Stellar Hearth Products GALAXY Series Installation And Operating Manual

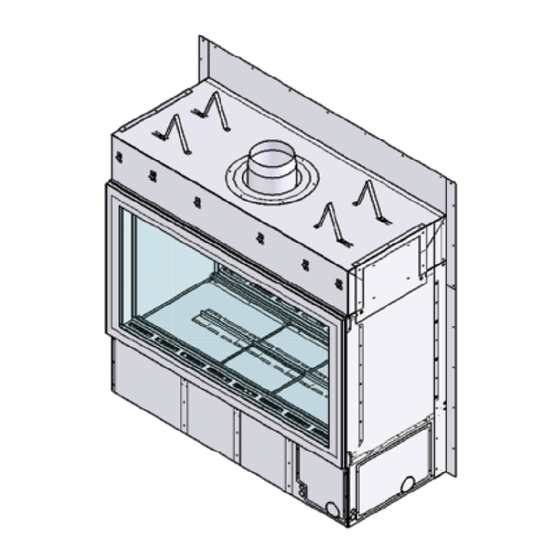

Co-linear direct vent gas fireplaces indoor/outdoor see through

Hide thumbs

Also See for GALAXY Series:

- Installation and operating manual (55 pages) ,

- Installation and operating manual (52 pages) ,

- Installation and operating manual (52 pages)

Table of Contents

Advertisement

Quick Links

www.stellarhearth.com

Custom Fireplace Program

Co-linear Direct Vent Gas Fireplaces

GALAXY SERIES

Indoor/Outdoor See Through

Installation and Operating Manual

NG & Propane

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

—

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

•

If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Stellar Hearth Products

, a division of Hearth & Home Technologies

TM

INTERIOR

Installer:

Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

®

- 16873 Fish Point Rd. SE, Prior Lake, MN 55372 - (952) 224 - 4072

Page 1

Advertisement

Table of Contents

Summary of Contents for Stellar Hearth Products GALAXY Series

- Page 1 Custom Fireplace Program Co-linear Direct Vent Gas Fireplaces GALAXY SERIES Indoor/Outdoor See Through Installation and Operating Manual NG & Propane INTERIOR Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference. WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. — Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

- Page 2 Listing Label Information This manual should be read thoroughly before installing or operating the fireplace. Installers, please leave manual for the homeowner to use for future reference. Please have the fireplace model information available when contacting Stellar Hearth for additional information and service work. PRODUCT SERIAL NUMBER & MANUFACTURING DATE CODE STICKER WILL BE PLACE ON FRONT COVER Page 2 INS_CUST UL REV E...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Safety Information Venting Continued A. Safety Icon Designations K. Vertical Terminations B. Important Safety Considerations L. Horizontal Cap Location & Clearances M. Horizontal Termination Commonwealth of Massachusetts Requirements N. Not Applicable For IDOD - Blank Page O. Vertical Cap Location & Clearances Specifications P.1. -

Page 4: Safety Information

1 - SAFETY INFORMATION This fireplace complies with ANSI Z21.50-2019/CSA 2.22-2019 Vented Gas Fireplaces and CAN/CSA P.4.1-15. Installation must conform with local building codes or in the absence of local building codes, with the National Fuel Gas Code, ANSIZ223.1/NFPA 54 - Current Edition, or the Natural or Propane Installation Code, CSAB149.1 A. SAFETY ICON DESIGNATIONS Various safety icons appear throughout this installation manual. Please familiarize yourself with the icons making sure you understand the serious consequences that may occur if ignored or of handling the products inappropriately. IMPORTANT NOTE HOT GLASS WARNING This indicates additional instructions that you should consider... -

Page 5: Commonwealth Of Massachusetts Requirements

2 - COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS NOTE: THE FOLLOWING REQUIREMENTS REFERENCE VARIOUS MASSACHUSETTS AND NATIONAL CODES NOT CONTAINED IN THIS MANUAL. For all sidewall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purpos- es, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than (7) feet above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied: INSTALLATION OF CARBON MONOXIDE DETECTORS EXEMPTIONS... -

Page 6: Specifications

3 - SPECIFICATIONS A. IDOD SEE THROUGH DIMENSIONS - INTERIOR TOP VIEW INTERIOR FRONT VIEW FLUE B-VENT [610] [381] Model # (INCHES/ Finishing Finishing Finishing Firebox Top Overall Edge To Depth Overall B-VENT AIR INTAKE MILLIMETERS) FLUE COLLAR Width Height Height Height Height... - Page 7 3 - SPECIFICATIONS A. IDOD SEE THROUGH DIMENSIONS - EXTERIOR EXTERIOR FRONT VIEW OVERALL DEPTH WITH DECORATIVE FRAMES 25 9/16 [649] [25] 3 [76] 7 1/2 [190] Glass Frame Model # (INCHES/MILLIME- Viewing Area Viewing Area Glass Frame Glass Frame Outer Flange Outer Flange Height With...

-

Page 8: Gas & Electric Access Dimensions (3', 4', 5', 6' & 7')

3 - SPECIFICATIONS B.1 GAS & ELECTRIC ACCESS LOCATIONS (3', 4', 5', 6' & 7') 3" GAS KNOCK OUT 2 27/32" 1 11/16" 1 1/2" 1 11/16" 1 19/32" 3 5/8" 2 3/4" 1 5/8" 10 27/32" 1" 14 1/8" ELECTRICAL 2X 8 5/16" 3" GAS KNOCK OUT 2X 6 13/16" ELECTRICAL 2X 3 13/16"... -

Page 9: Gas & Electric Access Dimensions (8')

3 - SPECIFICATIONS B. 2 GAS & ELECTRIC ACCESS LOCATIONS (8') GAS KNOCK OUT GAS KNOCK OUT 2 27/32" 1 11/16" 1 1/2" 1 11/16" 1 19/32" 2 3/4" 3 5/8" 1" 1 5/8" 10 27/32" 14 1/8" ELECTRICAL KNOCK OUTS ELECTRICAL KNOCK OUTS 2X 8 5/16" 2X 6 13/16"... -

Page 10: Fireplace Specifications

3 - SPECIFICATIONS C. SPECIFICATIONS Propane Model # DESCRIPTION B-VENT REG PV IN-LINE PV BTU’S ORIFICE ORIFICE 3-IDOD-X-GL X = ANY HEIGHT 8" 10" RS012 RSIF160 40,000 (2X) #43 (2X) #55 4-IDOD-X-GL X = ANY HEIGHT 8” 10” RS012 RSIF160 60,000 (3X) #43 (3X) #55... -

Page 11: Clearances

3 - SPECIFICATIONS F. CLEARANCES Figure 3F CLEARANCES SHOWN ARE MINIMUM TO COMBUSTIBLES NON-COMBUSTIBLE FRAMING AND FINISHING MATERIALS 1/2” [13] ALLOWED RIGHT UP TO THE FIREPLACE. 1” 1” [25] [25] X4 6” [152] 6” [152] Top Standoffs; shipped flat. Top Standoffs Refer to Prepare The Fireplace section for assembly instructions. -

Page 12: Prepare The Fireplace

4 - PREPARE THE FIREPLACE CAUTION: FIREPLACE IS NOT LOAD-BEARING. NOTE: OTHER CLEARANCES APPLY. ALL CLEARANCES MUST BE MAINTAINED. A. STANDOFF INSTALLATION LOOSEN SCREW LOOSEN SCREW AND FOLD EACH AND FOLD EACH STANDOFF STANDOFF LOOSENED SCREW REMOVE REMOVE SECOND SCREW SECOND SCREW PIVOT FOLDED STANDOFF AND SECURE Figure 4A.2 Figure 4A.1... -

Page 13: Framing & Mantel Requirements

5 - FRAMING & MANTEL REQUIREMENTS NOTE: Framing dimensions should allow for wall covering thickness and fireplace facing materials. When using a hearth, adjust rough opening size as necessary to maintain at least minimum clearance requirements. CAUTION: Install fireplace on metal, concrete or hard wood surface extending the full width and depth of fireplace. CAUTION: Vent cap location must be in compliance with guidelines in Section 8 (Venting) of this manual. If masonry is to be used (optional), prepare the necessary foundation for the masonry load. When masonry construction is being used, a lintel must be used over top of fireplace to support the added weight. Build hearth to desired size and height. If a hearth extension is desired, combustible material may be used. - Page 14 5 - FRAMING & MANTEL REQUIREMENTS Interior Exterior Refer to Section 5 (Non-combustible Zone) for more Firebox Overall Framing INCHES [MM] Framing Framing information on the 1/2" [13] clearance standoffs. Height Height Top Height Width Width X - WALL SHEATHING THICKNESS Y = WALL FRAMING THICKNESS 42-1/2 44-17/32 44-17/32 Z = INTERIOR SHEATHING PLUS FINISH THICKNESS 3-IDOD-2-GL [1,068] [1,295]...

- Page 15 5 - FRAMING & MANTEL REQUIREMENTS IMPORTANT FRAMING NOTE: INTERIOR FRAMING IS RECOMMENDED TO BE DONE AFTER THE FIREPLACE IS INSTALLED FOR GREATER ACCURACY. The steel 3” [76] surface all around the fireplace opening can not be covered with any type of material. Glass and decorative framing will be placed on top. 1 [25] *** 1 [25] *** INTERIOR...

-

Page 16: Mantel Requirements

5 - FRAMING & MANTEL REQUIREMENTS 5.1 NON-COMBUSTIBLE ZONE - USING THE PROVIDED 1/2" STANDOFFS The fireplace has standoffs installed on the front of the fireplace standard from the factory. They are located on the upper left, center and right front of the fireplace and are to ensure that the 1/2" [12.7mm] required clearance to combustibles on the surface of the fireplace is maintained. -

Page 17: Non-Combustible Zone Using 1/2" Standoffs

5 - FRAMING & MANTEL REQUIREMENTS 5.1 NON-COMBUSTIBLE ZONE - USING THE PROVIDED 1/2" STANDOFFS THIS EXAMPLE OF FRAMING AND FINISHING IS FOR REFERENCE. PLEASE MAKE SURE TO MAKE CONSIDERATIONS FOR THE FRAMING AND FINISHING MATERIALS THAT YOU ARE USING FOR YOUR PARTICULAR INSTALLATION. INTERIOR SHOWN.MANTEL AND FRAMING EXAMPLE APPLIES TO BOTH SIDES FOR SEE THROUGH FIREPLACE. COMBUSTIBLE OR NON-COMBUSTIBLE BACKING MATERIAL (I.E. -

Page 18: Mantel Requirements

5 - FRAMING & MANTEL REQUIREMENTS 5.2 NON-COMBUSTIBLE ZONE - NOT USING THE PROVIDED 1/2" STANDOFFS The fireplace has standoffs installed on the front of the fireplace standard from the factory. They are located on the left, center and right front hood of the fireplace and are to ensure that the 1/2" [12.7mm] required clearance to combustibles on the surface of the fireplace is maintained. -

Page 19: Non-Combustible Zone Not Using The 1/2" Standoffs

5 - FRAMING & MANTEL REQUIREMENTS 5.2 NON-COMBUSTIBLE ZONE - NOT USING THE PROVIDED 1/2" STANDOFFS THIS EXAMPLE OF FRAMING AND FINISHING IS FOR REFERENCE. PLEASE MAKE SURE TO MAKE CONSIDERATIONS FOR THE FRAMING AND FINISHING MATERIALS THAT YOU ARE USING FOR YOUR PARTICULAR INSTALLATION. INTERIOR SHOWN.MANTEL AND FRAMING EXAMPLE APPLIES TO BOTH SIDES FOR SEE THROUGH FIREPLACE. COMBUSTIBLE FRAMING COMBUSTIBLE OR NON-COMBUSTIBLE BACKING MATERIAL (I.E. -

Page 20: Glass Frame Assembly Installation

6 - GLASS FRAME ASSEMBLY A. INNER GLASS FRAME ASSEMBLY IDENTIFICATION & INSTALLATION Inner Glass Installation Unwrap the panes of glass carefully making sure to protect the edges. Apply the suction cups to the inner glass assembly, following instructions included with the suction cups. Lift the glass into place. -

Page 21: Interior Outer Glass Assembly Installation

6 - GLASS FRAME ASSEMBLY B. GLASS TRIM PIECES - BOTH INTERIOR AND EXTERIOR Horizontal Trim Right Vertical Trim Left Figure 6B.3 Vertical Trim Align Holes Figure 6B.1 Figure 6B.2 After setting the inner glass pieces in place (Figure 6A), put the left and right vertical trim filler pieces into place: the left and right vertical trim will sit on the lower support and the front side with the pre-drilled holes will go outside the fireplace lip, and the holes will align with the holes on the fireplace face. -

Page 22: Interior Decorative Frame Installation

6 - GLASS ASSEMBLY & DECORATIVE FRAME ASSEMBLY D. INTERIOR DECORATIVE GLASS FRAME Figure 6D.1 The interior side glass trim now simply sits in front of the interior outer glass assembly and is held on by the round magnets. Figure 6D.2 The interior side fully installed. -

Page 23: Exterior Outer Glass Assembly Installation

6 - GLASS ASSEMBLY & DECORATIVE FRAME ASSEMBLY E. EXTERIOR OUTER GLASS ASSEMBLY - NO MAGNETS If you haven't already done so, install the exterior inner glass, and the exterior left, right and horizontal trim pieces. Refer to Pages 20-21. Figure 6E.1 The exterior outer glass frame assembly will have bolt holes around the perimeter. -

Page 24: Gas Line Specifications & Connection

7 - GAS LINE SPECIFICATIONS This fireplace is manufactured for use with Natural Gas or Propane. CAUTION: Installation of the gas line must only be done by a qualified person in accordance with local building codes, if any. If not, follow ANSI 223.1. NOTE: The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at pressures in excess of ½ psi. NOTE: The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas line at test pressures equal to or less than ½ psi (3.5 kPa). NOTE: For high altitude installations, consult Stellar Hearth Products directly for proper rating methods. GAS LINE CONNECTION Propane 11.0 inches W.C. 7.0 inches W.C. MINIMUM INLET GAS PRESSURE (recommended) (recommended) MAXIMUM INLET GAS PRESSURE 14.0 inches W.C. 10.0 inches W.C. MANIFOLD PRESSURE (HI) 10.0 inches W.C. -

Page 25: Venting

8 - VENTING CAUTION: Consult the local and national installation codes to assure adequate combustion and ventilation air is available. NOTE: Flame height and appearance will vary depending upon venting configuration and type of fuel used. Venting requirements apply to both Natural and Propane gas. STOP: MAINTAIN ALL CLEARANCES AS STATED IN THIS INSTALLATION MANUAL. Figure 7 A. APPROVED VENTING OUTSIDE STANDARD IN-LINE Model # DESCRIPTION B-VENT POWERVENT POWERVENT 3-IDOD-X-GL X = ANY HEIGHT 8" 10" RS012 RSIF160 4-IDOD-X-GL X = ANY HEIGHT 8”... -

Page 26: Rs Series Powervent Specifications

8 - VENTING D. RS SERIES POWERVENT SPECIFICATIONS Available Power Venting A power vent (RS-12 & RS014) is approved for use with this appliance. It is crucial that all B-Vent pipe and elbow joints, and the longitudinal seam are sealed using a high temperature RTV Silicone and/or foil tape. MODEL RS012 RS014... -

Page 27: Rsif Series Powervent Specifications

8 - VENTING F. RSIF SERIES POWERVENT SPECIFICATIONS Available In-Line Power Venting An in-line power vent (RSIF160 or RSIF180 is approved for use with this appliance. It is crucial that all B-Vent pipe and elbow joints, and the longitudi- nal seam are sealed using a high temperature RTV Silicone and/or foil tape. MODEL RSIF160 RSIF180... -

Page 28: In-Line Powervent Preparations - Rsif 180

D. IN-LINE POWERVENT PREPARATIONS G. IN-LINE POWERVENT PREPARATIONS- RSIF 180 Perform the following steps when installing the RSIF180 on 6', 7' & 8' models. Attach the provided 10 inch B-Vent collar to the intake side of the powervent. The intake side is located opposite the fan motor as shown in Figure 8G.1. -

Page 29: Horizontal Vent System Clearance

8 - VENTING H. HORIZONTAL VENT SYSTEM CLEARANCES ALL APPROVED VENTING BOTTOM SIDES HORIZONTAL 1 inch [25mm] 1 inch [25mm] 1 inch [25mm] I. WALL PASS-THROUGH - Follow all local codes for requirement of firestops. 8 - VENTING J. PITOT TUBE INFORMATION Figure 8J There is a 1/4" pitot tube mounted in the center of the flue collar and is connected to the pressure switch. (Figure 8E) This monitors the pressure in the flue and is necessary for proper operation. -

Page 30: Vertical Terminations

8 - VENTING K. VERTICAL TERMINATIONS • The fireplace must terminate with the included approved powered termination cap. • NO SUBSTITUTION IS ACCEPTABLE. • Carefully follow the instructions included with the approved powered termination cap. DO NOT use an additional speed control on this powervent. • • You must use the included Capacitor. L. HORIZONTAL TERMINATION VENT CAP LOCATION & CLEARANCES This gas appliance must not be connected to a chimney serving any other appliance. • DO NOT RECESS TERMINATION KIT INTO OUTSIDE BUILDING MATERIALS - i.e.: brick, stone, siding, etc. If necessary, extend framing so that termination kit will be exposed once building materials are installed. - Page 31 8 - VENTING M. HORIZONTAL TERMINATION VENT CAP LOCATION & CLEARANCES Inside Corner Outside Corner Recessed Location A = Combustible 24” (609.6mm) F = Combustible 6” (152mm) = Non-combustible 6” (152mm) = Non-combustible 12” (304.8mm) Balcony Balcony with perpendicular side wall with no side wall C = Clearance from corner in recessed location = Combustible 24”...

- Page 32 Page 32 INS_CUST UL REV E...

- Page 33 8 - VENTING O. VERTICAL VENT CAP LOCATION AND CLEARANCES ROOF PITCH H (Min.) Ft. H (Min.) M. FLAT TO 6/12 1.0* 0.30 OVER 6/12 TO 7/12 1.25* 0.38 OVER 7/12 TO 8/12 1.5* 0.46 OVER 8/12 TO 9/12 2.0* 0.61 OVER 9/12 TO 10/12 2.5* 0.76 OVER 10/12 TO 11/12 3.25* 0.99 OVER 11/12 TO 12/12 1.22 OVER 12/12 TO 14/12 1.52 OVER 14/12 TO 16/12 1.83 OVER 16/12 TO 18/12 2.13 * = 3 foot minimum in OVER 18/12 TO 20/12 2.27...

- Page 34 8 - VENTING P. ROOF TERMINATION CAP INSTALLATION - WITH AND WITHOUT DAMPER Roof Termination Without Optional Mechanical Damper POWERVENT MOUNTING BRACKETS OR DRILL MOUNTING HOLES TO MATCH BASE INSULATION PAD MUST BE CUT IN CENTER TO ACCOMMODATE VENT SIZE STEEL CHIMNEY ADAPTER Figure 8P.1 Roof Termination With...

- Page 35 8 - VENTING Q. WALL TERMINATION - WITH AND WITHOUT DAMPER Wall Termination Without Optional Mechanical Damper FRAMING: 8" = 11-3/4" W X 11-3/4" H 10" = 13-1/4"" W X 13-1/4" H DRILL 1/4” HOLES TO MATCH POWER VENT BASE INSULATION PAD MUST BE CUT IN CENTER TO ACCOMMODATE VENT SIZE USE APPROPRIATE HEAVY DUTY FASTENERS TO SECURE POWER VENT Figure 8Q.1 Wall Termination With Optional Mechanical Damper...

-

Page 36: Outside Air Intake

8- OUTSIDE AIR R. OUTSIDE AIR Figure 8R Quantity three air intake vents are located on the exterior face of the fireplace. Must not be obstructed by finishing materials. If a hearth is used, it has to be placed below the air intake vents. You must properly flash and slope the hearth so water drains away from the wall. Page 36 INS_CUST UL REV E... - Page 37 9- VENTING OPTIONS OPTIONAL UNIVERSAL EXHAUST LOUVER MODEL UNITS LOUVER-8 3', 4' & 5' Exhaust and Air-Intake LOUVER-10 6' & 7' Exhaust and Air-Intake This kit is an optional method of terminating the exhaust for the appliance. Exhaust terminations must be installed with an in-line powervent. FOLLOW COMPLETE INSTALLATION INSTRUCTIONS PROVIDED WITH THE LOUVER KIT...

- Page 38 10 - ELECTRIC A. ELECTRIC - AT INSTALL Figure 10A Powervent Voltage Chart Supply Voltage Chart (N/L1) To light the replace: Activate the switch. The replace has a pre and post timer, set at the factory for 30 seconds. The powervent will start after the switch is activated. The ame will not turn on for 30-60 seconds after switch is activated and the powervent will run for 30 seconds after it has been shut o .

- Page 39 10 - ELECTRIC B. ELECTRIC - SERVICE & TROUBLESHOOTING Figure 10B Page 39 16400-7820 GIDOD REV A...

- Page 40 10 - ELECTRIC C.1 TERMINALS 1 & 2 - LED Lights Figure 10C.1 Terminals 1 & 2 C.2 TERMINALS 3 & 4 - Main Flame Figure 10C.2 Terminals 3 & 4 Page 40 INS_CUST UL REV E...

- Page 41 10 - ELECTRIC C.3 TERMINALS 5 & 6 - Fireplace Power GROUND - LOCATE THE GREEN WIRE CLUSTER CONNECT THE GREEN WIRE TAIL TO BUILDING GROUND Figure 10C.3 Terminals 5 & 6 C.4 TERMINALS 7 & 8 - Powervent Connection Figure 10C.4 Terminals 7 & 8 Page 41 16400-7820 GIDOD REV A...

- Page 42 10 - ELECTRIC C.5 TERMINALS 9 & 10 - OPTIONAL Flue Damper Connection OPTIONAL Figure 10C.5 Terminals 9 & 10 TERMINALS 9 & 10 FLUE DAMPER CONNECTION TERMINAL #9 IS THE NEUTRAL CONNECTION FOR THE DAMPER MOTOR. BLACK WIRE TERMINAL #10 IS THE HOT CONNECTION FOR THE DAMPER MOTOR. RED WIRE THIS IS LOW VOLTAGE AND EXTERNAL POWER MUST NOT BE APPLIED 24 VAC DAMPER MOTOR - RED NEUTRAL DAMPER MOTOR - BLACK...

- Page 43 10 - ELECTRIC C.6 TERMINALS 11 & 12 - OPTIONAL Flue Damper Connection OPTIONAL Figure 10C.6 Terminals 11 & 12 NOTE: OPTIONAL IF A DAMPER IS NOT USED TERMINALS 11 AND 12 HAVE A JUMPER ACROSS THEM NOTE: RED IS NOT USED AND SHOULD BE SAFELY CAPPED Page 43 16400-7820 GIDOD REV A...

- Page 44 11 - FINISHING A.1 FINISHING THE WALL - USING THE PROVIDED 1/2" STANDOFFS - INTERIOR NOTE: REFER TO DIMENSIONS SECTION FOR ALLOWABLE FINISHING DIMENSIONS REQUIRED TO FIT THE GLASS PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON PAGE 5. NEVER COVER THE GLASS WITH FINISHING MATERIALS. NOTE: REFER TO SECTION 5 FRAMING & MANTEL REQUIREMENTS: NON-COMBUSTIBLE ZONE USING PROVIDED 1/2" STANDOFFS FOR MORE INFORMATION. Figure 11A.1 D - NON-COMBUSTIBLE BOARD OR COMBUSTIBLE BACKER MATERIAL (I.E.

- Page 45 11 - FINISHING A.2 FINISHING THE WALL - USING THE PROVIDED 1/2" STANDOFFS - EXTERIOR NOTE: REFER TO DIMENSIONS SECTION FOR ALLOWABLE FINISHING DIMENSIONS REQUIRED TO FIT THE GLASS PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON PAGE 5. NEVER COVER THE GLASS WITH FINISHING MATERIALS. NOTE: REFER TO SECTION 5 FRAMING & MANTEL REQUIREMENTS: NON-COMBUSTIBLE ZONE USING PROVIDED 1/2" STANDOFFS FOR MORE INFORMATION. Figure 11A.2 B - NON-COMBUSTIBLE BOARD C.

- Page 46 11 - FINISHING B.1 FINISHING THE WALL - NOT USING THE PROVIDED 1/2" STANDOFFS - INTERIOR NOTE: REFER TO DIMENSIONS SECTION FOR ALLOWABLE FINISHING DIMENSIONS REQUIRED TO FIT THE GLASS PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON PAGE 5. NEVER COVER THE GLASS WITH FINISHING MATERIALS. NOTE: REFER TO SECTION 5 FRAMING & MANTEL REQUIREMENTS: NON-COMBUSTIBLE ZONE USING PROVIDED 1/2" STANDOFFS FOR MORE INFORMATION. Figure 11B.1 D - NON-COMBUSTIBLE BOARD OR COMBUSTIBLE BACKER MATERIAL B - NON-COMBUSTIBLE BOARD (I.E.

- Page 47 11 - FINISHING B.2 FINISHING THE WALL - NOT USING THE PROVIDED 1/2" STANDOFFS - EXTERIOR NOTE: REFER TO DIMENSIONS SECTION FOR ALLOWABLE FINISHING DIMENSIONS REQUIRED TO FIT THE GLASS PANELS INTO THE FIREPLACE. FINISHING MATERIALS MUST NOT OVERLAP THE DIMENSIONS HIGHLIGHTED IN GREEN ON PAGE 5. NEVER COVER THE GLASS WITH FINISHING MATERIALS. NOTE: REFER TO SECTION 5 FRAMING & MANTEL REQUIREMENTS: NON-COMBUSTIBLE ZONE USING PROVIDED 1/2" STANDOFFS FOR MORE INFORMATION. Figure 11B.2 B - NON-COMBUSTIBLE BOARD C.

- Page 48 12 - LIGHTING & SHUTDOWN FOR YOUR SAFETY - READ BEFORE LIGHTING STOP: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. UE TO HIGH SURFACE TEMPERATURES, KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. This appliance needs fresh air for safe operation and must be installed so there are provisions for adequate combustion and ventilation air. It is important to make sure the termination cap remains unobstructed at all times from snow, ice, leaves or other debris. •...

- Page 49 12 - LIGHTING & SHUTDOWN STOP! Read safety information on previous page and front cover of this manual before continuing. NOTE: This fireplace is equipped with an ignition device which automatically lights the pilot. DO NOT try to light the pilot by hand. B. IF THE FIREPLACE DOES NOT LIGHT Turn off the fireplace at switch. Turn off all electrical power to fireplace. Wait five (5) minutes to allow any gas that may have accumulated inside firebox to escape. If you then smell gas, STOP! Follow safety information on front cover and on previous page of the installation manual.

- Page 50 NOTE: DO NOT SUBSTITUTE THE SUPPLIED MEDIA WITH ANY OTHER KIND OF MEDIA WITHOUT WRITTEN APPROVAL OF STELLAR HEARTH PRODUCTS. B. FLAME APPEARANCE Flame appearance is affected by several factors including altitude, venting configuration and fuel quality. Although the venturi setting has been factory set, adjustments may be necessary for optimal performance and visual aesthetics.

- Page 51 15 - MAINTENANCE The appliance is required to be inspected at least once a year by a professional service person. The compartment below firebox (behind lower access panel) must be cleaned at least once a year, more frequent cleaning may be required due to excessive lint from carpeting, bedding materials, or other fibrous materials. It is imperative that the burner be cleaned once a year. VALVE AND ELECTRICAL ACCESS There is an access panel under the floor of the firebox should more extensive service be needed. Remove the inner and outer glass panels. Remove the glass media on the end with the pilot. The end floor lifts out; remove the screws and lift it out. Remove the burner and loosen the pilot bracket. There is a panel under the floor you removed. Remove the 6 screws and slide the panel up. NOTE: INSTALLATION AND REPAIR SHOULD BE DONE ONLY BY QUALIFIED SERVICE PERSON. THE APPLIANCE SHOULD BE INSPECTED BEFORE USE AND ANNUALLY BY A QUALIFIED SERVICE PERSON. MORE FREQUENT CLEANING MAY BE REQUIRED DUE TO EXCESSIVE LINT FROM CARPETING, BEDDING MATERIALS, ETC. IT IS IMPERATIVE THAT CONTROL COMPARTMENTS, BURNERS AND CIRCULATION AIR PASSAGEWAYS OF THE APPLIANCE BE KEPT CLEAN. A. VENT SYSTEM • Annual examination of venting system by a qualified agency is required. • IF VENT-AIR INTAKE SYSTEM IS DISASSEMBLED FOR ANY REASON, RE-INSTALL PER INSTRUCTIONS PROVIDED WITH INITIAL INSTALLATION. • The flow of combustion air must not be obstructed. B. GLASS CLEANING & REPLACEMENT WARNING! RISK OF INJURY! DO NOT remove glass until it is cooled to room temperature. Glass breakage could occur. See Section 6 for glass installation and removal instructions. •...

- Page 52 16 - REPLACEMENT PARTS LIST REPLACEMENT PARTS LIST PART PART NUMBER PART PART NUMBER Replacement Capacitor - RS012 601.0400.0064 Gas Valve SV9501 Pilot 112-5000 Replacement Capacitor - RS014 604.0400.0064 Vacuum Switch 112-5003 Replacement Capacitor - RSIF160 604.0600.0064 Transformer, 24 VAC 112-5002 Replacement Capacitor -RSIF180 604.0800.0064 Orifice, NG #43 16400-2043 Orifice, Propane #55 16400-2055 Propane Conversion Kit LPK-FDN Timer Relay 112-5014 Solid State Relay...

- Page 53 16 - REPLACEMENT PARTS LIST REPLACEMENT PARTS LIST Vertical Trim Pieces Horizontal Trim Pieces Between Glass Between Glass MODEL Part # Part # 3-IDOD-2-GL SRV20200-1925 SRV20199-1844 3-IDOD-3-GL SRV20200-1945 SRV20199-1844 4-IDOD-2-GL SRV20200-1925 SRV20200-1844 4-IDOD-3-GL SRV20200-1945 SRV20200-1844 5-IDOD-2-GL SRV20200-1925 SRV20201-1844 5-IDOD-3-GL SRV20200-1945 SRV20201-1844 6-IDOD-2-GL SRV20200-1925 SRV20202-1844 6-IDOD-3-GL SRV20200-1945 SRV20202-1844 7-IDOD-2-G SRV20200-1925...

- Page 54 Hearth & Home Technologies LIMITED LIFETIME WARRANTY Hearth & Home Technologies, on behalf of its hearth brands (“HHT”), extends the following warranty for HHT gas, wood, pellet, coal and electric hearth appliances that are purchased from an HHT authorized dealer. WARRANTY COVERAGE: HHT warrants to the original owner of the HHT appliance at the site of installation, and to any transferee taking ownership of the appliance at the site of installation within two years following the date of original purchase, that the HHT appliance...

- Page 55 WARRANTY CONDITIONS: • This warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of HHT authorized dealers is available on the HHT branded websites. • This warranty is only valid while the HHT appliance remains at the site of original installation. •...

Need help?

Do you have a question about the GALAXY Series and is the answer not in the manual?

Questions and answers