Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Wilton 7060

-

Page 1: Cover Page

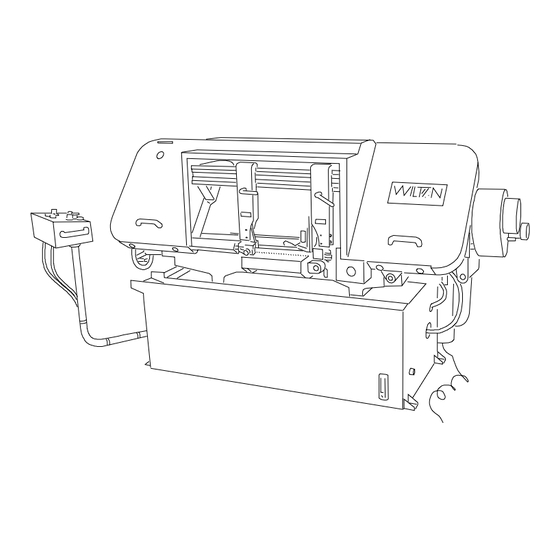

Operating Instructions — Parts Manual 20-Inch x 20-Inch Semi Automatic Horizontal Cut-Off Band Saw Model: 7060 WHM TOOL GROUP 2420 Vantage Drive Elgin, Illinois 60124 Ph.: 800-274-6848 www.wmhtoolgroup.com Part No. 5511736 Revision A2 08/06 Copyright © WMH Tool Group... -

Page 3: Table Of Contents

Table of Contents Cover Page ... 1 General Specifications ... 4 Operating Precautions ... 5 Operating Instructions ... 7 Blade Selection/Break-in Procedures... 9 Work Set-up ... 10 Adjustments ...11 Maintenance ... 14 Wiring Diagram ... 19 Troubleshooting ... 20 Replacement Parts ... 22... -

Page 4: General Specifications

General Specifications The Wilton 7060 Semi-Automatic Horizontal Cut-Off Band Saw incorporates a number of exclusive design features and innovations to make this saw a powerful and productive addition to machine shops, mainte- nance shops, tool rooms, and fabrication and welding shops. -

Page 5: Machinery General Safety Warnings

Read and follow these simple rules for best results and full benefits from your machine. Used properly, Wilton’s machinery is among the best in design and safety. However, any machine used improperly can be rendered inefficient and unsafe. It is absolutely mandatory that those who use our products be properly trained in how to use them correctly. -

Page 6: Safety Instructions On Sawing Systems

from the work area. Make the workshop com- pletely safe by using padlocks, master switches, or by removing starter keys. General Electrical Cautions This saw should be grounded in accordance with the National Electrical Code and local codes and ordinances. This work should be done by a qualified electrician. -

Page 7: Cover

Introduction This manual includes operating and maintenance instructions for the Wilton 12-inch by 20-inch Cut Off Band Saw, Model 7060. This manual also includes parts listings and illustrations of replaceable parts. Cut-Off Saw Features Refer to Figure 1 and 2 for cut-off saw features... -

Page 8: Setting Blade Speed

The bottom row of controls include the following: 1. Stop pushbutton is used to stop the saw blade drive motor. 2. Emergency stop pushbutton is used to quickly disconnect electrical power to the machine. 3. Coolant On/Off selector switch is used to start and stop the coolant pump motor. -

Page 9: Evaluating Cutting Efficiency

Consult the blade manufacturer’s literature for break-in of specific blades on specific materials. However, the following procedure will be adequate for break-in of Wilton- supplied blades on lower alloy ferrous materials. 1. Clamp a round section workpiece in the vise. The workpiece should be 2 inches or larger in diam- eter. -

Page 10: Work Set-Up

Work Set-up Securing the Workpiece for Square Cuts (see figure 5) 1. Raise the saw head. 2. Slide the left vise jaw far enough to the left to allow the workpiece to be placed in the vise. 3. Place the workpiece on the work table. If the workpiece is long, provide support at the other end. -

Page 11: Starting The Saw

rod. Position the stop post against the work piece and tighten the knob in the stop L-bracket. The stop post can be moved left or right as required to place the stop post against the work piece. Starting the Saw WARNING: NEVER OPERATE THE SAW WITH- OUT BLADE COVERS IN PLACE AND SECURED. -

Page 12: Factory Or Field Procedure

Blade Tracking Hex Adjustment Screws Single Adjustment Screw Figure 10: Blade tracking and tensioning screws.) Factory or Field Procedure 1. Raise the saw head enough to allow the saw motor to operate. 2. Loosen four knobs securing the blade cover. Lift the cover and swing it backward. -

Page 13: Blade Guide Bearing Adjustment

Blade Guide Bearing Adjustment Proper adjustment of the blade guide bearings is critical to efficient operation of the cut-off saw. The blade guide bearings are adjusted at the Factory. They should rarely require adjustment. When adjustment is required, adjust immediately. Failure to maintain proper blade adjustment may cause serious blade damage or inaccurate cuts. -

Page 14: Adjustment Of Limit Switches

Test cuts can be used to determine whether or not you have adjusted the blade accurately. Use 2-inch round bar stock to perform these test cuts, as follows: 1. With the bar stock securely clamped in the vise, make a cut through the bar stock. (See figure 14.) 2. -

Page 15: Changing The Drive Belt

Servicing Hydraulic Oil WARNING: SHUT OFF ALL ELECTRICAL POWER TO THE MACHINE 1. Remove hydraulic oil reservoir access panel. 2. Check oil level (refer to Figure 16). If level is below the yellow (upper) line, the reservoir should be filled. 3. -

Page 16: Replacing Idler Wheel Or Idler Bearing

2. Remove the drive belt from the drive motor pulley (see Changing the Drive Belt). 3. Remove motor pulley. 4. Open the motor junction box and disconnect the power cord wires from their terminals. 5. Remove the nuts, washers and bolts that secure the motor to the mounting plate. -

Page 17: Replacement Of Guide Bearings

1. Remove front blade guide by removing adjust- ment knob, spring, and shaft. 2. Remove the rear blade guide by removing its attachment screw 3. Install replacement blade guide in the rear guide location. Secure with attachment screw. 4. Install replacement blade guide in the front guide location. -

Page 18: Uncrating And Spotting

Observe the following when connecting to the power source. (The cut-off saw wiring diagrams are provided in Figures 21 and 22.) WARNING: WILTON RECOMMENDS THAT ANY WIRING INVOLVING HARD WIRING OF THE SAW TO A BRANCH, OR ANY CHANGE OF VOLTAGE SUPPLIED TO THE MOTOR BE PERFORMED BY A LICENSED ELECTRICIAN. -

Page 19: Wiring Diagram

Wiring Diagram... -

Page 20: Troubleshooting

Troubleshooting Fault Excessive blade breakage Premature blade dulling Bad cuts (out-of-square) Bad cuts (rough) Probable cause 1. Material loose in vise. 2. Incorrect speed or feed. 3. Teeth too coarse for material. 4. Incorrect blade tension. 5. Saw blade is in contact with workpiece before the saw is started. - Page 21 Troubleshooting Blade is twisting 1. Blade is binding in the cut. 2. Blade tension too high. Unusual wear on 1. Blade guides worn side/back of blade 2. Blade guide bearings not adjusted. 3. Blade guide bearing bracket is loose. Teeth missing/ripped 1.

-

Page 22: Replacement Parts

Replacement Parts This section provides exploded view illustrations that show the replacement parts for the Model 7060 12-Inch x 20-Inch Semi-Automatic Horizontal Cut-Off Band Saw. Also provided are parts listings that provide part number and description. The item numbers shown on the illustration relate to the item number in the facing parts listing. - Page 23 Exploded View – Saw Base - Model 7060 Semi-Automatic Cut-Off Band Saw 114 115 31 32 63 64 55 56 57...

- Page 24 Parts List – Saw Base - Model 7060 Semi-Automatic Cut-Off Band Saw Part Number Description 5512120 Bolt, Hex Cap (M12X35) 5512121 Washer, Lock (M12) 5512122 5512123 Rack 5512124 Bracket, Slide 5512125 Block, Rack 5512126 Screw, Set (M6X10) 5512127 Jaw, Vise (Left)

- Page 25 Parts List – Saw Base - Model 7060 Semi-Automatic Cut-Off Band Saw, (Continued) Part Number Description 5512222 Screw, Pan Head (M6X15) 5512223 Valve, Relief 5512224 Plate, Cover 5512225 Box, Stationary 5512226 Screw (M8X16) 5512227 Plate, Sole 5512228 Screw (1/4X5/8 In.)

- Page 26 Exploded View – Saw Head - Model 7060 Semi-Automatic Cut-Off Band Saw See Detail 'A' Detail 'A'...

- Page 27 Parts List – Saw Head - Model 7060 Semi-Automatic Cut-Off Band Saw Part Number Description 5512248 Bearing, Thrust (51194NJK) 5512249 Indicator, Tension 5512250 Washer, Flat 5512251 Washer, Special Spring 5512252 Bracket, Slide 5512253 Washer, Lock 5512254 Screw, Hex Cap 5512255...

- Page 28 WHM TOOL GROUP 2420 Vantage Drive Elgin, Illinois 60124 Ph.: 800-274-6848...

Need help?

Do you have a question about the 7060 and is the answer not in the manual?

Questions and answers