input shaft upper bearing housing (20.1) from the gearbox (5). 2.

- Page 28 2. Examine the gears of the four different stages for any worn or broken teeth. Also, examine the main internal ring gear for bent or sharp teeth. If any damage is found contact Alfa Laval GJ immediately. 3. The gears of the bottom (14 teeth) and top (17 teeth) stages must be reinstalled in their respective locations.

- Page 29 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Input shaft and housings Step 1 20.3 1. Inspect the input pinion (33.3) for hairline cracks on the end face or for worn, damaged, or sharp/pointed teeth. (33.3) should be tight to the input shaft (33.1) and the input 20.1 shaft washer (33.2).

- Page 30 A good maintenance program will require replacing many (9.3), therefore, it may be worthwhile to make or obtain press tools for pressing (9.3) out of (9). The press tools are available from Alfa Laval GJ cleaning systems.

- Page 31 4125-0027 worthwhile to make or obtain press tools for pressing (8.2) out of (8.1). The press tools are available from Alfa Laval. 10. Before installing new (8.2), clean the housing bores and remove any burrs resulting from (8.2) removal. Press them in so that their flanges are flush against (8.1).

- Page 32 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Stem and stem base Step 1 1. The pin (22.2) should be firmly pressed into the (22.1). 2. Inspect the water outlets of the stem (7.1); they should be free of debris.

-

Page 33: Reassembly

All parts must be cleaned thoroughly before reassembling. Any deposits remaining on the parts can cause difficult disassembly the next time the Alfa Laval GJ needs to be serviced. Also, it may cause misalignment of parts and the potential for premature failure. - Page 34 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 2 1. Install the planetary gearhead back into the gearbox (5). 2. After aligning the screw holes, thread the gearhead screws (39) back into the gearhead using a #2 Phillips screwdriver. Make hand tight.

- Page 35 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 4 1. Place the rotor (32.1) over the end of the input shaft (33.1). 2. Install the rotor lockwasher (3) and rotor nut (4) using an 11/32” socket.

- Page 36 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Body assembly Step 1 1. Slide the tee housing bevel gear (17.1) over the end of the stem (7.1). Align the hole in the (17.1) with the pin (7.2). 2.

- Page 37 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Step 3 1. Align the through-holes of the (22.1) with the threaded holes in the top of the (7.1). 2. Using a 5/32” hex key, thread cap screws (28) and lockwasher (38) into the (7.1).

- Page 38 6 Maintenance Read the instructions carefully. The items refer to the parts list and service kits section. Nozzle housing Step 1 1. Place the larger nozzle housing bearing (25) and seal (27) (spring side out) onto the nose of the tee housing (8.1). Ensure the pin (8.3) is aligns with the hole in the (25).

-

Page 39: Technical Data

7 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.1 Technical data The PF tank cleaning machine is a highly efficient machine at a range of pressures and flows. The instruction manual is part of the delivery. -

Page 40: Performance Data

7 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.2 Performance data Flow rate /h/USgpm Nozzle 19.4 17.4 15.4 13.4 11.4 A. = 6.4 mm (1/4in) B. = 7.9 mm (5/16in) C. - Page 41 7 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. Cleaning time rpm/min. Stator A. = LP B. = STD C. = MV USgpm/ D. = LM 10.5 13.5 16.5 19.5...

-

Page 42: Dimensions

7 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 7.3 Dimensions Dimensions Dimensions 10.70 8.01 6.88 1.73 3.69 6.90 7.95 3.83 5.05 NOTE 1: 1-1/2" FNPT/2" camlock or 1-1/2" BSP/2" camlock (option shown above). -

Page 44: Parts List And Service Kits

8 Parts list and service kits 8.1 Parts list and service kits 21.1 21.2 21.3 21.4 32.1 32.2 20.3 17.1 20.1 20.2 17.2 16.1 16.2 16.3 33.1 33.2 10.2 10.1 33.3 16.3 22.3 16.2 16.1 22.2 22.1 16.3 16.2 16.1 16.3 16.2 16.1... - Page 45 8 Parts list and service kits Parts list Parts list Pos. Denomination Pos. Denomination ♦▲ Small collar o-ring and tee housing 20.1 Input shaft upper bearing housing cap o-ring 20.2 Gearbox pin ♦▲ Rotor shaft lower bearing housing 20.3 Input shaft carbide bearing - o-ring upper housing Rotor lock washer...

- Page 46 © Alfa Laval Corporate AB This document and its contents is owned by Alfa Laval Corporate AB and protected by laws governing intellectual property and thereto related rights. It is the responsibility of the user of this document to comply with all applicable intellectual property laws. Without limiting any rights related to this document, no part of this document may be copied, reproduced or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), or for any purpose, without the expressed permission of Alfa Laval Corporate AB.

Need help?

Do you have a question about the GJ PF and is the answer not in the manual?

Questions and answers