Summary of Contents for Bailey INFI 90 NTDI01

- Page 1 E96-424 ® ® Digital I/O Termination Unit (NTDI01) Process Control and Automation Solutions from Elsag Bailey Group...

- Page 2 The information contained in this document is subject to change without notice. Elsag Bailey, its affiliates, employees, and agents, and the authors and contributors to this publication specif- ically disclaim all liabilities and warranties, express and implied (including warranties of merchantability and...

- Page 3 In addition, a complete under- standing of the INFI 90 system is beneficial to the user. ® INFI 90 is a registered trademark of the Elsag Bailey Process Automation I-E96-424A...

- Page 4 ® List of Effective Pages Total number of pages in this manual is 48, consisting of the following: Page No. Change Date Preface Original List of Effective Pages Original iii through vi Original 1-1 through 1-5 Original 2-1 through 2-8 Original Original 4-1 through 4-2...

- Page 5 ® Safety Summary GENERAL Equipment Environment WARNINGS All components, whether in transportation, operation or storage, must be in a noncorrosive environment. Electrical Shock Hazard During Maintenance Disconnect power or take precautions to insure that contact with energized parts is avoided when servicing. SPECIFIC We strongly recommend that you turn the cabinet power off before CAUTIONS...

-

Page 6: Table Of Contents

Table of Contents Page SECTION 1 - INTRODUCTION ....................1-1 OVERVIEW ........................1-1 INTENDED USER ......................1-1 HARDWARE DESCRIPTION..................1-2 FEATURES........................1-2 INSTRUCTION CONTENT .....................1-3 HOW TO USE THIS MANUAL ..................1-3 GLOSSARY OF TERMS AND ABBREVIATIONS .............1-3 REFERENCE DOCUMENTS..................1-4 NOMENCLATURE ......................1-5 SPECIFICATIONS ......................1-5 SECTION 2 - INSTALLATION .....................2-1 INTRODUCTION......................2-1 SPECIAL HANDLING ....................2-1 UNPACKING AND INSPECTION ..................2-1... - Page 7 ® Table of Contents (continued) Page APPENDIX E - DIGITAL SLAVE OUTPUT MODULE (IMDSO04) ..........................E-1 INTRODUCTION ......................E-1 APPENDIX F - PULSE INPUT SLAVE MODULE (IMDSM04) ...........................F-1 INRODUCTION ......................F-1 APPENDIX G - FREQUENCY COUNTER SLAVE MODULE (IMFCS01) ........................G-1 FREQUENCY COUNTER SLAVE MODULE (IMFCS01) ..........G-1 APPENDIX H - HYDRAULIC SERVO SLAVE MODULE (IMHSS01)...........................

- Page 8 List of Figures Title Page 1-1. Termination Unit Application .................1-1 2-1. TDI Component Locations ..................2-2 2-2. TDI Installation ......................2-3 2-3. Point Configuration Socket Circuit Diagram ............2-4 2-4. Termination Unit Configuration Socket Circuit Diagram .........2-4 2-5. TDI Cable Connections...................2-6 A-1. NTDI01 to IMASO01 Diagram (Voltage Mode) ............A-1 A-2.

-

Page 9: Section 1 - Introduction

SECTION 1 - INTRODUCTION OVERVIEW The Digital I/O Termination Unit (NTDI01) is an interface for INFI 90 Process Management System I/O signals. These sig- nals are used to control and monitor processes. Termination units provide the physical connection points for process field wiring, and configure the system I/O signals. -

Page 10: Hardware Description

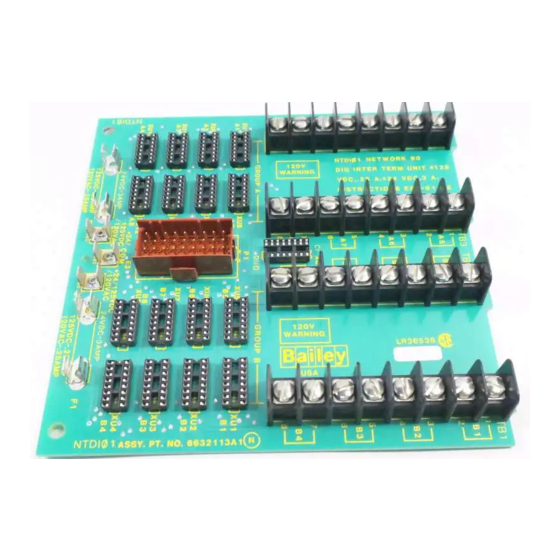

INTRODUCTION ® HARDWARE DESCRIPTION A TDI is a single printed circuit board that attaches to a Field Termination Panel (NFTP01) inside an INFI 90 cabinet. Two screws and spacers secure the TDI in place. Up to sixteen indi- vidual I/O signals can be connected to the TDI. The printed cir- cuit board consists of: 1. -

Page 11: Instruction Content

Procedures Support Services Provides replacement part ordering information. It explains other areas of support Bailey Controls provides. HOW TO USE THIS MANUAL Read this entire manual through in sequence. It is important to become familiar with the entire contents of this manual before using the TDI. -

Page 12: Reference Documents

INTRODUCTION ® Term Definition Dipshunt Dual in-line package with shorting bars. Field Termination INFI 90 cabinet assembly used to mount termination units. Panel Master Module One of a series of controller modules designed to direct field processes through a slave module. The multi-function processor is an example. Module Bus The serial communication link between a process control module and other process control modules. -

Page 13: Nomenclature

INTRODUCTION NOMENCLATURE The following modules and equipment can be used with a TDI: Nomenclature Hardware Modules IMASO01 Analog Slave Output Module IMDSI02 Digital Slave Input Module IMDSM04 Pulse Input Slave Module IMDSM05 Digital I/O Slave Module IMDSO01/02/03 Digital Slave Output Module IMDSO04 Digital Slave Output Module IMLMM02... -

Page 14: Section 2 - Installation

INFI 90 system use electrostatic sensitive devices, and require special handling. NOTE: Always use Bailey's Field Static Kit (P/N 1948385A2 - con- sists of wrist strap, ground cord assembly, alligator clip) when work- ing with modules. The kit is designed to connect a technician and the static dissipative work surface to the same ground point to pre- vent damage to the modules by electrostatic discharge. -

Page 15: Physical Installation

INSTALLATION ® XU17 XU13 XU14 XU10 XU15 XU11 XU16 XU12 T00642A Figure 2-1. TDI Component Locations Physical Installation NOTE: The installation section provides instructions pertaining to the physical installation of the termination unit only. For complete master/slave module information, refer to the appropriate product instruction. -

Page 16: Tdi Installation

INSTALLATION TABS STANDOFF MOUNTING SCREWS FIELD TERMINATION PANEL T00643A Figure 2-2. TDI Installation configure TDI signal routing for some applications. Figure shows the location of these sockets on the TDI. Figure is a circuit diagram of a point configuration socket. Figure is a circuit diagram of the termination unit configuration socket. -

Page 17: Point Configuration Socket Circuit Diagram

INSTALLATION ® E2 E TERMINAL BLOCKS TB1-TB4 DIPSHUNTS CO M XU1-XU16 T00644A Figure 2-3. Point Configuration Socket Circuit Diagram E2 E E2 E CO M CO M POINT POINT DIPSHUNT DIPSHUNT CO M CO M XU10 DIPSHUNT XU17 E2 E E2 E CO M CO M... -

Page 18: Installing Fuses

INSTALLATION 3. Break the connection straps to configure the dipshunt as defined in the appendix. Cut the dipshunt straps using a stan- dard shunt cutting tool (AMP PN 435862-1). Always make sure that the cut straps are completely broken and that adjacent straps are not touching. -

Page 19: Terminal Block Wiring

INSTALLATION ® NKTU01 16 I/O POINTS MASTER/SLAVE MODULE NTDI01 T00646A Figure 2-5. TDI Cable Connections Terminal Block Wiring We strongly recommend that you turn the cabinet power off before doing any termination unit wiring. Failure to do so could CAUTION result in equipment damage. -

Page 20: Pre-Operating Adjustments

INSTALLATION provide connection points for system power wiring and ground. See Figure for the location of these terminals. System power connects to the termination unit through faston connectors E1 and E2, and it is distributed to the configura- tion sockets through the fuses. Any combination of power can be connected to these fastons depending on the application. -

Page 21: Nktu01 Cable I/O Signal Connections

INSTALLATION ® NKTU01 CABLE I/O SIGNAL CONNECTIONS Table shows the cable pin connections from P3 of a mas- ter/slave module to P1 of the TDI for the I/O signals. Table 2-2. NKTU01 Cable Connections for I/O Signals NKTU01 NKTU01 1 −− −− −− −− −− −− 1 J −−... -

Page 22: Section 3 - Maintenance

SECTION 3 - MAINTENANCE INTRODUCTION The Digital I/O Termination Unit (TDI) requires limited mainte- nance. This section contains a maintenance schedule. MAINTENANCE SCHEDULE Perform the tasks in Table at the specified intervals. Table 3-1. Maintenance Schedule Task Interval Clean and tighten all power and Every six months or during plant grounding connections shutdown, whichever occurs first... -

Page 23: Section 4 - Repair/Replacement Procedures

SECTION 4 - REPAIR/REPLACEMENT PROCEDURES INTRODUCTION This section explains the replacement procedures for a Digital I/O Termination Unit (TDI). The tools required to remove and replace a termination unit are: Flat head screwdriver. • Cross head screwdriver. • Chip puller. •... - Page 24 REPAIR/REPLACEMENT PROCEDURES ® 7. Insert fuses into the circuit board fuse holders. Refer to Installing Fuses in the installation section. 8. Insert the TDI circuit board tabs into the termination panel standoff slots; slide the circuit board into position. Refer to Fig- ure 2-2.

-

Page 25: Section 5 - Support Services

SECTION 5 - SUPPORT SERVICES INTRODUCTION Bailey Controls is ready to help in the use, application and repair of its products. Contact your nearest sales office to make requests for sales, applications, installation, repair, overhaul and maintenance contract services. REPLACEMENT PARTS AND ORDERING INFORMATION When making repairs at your facility, order replacement parts from a Bailey Controls sales office. -

Page 26: Appendix A - Analog Slave Otput Module (Imaso01

APPENDIX A - ANALOG SLAVE OTPUT MODULE (IMASO01) INTRODUCTION The IMASO01 uses an NTDI01 for termination. Dipshunts on the termination unit configure the analog outputs that are sent to the process. The Analog Slave Output (ASO) module output signals are 4 to 20 mA or 1 to 5 VDC depending on the ASO module configuration. -

Page 27: Ntdi01 With Imaso01 Dipshunt Configuration

ANALOG SLAVE OTPUT MODULE (IMASO01) ® +24 VDC E2 E CO M LOAD – – FEEDBACK TERMINAL BLOCKS TB1-TB4 DIPSHUNTS CO M XU1-XU7, XU9-XU11, XU13-XU16 IMASO01 NKTU01 NTDI01 FIELD FIELD (REPRESENTATIVE WIRING DEVICE CIRCUIT) T00648A Figure A-2. NTDI01 to IMASO01 Diagram (Current Mode) Table A-1. -

Page 28: Ntdi01 With Imaso01 Terminal Assignments

ANALOG SLAVE OTPUT MODULE (IMASO01) ® DIPSHUNT DIPSHUNT DIPSHUNT DIPSHUNT USED USED USED USED XU13 AO12 – – – – XU14 XU10 AO13 – – – – TERMINAL NUMBER XU15 XU11 AO14 AO10 – – – – XU16 XU12 AO11 –... -

Page 29: Appendix B - Digital I/O Slave Module (Imdsm05

APPENDIX B - DIGITAL I/O SLAVE MODULE (IMDSM05) DIGITAL I/O SLAVE MODULE (IMDSM05) The IMDSM05 uses an NTDI01 for termination. Dipshunts on the termination unit configure the digital I/O signals. The 16 Digital I/O Slave (DSM) module I/O signals are divided into two groups of eight (group A and group B). -

Page 30: Digital I/O Slave Module (Imdsm05

DIGITAL I/O SLAVE MODULE (IMDSM05) ® E2 E CO M – – FIELD CONTACT TERMINAL BLOCKS TB1-TB4 DIPSHUNTS CO M XU1-XU16 IMDSM05 NKTU01 NTDI01 FIELD FIELD (REPRESENTATIVE WIRING DEVICE CIRCUIT) T00651A Figure B-2. NTDI01 to IMDSM05 Diagram (Digital Output) Table B-1. NTDI01 with IMDSM05 Dipshunt Configuration Application/ Signal Dipshunt Configuration Dipshunt Configuration... -

Page 31: Ntdi01 With Imdsm05 Terminal Assignments

DIGITAL I/O SLAVE MODULE (IMDSM05) DIPSHUNT DIPSHUNT DIPSHUNT DIPSHUNT USED USED USED USED – – – – XU13 – – – – XU14 XU10 TERMINAL NUMBER – – – – XU15 XU11 – – – – XU16 XU12 T00653A NOTE: When using the Sinking An External Load configuration, make external connections to the negative terminals only. Figure B-3. -

Page 32: Appendix C - Digital Slave Input Module (Imdsi02

APPENDIX C - DIGITAL SLAVE INPUT MODULE (IMDSI02) INTRODUCTION The IMDSI02 uses an NTDI01 for termination. Dipshunts on the termination unit configure the digital inputs. The Digital Slave Input (DSI) module accepts inputs of 24 VDC, 125 VDC and 120 VAC. Figure shows an NTDI01 point configuration dipshunt without strapping, and the digital signal path from the field... -

Page 33: Ntdi01 With Imdsi02 Dipshunt Configuration

DIGITAL SLAVE INPUT MODULE (IMDSI02) ® Table C-1. NTDI01 with IMDSI02 Dipshunt Configuration Application/Signal Type Dipshunt Configuration Field Powered Contact XU1-XU16 XU17 System Powered from E1, XU1-XU16 24 VDC, 125 VDC, 120 VAC XU17 System Powered from E2, XU1-XU16 24 VDC, 125 VDC, 120 VAC XU17 T00654A NOTE: Each TDI input point dipshunt configuration must match the DSI input jumper configuration. -

Page 34: Ntdi01 With Imdsi02 Terminal Assignments

DIGITAL SLAVE INPUT MODULE (IMDSI02) DIPSHUNT DIPSHUNT DIPSHUNT DIPSHUNT USED USED USED USED XU13 – – – – XU14 XU10 – – – – TERMINAL NUMBER XU15 XU11 – – – – XU16 XU12 – – – – T00655A NOTE: When using the System Powered contact configuration, the polarities shown in Figure C-2 should be reversed. Figure C-2. -

Page 35: Appendix D - Digital Slave Output Module (Imdso01/02/03

APPENDIX D - DIGITAL SLAVE OUTPUT MODULE (IMDSO01/02/03) DIGITAL SLAVE OUTPUT MODULE (IMDSO01/02/03) The IMDSO01/02/03 uses an NTDI01 for termination. Dip- shunts on the termination unit configure the digital outputs that are sent to the process. The Digital Slave Output (DSO) module switches voltages of 24 to 240 VAC (IMDSO01), 4 to 60 VDC (IMDSO02) or 5 to 160 VDC (IMDSO03). -

Page 36: Digital Slave Output Module (Imdso01/02/03

DIGITAL SLAVE OUTPUT MODULE (IMDSO01/02/03) ® Table D-1. NTDI01 with IMDSO01/02/03Dipshunt Configuration Dipshunt Configuration Application/Signal Type XU1, 3, 5, 7, 9, 11, 13, 15 Externally Powered System Powered from E1 System Powered from E2 T00657A NOTES: 1. XU17 does not require a dipshunt for this application. 2. -

Page 37: Appendix E - Digital Slave Output Module (Imdso04

APPENDIX E - DIGITAL SLAVE OUTPUT MODULE (IMDSO04) INTRODUCTION The IMDSO04 uses an NTDI01 for termination. Dipshunts on the termination unit configure the digital outputs that are sent to the process. The Digital Slave Output (DSO) module can switch a voltage of 24 VDC at 250 mA. Figure shows an NTDI01 point configuration dipshunt without strapping, and the digital signal path from the DSO... -

Page 38: Ntdi01 With Imdso04 Dipshunt Configuration

DIGITAL SLAVE OUTPUT MODULE (IMDSO04) ® Table E-1. NTDI01 with IMDSO04 Dipshunt Configuration Application/Signal Type Dipshunt Configuration Externally Powered XU1-XU16 XU17 System Powered from E1 XU1-XU16 XU17 System Powered from E2 XU1-XU16 XU17 T00661A NOTE: 1. XU17 does not require a dipshunt for this application. 2. -

Page 39: Ntdi01 With Imdso04 Terminal Assignments

DIGITAL SLAVE OUTPUT MODULE (IMDSO04) DIPSHUNT DIPSHUNT DIPSHUNT DIPSHUNT USED USED USED USED XU13 – – – – XU14 XU10 – – – – TERMINAL NUMBER XU15 XU11 – – – – XU16 XU12 – – – – T00655A NOTE: DO = Digital Output Figure E-2. -

Page 40: Appendix F - Pulse Input Slave Module (Imdsm04

APPENDIX F - PULSE INPUT SLAVE MODULE (IMDSM04) INRODUCTION The IMDSM04 uses an NTDI01 for termination. Dipshunts on the termination unit configure the digital inputs from the pro- cess. The pulse input slave module can input pulsed voltages of 50 mV (p-p) to 10 mV (p-p), 4 to 6 VDC or 21.6 to 27 VDC depending on the slave module configuration. -

Page 41: Ntdi01 With Imdsm04 Dipshunt Configuration

PULSE INPUT SLAVE MODULE (IMDSM04) ® Table F-1. NTDI01 with IMDSM04 Dipshunt Configuration Dipshunt Dipshunt Application/Signal Configuration Configuration Type XU1-XU4, X13-X16 System Powered from T00663A Field Powered Input T00663A NOTE: XU7, in this application, connects 24 VDC I/O power to the IMDSM04 preamplifiers. If the reamplifiers are not used, a dipshunt is not required for XU7. -

Page 42: Appendix G - Frequency Counter Slave Module (Imfcs01

APPENDIX G - FREQUENCY COUNTER SLAVE MODULE (IMFCS01) FREQUENCY COUNTER SLAVE MODULE (IMFCS01) The IMFCS01 uses an NTDI01 for termination. Dipshunts on the termination unit configure a frequency input from the pro- cess. The Frequency Counter Slave (FCS) module can input a voltage of 300 mV (p-p) to 120 VAC at a frequency range from 1HZ to 12.5 KHZ. -

Page 43: Ntdi01 With Imfcs01 Dipshunt Configuration

FREQUENCY COUNTER SLAVE MODULE (IMFCS01) ® Table G-1. NTDI01 with IMFCS01 Dipshunt Configuration Application/Signal Type Dipshunt Configuration Analog Inputs 0.3 Vp-p to 120 VAC XU13 XU1-XU12 AND XU14-XU17 DO NOT INSTALL DIPSHUNTS (ALL STRAPS OPEN) T00666A DIPSHUNT USED – INPUT XU13 TERMINAL NUMBER... -

Page 44: Appendix H - Hydraulic Servo Slave Module

APPENDIX H - HYDRAULIC SERVO SLAVE MODULE (IMHSS01) INTRODUCTION The IMHSS01 uses an NTDI01 for termination. Dipshunts on the termination unit configure the I/O signals. The Hydraulic Servo Slave (HSS) module provides one digital and four analog outputs, and three digital and two analog inputs for control of hydraulic actuators. -

Page 45: Ntdi01 To Imhss01 Diagram (Digital Output

HYDRAULIC SERVO SLAVE MODULE (IMHSS01) ® +5 VDC E2 E CO M LOAD – – TERMINAL BLOCK DIPSHUNT CO M IMHSS01 NKTU01 NTDI01 FIELD FIELD (REPRESENTATIVE WIRING DEVICE CIRCUIT) T00669A Figure H-2. NTDI01 to IMHSS01 Diagram (Digital Output) E2 E CO M FIELD DEVICE... -

Page 46: Ntdi01 To Imhss01 Diagram (Analog Output

HYDRAULIC SERVO SLAVE MODULE (IMHSS01) E2 E CO M – FIELD DEVICE – – TERMINAL BLOCK TB1/TB4 DIPSHUNTS CO M XU1, XU4, XU13, XU14 IMHSS01 NKTU01 NTDI01 FIELD (REPRESENTATIVE WIRING CIRCUIT) T00671A Figure H-4. NTDI01 to IMHSS01 Diagram (Analog Output) DIPSHUNT DIPSHUNT DIPSHUNT... -

Page 47: Ntdi01 With Imhss01 Dipshunt Configuration

HYDRAULIC SERVO SLAVE MODULE (IMHSS01) ® Table H-1. NTDI01 with IMHSS01 Dipshunt Configuration Dipshunt Application/Signal Type Configuration All Types XU17 Analog Inputs XU2, XU3 LVDT Secondary 1 LVDT Secondary 2 Analog Outputs XU1, XU4, XU13, XU14 LVDT Primary Drive Simulation Mode Servo 1 Drive Servo 2 Drive Digital Inputs... -

Page 48: Appendix I - Logic Master Module (Imlmm02

APPENDIX I - LOGIC MASTER MODULE (IMLMM02) INTRODUCTION The IMLMM02 uses an NTDI01 for termination. Dipshunts on the termination unit configure the digital I/O signals. The six- teen Logic Master Module (LMM) I/O signals are divided into two groups of eight: group A for outputs and group B for inputs. -

Page 49: Ntdi01 With Imlmm02 Dipshunt Configuration

LOGIC MASTER MODULE (IMLMM02) ® +5 VDC E2 E CO M – – LOAD TERMINAL BLOCKS TB3/TB4 DIPSHUNTS CO M XU9-XU16 IMLMM02 NKTU01 NTDI01 FIELD FIELD (REPRESENTATIVE WIRING DEVICE CIRCUIT) T00675A Figure I-2. NTDI01 to IMLMM02 Diagram (Digital Output) Table I-1. NTDI01 with IMLMM02 Dipshunt Configuration Outputs Inputs Application/Signal... -

Page 50: Ntdi01 With Imlmm02 Terminal Assignments

LOGIC MASTER MODULE (IMLMM02) DIPSHUNT DIPSHUNT DIPSHUNT DIPSHUNT USED USED USED USED – – XU13 – – – – XU14 XU10 – – TERMINAL NUMBER – – XU15 XU11 – – – – XU16 XU12 – – T00677A NOTES: 1. When using the Sinking An External Load configuration, make external connections to the positive terminals only. 2. - Page 51 Telefax 39-10-6582-941 Telephone 49-69-799-0 Telefax 65-292-9011 Telefax 49-69-799-2406 Form I-E96-424A Litho in U.S.A. 791 Copyright © 1991 by Elsag Bailey Process Automation, As An Unpublished Work ® Registered Trademark of Elsag Bailey Process Automation ™ Trademark of Elsag Bailey Process Automation...

Need help?

Do you have a question about the INFI 90 NTDI01 and is the answer not in the manual?

Questions and answers