Summary of Contents for Windsor Dominator 10070090

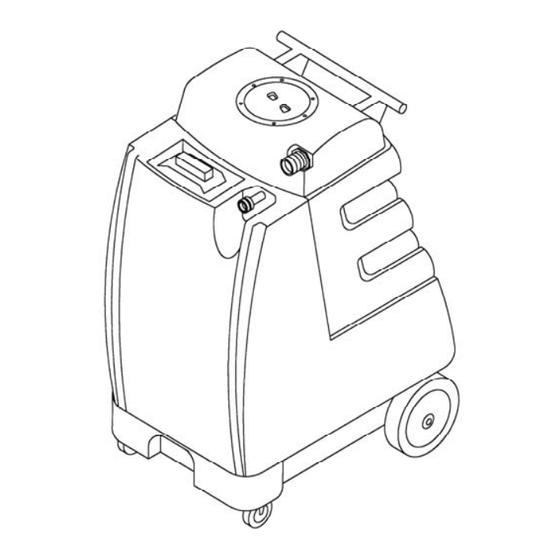

- Page 1 CARPET EXTRACTOR MODEL: D100 10070090 86038260 – AA 07/09/08 PRV NO. 98636 Operating Instructions (ENG) Read these instructions before operating the machine...

-

Page 2: Machine Data Log

DATE OF PURCHASE __________________________ SERIAL NUMBER ______________________________ SALES REPRESENTATIVE # _____________________ DEALER NAME ________________________________ OPERATIONS GUIDE NUMBER ___________________ PUBLISHED Name: __________________________________________________________________________________________________ Address: _______________________________________________________________________________________________ For the name and address of your dealer contact: Windsor Industries Phone Number: _________________________________________________________________________________________ __________________________________________ YOUR DEALER D100 86038260 05/21/07... -

Page 3: Table Of Contents

TABLE OF CONTENTS Machine Data Log...2 Table of Contents...3 HOW TO USE THIS MANUAL How to use this Manual...1-1 SAFETY Important Safety Instructions ...2-1 Hazard Intensity Level..2-2 Grounding Instructions...2-3 OPERATIONS Technical Specifications..3-1 Carpet Inspection...3-2 Accessories...3-2 General Information ...3-2 Equipment Set-Up...3-2 MAINTENANCE Daily Maintenance ...4-1... -

Page 4: How To Use This Manual

The HOW TO USE THIS MANUAL section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized Windsor dealers. When placing an order for parts, the machine model and machine serial number are important. -

Page 5: Important Safety Instructions

SAFETY INSTRUCTIONS IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic precaution must always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE. This machine is for commercial use. To reduce the risk of fire, electric shock, or injury: Connect to a properly grounded outlet. -

Page 6: Hazard Intensity Level

Unless Operation Guide is Read and understood. In Flammable or Explosive areas. In areas with possible falling objects. WHEN SERVICING MACHINE: Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use Windsor approved replacement parts. D100 86038260 05/21/07... -

Page 7: Grounding Instructions

THIS PRODUCT IS FOR COMMERCIAL USE ONLY. ELECTRICAL: In the USA this machine operates on a standard 15 amp 115V, 60 hz, A.C. power circuit . The amp, hertz, and voltage are listed on the data label found on each machine. above or below those indicated on the data label will cause serious damage to the motors. -

Page 8: Technical Specifications

TECHNICAL SPECIFICATIONS ITEM Electrical Electric Vacuum Motor Waterlift Solution Pump Solution Capacity Recovery Capacity Dimensions - Weight Dimensions – Length Dimensions - Height Dimensions - Width Power Cable DIMENSION/CAPACITY 115V, 60Hz, 15A 2HP, 3 Stage 137” (348 cm) 100 psi 17 gallons (64.3 l) 15 gallons (56.75 l) 69 lbs. -

Page 9: Carpet Inspection

(86041760 – PRVNO. PJ2A), Standard Floor Wands(SFW, 86000610 – PRV NO. 89227, 86000600 PRV NO. 89226, & Wind Blower carpet dryer(AM3). Contact an authorized Windsor dealer for assistance in choosing the right equipment . GENERAL INFORMATION: On heavily soiled carpets, or on areas of... -

Page 10: Maintenance

MAINTENANCE DAILY MAINTENANCE: (At the end of each working day) : 1) Flush the entire system, including floor tool, hand tool, etc., with 1 to 3 gallons of clean, hot water. 2) Vacuum out the solution tank . 3) Rinse tank with fresh water. Periodically inspect the recovery tank and decontaminate if necessary, using a Hospital Grade Virucide or a 1-10 bleach to... -

Page 11: Vacuum Motor Replacement

2. Remove recovery tank. 3. Locate the vacuum motor wires and disconnect at the connector. 4. Remove the vacuum motor. 5. Reverse process to install vacuum motor. Vacuum Motor Carbon Brushes Replacement (Windsor) End Cap WARNING: The green Carbon ground wire must be Brushes attached for safe operation. -

Page 12: Solution Pump Replacement

MAINTENANCE WARNING: ONLY QUALIFIED MAINTENANCE PERSONNEL ARE TO PERFORM THE FOLLOWING REPAIRS. PUMP REPLACEMENT PARTS FOR SHURFLO 100 PSI (86201430 - PRV NO. 250-64A) Pump Head Replacement Pump Head Replacement 86251040 65187 PRV NO. 65187 PUMP REPLACEMENT PARTS FOR FLOJET 100 PSI (86251110 – PRV NO. 65219) 86251090 PRV NO. -

Page 13: Troubleshooting

PROBLEM. CAUSE No power to machine. Faulty power cord. Dead electrical circuit. Electrical shock. Equipment not grounding. Receptacle not grounded. Internal wiring problem. Vac motor speed varies Worn motor brushes. or doesn’t run. Motor worn out. Faulty switch. Loss of vacuum. Loose vacuum dome. -

Page 14: Wiring Diagram

WIRING DIAGRAM D100 86038260 07/09/08... -

Page 15: Service Schedule

SERVICE SCHEDULE MAINTENANCE Check machine for cord damage Check recovery dome and gasket for damage and cleanliness Check hoses for wear, blockages, or damage Check handles, switches, and knobs for damage Check vac motor intake filter and clean Run one gallon of water through system Clean out recovery tank and check float valve to make sure it moves freely... -

Page 16: Recovery Tank Assembly

RECOVERY TANK ASSEMBLY D100 86038260 05/21/07... - Page 17 PART NO. PRV NO. 86033260 05151 86242230 500009 86002620 260-64A 86275800 70546 86199840 090-12A 86033330 78475 86202160 320-05 86161460 15-808123 86161470 11-800444 86239890 39276 86002390 20063 86200290 260-33 86033540 75358 86010630 87013 86273780 70015 86091150 065-25 86273830 70020 86200310 39573 86201990 150-44A 86241920...

-

Page 18: Solution Tank Assembly

SOLUTION TANK ASSEMBLY D100 86038260 07/09/08... - Page 19 SOLUTION TANK ASSEMBLY DESCRIPTION CLAMP, 1.75” WORM GEAR X .312 VAC MTR ASM, D/B SLTN 115V 3ST BRUSH SET, 120V VAC WINDSOR BRUSH SET, 120V 3ST VAC AMETEK HOSE, VAC EXHAUST X 9” CLAMP, 2.25” WORM GEAR WIRE, 4” GRN/14 76010 X 76014...

-

Page 20: Suggested Spare Parts

86251040 65187 86258830 84161 86235100 29206 DESCRIPTION BRUSH SET, 120V VAC WINDSOR BRUSH SET, 120V 3ST VAC AMETEK VAC MOTOR ASM, 115 3ST D/B PUMP ASM, 100 PSI SWITCH, SPST 15A EURO ROCKER WHEEL, 8” BLK OFF-SET HUB NUT, 1/2 PUSH-ON DOME CAP CASTER SWIVEL 4”...

Need help?

Do you have a question about the Dominator 10070090 and is the answer not in the manual?

Questions and answers