Table of Contents

Advertisement

USER/SERVICE MANUAL

O

IL

C

OMPRESSED

WITH ACTIVATED CHARCOAL FILTERS FOR

CONDENSATE AND EXHAUSTED AIR

WARRANTY NOTICE

Failure to follow the instructions

and procedures in this manual or,

misuse of this equipment will

VOID its warranty!

W

S

ATER

EPARATOR FOR

A

OWS-88 • OWS-2I0 • OWS-420

OWS-880 • OWS-I700 • OWS-2I00

C

IR

ONDENSATE

PART NUMBER:

02250194-770 R00

KEEP FOR

FUTURE

REFERENCE

SULLAIR CORPORATION

©

Advertisement

Table of Contents

Summary of Contents for Sullair OWS-88

- Page 1 USER/SERVICE MANUAL ATER EPARATOR FOR OMPRESSED ONDENSATE WITH ACTIVATED CHARCOAL FILTERS FOR CONDENSATE AND EXHAUSTED AIR OWS-88 • OWS-2I0 • OWS-420 OWS-880 • OWS-I700 • OWS-2I00 PART NUMBER: 02250194-770 R00 WARRANTY NOTICE KEEP FOR Failure to follow the instructions FUTURE...

- Page 2 AIR CARE SEMINAR TRAINING Sullair Air Care Seminars are courses that provide hands-on instruction for the proper operation, maintenance, and servicing of Sullair products. Individual seminars on Industrial compressors and compressor electrical systems are offered at regular intervals throughout the year at Sullair’s corporate headquarters training facility located at Michigan City, Indiana.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1—DESCRIPTION OIL WATER SEPARATOR MODELS SECTION 2—INSTALLATION & MAINTENANCE PLACE OF INSTALLATION FLOW OF CONDENSATE CONNECTIONS START-UP CONDENSATE FLOW RATE WASTE OIL DISCHARGING CLEAN WATER INSPECTIONS FILTERING 2.10 FILTERS CHANGING 2.11 CHECKING OF DISCHARGING WATER 2.12 DISPOSAL 2.13 ENCLOSURES... - Page 4 TABLE OF CONTENTS...

-

Page 5: Section 1-Description

The condensate is approximately 95% water and 5%. therefore a Sullair OWS has been specially developed to reduce or eliminate the amount of oil in the condensate and reducing or eliminating disposal costs and related issues. -

Page 6: Oil Water Separator Models

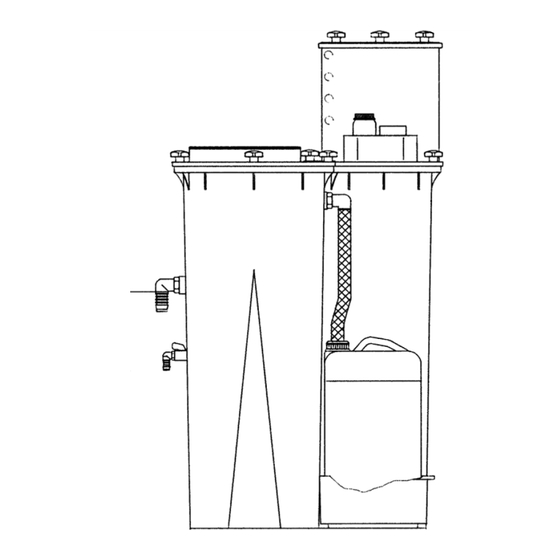

OIL WATER SEPARATOR SECTION 1 OIL WATER SEPARATOR MODELS Figure 1-1: OWS-88... - Page 7 SECTION 1 OIL WATER SEPARATOR Figure 1-2: OWS-210...

- Page 8 NOTES Figure 1-3: OWS-420...

- Page 9 SECTION 1 OIL WATER SEPARATOR Figure 1-4: OWS-880...

- Page 10 OIL WATER SEPARATOR SECTION 1 Figure 1-5: OWS-1700/2100...

-

Page 11: Section 2-Installation & Maintenance

The waste oil flows out of the tube to which an oil See Table 2-1. drain hose will be connected, leading to an oil- container. The OWS-88-2I0-420 does not have an oil START-UP discharge (oil-container). The separated oil will be... - Page 12 OIL WATER SEPARATOR SECTION 2...

-

Page 13: Filtering

(OWS-2I0-420), and/or remove lid and filter It is recommended to soak the Charcoal (OWS-88). Carefully remove the combined filter from filter for 4 to 6 hours in clean water before the filter chamber. Clean the entire OWS. Insert the it is placed into the OWS. -

Page 14: Checking Of Discharging Water

OIL WATER SEPARATOR SECTION 2 2.11 CHECKING OF EMIANNUAL DISCHARGING WATER • Replace filters and clean tank as needed NNUAL (see also Test & Service Log) • Replace filters (min. once a year, if necces- A test sample should be taken from the test valve (8). sary more often!) The water must be clean and clear. -

Page 15: Technical Information On The Oil-Water Separator

OWS. Below are SEPARATOR some information and rules which will help you. Table 2-4: Capacity of OWS - Oil Water Separators in cfm of installed compressor-capacity Type of Compressor Screw-Compressor OWS Model OWS-88 OWS-210 OWS-420 OWS-880 OWS-1700 OWS-2100 non emulsified oils... -

Page 16: Consequence

We recommmend to visually control the When the filters are unused, they are able to absorb discharging condensate regularly and to change the some of the oil from the emulsion. Sullair can not filters if necessary. guarantee that the OWS will work on all emulsion. -

Page 17: Optional Level Control Installation

The Level/Filter control, which can be field installed on all OWS separators, except the OWS-88. The level-switch is available in two versions: A. The Single Pole Double Throw level switch. The contacts are not energized. - Page 18 NOTES...

-

Page 19: Section 3-Test & Service Log

OIL WATER SEPARATOR Section 3 TEST & SERVICE LOG GENERAL INFORMATION 2. Free the test strips of water droplets by lightly shaking them. Environmental control officers may want to see proof 3. Observe color changing of the strips: oil in of the regular inspect and maintenance records of the condensate will turn the strip dark blue. - Page 20 OIL WATER SEPARATOR SECTION 3 Test and Service Log (unit should be checked 1-4 times a month Filtrate Controls Service Completed Color Change of Optical Control Water Filter Air Filter Date Name Oil Test Paper None Few spots Dark blue Clear Cloudy Tested...

- Page 21 SECTION 3 OIL WATER SEPARATOR Test and Service Log (unit should be checked 1-4 times a month Filtrate Controls Service Completed Color Change of Optical Control Water Filter Air Filter Date Name Oil Test Paper None Few spots Dark blue Clear Cloudy Tested...

- Page 22 NOTES Test and Service Log (unit should be checked 1-4 times a month Filtrate Controls Service Completed Color Change of Optical Control Water Filter Air Filter Date Name Oil Test Paper None Few spots Dark blue Clear Cloudy Tested Changed Tested Changed 1-5 mg/ltr.

- Page 23 NOTES...

- Page 24 Always air. Always there. WWW.SULLAIR.COM SULLAIR CORPORATION 3700 East Michigan Boulevard • Michigan City, Indiana, 46360 U.S.A. Telephone: 1-219-879-5451 Printed in the U.S.A. Specifications subject to change without prior notice. E11EP...

Need help?

Do you have a question about the OWS-88 and is the answer not in the manual?

Questions and answers