Summary of Contents for MFZ Ovitor MDF Series

- Page 1 Operating Instructions for Roll-Up Door Operators / MDF Roll-Up Door Operator / MDF / Rev. 0.0 – 1...

- Page 2 Contents General safety instructions Contents Guarantee Key to symbols The function and safety of the equipment is only guaranteed General safety instructions if the warning and safety instructions included in these opera- Overview of products ting instructions are adhered to. Installation MFZ Antriebe GmbH + Co.KG is not liable for any personal Initial Operation...

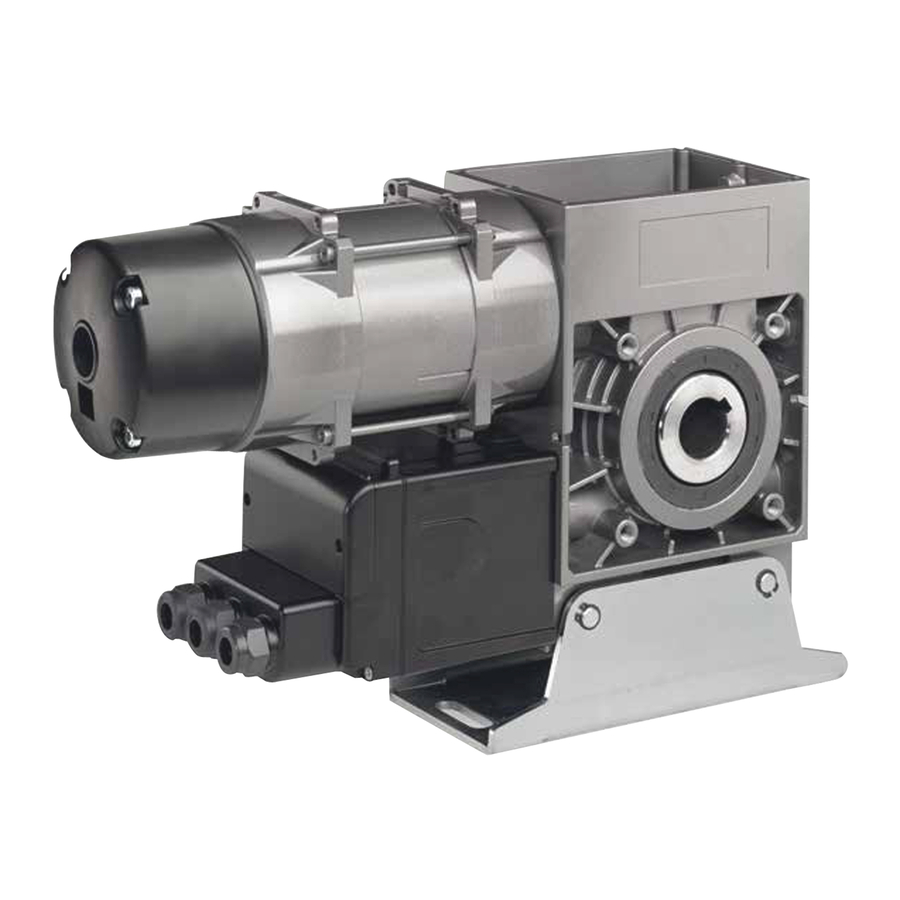

- Page 3 Overview of products 4.1 Safety catch device as a safety feature Regulations and bases for testing For connecting, programming and servicing, the following The MDF roll-up door operator is a slip-on drive with an regulations must be observed (the list is not exhaustive). incorporated safety catch device.

- Page 4 Overview of products Installation 5.1 Preparation - MDF 30-30-12 KU - MDF 30-42-12 KU - MDF 30-29-17 KU Danger! - MDF 30-27-12 100% KU - MDF 30-19-17 100% KU To avoid injury, the following points must be - MDF 30-50-12 KU observed: - The operator must be installed free of any - MDF 30-30-12 KE...

- Page 5 Slip-on assembly Warning! To avoid damage to the operator and to the door, the operator must be mounted on a bracket with a pendulum foot or a torque support bracket so that it is vibration dampened. Information: The relevant instructions for the door must be observed when fitting the operator to the door.

- Page 6 Installation Initial Operation Installation of the emergency hand chain 6.1 Preparation (only for operators with emergency hand chain) Warning! Information: To avoid damage to the operator, the To ensure that they work correctly, the chain following points must be observed: links must not be twisted.

- Page 7 Connection of model MDF 05 6.3 Connection of model MDF 20 and subsequent models Open the operator Insert the cables Danger! Danger! To avoid injury, the system must be discon- nected from the power supply during the To avoid injury, the system must be discon- cabling work.

- Page 8 Initial Operation 3 x 400 V star connection Close the operator (standard, pluggable) The motor is factory-wired for connection to a 3 x 400 V mains supply in star connection. ☞ Place the cap on the operator. ☞ Screw the cap on tightly. ☞...

- Page 9 Identification of wires 3 x 400 V star connection Blue White Black Brown Green Potential-free connection OPEN Potential-free connection CLOSE OPEN additional limit Switch off safety circuit Switch off OPEN end position switch (standard only in Switch off CLOSED end position the case of operators Internal safety circuit without integrated control...

- Page 10 Initial Operation Manual settings for model MDF 05 The locking screw (H) is used to lock the corresponding control cam in the desired position. Finer adjustment can be made with the fine adjustment screw (G). Set the CLOSED end position ☞...

- Page 11 Manual settings for model MDF 20 and subsequent models Use the adjusting tool (I) to tune the fine adjustment screw and the locking screw. Set the CLOSED end position ☞ Drive the door to the CLOSED end position. ☞ Set the control cam so that the CLOSED limit switch (E) is actuated.

- Page 12 Initial Operation Digital settings – Wiring allocation, Limit switch and safety circuit for drive AVE (absolute value encoder) plug Electronic interface The numbers on the plug are also the wire-numbers. Safety circuit input RS 485 B RS485 A Safety circuit output AVE plug (absolute value encoder plug) 7...18V AVE plug terminal (absolute value encoder plug...

- Page 13 Emergency operation Check the system Danger! To avoid injury, the following points must be Check the direction of travel observed: ☞ Drive the door in the CLOSED direction. - Emergency operation may only be carried The operator must close the door. out from a safe standing position.

- Page 14 Emergency operation Operation with emergency hand chain Operation with emergency hand crank ☞ Push the emergency hand crank into the operator as far as it Releasing ☞ will go. The control voltage will be interrupted and the door Gently pull the chain with the red handle downwards as far can no longer be operated electrically.

- Page 15 Maintenance Warning! To avoid damage to the operator and door, the following points must be observed: - Maintenance must only be carried out by authorized persons. - Directive BGR 232 must be complied with. - Worn or faulty parts must be replaced. - Only approved parts may be installed.

- Page 16 Technical data MDF 05-10-15 KU MDF 20-22-12 KU MDF 20-15-12 KU 100% MDF 05-10-15 KE MDF 20-22-12 KE MDF 20-15-12 KE 100% Type (KU / KE): MDF 05-14-12 KU MDF 20-15-17 KU MDF 20-10-17 KU 100% MDF 05-14-12 KE MDF 20-15-17 KE MDF 20-10-17 KE 100% Driving torque (Nm): 100 / 140...

- Page 17 MDF 30-42-12 KU MDF 30-27-12 KU 100% MDF 30-50-12 KU MDF 30-30-12 KU MDF 30-42-12 KE MDF 30-27-12 KE 100% MDF 30-50-12 KE Type (KU / KE): MDF 30-29-17 KU MDF 30-19-17 KU 100% MDF 30-45-15 KU MDF 30-30-12 KE MDF 30-29-17 KE MDF 30-19-17 KE 100% MDF 30-45-15 KE...

- Page 18 Technical data MDF 50-65-10 KU MDF 50-75-10 KU MDF 6-100-9 KU Type (KU / KE): MDF 6-100-9 KU 100% MDF 50-75-10 KE MDF 6-100-9 KE MDF 50-65-10 KE Driving torque (Nm): 1000 1000 Maximum safety catch torque 3494 3494 5599 5599 (Nm): Permissible torque (Nm):...

- Page 19 MDF 05-10-15 KU (Crank) MDF 05-14-12 KU (Crank) MDF 05-10-15 KE (Chain) MDF 05-14-12 KE (Chain) Roll-Up Door Operator / MDF / Rev. 0.0 – 19...

- Page 20 Technical data MDF 20-22-12 KU (Crank) MDF 20-15-17 KU (Crank) 20 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 21 MDF 20-22-12 KE (Chain) MDF 20-15-17 KE (Chain) Roll-Up Door Operator / MDF / Rev. 0.0 – 21...

- Page 22 Technical data MDF 20-15-12 KU 100% (Crank) MDF 20-10-17 KU 100% (Crank) MDF 20-15-12 KE 100% (Chain) MDF 20-10-17 KE 100% (Chain) 22 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 23 MDF 30-42-12 KU (Crank) MDF 30-42-12 KE (Chain) Roll-Up Door Operator / MDF / Rev. 0.0 – 23...

- Page 24 Technical data MDF 30-29-17 KU (Crank) MDF 30-29-17 KE (Chain) 24 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 25 MDF 30-27-12 KU 100% (Crank) MDF 30-30-12 KU (Crank) Roll-Up Door Operator / MDF / Rev. 0.0 – 25...

- Page 26 Technical data MDF 30-30-12 KE (Chain) MDF 30-50-12 KU (Crank) 26 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 27 MDF 30-50-12 KE (Chain) MDF 50-65-10 KU (Crank) Roll-Up Door Operator / MDF / Rev. 0.0 – 27...

- Page 28 Technical data MDF 50-65-10 KE (Chain) MDF 50-75-10 KU (Crank) 28 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 29 MDF 50-75-10 KE (Chain) MDF 6-100-9 KU (Crank) Roll-Up Door Operator / MDF / Rev. 0.0 – 29...

- Page 30 Technical data MDF 6-100-9 KE (Chain) MDF 6-100-9 KU 100% (Crank) 30 – Roll-Up Door Operator / MDF / Rev. 0.0...

- Page 31 10. EU Declaration of Conformity Manufacturer: MFZ Antriebe GmbH & Co. Kg, Neue Muehle 4, 48739 Legden, Germany We hereby declare that by virtue of their conceptual develop- ment and design, as well as their manufacture as we have brought them onto the market, the products cited below: Roll-Up Door Operator / MDF conform to the relevant basi c health and safety regulations of the following EU directives and standards:...

Need help?

Do you have a question about the MDF Series and is the answer not in the manual?

Questions and answers