Table of Contents

Advertisement

USER'S MANUAL

Thank you very much for purchasing this product.

To ensure correct and safe usage with a full understanding of this product's performance, please be

sure to read through this manual completely and store it in a safe location.

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

The contents of this operation manual and the specifications of this product are subject to change

without notice.

The operation manual and the product have been prepared and tested as much as possible. If you

find any misprint or error, please inform us.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur through use of this product, regardless of any failure to perform on the part of this product.

Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may

occur with respect to any article made using this product.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Roland Hi-Fi Express FP-740

- Page 1 Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur through use of this product, regardless of any failure to perform on the part of this product.

- Page 2 AVIS Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada. ROLAND DG CORPORATION 1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103 MODEL NAME : See the MODEL given on the rating plate.

-

Page 3: Table Of Contents

Contents To Ensure Safe Use ........................4 Pour utiliser en toute sécurité ....................11 Important Notes on Handling and Use ......................... 18 Printer Unit ............................ 18 Ink Cartridges ..........................19 Chapter 1 Introduction ........................21 1-1 Part Names and Functions ..........................22 Printer Unit ............................ - Page 4 Contents 4-4 Optimizing Printing to Match Media Thickness .................... 72 Adjusting Head Height to Match Media Thickness ................ 72 Correcting for Misalignment in Bidirectional Printing ..............73 Correcting for Misalignment in Bidirectional Printing More Precisely ........... 75 Performing Feed Correction to Alleviate Horizontal Bands and the Like ........78 4-5 Accommodating Various Kinds of Media ......................

- Page 5 6-3 Locations of the Power Rating and Serial Number Labels ..............114 Printer ............................114 Take-up unit ..........................114 6-4 Specifications ............................... 115 Company names and product names are trademarks or registered trademarks of their respective holders. Copyright© 2006 Roland DG Corporation http://www.rolanddg.com/...

-

Page 6: To Ensure Safe Use

To Ensure Safe Use Improper handling or operation of this machine may result in injury or damage to property. Points which must be observed to prevent such injury or damage are described as follows. About WARNING and CAUTION Notices Used for instructions intended to alert the user to the risk of death or severe WARNING injury should the unit be used improperly. - Page 7 To Ensure Safe Use Incorrect operation may cause injury WARNING CAUTION Keep children away from the machine. Exercise caution to avoid being pinched The machine includes areas and components or becoming caught. that pose a hazard to children and may result in Inadvertent contact with certain areas may cause injury, blindness, choking, or other serious acci- the hand or fingers to be pinched or become...

- Page 8 Contact your autho- ity may occur. Never touch with wet hands. rized Roland DG Corp. dealer. Doing so may result in fire or electrical shock. When the machine will be out of use for a...

- Page 9 To Ensure Safe Use Important notes about the power cord, plug, and electrical outlet Never place any object on top or subject to Never allow to get wet. damage. Never bend or twist with undue force. Never make hot. Never pull with undue force. Dust may cause fire.

- Page 10 To Ensure Safe Use Ink, cleaning fluid, and discharged fluid are toxic CAUTION Never drink or sniff ink, cleaning fluid, or discharged fluid, or allow them to come in contact with the eyes or skin. Doing so may be hazardous to the health. Never allow an ink cartridge to be sub- jected to impact, and never attempt to disassemble.

- Page 11 To Ensure Safe Use This machine weighs 300 kg (662 lb.). WARNING CAUTION Entrust operations such as transportation, Handling roll media is an operation that unloading, and emplacement to trained must be performed by two persons or workers. more, and care must be taken to prevent Handling requires special equipment and train- falls.

- Page 12 To Ensure Safe Use Warning Labels Warning labels are affixed to make areas of danger immediately clear. The meanings of these labels are as follows. Be sure to heed their warnings. Also, never remove the labels or allow them to become obscured. Caution: Moving Print Heads The print heads inside the cover move at high speed and pose a hazard.

-

Page 13: Pour Utiliser En Toute Sécurité

Pour utiliser en toute sécurité La manipulation ou l'utilisation inadéquates de cet appareil peuvent causer des blessures ou des dommages matériels. Les précautions à prendre pour prévenir les blessures ou les dommages sont décrites ci-dessous. Avis sur les avertissements Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave en ATTENTION cas de mauvaise utilisation de l'appareil. - Page 14 Pour utiliser en toute sécurité L'utilisation incorrecte peut causer des blessures ATTENTION PRUDENCE Garder les enfants loin de l'appareil. Faire preuve de prudence pour éviter L'appareil comporte des zones et des l'écrasement ou le coincement. composants qui présentent un danger pour les La main ou les doigts peuvent être écrasés ou enfants et qui pourraient causer des blessures, coincés s'ils entrent en contact avec certaines...

- Page 15 électrique ou des blessures. peuvent causer un incendie ou un choc Communiquer avec le représentant Roland DG électrique. Si un objet ou du liquide s'infiltre dans Corp. Autorisé. l'appareil, débrancher immédiatement le câble d'alimentation et communiquer avec le Si l'appareil doit rester inutilisé...

- Page 16 Pour utiliser en toute sécurité Remarques importantes à propos du câble d'alimentation, de la fiche et de la prise électrique Ne jamais déposer aucun objet sur le câble, sur la fiche Ne jamais laisser l'eau toucher le câble, la ou sur la prise car cela risque de les endommager. fiche ou la prise.

- Page 17 Pour utiliser en toute sécurité L'encre, les liquides nettoyants et les liquides usées sont toxiques PRUDENCE Ne jamais boire l'encre, le liquide de nettoyage ni les liquides usés, ne pas en respirer les vapeurs et ne pas laisser les produits entrer en contact avec les yeux ou la peau.

- Page 18 Pour utiliser en toute sécurité Le poids de cet appareil est de 300 kg (662 lb.) ATTENTION PRUDENCE Confier les opérations comme le trans- La manutention du support en rouleau port, le déchargement et la mise en place doit être faite par deux personnes ou plus à...

- Page 19 Pour utiliser en toute sécurité Vignettes d'avertissement Des vignettes d'avertissement sont apposées pour qu'il soit facile de repérer les zones dangereuses. La signification des vignettes est donnée ci-dessous. Respecter les avertissements. Ne jamais retirer les vignettes et ne pas les laisser s'encrasser. Attention : Têtes d'impression mobiles Les têtes d'impression sous le couvercle se déplacent à...

-

Page 20: Important Notes On Handling And Use

Never cover the ventilation holes with cloth, tape, or anything else. When Moving the Machine Special preparations are required when moving the machine. Please check with your authorized Roland DG Corp. dealer or Roland DG Corp. service center ahead of time. -

Page 21: Ink Cartridges

Ink Cartridges Ink Cartridges Come in Various Types Use a type that is compatible with the printer. Also, be sure to use only genuine items from Roland DG Corp. Never Subject to Impact or Attempt to Disassemble Never drop or shake forcefully. The impact may rupture the internal pouch and cause the ink to leak. -

Page 23: Chapter 1 Introduction

Chapter 1 Introduction... -

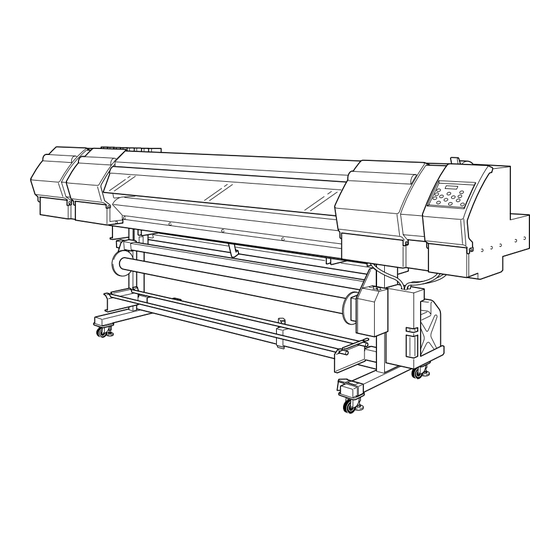

Page 24: Part Names And Functions

1-1 Part Names and Functions Printer Unit Loading Lever You operate this when you load media. Left Side Cover You remove this when you perform maintenance. Front Cover Right Side Cover Be sure to close this when you You remove this when you perform printing. - Page 25 1-1 Part Names and Functions Platen This is the path over which the media passes. A suction fan that keeps the media from coming loose. Pinch Rollers These clamp the media when the loading lever is pulled back toward you. Print-head Carriage The print heads are inside this.

-

Page 26: Operation Panel

1-1 Part Names and Functions Operation Panel BUSY Light This lights up during printing and other such operations. Display Screen This displays various setting menus and other information. SETUP Key You press this when you TEST PRINT Key load media. This lights up Holding this down for one when media is loaded and second or longer performs... -

Page 27: Media Take-Up System

1-1 Part Names and Functions Media Take-up System MANUAL Switch You use this when you want to operate the take-up unit manually. Main Power Switch This switch take-up on and off. AUTO Switch This makes the direction of rotation for take-up during printing change automati- cally. -

Page 29: Chapter 2 Operation

Chapter 2 Operation... -

Page 30: Switching The Power On And Off

2-1 Switching the Power On and Off Switching the Power On and Off This machine has three power switches. You switch on all three when using the machine. Whenever printing or cutting is finished, you turn off switches 2 and 3 as required. You also flip down the loading lever to the rear of the machine. -

Page 31: The Power-Saving Feature

2-1 Switching the Power On and Off The Power-saving Feature This machine is provided with a power-saving feature that switches to a low-power "sleep mode" when a fixed interval passes with no operation. The factory default for the time after which the machine switches to the sleep mode is 30 minutes. -

Page 32: Loading And Removing Media

2-2 Loading and Removing Media How to Load Media Load roll media correctly. CAUTION Otherwise the media may fall and cause injury. Roll media weighs about 20 kg (44 lb.). To avoid injury, handle with care. CAUTION Never load media that weights more than 20 kg (44 lb.). CAUTION The machine may fail to withstand the weight and tip over or cause the media to fall. - Page 33 2-2 Loading and Removing Media Insert the reinforcement pipe into the paper tube. Paper tube Reinforcement pipe Mount the paper tube to flange. Flange Paper tube Move the arm to match the length of the paper tube. Tighten the mounting screw securely. Mounting screw Chapter 2 Operation...

- Page 34 2-2 Loading and Removing Media Load the media onto the roll shaft. Front cover Open the front cover. Line up with the core diameter of the loaded roll media and refit the left- and right-hand media flanges. Remove the stopper. Line up the ridges and grooves.

- Page 35 2-2 Loading and Removing Media Fit the roll media onto the media flange that is on the left side when viewed from the back. Press in all the way. Media flange Roll media Move the media flange on the right side (as seen from the back) sideways and fit it into the roll media.

- Page 36 2-2 Loading and Removing Media Fasten the media to the paper tube. Pass the media between the pinch rollers and the grit rollers. Pull the media to a position next to the paper tube. Hold the media at the center and slowly pull it out, being sure to keep it straight. Set the AUTO switch off.

- Page 37 2-2 Loading and Removing Media Use adhesive tape to fasten the media securely to the paper tube. To prevent the pulled-out media from becoming crooked, secure with tape at the two edges and center. First fasten the center in place, then fasten the edges. Take-up with outward curl Paper tube Adhesive tape...

- Page 38 2-2 Loading and Removing Media Operate the MANUAL switch to take up the media. Take up the media for one turn or more. Take-up with outward curl Take up one turn or more. Take-up with inward curl Take up one turn or more.

- Page 39 2-2 Loading and Removing Media Adjust the positioning of the slider unit to match the width of the media. Adjust so that the gap between the media and the slider unit is 1 to 3 millimeters. 1 to 3 mm 1 to 3 mm Slider units Tighten the knobs at the back.

- Page 40 2-2 Loading and Removing Media Set the orientation for automatic take-up. Make the setting for the AUTO switch. Media having an inward curl Media having an outward curl Set the media clamps and close the front cover. Set the media clamps. The media clamps are magnetic.

- Page 41 2-2 Loading and Removing Media When using the core from used-up rolled media as the paper tube Side view of flange When mounting the paper tube on the flanges, make sure that the paper tube fits snugly. Attempting to take up media when the paper tube is not stable may cause problems such as the paper tube coming loose.

-

Page 42: Removing Media

2-2 Loading and Removing Media Removing Media Removal of taken-up roll media from the unit is a task which must be carried out CAUTION by two or more persons. Injury may result if attempted by one person without assistance. CAUTION When the reinforcement pipe is inserted into the paper tube, do not angle the paper tube. - Page 43 2-2 Loading and Removing Media Remove the media that has been taken up. Retaining screw Support the paper tube to prevent from falling. The second person loosens the retaining screw and moves the arm. Detach the media from the flanges. Flange Media Detach the reinforcement pipe from the paper tube.

-

Page 44: Starting Printing

2-3 Starting Printing Getting Ready to Receive Data from a Computer When you have finished loading media, then follow the steps below. This procedure enables the machine to receive data from the computer and perform printing. Procedure Close the front cover. Press (making the light come on). -

Page 45: Printing Test And Cleaning

2-3 Starting Printing Printing Test and Cleaning We recommend performing a printing test to check for problems such as dot drop-out before you carry out actual printing. If problems such as dot drop-out are found, clean the print heads. How to Perform a Printing Test Printing test Dot drop-out Holding down... - Page 46 2-3 Starting Printing How to Perform Cleaning When a printing test reveals dot drop-out or the like, perform cleaning for just the head that is incapable of correct printing. Compared with performing cleaning for all heads, this can reduce the amount of ink consumed. Procedure Press CLEANING...

-

Page 47: If Ink Runs Out

2-4 If Ink Runs Out Checking for Remaining Ink Checking Via the Remaining-ink Indicator Displays the amount of ink remaining in each of the ink cartridges. Amount remaining : 50 to 100% Lighted Lighted Amount remaining : 50% or less Dark Lighted No ink... - Page 48 2-4 If Ink Runs Out Checking Via the Screen Display Procedure Press MENU Press several times. INK REMAINING Press " & W 1839 mm Press SETUP SHEET Press to go back to the original screen. " Cartridge slot & number Amount of ink Much remaining...

-

Page 49: When Ink Cartridges Become Empty

2-4 If Ink Runs Out When Ink Cartridges Become Empty When an ink cartridge is empty, a warning beep sounds and a screen like the one shown in the figure appears. The light for the remaining-ink indica- Flashing tor also flashes. Number and color displayed in alternation Replace the cartridge immediately. -

Page 51: Chapter 3 Maintenance And Adjustment

Chapter 3 Maintenance and Adjustment... -

Page 52: Daily Care And Maintenance

3-1 Daily Care and Maintenance Disposing of Discharged Ink The drain bottle collects discharged fluid. Dispose of collected material before CHECK the bottle becomes full. A message appears when a certain amount of discharged DRAIN BOTTLE fluid collects in the bottle. Follow the procedure below to discard the discharged fluid. - Page 53 3-1 Daily Care and Maintenance Attach the emptied bottle and reset the discharged-fluid count. RESET DRAIN Press COUNT Press a second time. MAINTENANCE DRAIN BOTTLE Press W 1839 mm Press to go back to the original screen. SETUP SHEET Dispose of discharged fluid properly, in accordance with the laws in effect in your locale. Discharged fluid is flammable and contains toxic ingredients.

-

Page 54: Cleaning

3-1 Daily Care and Maintenance Cleaning Pinch rollers Periodically wipe away any grime. Fail- ure to clean properly may result in the transfer of grime to the surface of me- dia. Grit rollers Remove buildup of media and other ma- terial using a brush. -

Page 55: Care And Maintenance Of The Print Heads

56 "Cleaning the Heads Using the Cleaning Kit" *The print heads are components that wear out. Periodic replacement is required, with the frequency of replace- ment depending on use. Purchase them from your authorized Roland DG Corp. dealer or Roland DG Corp. service center. -

Page 56: When Head Cleaning Is Not Effective

3-2 When Head Cleaning Is Not Effective Performing More Powerful Cleaning When the problems such as dot drop-out are not cleared up by the "normal cleaning," try the more forceful "medium cleaning" or the even more forceful "powerful cleaning." Note, however, that this consumes more ink than "normal cleaning,"... -

Page 57: When Powerful Cleaning Is Not Effective

3-2 When Head Cleaning Is Not Effective When Powerful Cleaning Is Not Effective If problems such as dot drop-out persist even after you have performed powerful cleaning several times, then use the cleaning kit to clean the heads. Such cleaning can be effective when carried out periodically, according to the fre- quency of use. -

Page 58: Cleaning The Heads Using The Cleaning Kit

When the machine's head-cleaning feature does not correct the problem, clean the heads using the cleaning kit. If you use up the cleaning kit, purchase a new one from your authorized Roland DG Corp. dealer. The print heads are components that wear out. Periodic replacement is required, with the frequency of re- placement depending on use. - Page 59 3-3 Cleaning the Heads Using the Cleaning Kit Change to the print-head manual-cleaning mode. Press MENU Press several times. SUB MENU Press SUB MENU Press MAINTENANCE Press MAINTENANCE Press CLEANING Preparations are complete when this screen appears. FINISHED? Remove the left and right side covers and maintenance cover. Remove the left and right side covers.

- Page 60 3-3 Cleaning the Heads Using the Cleaning Kit Clean using the cleaning stick. Be especially careful to clean away any fibrous dust (lint). Clean in the sequence shown in the figure below. Cleaning stick Be sure to clean using one of the included cleaning sticks. Gently stroke the sponge.

- Page 61 3-3 Cleaning the Heads Using the Cleaning Kit Reattach the maintenance cover and the side covers and quit the manual cleaning mode. Attach the maintenance cover. Maintenance cover Attach the left and right side covers. Engage the covers on the hooks to install. Screw Screw Side cover...

-

Page 62: Replacing Consumable Parts

3-4 Replacing Consumable Parts Replacing the Wipers The wipers are components that you use when cleaning the print heads. When TIME FOR the screen displays a message like the one shown, it means the item needs to be WIPER REPLACE replaced. - Page 63 3-4 Replacing Consumable Parts Remove the right side cover. Remove the right side cover. Right side cover Touch the location shown in the figure to discharge any static electricity. Replace the wipers. Use the included tweezers. Detach the old wipers. Detach the hook and pull up and out.

- Page 64 3-4 Replacing Consumable Parts Reattach the right side cover and quit the [REPLACE WIPER] menu. Attach the right side cover. Side cover Hook Press NOW PROCESSING.. After the processing to quit the [REPLACE WIPER] menu ends, the MAINTENANCE screen shown in the figure appears. REPLACE WIPER Press W 1839 mm...

-

Page 65: Replacing The Separating Knife

3-4 Replacing Consumable Parts Replacing the Separating Knife If the separating knife becomes dull, replace it with the included replacement blade. CAUTION Be sure to perform operations as specified by these instructions, and never touch any area not specified in the instructions. Sudden movement of the machine may cause injury. - Page 66 3-4 Replacing Consumable Parts Slowly insert it into the groove. Tighten the screw. Take care to ensure that the knife does not slip out of position at this time. Screw Quit the [REPLACE KNIFE] menu. Close the front cover, and press Chapter 3 Maintenance and Adjustment...

-

Page 67: When Not In Use For A Prolonged Period

If the machine will be out of use for a month or longer, follow "Draining Ink and Performing Internal Washing" to wash the heads. This operation requires eight-unused genuine Roland DG Corp. cleaning cartridges. Have these on hand before you start. -

Page 69: Chapter 4 Feature Reference

Chapter 4 Feature Reference... -

Page 70: Pausing Or Canceling Printing

4-1 Pausing or Canceling Printing Canceling Printing Before It Finishes Procedure Press Hold down for one second or longer. Stop sending printing data from the computer. Description pauses printing. Pressing a second time here resumes printing, but a horizontal stripe is produced at the location where printing was stopped. -

Page 71: Setting The Printing Position And Margins

4-2 Setting the Printing Position and Margins Shifting the Print-start Position to the Rear Procedure to move the media. Print-start position Description Using to move the media lets you shift the print-start position toward the rear. Never use . Doing so may cause the take-up unit to pull the media with undue force, resulting in an error or malfunction. -

Page 72: Making Simple Changes To The Printer Settings To Match The Media

4-3 Making Simple Changes to the Printer Settings to Match the Media Saving Optimized Media Settings As Preset Values Procedure Press MENU PRESET Press PRESET Press SAVE Press SAVE to select any one from NAME1 to NAME8. NAME1 Press to save. The present menu settings are saved in the preset you chose in step Press W 1839 mm... -

Page 73: Loading A Saved Preset

4-3 Making Simple Changes to the Printer Settings to Match the Media Loading a Saved Preset Procedure Press MENU PRESET Press twice. LOAD to select the name of a present you want to load. NAME1 Press to load. SETUP SHEET The settings are changed and the screen shown in the figure appears. -

Page 74: Optimizing Printing To Match Media Thickness

4-4 Optimizing Printing to Match Media Thickness Adjusting Head Height to Match Media Thickness Procedure Press MENU Press several times. HEAD HEIGHT HEAD HEIGHT Press MIDDLE MIDDLE Move the lever to adjust the height of the head. High Height-adjustment lever Move firmly, until it stops. -

Page 75: Correcting For Misalignment In Bidirectional Printing

4-4 Optimizing Printing to Match Media Thickness Correcting for Misalignment in Bidirectional Printing Procedure Switch off the power to the take-up unit. Print a test pattern. Press MENU Press ADJUST BI-DIR Press ADJUST BI-DIR Press to start printing. TEST PRINT Read the correction values from the test pattern. - Page 76 4-4 Optimizing Printing to Match Media Thickness Go back to the original screen. Press W 1839 mm Press to go back to the original screen. SETUP SHEET Description The bidirectional-printing mode (in which the heads perform printing during both their outbound pass and return pass) offers the advantage of being fast, but subtle misalignment occurs between the outbound and return passes.

-

Page 77: Correcting For Misalignment In Bidirectional Printing More Precisely

4-4 Optimizing Printing to Match Media Thickness Correcting for Misalignment in Bidirectional Printing More Precisely Procedure Switch off the power to the take-up unit. Print a test pattern. Press MENU Press ADJUST BI-DIR Press ADJUST BI-DIR Press twice. DETAIL SETTING Press DETAIL SETTING TEST PRINT... - Page 78 4-4 Optimizing Printing to Match Media Thickness Enter the correction values that you read. Enter the corresponding correction values for H1 through H8. Press DETAIL SETTING SETTING NO.1 Press to select. to set the correction values. Press for finish making the settings for SETTING NO.1. 0&...

- Page 79 4-4 Optimizing Printing to Match Media Thickness Press to select. to set the correction values. Press for finish making the settings for SETTING NO.4. 0& Go back to the original screen. Press W 1839 mm Press to go back to the original screen. SETUP SHEET Description This corrects, for each head, the minute misalignment that occurs in the bidirectional-printing mode.

-

Page 80: Performing Feed Correction To Alleviate Horizontal Bands And The Like

4-4 Optimizing Printing to Match Media Thickness Performing Feed Correction to Alleviate Horizontal Bands and the Like Procedure Print a test pattern. Press MENU Press several times. CALIBRATION Press CALIBRATION TEST PRINT Press to start printing. Check the test pattern you printed. Gap present Correct results Overlap... - Page 81 4-4 Optimizing Printing to Match Media Thickness Description The movement transfer of media experiences subtle changes due to the thickness of the media. When the movement distance becomes discrepant, horizontal stripes are more likely to occur during printing. We recommend performing correction to match the media you're using.

-

Page 82: Accommodating Various Kinds Of Media

4-5 Accommodating Various Kinds of Media Loading Media Whose Width Cannot Be Detected Automatically The width and the location of the right edge of the media can normally be SHEET SET ERROR SET AGAIN detected automatically by pressing . Depending on the type of media, however, automatic detection of media width may not be possible. -

Page 83: Printing Hard-To-Dry Media

4-5 Accommodating Various Kinds of Media After positioning, close the front cover. SHEET POS. Press to enable the setting. SAVE Press W 1839 mm Press to go back to the original screen. SETUP SHEET Description Depending on the type of media, it may not be possible to detect the width of the media automatically. If this happens, you must set the media type to "CLEAR"... -

Page 84: Preventing Media From Coming Loose

4-5 Accommodating Various Kinds of Media Description You use this when ink dries poorly. Larger values produce progressively slower movement of the media, enabling you to extend the drying time accordingly. Printing time takes correspondingly longer. You can also make this setting on the computer. When you have made the setting on the computer, the computer's setting is used and the printer's setting is ignored. -

Page 85: Speeding Up Printing For Narrow Media

4-5 Accommodating Various Kinds of Media Speeding Up Printing for Narrow Media Procedure Press MENU Press several times. SUB MENU Press SUB MENU Press several times. FULL WIDTH S Press FULL WIDTH S FULL to select [SHEET] or [OFF]. Press to enable the setting. - Page 86 4-5 Accommodating Various Kinds of Media Description Ink tends to collect on the surface of the heads when you use media prone to build up a static charge, when the ambient temperature is low, and at other such times. Under some conditions, this ink may be transferred to the media. Use this feature at such times.

-

Page 87: Changing How The Printer Operates

4-6 Changing How the Printer Operates Determining What Happens When an Ink Cartridge Is Empty Procedure Press MENU Press several times. SUB MENU Press SUB MENU Press twice. INK CONTROL Press twice. EMPTY MODE to make the setting. STOP CONT. Press to enable the setting. -

Page 88: Setting The Interval Until Activation Of The Sleep Mode

4-6 Changing How the Printer Operates Description Choosing "5 mm" at this menu reduces the left and right margins, expanding the printing area. "20 mm" sets the margins for the printing area at 20 millimeters. "5 mm" sets the margins for the printing area at 5 millimeters. When "5 mm"... -

Page 89: Changing The Menu Language And The Units Of Measurement

4-6 Changing How the Printer Operates Press SLEEP Press SETTING Press SETTING to select [DISABLE]. ENABLE DISABLE Press to enable the setting. Press W 1839 mm Press to go back to the original screen. SETUP SHEET Default Setting [SETTING]: ENABLE Changing the Menu Language and the Units of Measurement Procedure Hold down... - Page 90 4-6 Changing How the Printer Operates Description This menu returns all settings to the same as their factory defaults. However, the settings for "LANGUAGE," and "LENGTH UNIT" are not returned to the factory defaults. Chapter 4 Feature Reference...

-

Page 91: Recording The Amount Of Remaining Media

4-7 Recording the Amount of Remaining Media Displaying the Amount of Remaining Media on the Screen Procedure Press MENU SHEET REMAIN Press Press SHEET REMAIN SET LENGTH Press Press SET LENGTH to set the amount of media remaining. 0.0 m 25.0 m Press to enable the setting. -

Page 92: Printing The Amount Of Remaining Media

4-7 Recording the Amount of Remaining Media Press AUTO DISPLAY to select [ENABLE] . DISABLE ENABLE Press to enable the setting. Press W 1839 mm L 25.0 m Press to go back to the original screen. SETUP SHEET L 25.0m Description Setting this to [ENABLE] automatically displays [SHEET REMAIN] whenever you change the media and finish setup. -

Page 93: Viewing System Information

4-8 Viewing System Information Viewing the Serial Number, Firmware Version, and Other Information Procedure Press MENU Press several times. SYSTEM INFO. Press SYSTEM INFO. to choose the information you want to view. SERIAL NO. Press SERIAL NO. ZS00001 W 1839 mm Press SETUP SHEET Press... -

Page 94: Performing Maintenance

4-9 Performing Maintenance Draining Ink and Performing Internal Washing Procedure Press MENU Press several times. SUB MENU Press SUB MENU Press twice. INK CONTROL Press INK CONTROL HEAD WASH Press Press to execute. Description This drains the ink inside the printer and washes the interior using cleaning cartridges as a preliminary for moving the printer or conducting maintenance. -

Page 95: Menu List

4-10 Menu List Main menu Press To the [SHEET REMAIN] menu To the [NAME8] menu To the [NAME] menu MENU PRESET LOAD p 70, p 71 PRESET LOAD NAME1 LOAD NAME2 LOAD NAME3 LOAD NAME4 LOAD NAME5 LOAD NAME6 LOAD NAME7 LOAD NAME8... - Page 96 4-10 Menu List Continue Continue Continue To the [NAME8] menu PRESET NAME NAME NAME NAME1 To the [LOAD] menu NAME NAME NAME2 NAME NAME NAME3 NAME NAME NAME4 NAME NAME NAME5 NAME NAME NAME6 NAME NAME NAME7 NAME NAME NAME8 To the [NAME1] menu To the [DETAIL SETTING] menu MENU...

- Page 97 4-10 Menu List Continue Continue Continue SUB MENU SIDE MARGIN p 85 SIDE MARGIN 20 mm 20 mm SUB MENU p 63 REPLACE KNIFE SUB MENU SCAN INTERVAL p 81 SCAN INTERVAL SUB MENU VACUUM POWER p 82 VACUUM POWER AUTO AUTO SUB MENU...

- Page 98 4-10 Menu List Continue To the [AUTO DISPLAY] menu MENU SHEET REMAIN p 89, p 90 SHEET REMAIN PRINT MEMO To the [PRESET] menu SHEET REMAIN SET LENGTH SET LENGTH 0.0 m 0.0 m SHEET REMAIN AUTO DISPLAY AUTO DISPLAY DISABLE DISABLE To the [PRINT MEMO] menu...

-

Page 99: Language And Unit Menu

4-10 Menu List Language and Unit Menu Hold down and switch on the sub power. MENU LANGUAGE p 87 ENGLISH LENGTH UNIT p 87 SETUP SHEET Cleaning Menu Press Hold down for one second or longer To the [POWERFUL CL.] menu CLEANING NORMAL CL. -

Page 101: Chapter 5 What To Do If

Chapter 5 What to Do If... -

Page 102: The Machine Doesn't Run

5-1 The Machine Doesn't Run The Printer Unit Doesn't Run Is there some obstruction between the mirror and sensor? If no corrective action is taken when the sensor has de- Is the power switched on? Switch on the printer's main power, then press the sub power tected an obstruction, take-up is automatically switched off. -

Page 103: Attractive Printing Is Impossible

5-2 Attractive Printing Is Impossible Printed Results Are Coarse or Contain Horizontal Stripes Colors Are Unstable or Uneven Do the print heads show dot drop-out? Is the media wrinkled? Carry out a printing test and make sure no dot drop-out If the media is wrinkled and comes loose from the platen, occurs. - Page 104 5-2 Attractive Printing Is Impossible Are the print heads dirty? The following may cause ink to drip on the media during printing. • Buildup of fibrous dust (lint) around the heads • Ink transferred to the heads due to rubbing against the media.

-

Page 105: The Media Jams

5-3 The Media Jams The Media Jams If an error message is displayed because the media has jammed, immediately correct the problem. Fail- ure to do so may damage the print heads. p 108 [MOTOR ERROR TURN POWER OFF] Is the media warped or wrinkled? Many factors can cause warping or wrinkling. -

Page 106: The Media Cannot Be Taken Up Smoothly

5-4 The Media Cannot Be Taken Up Smoothly The Media Cannot Be Taken Up Smoothly Is media feed unstable? Various factors can make media feed unstable. Refer to the following and correct the problem. p 105 "Media Wrinkles or Shrinks, or Feed Is Unstable" The Media Is Not Straight Is the width of the media 710 millimeters or more? Media cannot be rerolled straight when its width is less... -

Page 107: Media Wrinkles Or Shrinks, Or Feed Is Unstable

5-5 Media Wrinkles or Shrinks, or Feed Is Unstable A variety of problems can occur if the media feed is not smooth. This can cause such problems as poor printing quality, contact with the media by the print heads, mis- aligned positioning, media jams, or poor take-up. -

Page 108: The Print Heads Stopped Moving

If the heads still do not move, carry out the following emer- gency response measure, then contact your authorized Roland DG Corp. dealer or Roland DG Corp. service cen- ter. 1. Switch off the main power and detach the right side cover. -

Page 109: If A Message Appears

5-7 If a Message Appears These are the main messages that appear on the machine's [TIME FOR MAINTENANCE] display to prompt correct operation. They do not indi- It is time to clean the heads using the cleaning kit. After cate any error. Follow the prompts and take action ac- verifying, press cordingly. -

Page 110: If An Error Message Appears

Roland DG Corp. Press any key to clear the error. Pull back the loading lever, dealer. then press... - Page 111 5-8 If an Error Message Appears [TEMPERATURE IS TOO HIGH **°C] The temperature of the location where the machine is installed has risen above the ambient tempera- ture at which the machine can operate. Operation cannot be continued. Switch off the sub power. The displayed temperature is room temperature of installa- tion location now.

-

Page 113: Chapter 6 Specifications

Chapter 6 Specifications... -

Page 114: Usable Media

6-1 Usable Media Conditions for Usable Media Media width 28 to 74 inches (710 to 1879 mm) Roll outer diameter ( A) Maximum 180 mm (7-1/16 inches) Paper tube (core) inner diameter (B) 3 inches (76.2 mm) or 2 inches (50.8 mm) Media thickness (C) Maximum 1.0 mm (39 mil) Roll weight... -

Page 115: Printing Area

6-2 Printing Area Printing Area and Margins Media 10 mm (0.4 in.) (*3) 10 mm (0.4 in.) (*3) Approx. 20 mm Approx. 20 mm (0.8 in.) (*3) (0.8 in.) (*3) Printing area Media clamp Media clamp Left margin Right margin (*1) Approx. -

Page 116: Locations Of The Power Rating And Serial Number Labels

6-3 Locations of the Power Rating and Serial Number Labels Printer Serial Number This is required when you seek maintenance, servic- ing, or support. Never peel off the label or let it get dirty. Power Rating Use an electrical outlet that meets the requirements for voltage, frequency, and amperage given here. -

Page 117: Specifications

RIP, User's Manual, Setup Guide, Roland-PrintServer Network Set- tings Guide, Roland-PrintServer CD-ROM, cleaning kit, The length of printing is subject to the limitations of the program. - Page 120 R2-070228...

Need help?

Do you have a question about the Hi-Fi Express FP-740 and is the answer not in the manual?

Questions and answers