Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Toro FP-2200

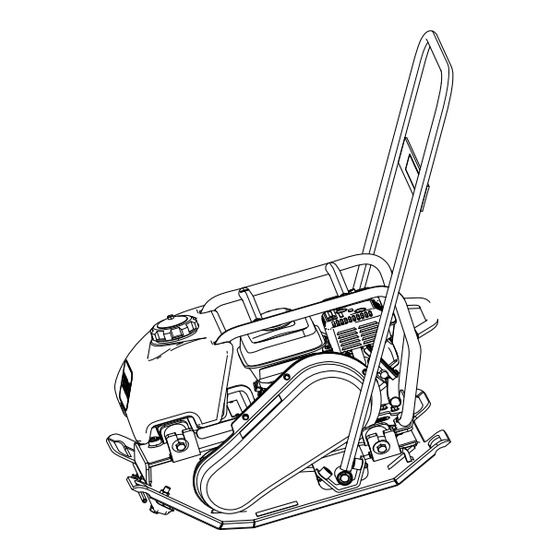

- Page 1 Form No. 3429-692 Rev A FP-2200, FP-3000, and FP-4000 Forward Plate Compactors Model No. 68025—Serial No. 404320000 and Up Model No. 68026—Serial No. 404320000 and Up Model No. 68027—Serial No. 404320000 and Up *3429-692* A Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or recommended precautions. additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure illustrates the location of the model and serial numbers on the product.

-

Page 3: Table Of Contents

Contents Safety Improper use or maintenance by the operator or owner Safety ............... 3 can result in injury. To reduce the potential for injury, Safe Operating Practices........3 Safety and Instructional Decals ......5 comply with these safety instructions and always pay attention to the safety alert symbol, which means Setup ................ - Page 4 • Ensure that the area is clear of other people before • Use only genuine Toro replacement parts to operating the machine. Shut off the machine if ensure that original standards are maintained. anyone enters the area. •...

-

Page 5: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal133-8062 133-8062 decal93-9084 93-9084 1. Lift point decal117-4979 117-4979 1. -

Page 6: Setup

Setup Installing the Handle Secure each side of the handle to the plate compactor frame using a bolt, flat washer, spacer, bearing, and locknut (Figure 3 Figure g027147 Figure 4 Model 3000/4000 1. Locknut 4. Spacer 2. Bearing 5. Flat washer g019697 Figure 3 3. -

Page 7: Product Overview

Product Overview Operation Note: Determine the left and right sides of the machine from the normal operating position. Checking the Engine-Oil Level Service Interval: Before each use or daily Oil crankcase capacity: • 0.56 L (0.59 US qt) for Model 68025 •... -

Page 8: Cleaning Debris From The Machine

Important: • Running the engine with a low Do not store fuel either in the fuel tank or fuel oil level can cause engine damage. This type containers over the winter unless a fuel stabilizer of damage is not covered by warranty. is used. - Page 9 Add the correct amount of gas stabilizer/conditioner DANGER to the gas. In certain conditions during fueling, static Note: A fuel stabilizer/conditioner is most electricity can be released causing a spark effective when mixed with fresh fuel. To minimize which can ignite the fuel vapors. A fire or the chance of varnish deposits in the fuel system, explosion from fuel can burn you and others use fuel stabilizer at all times.

-

Page 10: Compacting Asphalt

Compacting Asphalt Adding Water with the Tank Removed When using the machine on asphalt, the water system is used to wet the surface of the compactor to prevent Detach the valve coupler (Figure 10). the asphalt from sticking to the compactor. Adding Water with the Tank Installed Remove the cap from the water tank... -

Page 11: Starting The Engine

Starting the Engine Move the engine switch to the O position (Figure 12). g019774 Figure 14 1. Choke g019703 Move the throttle lever midway between the Figure 12 (turtle) and F (rabbit) positions (Figure 1. Engine switch 15). Note: A warm or hot engine may not require Move the fuel valve to the O position (Figure... -

Page 12: Shutting Off The Engine

Important: If the engine stalls or hesitates, move the choke left again until the engine warms up. Move the throttle lever to maximum throttle. Shutting Off the Engine Move the throttle lever to the S (turtle) position. Turn the engine switch and fuel valve off. Operating the Compactor With the engine at full throttle, the compactor moves forward while vibrating. -

Page 13: Maintenance

Maintenance Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the engine oil. After the first 25 hours • Check the engine-oil level. • Clean debris from the air cleaner. Before each use or daily • Inspect the air-cleaner elements. •... - Page 14 r:\g000533 Figure 18 1. Center electrode insulator 2. Side electrode 3. Air gap (not to scale) Carefully install the spark plug by hand (to avoid g027313 cross threading) until it is hand tight. Figure 19 Tighten the spark plug an additional 1/2 turn if 1.

- Page 15 Allow the foam filter element to completely dry. Shut off the engine and wait for all moving parts to stop. Dip the foam element in clean engine oil, then squeeze out the excess oil. Disconnect the wire from the spark plug. Note: If too much oil is left in the foam element Move the fuel-shutoff valve to the O...

- Page 16 Servicing the Engine Oil Oil Type: Detergent oil (API service SJ or higher) Oil crankcase capacity: • 0.56 L (0.59 US qt) for Model 68025 • 0.58 L (0.61 US qt) for Models 68026 and 68027 Viscosity: See table below g019692 Figure 22 1.

- Page 17 Servicing the Eccentric Oil Changing the Eccentric Oil Service Interval: Every 300 hours Oil type: 10W30 (API service SJ or higher) Set the throttle to slow, shut off the engine, and Oil capacity: wait for all moving parts to stop. •...

-

Page 18: Belt Maintenance

Belt Maintenance Checking the Belt Tension Service Interval: Every 100 hours Removing the Belt Cover Important: The best belt tension for the machine is the lowest tension at which the belts do not slip Remove the flanged-head bolts that secure the under full power. - Page 19 Adjusting the Belt Tension Tighten the 2 flange nuts (8 mm) that secure the back of the engine to 23 to 29 N∙m (17 to 21 Remove the water tank; refer to Adding Water ft-lb) as shown in Figure with the Tank Removed (page 10).

-

Page 20: Storage

Storage Shut off the engine and disconnect the spark-plug wire from the spark plug. Remove dirt and grime from the entire machine. Important: You can wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water, especially near the engine. -

Page 21: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine does not start, starts hard, or 1. The fuel tank is empty. 1. Fill the fuel tank with fuel. fails to keep running. 2. The spark plug is pitted, fouled, or the 2. - Page 22 Notes:...

- Page 23 Notes:...

- Page 24 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

Need help?

Do you have a question about the FP-2200 and is the answer not in the manual?

Questions and answers