Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for ProSoft MVI46-S3964R

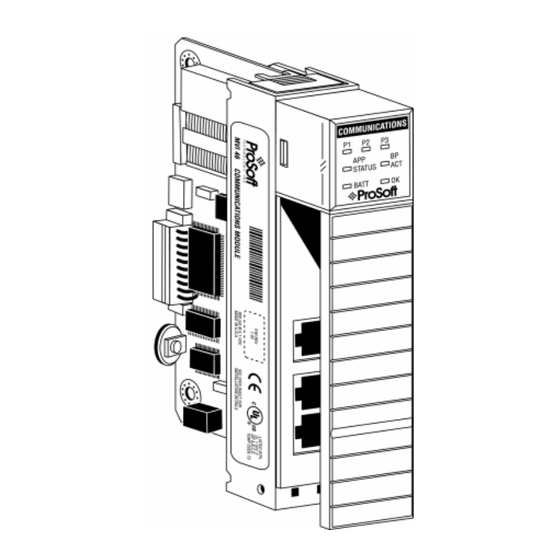

- Page 1 MVI46-S3964R SLC Platform Siemens 3964R Protocol User Manual April 17, 2008...

-

Page 2: Please Read This Notice

Successful application of this module requires a reasonable working knowledge of the Rockwell Automation SLC hardware, the MVI46-S3964R Module and the application in which the combination is to be used. For this reason, it is important that those responsible for implementation satisfy themselves that the combination will meet the needs of the application without exposing personnel or equipment to unsafe or inappropriate working conditions. -

Page 3: Prosoft® Product Documentation

MVI46-S3964R User Manual April 17, 2008 PSFT.S3964R.MVI46.UM.08.04.17 ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk® and RadioLinx ® are Registered Trademarks of ProSoft Technology, Inc. ProSoft® Product Documentation In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments. -

Page 5: Table Of Contents

PLEASE READ THIS NOTICE........................ 2 Battery Life Advisory.......................... 2 Your Feedback Please ........................2 ProSoft® Product Documentation ..................... 3 GUIDE TO THE MVI46-S3964R USER MANUAL .................. 7 START HERE............................ 9 1.1 System Requirements......................... 9 1.2 Package Contents........................10 1.3 Install ProSoft Configuration Builder Software................10 1.4 Setting Jumpers ........................ - Page 6 MVI46-S3964R ♦ SLC Platform Contents Siemens 3964R Protocol 4.1.1 Required Hardware ........................31 4.1.2 The Configuration/Debug Menu ....................32 4.1.3 Main Menu..........................34 4.1.4 Database View Menu ........................ 37 4.1.5 Backplane Menu........................39 4.1.6 Protocol Serial 3964R Menu...................... 40 4.2 LED Status Indicators....................... 41 4.2.1...

-

Page 7: Guide To The Mvi46-S3964R User Manual

Start Here MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Guide to the MVI46-S3964R User Manual Function Section to Read Details → Introduction This Section introduces the customer to the module. Included are: package contents, (Must Do) Start Here (page 9) system requirements, hardware installation, and basic configuration. - Page 8 MVI46-S3964R ♦ SLC Platform Start Here Siemens 3964R Protocol Page 8 of 74 ProSoft Technology, Inc. April 17, 2008...

-

Page 9: Start Here

The MVI46-S3964R module requires the following minimum hardware and software components: Rockwell Automation SLC 5/02 M0/M1 capable processors (or newer), with compatible power supply and one free slot in the rack, for the MVI46-S3964R module. The module requires 800mA of available power. Rockwell Automation RSLogix 500 programming software. -

Page 10: Package Contents

Install ProSoft Configuration Builder Software You must install the ProSoft Configuration Builder (PCB) software in order to configure the MVI46-S3964R module. You can always get the newest version of ProSoft Configuration Builder from the ProSoft Technology web site. To install ProSoft Configuration Builder from the ProSoft Web Site Open your web browser and navigate to http://www.prosoft-... - Page 11 When the download is complete, locate and open the file, and then follow the instructions on your screen to install the program. If you do not have access to the Internet, you can install ProSoft Configuration Builder from the ProSoft Solutions CD-ROM, included in the package with your MVI46-S3964R module.

-

Page 12: Setting Jumpers

Install the Module in the Rack If you have not already installed and configured your SLC processor and power supply, please do so before installing the MVI46-S3964R module. Refer to your Rockwell Automation product documentation for installation instructions. Warning: You must follow all safety instructions when installing this or any other electronic devices. - Page 13 Start Here MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Align the module with the top and bottom guides, and slide it into the rack until the module is firmly against the backplane connector. With a firm but steady push, snap the module into place.

-

Page 14: Connect Your Pc To The Processor

MVI46-S3964R ♦ SLC Platform Start Here Siemens 3964R Protocol Connect your PC to the Processor Connect the right-angle connector end of the cable to your controller at the communications port. Connect the straight connector end of the cable to the serial port on your computer. -

Page 15: Configuring Rslinx

Start Here MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol If you are not already online to the processor, open the Communications menu, and then choose Download. RSLogix will establish communication with the processor. Click the Download button to transfer the sample program to the processor. - Page 16 MVI46-S3964R ♦ SLC Platform Start Here Siemens 3964R Protocol Open the Communications menu, and choose Configure Drivers. This action opens the Configure Drivers dialog box. Note: If the list of configured drivers is blank, you must first choose and configure a driver from the Available Driver Types list.

-

Page 17: Connect Your Pc To The Module

Start Here MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Click to select the driver, and then click Configure. This action opens the Configure Allen-Bradley DF1 Communications Device dialog box. Click the Auto-Configure button. RSLinx will attempt to configure your serial port to work with the selected driver. -

Page 18: April

MVI46-S3964R ♦ SLC Platform Start Here Siemens 3964R Protocol Attach the other end to the serial port on your PC or laptop. Page 18 of 74 ProSoft Technology, Inc. April 17, 2008... -

Page 19: Module Configuration

PRT2 of the MVI46-S3964R. The serial parameters of the communication partners are to be set to 9600 Baud, even parity, 8 bit and 1 stop bit if the standard parameters of the MVI46-S3964R will be used. The assignment of the RS-232 connection cable between PRT1/2 (9 pole) and... -

Page 20: Prosoft Configuration Builder

The following illustration shows the ProSoft Configuration Builder window with a new project. Your first task is to add the MVI46-S3964R module to the project. Use the mouse to select "Default Module" in the tree view, and then click the right mouse button to open a shortcut menu. - Page 21 Choose Module Type dialog box. In the Product Line Filter area of the dialog box, select MVI46. In the Select Module Type dropdown list, select MVI46-S3964R, and then click OK to save your settings and return to the ProSoft Configuration Builder window.

- Page 22 MVI46-S3964R ♦ SLC Platform Module Configuration Siemens 3964R Protocol Adding a Module To add a module to your project: Double-click the Default Module icon to open the Choose Module Type dialog box. On the Choose Module Type dialog box, select the module type.

-

Page 23: Set Module Parameters

2.2.2 Set Module Parameters Notice that the contents of the information pane and the configuration pane changed when you added the MVI46-S3964R module to the project. At this time, you may wish to rename the "Default Project" and "Default Location"... -

Page 24: Module]

MVI46-S3964R ♦ SLC Platform Module Configuration Siemens 3964R Protocol Comment Entries To add comments to your configuration file: Click the plus sign to the left of the icon to expand the Module Comments. Double-click the icon. The Edit - Module Comment dialog appears. -

Page 25: Backplane 46]

Module Configuration MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol This parameter assigns a name to the module that can be viewed using the configuration/debug port. Use this parameter to identify the module and the configuration file. [Backplane 46] This section identifies the method of failure for the communications for the module if the processor is not in run. -

Page 26: Baud Rate

MVI46-S3964R ♦ SLC Platform Module Configuration Siemens 3964R Protocol 2.5.2 Baud Rate 300 to 115200 This parameter specifies the baud rate to be used on the port. Valid values are 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200. -

Page 27: Priority

(copy) the updated Project file from your PC to the module. To Download the Project File In the tree view in ProSoft Configuration Builder, click once to select the MVI46-S3964R module. Open the Project menu, and then choose Module / Download. The program will scan your PC for a valid com port (this may take a few seconds). - Page 28 Download button. The module will perform a platform check to read and load its new settings. When the platform check is complete, the status bar in ProSoft Configuration Builder will be updated with the message "Module Running". Page 28 of 74 ProSoft Technology, Inc.

-

Page 29: Ladder Logic

Introduction.................... 29 Commands .................... 30 Ladder logic is required for application of the MVI46-S3964R module. Tasks that must be handled by the ladder logic are module data transfer, special block handling and status data receipt. Additionally, a power-up handler may be needed to handle the initialization of the module's data and to clear any processor fault conditions. -

Page 30: The 3964R Communication Program

During the processes described above additional status/error messages may be transferred from the MVI46-S3964R to the SLC processor (refer to Module Status Data Table (page 60)). Refer to Error Processing for more information. Commands The CMDS sub-routine is used to handle special block processing. -

Page 31: Diagnostics And Troubleshooting

You can connect directly from your computer's serial port to the serial port on the module to view configuration information, perform maintenance, and send (upload) or receive (download) configuration files. ProSoft Technology recommends the following minimum hardware to connect your computer to the module: 80486 based processor (Pentium preferred) 1 megabyte of memory At least one UART hardware-based serial communications port available. -

Page 32: The Configuration/Debug Menu

Because this is a text-based menu system, you enter commands by typing the command letter from your computer keyboard in the diagnostic window in ProSoft Configuration Builder (PCB). The module does not respond to mouse movements or clicks. The command executes as soon as you press the command letter —... - Page 33 On computers with more than one serial port, verify that your communication program is connected to the same port that is connected to the module. If you are still not able to establish a connection, contact ProSoft Technology for assistance.

-

Page 34: Main Menu

MVI46-S3964R ♦ SLC Platform Diagnostics and Troubleshooting Siemens 3964R Protocol The organization of the menu structure is represented in simplified form in the following illustration: The remainder of this section shows you the menus available for this module, and briefly discusses the commands available to you. - Page 35 Only use these commands if you are specifically directed to do so by ProSoft Technology Technical Support staff. Some of these command keys are not listed on the menu, but are active nevertheless. Please be careful when pressing keys so that you do not accidentally execute an unwanted command.

- Page 36 Only use these commands if you are specifically directed to do so by ProSoft Technology Technical Support staff. Some of these command keys are not listed on the menu, but are active nevertheless. Please be careful when pressing keys so that you do not accidentally execute an unwanted command.

-

Page 37: Database View Menu

Diagnostics and Troubleshooting MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Press [Esc] to restart the module and force all drivers to be loaded. The module will use the configuration stored in the module's Flash ROM to configure the module. 4.1.4 Database View Menu Press [D] from the Main Menu to open the Database View menu. - Page 38 MVI46-S3964R ♦ SLC Platform Diagnostics and Troubleshooting Siemens 3964R Protocol Displaying the Current Page of Registers Again This screen displays the current page of 100 registers in the database. Moving Back Through 5 Pages of Registers Press [-] from the Database View menu to skip back to the previous 500 registers of data.

-

Page 39: Backplane Menu

Diagnostics and Troubleshooting MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Returning to the Main Menu Press [M] to return to the Main Menu. 4.1.5 Backplane Menu Press [B] from the Main Menu to view the Backplane Data Exchange List. Use this command to display the configuration and statistics of the backplane data transfer operations. -

Page 40: Protocol Serial 3964R Menu

MVI46-S3964R ♦ SLC Platform Diagnostics and Troubleshooting Siemens 3964R Protocol Use this command to display the configuration and statistics of the backplane data transfer operations between the module and the processor. The information on this screen can help determine if there are communication problems between the processor and the module. -

Page 41: Led Status Indicators

The battery voltage is low or battery is not present. Allow battery to charge by keeping module plugged into rack for 24 hours. If BAT LED still does not go off, contact ProSoft Technology, as this is not a user serviceable item. -

Page 42: Clearing A Fault Condition

Verify the configuration data being transferred to the module from the SLC processor. If the module's OK LED does not turn green, verify that the module is inserted completely into the rack. If this does not cure the problem, contact ProSoft Technology Support. 4.2.2 Troubleshooting Use the following troubleshooting steps if you encounter problems when the module is powered up. - Page 43 Diagnostics and Troubleshooting MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Module Errors Problem Description Steps to take BP ACT LED remains This indicates that backplane transfer operations are failing. Connect to off or blinks slowly the module's Configuration/Debug port to check this.

- Page 44 MVI46-S3964R ♦ SLC Platform Diagnostics and Troubleshooting Siemens 3964R Protocol Page 44 of 74 ProSoft Technology, Inc. April 17, 2008...

-

Page 45: Reference

Reference Documents................60 Status Data.................... 60 Error Codes ................... 61 Product Specifications The MVI46 S3964R module from ProSoft Technology allows point-to-point communication between an SLC processor and a partner with 3964R (with or without RK512) communication capability. 5.1.1 Features and Benefits The 3964R protocol (with or without RK512) was designed by Siemens for bi- directional data communication through a point-to-point connection. -

Page 46: Hardware Specifications

MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol 5.1.3 Hardware Specifications Specification Description Backplane Current Load 800 ma @ 5V (from backplane) Operating Temperature 0 to 60°C (32 to 140°F) Storage Temperature -40 to 85°C (-40 to 185°F) Shock 30g operational, 50g non-operational... -

Page 47: Functional Overview

The safety of data transmission on the line is guaranteed by a BCC checksum. You should have sufficient knowledge about the 3964R protocol in order to understand the operation of the driver for the MVI46-S3964R and to make efficient use of the example programs. -

Page 48: General Concepts

Siemens 3964R Protocol Immediately after power-up and completion of the internal/external initialization procedures the MVI46-S3964R with installed 3964R protocol is ready to serve as an interface between a SLC processor and one or two communication partners using 3964R protocol. The parameterization of the module is realized through a configuration file. - Page 49 Reference MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Main Logic Loop Upon completing the power up configuration process, the module enters an infinite loop that performs the functions shown in the following diagram. From Power Up Logic Call I/O Handler...

- Page 50 MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol Send to CP Request from CP Block ID for the transfer of data from the processor to the module to be sent out the serial port Always 9 Not Last Block Block 1...

- Page 51 Reference MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Send Block for Module to send to CP (Block 1) Offset Data Length 9X1X Header Data Send Block for Module to send to CP (Blocks 2 to 4) Offset Data Length 9X2X, 9X3X, 9X4X...

-

Page 52: Communications

This section describes the different types of jobs and the relevant parameters to be entered. For a better understanding a printout of the sample ladder file is recommended. Every job that is transferred to or from the MVI46-S3964R consists of defined header data and user data. The Job structure in general:... - Page 53 3964R with RK512: DB-FETCH to CP 0045hex The MVI46-S3964R receives jobs from a CP automatically without extra parameterization. To differentiate the header data the MVI46-S3964R adds a header to the user data received and transfers it to the SLC processor.

- Page 54 MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol Word: High Byte: Low Byte: 1141hex Data Block (DB) Data Word (DW) Number of data words (total number) Number of data words (actual block) = This is the total number of data words for the whole job.

-

Page 55: Job Processing

The MVI46-S3964R rejects its send job and sends the 3964R acknowledge (DLE) to the CP. Important: If the MVI46-S3964R has rejected its send job due to "Low Priority", you must restart its send job completely (starting with the copying of the job data). - Page 56 The communication port driver in RSLinx can occasionally prevent other applications from using the PC's COM port. If you are not able to connect to the module's configuration/debug port using ProSoft Configuration Builder (PCB), HyperTerminal or another terminal emulator, follow these steps to disable the RSLinx Driver.

- Page 57 Reference MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol You may see something like this: If you see the status as running, you will not be able to use this com port for anything other than communication to the processor. To stop the driver press the "Stop"...

-

Page 58: Rs-232 Cable

MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol 5.3.2 RS-232 When the RS-232 interface is selected, the use of hardware handshaking (control and monitoring of modem signal lines) is user definable. If no hardware handshaking will be used, the cable to connect to the port is as shown below: 5.3.3 RS-232 Cable... -

Page 59: Db9 To Rj45 Adaptor (Cable 14)

"write protected" mode, the Setup pins are not connected, and the module's firmware cannot be overwritten. Do not jumper the Setup pins together unless you are directed to do so by ProSoft Technical Support. ProSoft Technology, Inc. Page 59 of 74... -

Page 60: Reference Documents

MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol Reference Documents Siemens Simatic CP544 Handbuch zum Kommunikationspartner CP544 Ausgabe 01 Bestell-Nr. 6ES5 998-2DB11 Status Data Value Description Pass Count Product Code Revision Operating System Run Number Port 1 Requests Port 1 Responses... -

Page 61: Error Codes

Reference MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol Error Codes Error Code Description 0xFFFE DLE could not be sent 0xFFF6 DLE not received in time 0xFFF5 Communication Timeout occurred 0xFFEC Invalid character or acknowledge received 0xFFE2 Amount of user data is 0 or greater than 256 words... - Page 62 MVI46-S3964R ♦ SLC Platform Reference Siemens 3964R Protocol Page 62 of 74 ProSoft Technology, Inc. April 17, 2008...

-

Page 63: Support, Service & Warranty

E-mail address: support@prosoft-technology.com Those of us at ProSoft Technology, Inc. want to provide the best and quickest support possible, so before calling please have the following information available. You may wish to fax this information to us prior to calling. -

Page 64: How To Contact Us: Sales And Support

Return Material Authorization (RMA) Policies and Conditions The following RMA Policies and Conditions apply to any returned product. These RMA Policies are subject to change by ProSoft without notice. For warranty information, see Section C below entitled "Limited Warranty". In the event of any inconsistency between the RMA Policies and the Warranty, the Warranty shall govern. -

Page 65: All Product Returns

A 10% Restocking Fee if Factory Seal is not broken B 20% Restocking Fee if Factory Seal is broken ProSoft retains the right, in its absolute and sole discretion, to reject any non- warranty returns for credit if the return is not requested within three (3) months... -

Page 66: Procedures For Return Of Units Out Of Warranty

If a defect is found and is determined to be customer generated or if the defect is otherwise not covered by ProSoft's Warranty, or if the module is not repairable, a credit is not issued and payment of the replacement module is due. -

Page 67: Purchasing Warranty Extension

ProSoft's expense. All warranty service will be performed at service centers designated by ProSoft. If ProSoft is unable to repair the Product to conform to this Warranty after a reasonable number of attempts, ProSoft will provide, at its option, one of the following: a replacement product, a full refund of the purchase price or a credit in the amount of the purchase price. -

Page 68: What Is Not Covered By This Warranty

Support, Service & Warranty Siemens 3964R Protocol B Warranty On Services: Material and labor used by ProSoft to repair a verified malfunction or defect are warranted on the terms specified above for new Product, provided said warranty will be for the period remaining on the original new equipment warranty or, if the original warranty is no longer in effect, for a period of 90 days from the date of repair. -

Page 69: Disclaimer Regarding High Risk Activities

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. 6.5.5 LIMITATION OF REMEDIES** IN NO EVENT WILL PROSOFT (OR ITS DEALER) BE LIABLE FOR ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES BASED ON BREACH OF WARRANTY, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY. -

Page 70: No Other Warranties

Warranty, including statements made by salesperson. No employee of ProSoft or any other party is authorized to make any warranty in addition to those made in this Warranty. The Customer is warned, therefore, to check this Warranty carefully to see that it correctly reflects those terms that are important to the Customer. -

Page 71: Controlling Law And Severability

Support, Service & Warranty MVI46-S3964R ♦ SLC Platform Siemens 3964R Protocol 6.5.11 Controlling Law and Severability This Warranty shall be governed by and construed in accordance with the laws of the United States and the domestic laws of the State of California, without reference to its conflicts of law provisions. - Page 72 MVI46-S3964R ♦ SLC Platform Support, Service & Warranty Siemens 3964R Protocol Page 72 of 74 ProSoft Technology, Inc. April 17, 2008...

-

Page 73: Index

9998 Warm Boot • 30 9999 Cold Boot • 30 General Concepts • 48 General Specifications • 45 Guide to the MVI46-S3964R User Manual • 7 ACK Delay • 27 Adding a Module • 22 Adding a Project • 22 Additional Restrictions Relating To Software And Other Hardware Specifications •... -

Page 74: Prosoft Technology, Inc

Printing a Configuration File • 24 Use CTS Line • 26 Priority • 27 Using the Diagnostic Window in ProSoft Configuration Procedures for Return of Units Out of Warranty • 66 Builder • 32 Procedures for Return of Units Under Warranty • 65 Product Compatibility •...

Need help?

Do you have a question about the MVI46-S3964R and is the answer not in the manual?

Questions and answers