Advertisement

Quick Links

Advertisement

Summary of Contents for Velodyne HD HDL-64E S2.1

- Page 1 Firmw are Version 4. 0 7 H L-64E S2 and S2.1 ™ High Definition LiD R Sensor...

- Page 2 S A F E T Y N O T I C E S I N T R O D U C T I O N In The Box P R I N C I P L E S O F O P E R A T I O N I N S T A L L A T I O N O V E R V I E W Front/Back Mounting Side Mounting...

- Page 3 c a u t i o n — saf e t y n ot ic e Caution To reduce the risk of electric shock and to avoid violating the warranty, do not open sensor body. Refer servicing to qualified service personnel. The lightning flash with arrowhead symbol is intended to alert the user to the presence of uninsulated “dangerous voltage”...

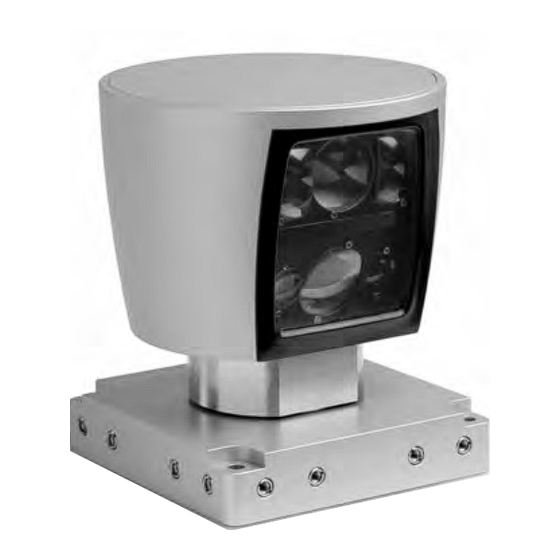

- Page 4 i n t r o d u c t i o n Congratulations on your purchase of a Velodyne HDL-64E S2 or S2.1 High Definition LiDAR Sensor. These sensors represent a breakthrough in sensing technology by providing more information about the surrounding environment than previously possible. The HDL-64E S2 or S2.1 High Definition LiDAR sensors are referred to as the sensor throughout this manual.

- Page 5 P r i n c i P L e s o f o Pe r ati on The sensor operates, instead of a single laser firing through a rotating mirror, with 64 lasers fixed mounted on upper and lower laser blocks, each housing 32 lasers.

- Page 6 i n s ta L L at i o n o V erVie W The sensor base provides the following mounting options: • Front/Back mount (Figure 2) • Side mount (Figure 3) • Top mount (Figure 4) The sensor can be mounted at any angle from 0 to 90° with respect to its base. Refer to Appendix A for complete dimensions. For all mounting options, mount the sensor to withstand vibration and shock without risk of detachment.

- Page 7 i ns ta L L at i on oVe rV ieW HDL-64E S2 and S2.1 User’s Manual [152.4mm] 6.00 [203.2mm] 8.00 [21mm] [25.4mm] 1.00 Figure 3. Side HDL mounting illustration. [ 4 ]...

- Page 8 i ns ta L L at i on oVe rV ieW HDL-64E S2 and S2.1 User’s Manual Four 0.41” [10.3mm] through holes for top mount option to secure the HDL to the vehicle. [33.8mm] 1.33 [177.8mm] [177.8mm] 7.00 7.00 [12.7mm] [12.7mm] Figure 4.

- Page 9 i n sta L L at i o n o Ve rV ie W The sensor comes with a pre-wired connector, wired with power, DB9 serial and standard RJ45 Ethernet connectors. The connector wires are approximately 10’ [3 meters] in length. Power.

- Page 10 u s aG e The following provides more detail on each of the above steps. 1. Establish communication with the sensor. The sensor broadcasts UDP packets. By using a network monitoring tool, such as Wireshark, you can capture and observe the packets as they are generated by the sensor.

- Page 11 u s aG e 3. Parse the packets for rotation, block, distance and intensity data. Each sensor’s LIFO data packet has a 1206 byte payload consisting of 12 blocks of 100 byte firing data followed by 6 bytes of calibration and other information pertaining to the sensor. Each 100 byte record contains a block identifier, then a rotational value followed by 32 3-byte combinations that report on each laser fired for the block.

- Page 12 u s aG e Available commands The following run-time commands are available with the sensor: Command #HDLRPMnnnn$ #HDLRPNnnnn$ #HDLIPAssssssssssssdddddddddddd$ #HDLFOVsssnnn$ You can also upload calibration data from db.xml into flash memory and use GPS time synchronization. Description Parameters Set spin rate from 300 to 1200 RPM nnnn is an integer between 0300 and 1200 n flash memory (default is 600 RPM) Set spin rate from 300 to 1200 RPM...

- Page 13 u s aG e Change Spin Rate in Flash Memory The sensor can spin at rates ranging from 300 RPM (5 Hz) to 1200 RPM (20 Hz). The default is 600 RPM (10 Hz). Changing the spin rate does not change the data rate – the unit sends out the same number of packets (at a rate of ~1.3 million data points per second) regardless of its spin rate.

- Page 14 u s aG e The HDL-64E comes with the following default IP addresses: • Source: 192.168.3.043 • Destination: 192.168.3.255 To change either of the above IP addresses, issue a serial command of the case sensitive format #HDLIPAssssssssssssdddddddddddd$ where, • ssssssssssss is the source 12-digit IP address •...

- Page 15 u s a G e HDL-64E S2 and S2.1 User’s Manual The images below show the GPS adaptor box, included with the HDL-64E, and optional GPS receiver. Optional) Included) [ 12 ]...

- Page 16 u s aG e The 6 bytes at the end of the data packet report GPS timing and synchronization data. For every packet, the last 6 bytes are formatted as follows: Timestamp Bytes in Reverse Order in Microseconds Bytes Description Notes GPS timestamp 32 bit unsigned integer timestamp.

- Page 17 u s a G e Lasers are numbered sequentially starting with 0 for the first lower block laser to 31 for the last lower block laser; and 32 for the first upper block laser to 63 for the last upper block laser. For example, laser 32 fires simultaneously with laser 0, laser 33 fires with laser 1, and so on. The sensor has an equal number of upper and lower block returns.

- Page 18 a P P en d i x a : M e c h an ic a L d r aW in Gs HDL-64E S2 and S2.1 User’s Manual [ 15 ]...

- Page 19 a P P en d i x B : W i r in G d ia Gr a M HDL-64E S2 and S2.1 User’s Manual [ 16 ]...

- Page 20 a P P en d i x c : d i Gi ta L se n s or r e c or d e r (dsr) Digital Sensor Recorder (DSR) DSR is a 3D point-cloud visualization software program designed for use with the sensor. This software is an “out of the box” tool for the rendering and recording of point cloud data from the HDL unit.

- Page 21 a P P e n di x c : di Gita L s en s or re c ord er (dsr) Record Data 1. Confirm the input of streaming data through the live playback feature. 2. Click the Record button. RECORD button = 5.

- Page 22 a P P e n di x c : di Gita L s en s or re c ord er (dsr) HDL-64E S2 and S2.1 User’s Manual Zoom: Z = Zoom in Shift, Z = Zoom out Z Axis Rotation: Y = Rotate CW Shift, Y = Rotate CCW X Axis Rotation:...

- Page 23 a P P en d i x d : M atLaB sa MP L e c od e Matlab sample code to read calibration data from HDL-64E output. fileFilter = '*.pcap'; [File_name,Directory]=uigetfile(fileFilter,'Open a .pcap file') ; Filename=[Directory File_name]; tic; fid=fopen(Filename); ttc=fread(fid,40);...

- Page 24 a P P e n di x d : Mat La B s aMP L e c od e % Add high and low bytes of Rotational Correction Factor together and check if positive or negative correction factor. RotationalCorr(i)=temp(5)*256+temp(4); if RotationalCorr(i)>32768 RotationalCorr(i)=RotationalCorr(i)-65536;...

- Page 25 a P P e n di x d : Mat La B s aMP L e c od e Version=dec2hex(value(s-1)) Temperature=value(s-2) GPS=value(s-3) speed=single(value(s-48))+single(value(s-47))*256 Fov_start=single(value(s-46))+single(value(s-45))*256 Fov_end=single(value(s-44))+single(value(s-43))*256 warning=value(s-13) power=value(s-12) Humidity=value(s-58) % Done with Unit Parameters. Reading Calibration and Sensor Parameter Data Laser ID # is a 1 byte integer. Most of the output calibration data are 2 byte signed integers, except minimum and maximum intensity, which use 1 byte each.

- Page 26 a P P en d i x e : d ata Pa c K e t for Mat HDL-64E S2 and S2.1 User’s Manual Data Packet Format The sensor outputs UDP Ethernet packets. Each packet contains a header, a data payload of firing data and status data. Data packets are assembled with the collection of all firing data for six upper block sequences and six lower block sequences.

-

Page 27: Firmware Version

a P P e n di x e : d ata Pac K e t for Mat HDL-64E S2 and S2.1 User’s Manual Firmware version 4.07 (sheet 1 of 3 Version 4.07 [ 24 ]... - Page 28 a P P e n di x e : d ata Pac K e t for Mat Upper Block Threshold Lower Block Threshold For Laser 63, these bytes will contain the time stamp representing when the calibration data was uploaded in the following sequence: Firmware version 4.07 (sheet 2 of 3 [ 25 ]...

- Page 29 a P P e n di x e : d ata Pac K e t for Mat HDL-64E S2 and S2.1 User’s Manual Firmware version 4.07 (sheet 3 of 3 Threshold Both = 2 Strongest = 0 Last = 1 [ 26 ]...

- Page 30 a P P e n di x e : d ata Pac K e t for Mat HDL-64E S2 and S2.1 User’s Manual Examples of the last row of 11 consecutive packets follows. In all cases, the “seconds” figure represents the origin of the packet expressed in seconds since the top of the hour.

- Page 31 a P P e n di x e : d ata Pac K e t for Mat HDL-64E S2 and S2.1 User’s Manual PACKET #7652: PACKET #7653: PACKET #7654: PACKET #7655: PACKET #7656: 40 = Ver 4.07 [ 28 ]...

- Page 32 a P P e n di x e : d ata Pac K e t for Mat PACKET #7657: PACKET #7658: HDL-64E S2 and S2.1 User’s Manual Not used (Spare) Not used (Spare) [ 29 ]...

- Page 33 a P P en d i x f : d u a L t W o P oin t ca L iB r ation MethodoLoG y Dual Two Point Calibration Methodology and Code Samples Velodyne uses a dual point calibration methodology to calculate the values in the db.xml file. This section describes this calibration methodology. The steps for the calibration are as follows: 1: Perform far point calibration at 25.04m 2: Perform near point X calibration at 2.4m...

- Page 34 a P P e n di x f : du a L t W o P oin t c aLiB r ation MethodoLoG y float cosRotCorrection = cal->getCosRotCorrection(); float sinRotCorrection = cal->getSinRotCorrection(); float cosRotAngle = rotCosTable[data->position]*cosRotCorrection + rotSinTable[data->position]*sinRotCorrection; float sinRotAngle = rotSinTable[data->position]*cosRotCorrection - rotCosTable[data->position]*sinRotCorrection;...

- Page 35 a P P e n di x f : du a L t W o P oin t c aLiB r ation MethodoLoG y Intensity Compensation vs Distance Intensity compensation is done in the software for different channels by changing a parameter in the calibration window until the measurement gets to a uniform intensity for a reference target.

- Page 36 a P P e n di x f : du a L t W o P oin t c aLiB r ation MethodoLoG y // Calculate corrected intensity vs distance float intensityVal1 = intensityVal + focalslope*(abs(focaloffset-256*(1- distance/65535)*(1-distance/65535))); if (intensityVal1 < minIntensity) intensityVal1=minIntensity; if (intensityVal1 >...

- Page 37 a P P en d i x G : et h e r n e t tr a n s it tiMi n G taBLe HDL-64E S2 and S2.1 User’s Manual HDL-64E Ethernet Timing Table Overview The Ethernet Timing Table shows how much time elapses between the actual capturing of a point’s data event and when that point is an event output from the sensor.

- Page 38 a P P e n di x G : e t he r n et tr a ns it ti Min G taBLe HDL-64E S2 and S2.1 User’s Manual How to use this table The table represents a sensor data packet. The laser returns come out in the order listed. Simply subtract from the timestamp of the output event of the packet each data value to arrive at the actual time the distance point was captured inside the sensor.

- Page 39 a P P en d i x h : L a s er a n d d e te c tor a r ranGeMent HDL-64E S2 and S2.1 User’s Manual SENSOR AS SEEN FROM THE BACK OF THE UNIT SENSOR BEAM ON THE WALL AS SEEN ON CAMERA IN NIGHT VISION MODE [ 36 ]...

- Page 40 a P P en d i x i : a n G uL a r r e s oLu tion Total Laser Points (Hz) per Revolution 266,627 133,333 88,889 1200 66,667 notes: These values apply equally to the upper and lower block. HDL-64E S2 and S2.1 User’s Manual Points Per Laser Angular Resolution...

- Page 41 t r o u B L es h o o t in G Use this chart to troubleshoot common problems with the sensor.Use this chart to troubleshoot common problems with the sensor. Unit doesn’t spin Unit spins but no data No serial communication s e rV i c e an d M ai n t e n an c e No service or maintenance requirements or procedures exist for the sensors.

- Page 42 s P e ci f i c at i o n s Sensor: • 64 lasers/detectors • 360 degree field of view (azimuth) • 0.09 degree angular resolution (azimuth) • Vertical Field of View: S2.1: +2 — -29.5 @ 1/2 degree spacing •...

- Page 43 345 Digital Drive Morgan Hill, CA 95037 408.465.2800 voice 408.779.9227 fax 408.779.9208 service fax Service Email: lidarservice@velodyne.com Product Email: help@velodyne.com Technical Email: lidarhelp@velodyne.com Sales Email: lidar@velodyne.com All Velodyne products are made in the U.S.A. Specifications subject to change without notice Other trademarks or registered trademarks are property of their respective owner.

Need help?

Do you have a question about the HD HDL-64E S2.1 and is the answer not in the manual?

Questions and answers