Table of Contents

Advertisement

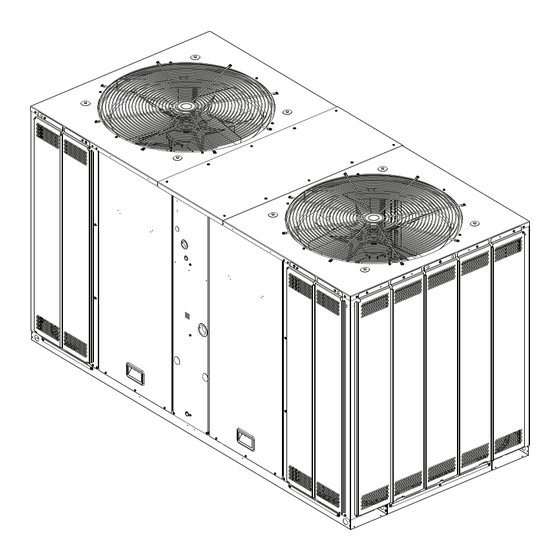

Installation, Operation, and Maintenance

Split System Air Conditioners

Odyssey™ with Symbio™

Controls

Heat Pump Condenser, R-454B 6 to 20 Tons

(60 Hz)

TWA072K*A

TWA072K*D

TWA090K*A

TWA090K*D

TWA120K*A

TWA120K*D

TWA180K*D

TWA240K*D

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment

can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are attached to the equipment.

August 2024

SAFETY WARNING

SS-SVX015A-EN

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Trane Odyssey TWA072K A Series

- Page 1 Installation, Operation, and Maintenance Split System Air Conditioners Odyssey™ with Symbio™ Controls Heat Pump Condenser, R-454B 6 to 20 Tons (60 Hz) TWA072K*A TWA072K*D TWA090K*A TWA090K*D TWA120K*A TWA120K*D TWA180K*D TWA240K*D SAFETY WARNING Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

- Page 2 (HCFCs). Not all refrigerants containing these compounds bump cap, fall protection, electrical PPE and arc have the same potential impact to the environment. Trane flash clothing). ALWAYS refer to appropriate advocates the responsible handling of all refrigerants.

- Page 3 This document and the information in it are the property of regulations. Trane, and may not be used or reproduced in whole or in part without written permission. Trane reserves the right to revise this publication at any time, and to make changes to...

-

Page 4: Table Of Contents

Table of Contents Model Number Description ....5 Refrigerant Piping Procedures (Indoor Unit) ........23 Heat Pump Condenser . -

Page 5: Model Number Description

Model Number Description Heat Pump Condenser Digit 1, 2, 3 — Unit Function Digit 8 — Voltage Digit 15 — Controls TWA = Split System Heat Pump 3 = 208-230 Vac - 3 PH (60Hz) S = Symbio™ 4 = 460 Vac - 3 PH (60Hz) Digit 4, 5, 6 —... -

Page 6: General Information

VFD manufacturer lines. Dual compressor/dual circuit models give true stand- requires a Trane Technical Support ticket by protection; if one compressor fails, the second will number FIRST. Removal of the VFD prior to automatically start-up. -

Page 7: A2L Information

• To be repaired only by trained service At all times, Trane’s maintenance and service guidelines personnel. shall be followed. If in doubt, contact Trane technical support for assistance. • Do not puncture refrigerant tubing. All maintenance staff and others working in the local area •... -

Page 8: Leak Detection

Verify continuity of earth bonding. The recovery equipment shall be in good working order • Replace electrical components with Trane replacement with instructions available. Equipment shall be suitable for parts, or those meeting the same ratings and qualified the recovery of the flammable refrigerant. For specific for flame arrest protection, UL LZGH2 category. -

Page 9: Decommissioning

A2L Information • Ensure that the refrigerating system is earthed prior to the equipment are removed from site promptly and all charging the system with refrigerant. isolation valves on the equipment are closed off. • Label the system when charging is complete (if not 11. -

Page 10: Minimum Room Area Limits

A2L Information Minimum Room Area Limits • The second threshold defines when additional ventilation airflow is required. If the room area, A or TA, (Refrigerant charge greater than 3.91 lb is below the adjusted A or TA threshold, per circuit) additional ventilation is required to remove refrigerant in the event of a leak. - Page 11 A2L Information Figure 2. Charge vs min room area (SI) Charge vs Min Room Area (SI) 280.0 260.0 Release Height-0.6m 240.0 Release Height-1.0m Release Height-1.4m 220.0 Release Height-1.8m Release Height-2.2m 200.0 180.0 160.0 140.0 120.0 100.0 80.0 60.0 40.0 20.0 10.0 12.0 14.0...

-

Page 12: Leak Detection System

A2L Information of refrigerant with a minimum room area requirement of mechanical ventilation system meets the requirements of 180 ft with a 2.2 m release height. ANSI\ASHRAE Standard 15-2022, Section 7.6.4. Leak Detection System = 180 ft x 1.05 x 2 = 378 ft min.adj (Refrigerant charge greater than 3.91 lb No additional ventilation is required. -

Page 13: Pre-Installation

Pre-Installation Unit Inspection NOTICE Equipment Damage! Inspect material carefully for any shipping damage. If damaged, it must be reported to, and claims made against Use spreader bars to prevent straps from damaging the transportation company. Compare the information that the unit. Install the bars between lifting straps, both appears on the unit nameplate with ordering and submittal underneath the unit and above the unit to prevent the data to ensure the proper unit was shipped. -

Page 14: Structural Preparation

Pre-Installation Snow Belt Recommendations Structural Preparation NOTICE In regions where deep snow is encountered, raise the unit a minimum distance of 8 to 12 inches above the mounting Roof Damage! surface. This will reduce the risk of snow blocking the coil System contains oil and refrigerant under high and improves runoff of water produced during the defrost pressure. -

Page 15: Dimensional Data

Dimensional Data Heat Pump Figure 4. Height, width and depth measurements H - in. (mm) W - in. (mm) D - in. (mm) 39.2 (996) 42.1 (1070) 36.3 (922) TWA072K*A, 090K*A TWA072K*D, 090K*D 39.2 (996) 51.9 (1317) 39.3 (999) TWA120 45.2 (1150) 51.9 (1317) 39.3 (999) - Page 16 Dimensional Data Figure 5. 6 and 7.5 ton heat pump, single compressor – in (mm) NOTES: SEE NOTE 3 1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESSORY. 2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36” (914.4) FROM WALLS, SHRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE BETWEEN ADJACENT UNITS IS 72”...

- Page 17 Dimensional Data Figure 6. 6 and 7.5 ton heat pump, dual compressor – in (mm) SEE NOTE 3 NOTES: 1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESSORY. 2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36” (914.4) FROM WALLS, SHRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE SERVICE PANEL BETWEEN ADJACENT UNITS IS 72”...

- Page 18 Dimensional Data Figure 7. 10 ton heat pump, single compressor – in (mm) SEE NOTE 3 NOTES: 1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESSORY. 2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36” (914.4) FROM WALLS, SHRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE SERVICE PANEL BETWEEN ADJACENT UNITS IS 72”...

- Page 19 Dimensional Data Figure 8. 10 ton heat pump, dual compressor – in (mm) SEE NOTE 3 NOTES: 1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESSORY. 2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36” (914.4) FROM WALLS, SHRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE SERVICE PANEL BETWEEN ADJACENT UNITS IS 72”...

- Page 20 Dimensional Data Figure 9. 15 and 20 ton heat pump, dual compressor – in (mm) NOTES: 1. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36” (914.4) FROM WALLS, SHRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE SEE NOTE 2 BETWEEN ADJACENT UNITS IS 72” (1828.8). RECOMMENDED SERVICE CLEARANCE 48”...

-

Page 21: Weights

Weights Heat Pump Condenser Table 2. TWA R-454B unit and corner weights — lbs (60 Hz) Corner Weights Shipping Net Max Tons Model No. Max (lbs) (lbs) TWA072K*A TWA072K*D TWA090K*A TWA090K*D TWA120K*A TWA120K*D TWA180K*D TWA240K*D 1004 Figure 10. TWA072, 090, 120 Figure 11. -

Page 22: Installation

Installation Refrigerant Piping Guidelines WARNING Refrigerant under High Pressure! Figure 12. Allowable elevation difference: TWA above indoor unit Failure to follow instructions below could result in an explosion which could result in death or serious injury or equipment damage. System contains refrigerant under high pressure. Not allowed for TWA units. -

Page 23: Refrigerant Piping Procedures

Installation 3. Install gauges to determine if the circuits are still 5. Shut off nitrogen supply. Shut off the manifold valve for pressurized. If not, the charge has escaped and should the line that is connected to the suction line access be repaired as required to obtain a leak-free circuit. -

Page 24: Leak Check

Installation Leak Check System Evacuation 1. After completion of leak check, evacuate the system. WARNING 2. Attach appropriate hoses from manifold gauge to gas Explosion Hazard! and liquid line pressure taps. Failure to follow these instructions could result in Note: Unnecessary switching of hoses can be avoided death or serious injury or equipment or property-only and complete evacuation of all lines leading to damage. -

Page 25: Insulating And Isolating Refrigerant

Table 3. R-454B TWA approved oils Approved Oils Unit Model Number TWA072K*A, TWA072K*D, TWA090K*A, TWA090K*D, Trane Oil Part Number OIL00094 TWA120K*A, TWA120K*D, (1 quart container) TWA180K*D, TWA240K*D For units equipped with compressors containing site glasses, the oil level must be visible through the sight glass when the compressor is running under stabilized conditions and a few minutes after the compressor has stopped. - Page 26 Installation Table 4. Estimated charge levels at ARI rated line lengths (25 feet) Refrigerant Charge Per Circuit Matched Set Liquid Line Diameter Vapor Line Diameter Circuit 1 Circuit 2 0.5 (1/2”) 1.375 (1 3/8”) TWA072K*A w/ TWE090K*A 17.3 0.5 (1/2”) 0.875 (7/8") TWA072K*D w/ TWE072K*B 0.625 (5/8”)

-

Page 27: Liquid Charging

All field wiring MUST be performed by qualified or other energy storing components provided by personnel. Improperly installed and grounded field Trane or others, refer to the appropriate wiring poses FIRE and ELECTROCUTION hazards. To manufacturer’s literature for allowable waiting periods avoid these hazards, you MUST follow requirements for discharge of capacitors. -

Page 28: Low Voltage Wiring

Installation NOTICE the Split System Air Conditioners Odyssey with Symbio™ Controls Wiring and Start-up (SS-SVN017*-EN). Use Copper Conductors Only! Note: Refer to thermostat or zone sensor wire installation Failure to use copper conductors could result in guide for proper wire gauge. equipment damage as the equipment was not designed or qualified to accept other types of Symbio™... -

Page 29: Field Wiring

Installation Notes: Table 5. Recommended thermostat wire size 1. When electric heater accessory is used, single Maximum Wire Length Wire Size point power entry or dual point power entry is (Gauge) Physical distance between Unit & field optional. Single point power entry option is T’stat through electric heater only. - Page 30 Installation Figure 18. Typical split system heat pump - heating - refrigerant circuit HEAT PUMP CIRCUIT DIAGRAM HEATING MODE FIELD SUPPLIED INTER-CONNECTING TUBING EQUALIZER NOTE A LINE NOTE A EQUALIZER 4-WAY LINE SWITCHOVER VALVE EXPANSION VALVE BULB HIGH PRESSURE SWITCH (HPCO) FILTER DRIER LOW PRESSURE SWITCH (LPCO)

-

Page 31: Pre-Start

Pre-Start Control Circuit Features has returned to normal, the compressor and outdoor fans will cycle back on. Note: Not all of these features may be required for your unit, check electrical schematic. High Pressure Cut-Out (HPCO) Discharge Temperature Limit (DTL) This control’s sensor is located in the discharge line. -

Page 32: Troubleshooting

Troubleshooting WARNING The leak detection sensor offers a visual diagnostic status in the form of one green and one red LED to indicate Live Electrical Components! diagnostic error state. Failure to follow all electrical safety precautions when Table 7. Leak detection system LED status exposed to live electrical components could result in death or serious injury. -

Page 33: Service Test Mode

Service Test Mode The Symbio™ 700 supports a Service Test Mode that can Figure 19. Symbio 700 service test mode be used to energize the various components of the system, either to support general system startup tasks or to support troubleshooting. -

Page 34: Maintenance

For variable frequency drives coils appear dirty, clean them. or other energy storing components provided by Trane or others, refer to the appropriate Coil Cleaning manufacturer’s literature for allowable waiting periods for discharge of capacitors. Verify with a CAT III or IV... -

Page 35: Maintenance Log

Maintenance Maintenance Log SS-SVX015A-EN... -

Page 36: Charging Data And Pressure Curves

Charging Data and Pressure Curves Table 8. TWA Charging data and pressure curves Refrigerant Charging Curve Condenser Air Handler Pressure Curves Superheat and Charge Table TWA072K*A TWE090K*A 436768330001 436768450001 TWA072K*D TWE072K*B 436768340001 436768460001 TWA090K*A TWE090K*A 436768350001 436768470001 TWA090K*D TWE090K*B 436768360001 436768480001 TWA120K*A TWE120K*A... -

Page 37: Location

Wiring Diagram Matrix and Device Location Table 9. TTA wiring diagrams Description Applicability Part Number Power Schematic (Wiring Diagram) for units with Dual Compressors and All Units with Digit 4-6 = 180/240 1213-4781 Dual Fans Power Schematic (Wiring Diagram) for units with Dual Compressors and All Units with Digit 4-6 = 072/090/120 and Digit 9 = "D"... -

Page 38: Warranty

The warrantor’s warranty is conditional on the Customer Products Covered — This warranty is extended by Trane, providing written notice to the warrantor within thirty (30) and applies to the following products: days of the discovery of the defect. - Page 39 Notes SS-SVX015A-EN...

- Page 40 For more information, please visit trane.com or americanstandardair.com. Trane and American Standard have a policy of continuous product and product data improvement and reserve the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Need help?

Do you have a question about the Odyssey TWA072K A Series and is the answer not in the manual?

Questions and answers