Table of Contents

Advertisement

This manual contains specific precautions related to worker safety. The hazard alert image denotes

safety related instructions and warnings in this manual. DO NOT operate or perform maintenance on this

collector until you have read and understood the instruction and warnings contained within this manual.

English

Master Language

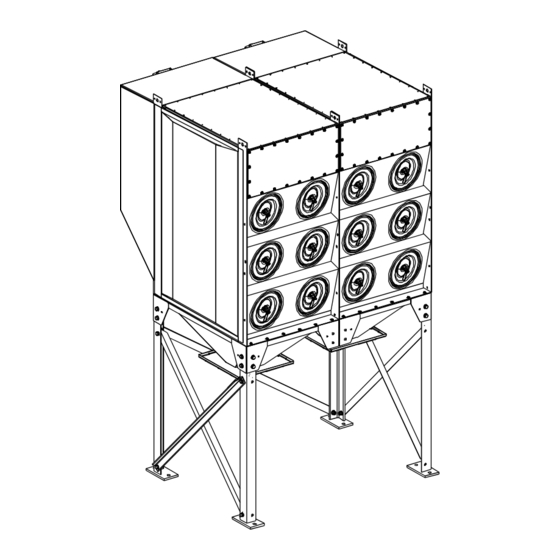

Downflo

Oval

®

DFO 2-8, 2-12, 2-16, 2-24, 2-36

3-10, 3-12, 3-18, 3-24, 3-36, 3-48, 3-60, 3-72,

4-16, 4-32, 4-48, 4-64, 4-80, 4-96, 4-112, and 4-128

Installation and Operation Manual

Installation, Operation, and Service Information

IOM 9343601 (ENG)

Revision 15

Advertisement

Table of Contents

Need help?

Do you have a question about the Downflo Oval and is the answer not in the manual?

Questions and answers