Man E0834 LE312 Assembly Instruction Manual

Hide thumbs

Also See for E0834 LE312:

- Operating instructions manual (90 pages) ,

- Maintenance manual (136 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Man E0834 LE312

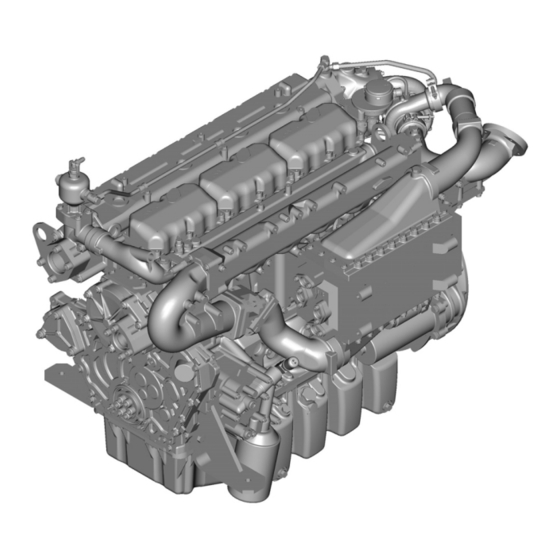

- Page 1 Assembly Instruction MAN Industrial Gas Engines E0834 LE302/312/322 / E0836 LE202/302 MAN Engines A Division of MAN Truck & Bus...

- Page 3 Assembly Instructions MAN Industrial Gas Engines E0834 LE302/ 312/ 322 E0836 LE202/302 50.99496-8001 “Translation of the original assembly instructions” Version 08...

-

Page 5: Information And Copyright

It is not permitted to change the contents of this document. The same applies to changes to the context of individual chapters and/or the whole document. MAN Truck & Bus AG assumes no liability for any damages arising from non-compliance with the above provisions. -

Page 6: Table Of Contents

Table of Contents Information and Copyright ............. . . Preface . - Page 7 Table of Contents 5.3.1 Installation drawing ............5.3.2 Threaded Connections .

-

Page 8: Preface

NOTE! Planning of the installation of the engines must have already been made in the project phase, the basis for which are the Installation Instructions for MAN Industrial Gas Engines for Cogeneration Power Stations (51.99496-8142). These Assembly Instructions are only valid after the installation planning has been completed and the engine is ready to be installed into the plant (cogeneration power station, power generator). -

Page 9: Key To Symbols

Foreword 1.2 Key to Symbols Warnings Warnings are identified in these Operating Instructions with symbols. These warnings are preceded by signal words that express the magnitude of the risk. Always heed these warnings and act prudently to prevent accidents, injuries and property damage. DANGER! ... -

Page 10: Limitation Of Liability

MAN and the law applicable at the time of contracting arrangements. 1.4 Copyright Please handle these Operating Instructions as confidential. They are only to be used by the persons working with the engine. Transfer to a third party without explicit written permission from MAN is strictly prohibited. NOTE! The information, texts, drawings, illustrations and other depictions are all protected by copyright and are subject to industrial property rights. -

Page 11: Spare Parts

Use only genuine MAN spare parts and accessories or those approved by MAN. Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines. Spare parts and accessories must either be MAN genuine parts or parts that have been specifically approved by MAN. -

Page 12: Warranty Terms

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of MAN and the law applicable at the time of contracting arrangements. Failure to observe these Assembly Instructions and any accompanying supplier assembly instructions leads to the loss of warranty claims. -

Page 13: General Safety Instructions

The engine is built for exclusive use in cogeneration power stations or power generators. Any other use is considered as "not intended". MAN is not liable for any damage resulting from use that is not intended. The risk is entirely borne by the operator. -

Page 14: Contents Of The Assembly Instructions

MAN. If changes are made without the written consent of MAN, the guarantee or warranty obligation for MAN is not longer valid for damage and defects, which are based on these unauthorised changes. Furthermore MAN assumes no liability for any damage caused as a result of unauthorised changes. -

Page 15: Personnel Requirements

General Safety Instructions 2.5 Personnel Requirements 2.5.1 Qualifications WARNING! Risk of injury caused by insufficient qualifications! Improper handling can result in significant personal injury and property damage For this reason: S Specific activities must only be performed by those persons who are named in the respective chapters in these Operating Instructions. -

Page 16: Personal Protective Equipment

General Safety Instructions 2.6 Personal Protective Equipment Wearing personal protective equipment is necessary to minimise the health risks when working. S The required personal protective equipment for the relevant job must always be worn while working. S All signs pertaining to personal protective equipment in the working area must be followed. Protective Clothing Close-fitting clothing with low initial tear strength, with narrow sleeves and with no protruding parts. -

Page 17: Specific Dangers

General Safety Instructions 2.7 Specific Dangers The following section describes residual risks which have been identified. S Observe the safety instructions listed here and the warnings in the other chapters of these instructions in order to reduce health hazards and avoid dangerous situations. Electrical Current DANGER! Risk of death caused by electrical current! - Page 18 General Safety Instructions Multiengine plants WARNING! Risk of injury caused by engines! Persons in the operating room are at a risk if engine damage occurs. For this reason: S Limit the time spent in the operating room to the absolute minimum. S Set up protective partitions to isolate running engines.

- Page 19 General Safety Instructions WARNING! Risk of fire caused by highly flammable substances! Highly flammable materials (lubricating oils, greases) can catch fire and cause serious to deadly injuries. For this reason: S Do not smoke in the hazard area or in the vicinity. No open fires or sources of ignition.

- Page 20 General Safety Instructions Noise WARNING! Risk of hearing damage caused by noise! The level of noise occurring in the working area can cause serious damage to hearing. For this reason: S Always wear hearing protection when working. S Do not unnecessarily remain in the hazard area. Leave hazard area when work is finished.

-

Page 21: Safety Equipment

General Safety Instructions 2.8 Safety Equipment The operator must have the following safety equipment in place: Before the engine is placed into operation, install the emergency-off equipment and connect it into the safety chain of the system. Connect the emergency-off equipment so that dangerous situations to people and property are avoided in case the its power supply is interrupted or is turned back on after an interruption. -

Page 22: Conduct In Dangerous Situations And When Accidents Occur

General Safety Instructions 2.9 Conduct in Dangerous Situations and When Accidents Occur Preventative Measures S Always be prepared for an accident! S Keep first aid equipment (first aid kit, blankets, etc.) and fire extinguishers at hand. S Check first aid equipment and fire extinguishers regularly for completeness and proper operation. S Familiarise the personnel with the emergency, first aid and rescue equipment. -

Page 23: Signs

General Safety Instructions 2.10 Signs The following symbols should be installed in the immediate vicinity of the hazard area. WARNING! Risk of injury caused by illegible symbols! Stickers and symbols can become dirty or made otherwise illegible in the course of time! For this reason: S Always keep the safety, warning and operational signs in good legible condition. -

Page 24: Environmental Protection

General Safety Instructions 2.11 Environmental Protection CAUTION! Environmental hazard caused by incorrect handling! Incorrect handling of environmentally hazardous substances, especially when incorrectly disposed of, can cause considerable damage to the environment. For this reason: S Always heed the information below. S If environmentally hazardous substances are accidentally released into the environment, immediately take suitable measures to minimise this. -

Page 25: Engine Model Plate

A clear identification is only possible using the information on the engine model plate. Engine model plate (1) is installed on the charge mixture cooler. MAN Nutzfahrzeuge Aktiengesellschaft Motor-Nr. / Engine No. NI/II Carefully read the Assembly Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 26: Explanation Of The Motor-Nr./Engine-No. (Engine Identification Number)

Identification of the Engine 3.1 Explanation of the Motor-Nr./Engine-No. (Engine Identification Number) Motor-Nr./Engine-No. Class identifier (assignment) Model number according to index of model codes 1234 Day of assembly (plant internal) Assembly order (sequence number on day of assembly) 3.2 Explanation of Model Designation Model designation Declaration Example... -

Page 27: Transport, Packaging And Storage

Transport, Packaging and Storage Transport, Packaging and Storage It is absolutely necessary to observe the “Installation Instructions” for the installation and commissioning of a new or reconditioned engine. NOTE! Installation and commissioning is only to be made by the employees of the manufacturer of the entire system or by manufacturer authorised personnel. - Page 28 Transport, Packaging and Storage Off-Centre Point of Gravity WARNING! Risk of injury caused by falling or tipping packages! Packages can have a centre of gravity that is off-centre. If the lifting equipment is not hooked up properly, these packages could tip over and fall causing serious injuries. For this reason: S Observe the information and markings on the package concerning centre of gravity.

-

Page 29: Transport Inspection

Transport, Packaging and Storage 4.3 Transport Inspection Check the delivery for missing items and for damage from transport. If external signs of transport damage are apparent: S Do not accept delivery or only accept under written protest. S List scope of damage on the transport documents or on the transportation company's packaging slip. S Initiate a claims process. -

Page 30: Transport

Transport, Packaging and Storage 4.4 Transport Lifting Points There are 2 lifting lugs (1) and (2) installed on the engine. WARNING! Risk of death caused by the load falling! During lifting operations, loads can fall down. This can cause serious injury and even death. For this reason: S The „crane lifting lugs“... - Page 31 Transport, Packaging and Storage Transport with Crane The engine can be transported with a crane under the following conditions. S The crane and the lifting equipment must be designed for the weight of the engine. S Make sure ropes and chains do not pull crookedly on the crane hooks. S The operator must be qualified for operating the crane.

-

Page 32: Packaging

Transport, Packaging and Storage 4.5 Packaging Packaging The individual packages are packed in accordance with the expected conditions of transport. The purpose of the packaging is to protect the components from transport damage, corrosion and other damage. For this reason do not unpack components until shortly before they are to be assembled. Handling Packing Material Dispose of packing material according to the valid local and statutory regulations. -

Page 33: Installation

S Safety Shoes S Safety Gloves 5.2 Safety Instructions Personnel S The installation and commissioning may only be performed by MAN employees or by MAN-trained qualified personnel. WARNING! Danger caused by faulty installation! Installation requires trained qualified personnel with sufficient experience. Faulty installation can cause life threatening situations and considerable property damage. -

Page 34: Interfaces Between Engine And Plant (E0836 Le202)

Installation Interfaces between Engine and Plant (E0836 LE202) Carefully read the Assembly Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. - Page 35 Installation The engine is a component of the entire plant (cogeneration power station, power generator). The following assembly work is to be made to the interfaces between the engine and the plant when installing the engine: 1 Connect starter (electrical system), see page 44 2 Connect coolant lines for mixture cooling, see page 40 3 Connect oil pressure sensor, see page 46 4 Bolt engine mounts to plant frame, see page 39...

-

Page 36: Interfaces Between Engine And Plant (E0836 Le302)

Installation Interfaces between Engine and Plant (E0836 LE302) Carefully read the Assembly Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 37: Installation Drawing

Installation The engine is a component of the entire plant (cogeneration power station, power generator). The following assembly work is to be made to the interfaces between the engine and the plant when installing the engine: 1 Connect starter (electrical system), see page 44 2 Connect coolant lines for mixture cooling, see page 40 3 Connect oil pressure sensor, see page 46 4 Bolt engine mounts to plant frame, see page 39... -

Page 38: Completing The Engine And Assembling The Plant

The engines are delivered from the factory with no ignition system installed (except for the spark plugs). The ignition system can be ordered from the usual manufacturers to fit the MAN Industrial Gas Engines. Installation of the ignition system is to be made according to the relevant manufacturer's guidelines. -

Page 39: Installing Generator

Installation 5.4.2 Installing Generator IMPORTANT! There are a variety of generators (single or dual bearing generators) and resilient couplings available on the market. For this reason: S Observe the installation instructions of the relevant manufacturer! Flywheel The interface dimensions of the flywheel are indicated in the installation drawing. -

Page 40: Checking Axial Play Of Crankshaft

Installation 5.4.3 Checking Axial Play of Crankshaft IMPORTANT! The designed crankshaft axial play of the engines must not in any event be reduced by the installation of couplings or other components. For this reason: S It is essential to record the axial play of the crankshaft before and after any components are installed by using a dial indicator held by a magnetic stand. -

Page 41: Installing Engine In A Cogeneration Power Station

Installation 5.5 Installing Engine in a Cogeneration Power Station NOTE! Before placing the engine in the plant with the aid of the installation drawing, check whether the interface dimensions of the lines (coolant, exhaust, etc.) to the connections at the engine fit. -

Page 42: Installing Cooling System

Installation 5.6 Installing Cooling System 5.6.1 Connecting Coolant Lines for Engine Cooling The installation drawing specifies the implementation of the coolant connections. E0834 LE302 1. Connect coolant inlet (1) 2 Connect coolant outlet (2) E0836 LE202 1. Connect coolant inlet (1) 2 Connect coolant outlet (2) 5.6.2 Connecting Coolant Lines for Mixture Cooling... -

Page 43: Installing Intake System

Installation 5.7 Installing Intake System 5.7.1 Installing Gas Mixer (E0836LE202) The location of the gas inlet at the engine (1) and the drilling pattern of the flange are both specified in the installation drawing. 5.7.2 Installing Gas Mixer (E0836LE302) The location of the gas inlet at the engine (1) and the drilling pattern of the flange are both specified in the installation drawing. -

Page 44: Installing Exhaust System

Installation 5.8 Installing Exhaust System 5.8.1 Installing Exhaust Line (E0836LE202) Install exhaust manifold at turbocharger (1). There is a counter flange (weld flange) at the exhaust outlet of the turbocharger (2) to connect the exhaust system. The dimensions are specified in the installation drawing. -

Page 45: Installing Exhaust Pipe Bellows

Installation 5.8.2 Installing Exhaust Pipe Bellows Install the exhaust pipe bellows as vertical as possible to support the rest of the exhaust line. The position of the guide pipe (4) determines the flow direction of the exhaust. Install exhaust pipe bellows under tensile prestress (2). -

Page 46: Connecting Electrical System

Installation 5.9 Connecting Electrical System 5.9.1 Connecting Starter (BOSCH) The threads of the cable connection (2) of the starter (1) are specified in the installation drawing. Battery capacity, cable length and cable cross- section should be selected to match. The required starter cable cross-section, which depends on the recommended starter cable lengths, are listed in the following table. -

Page 47: Connecting Starter (Mitsubishi)

Installation 5.9.1 Connecting Starter (MITSUBISHI) The threads of the cable connection (2) of the starter (1) are specified in the installation drawing. Battery capacity, cable length and cable cross- section should be selected to match. The required starter cable cross-section, which depends on the recommended starter cable lengths, are listed in the following table. -

Page 48: Connecting Sensors

Installation 5.9.2 Connecting Sensors NOTE! The location of sensors on the engine is shown in the installation drawing. Each sensor's drawing gives information on the pin assignment. To request drawings see page 3 for contact addresses. Coolant temperature sensor Oil pressure sensor (E0834 LE302/312/322) Oil pressure sensor (E0836 LE202) Carefully read the Assembly Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions... -

Page 49: Safety Equipment

Installation Exhaust temperature sensor (E0834 LE302/312/322 E0836 LE302) Exhaust temperature sensor (E0836 LE202) IMPORTANT! The purpose of the sensors is to monitor important operating parameters. Sensors that are not connected or are inoperative can lead to damage to the engine. For this reason: S Connect sensors to the engine monitoring system and check for proper operation. - Page 50 Installation Tightening torques according to plant standard M 3059 Bolt / nut with Allen or hexagon head with no collar or flange Thread size Strength classifications / tightening torque in Nm x pitch at 8.8 / 8 at 10.9 / 10 at 12.9 / 12 13.0 15.0...

-

Page 51: Commissioning

Commissioning Commissioning WARNING! Danger caused by faults during commissioning! Commissioning requires trained qualified personnel with sufficient experience. Faulty commissioning can cause life threatening situations and considerable property damage. For this reason: Commissioning is only to be performed by trained and qualified personnel. Ground Rules WARNING! Risk of injury caused by improper commissioning! -

Page 52: Filling Engine Oil

Commissioning 6.1.1 Filling Engine Oil IMPORTANT! Engine oil is harmful to the environment. For this reason: S Do not let engine oil spill while filling. Do not let engine oil leak out onto the ground or into bodies of water. The engines are as a rule supplied without oil. -

Page 53: Checking Engine Oil Level

Commissioning 6.1.2 Checking Engine Oil Level Check engine oil level 30 minutes after filling engine with oil. S Remove oil dipstick S Wipe off with lint-free cloth S Reinsert up to stop S Pull out dipstick again The oil level must be between both marks on the dipstick. -

Page 54: Filling Coolant

S Do not let coolant spill when filling. Do not let coolant leak out onto the ground or into bodies of water. For more information on the preparation of the coolant, refer to “Fuels, Lubricants and Coolants for MAN Industrial Gas Engines”. The amount of coolant to be prepared is given by the total filling capacity of the cooling system. -

Page 55: Commissioning Coolant System

Commissioning 6.2 Commissioning Coolant System When inspecting the coolant circuit make sure that S The coolant circuit can be quickly filled (w 8 l/min); S The coolant circuit is completely vented; S No vacuum can be produced ahead of coolant pump (cavitation); S A system pressure is achieved in the cooling circuit (0.4-0.5 bar static) and is maintained after engine is turned off;... -

Page 56: Commissioning Exhaust System

Commissioning 6.3 Commissioning Exhaust System 6.3.1 Measuring Exhaust Back Pressure The exhaust back pressure must be measured during commissioning. The measuring point of the exhaust back pressure Ø 3 mm (threads e.g. M14x1.5) must be selected in a straight part of the exhaust pipe. Measurements take directly downstream of the turbocharger will have distorted results by approx. - Page 57 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 58 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 59 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 60 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 61 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 62 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 63 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 64 Installation Drawings of the Engine E0834 LE302 Identification no. of installation drawing: 51.00504-7109, drawn September 03, 2012...

- Page 65 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 66 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 67 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 68 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 69 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 70 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 71 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 72 Installation Drawings of the Engine E0836 LE202 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 73 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 74 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 75 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 76 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 77 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 78 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 79 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 80 Installation Drawings of the Engine E0836 LE302 Identification no. of installation drawing: 51.00506-7817 “B”, drawn November 3, 2005...

- Page 82 MAN Truck & Bus AG Vogelweiherstraße 33 90441 Nuremberg Germany man-engines@man.eu www.man-engines.com MAN Truck & Bus – a member of the MAN Group...

Need help?

Do you have a question about the E0834 LE312 and is the answer not in the manual?

Questions and answers