Man E0834 LE302 Operating Instructions Manual

Industrial gas engines

Hide thumbs

Also See for E0834 LE302:

- Assembly instruction manual (82 pages) ,

- Maintenance manual (136 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Man E0834 LE302

- Page 1 Operating Instruction MAN Industrial Gas Engines E0834 LE302/312/322 / E0836 LE202/302 MAN Engines A Division of MAN Truck & Bus...

-

Page 3: Operating Instructions

Operating Instructions MAN Industrial Gas Engines E0834 LE302 / 312/ 322 E0836 LE202/ 302 51.99493-8538 “Translation of the original operating instructions” Version 07... - Page 5 It is not permitted to change the contents of this document. The same applies to changes to the context of individual chapters and/or the whole document. MAN Truck & Bus AG assumes no liability for any damages arising from non-compliance with the above provisions.

-

Page 6: Table Of Contents

............. . Engine Views E0834 LE302/ 312/ 322 . - Page 7 Table of Contents Transport, Packaging and Storage ..........Prerequisite .

- Page 8 ........10.4.1Commissioning of Preserved Engines according to MAN-Werknorm M 3059 .

- Page 9 Table of Contents 12 Indices ................12.1 Abbreviations .

-

Page 10: Preface

Use only genuine MAN spare parts and accessories or those approved by MAN. Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines. A particular concern of MAN is to improve environmental protection. This begins with the development and design of our engines. -

Page 11: Key To Symbols

Foreword 1.2 Key to Symbols Warnings Warnings are identified in these Operating Instructions with symbols. These warnings are pre ceded by signal words that express the magnitude of the risk. Always heed these warnings and act prudently to prevent accidents, injuries and property damage. DANGER! ... -

Page 12: Limitation Of Liability

MAN and the law applicable at the time of contracting arrangements. 1.4 Copyright Please handle these Operating Instructions as confidential. They are only to be used by the persons work ing with the engine. Transfer to a third party without explicit written permission from MAN is strictly prohib ited. NOTE! The information, texts, drawings, illustrations and other depictions are all protected by copy... -

Page 13: Spare Parts

Use only genuine MAN spare parts and accessories or those approved by MAN. Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines. Spare parts and accessories must either be MAN genuine parts or parts that have been specifically ap... -

Page 14: Warranty Terms

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of MAN and the law applicable at the time of contracting arrangements. Failure to observe these Operating Instructions and any accompanying supplier operating instructions leads to the loss of warranty claims. -

Page 15: General Safety Instructions

Any other use is considered as "not intended". MAN is not liable for any damage resulting from use that is not intended. The risk is entirely borne by the operator. Intended use also includes compliance with the country-specific, local environmental regulations. -

Page 16: Contents Of The Operating Instructions

MAN. If changes are made without the written consent of MAN, the guarantee or warranty obligation for MAN is not longer valid for damage and defects, which are based on these unauthorised changes. Furthermore MAN assumes no liability for any damage caused as a result of unauthorised changes. -

Page 17: Personnel Requirements

General Safety Instructions 2.5 Personnel Requirements 2.5.1 Qualifications WARNING! Risk of injury caused by insufficient qualifications! Improper handling can result in significant personal injury and property damage For this reason: S Specific activities must only be performed by those persons who are named in the re spective chapters in these Operating Instructions. -

Page 18: Personal Protective Equipment

General Safety Instructions 2.6 Personal Protective Equipment Wearing personal protective equipment is necessary to minimise the health risks when working. S The required personal protective equipment for the relevant job must always be worn while working. S All signs pertaining to personal protective equipment in the working area must be followed. Protective Clothing Close-fitting clothing with low initial tear strength, with narrow sleeves and with no pro... -

Page 19: Specific Dangers

General Safety Instructions 2.7 Specific Dangers The following section describes residual risks which have been identified. S Observe the safety instructions listed here and the warnings in the other chapters of these instructions in order to reduce health hazards and avoid dangerous situations. Electrical Current DANGER! Risk of death caused by electrical current! - Page 20 General Safety Instructions Multi-engine plants WARNING! Risk of injury caused by engines! Persons in the operating room are at a risk if engine damage occurs. For this reason: S Limit the time spent in the operating room to the absolute minimum. S Set up protective partitions to isolate running engines.

- Page 21 General Safety Instructions WARNING! Risk of fire caused by highly flammable substances! Highly flammable materials (lubricating oils, greases) can catch fire and cause serious to deadly injuries. For this reason: S Do not smoke in the hazard area or in the vicinity. No open fires or sources of ignition.

- Page 22 General Safety Instructions Noise WARNING! Risk of hearing damage caused by noise! The level of noise occurring in the working area can cause serious damage to hearing. For this reason: S Always wear hearing protection when working. S Do not unnecessarily remain in the hazard area. Leave hazard area when work is fin ished.

-

Page 23: Safety Equipment

General Safety Instructions 2.8 Safety Equipment The operator must have the following safety equipment in place: Before the engine is placed into operation, install the emergency-off equipment and connect it into the safety chain of the system. Connect the emergency-off equipment so that dangerous situations to people and property are avoided in case the its power supply is interrupted or is turned back on after an interruption. -

Page 24: Conduct In Dangerous Situations And When Accidents Occur

General Safety Instructions 2.9 Conduct in Dangerous Situations and When Accidents Occur Preventative Measures S Always be prepared for an accident! S Keep first aid equipment (first aid kit, blankets, etc.) and fire extinguishers at hand. S Check first aid equipment and fire extinguishers regularly for completeness and proper operation. S Familiarise the personnel with the emergency, first aid and rescue equipment. -

Page 25: Signs

General Safety Instructions 2.10 Signs The following symbols should be installed in the immediate vicinity of the hazard area. WARNING! Risk of injury caused by illegible symbols! Stickers and symbols can become dirty or made otherwise illegible in the course of time! For this reason: S Always keep the safety, warning and operational signs in good legible condition. -

Page 26: Environmental Protection

General Safety Instructions 2.11 Environmental Protection CAUTION! Environmental hazard caused by incorrect handling! Incorrect handling of environmentally hazardous substances, especially when incorrectly disposed of, can cause considerable damage to the environment. For this reason: S Always heed the information below. S If environmentally hazardous substances are accidentally released into the environment, immediately take suitable measures to minimise this. -

Page 27: Engine Model Plate

Engine Model Plate Engine Model Plate Always specify the engine typeand engine number when sending messages and making queries. For this reason before the engine is commis sioned, read off and enter in the data from the en gine model plates below. Engine model plate (1) is installed on the crankcase. -

Page 28: Explanation Of The Motor-Nr./Engine-No. (Engine Identification Number)

Engine Model Plate 3.1 Explanation of the Motor-Nr./Engine-No. (Engine Identification Number) Motor-Nr./Engine-No. Class identifier (assignment) Model number according to index of model codes 1234 Day of assembly (plant internal) Assembly order (sequence number on day of assembly) 3.2 Explanation of Model Designation Model designation Explanation Example... -

Page 29: Design And Function

Design and Function Design and Function 4.1 Engine, General The 4 and 6 cylinder engines described here is liquid-cooled 4-cycle spark ignition engine with turbochar ging and intercooling. Engine Monitoring Monitoring of the engine is made through various sensors. The sensors are designed, for example, as rpm and temperature sensors, which report the various operating conditions of the engine to the engine control unit. -

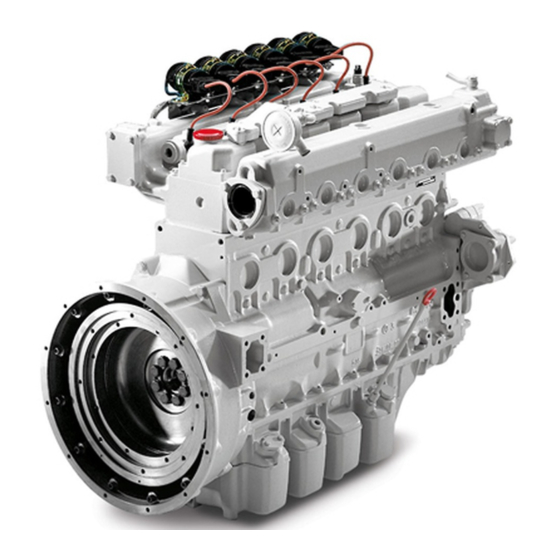

Page 30: Engine Views E0834 Le302/ 312/ 322

Design and Function 4.2 Engine Views E0834 LE302/ 312/ 322 4.2.1 Front Left View (1) Turbocharger (2) Intake manifold (3) Charge mixture cooler (4) Starter (5) Throttle valve (6) Oil drain screw (7) Oil filter (8) Coolant inlet, low‐temperature stage (9) Coolant outlet, low‐temperature stage... -

Page 31: Front Right View

NOTE! The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure regulator, gas mixer and air filter are not included in the MAN scope of delivery. Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 32: Engine Views E0836 Le202

Design and Function 4.3 Engine Views E0836 LE202 4.3.1 Front Left View (1) Turbocharger (2) Intake manifold (3) Charge mixture cooler (4) Starter (5) Throttle valve (6) Oil drain screw (7) Oil filter (8) Oil cooler (9) Flame protection filter (10) Ventilation connection for coolant to separate ventilation reservoir Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions... -

Page 33: Front Right View

NOTE! The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure regulator, gas mixer and air filter are not included in the MAN scope of delivery. Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 34: Engine Views E0836 Le302

Design and Function 4.4 Engine Views E0836 LE302 4.4.1 Front Left View (1) Turbocharger (2) Intake manifold (3) Charge mixture cooler (4) Starter (5) Throttle valve (6) Oil drain screw (7) Oil filter (8) Oil cooler (9) Flame protection filter (10) Ventilation connection Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions... -

Page 35: Front Right View

NOTE! The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure regulator, gas mixer and air filter are not included in the MAN scope of delivery. Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. - Page 36 Design and Function Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

- Page 37 Design and Function Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

-

Page 38: Transport, Packaging And Storage

Transport, Packaging and Storage Transport, Packaging and Storage It is absolutely necessary to observe the “Assembly Instructions” for the installation and commissioning of a new or reconditioned engine. NOTE! Installation and commissioning is only to be made by the employees of the manufacturer of the entire system or by manufacturer authorised personnel. - Page 39 Transport, Packaging and Storage Off-Centre Point of Gravity WARNING! Risk of injury caused by falling or tipping packages! Packages can have a centre of gravity that is off-centre. If the lifting equipment is not hoo ked up properly, these packages could tip over and fall causing serious injuries. For this reason: S Observe the information and markings on the package concerning centre of gravity.

-

Page 40: Transport Inspection

Transport, Packaging and Storage 5.3 Transport Inspection Check the delivery for missing items and for damage from transport. If external signs of transport damage are apparent: S Do not accept delivery or only accept under written protest. S List scope of damage on the transport documents or on the transportation company's packaging slip. S Initiate a claims process. -

Page 41: Transport

Transport, Packaging and Storage 5.4 Transport Lifting Points There are 2 lifting lugs (1) and (2) for the crane installed on the engine. WARNING! Risk of death caused by the load falling! During lifting operations, loads can fall down. This can cause serious injury and even death. For this reason: S The „crane lifting lugs“... - Page 42 Transport, Packaging and Storage Transport with Crane The engine can be transported with a crane under the following conditions. S The crane and the lifting equipment must be designed for the weight of the engine. S The operator must be qualified for operating the crane. 1.

-

Page 43: Packaging

Transport, Packaging and Storage 5.5 Packaging Packaging The individual packages are packed in accordance with the expected conditions of transport. The purpose of the packaging is to protect the components from transport damage, corrosion and other damage. For this reason do not unpack components until shortly before they are to be assembled. Handling Packing Material Dispose of packing material according to the valid local and statutory regulations. -

Page 44: Installation And Commissioning

S Safety Shoes S Safety Gloves 6.2 Safety Instructions Personnel S The installation and commissioning may only be performed by MAN employees or by MAN-trained quali fied personnel. WARNING! Danger caused by faulty installation and commissioning! Installation and commissioning require trained qualified personnel with sufficient experi... -

Page 45: Installation - Engine

6.3.2 Engine Model Plate Data Please always specify the engine model, engine number and order number when corresponding with MAN, see page . For this reason, before commissioning the engine, read off the data from the engine model plate and enter it into the Engine Model Plate chapter, see page 25. -

Page 46: Commissioning

For commissioning the engine is to be set for the use of a suitable gas/air mixture. Any deviations from this will negatively influence the output power, the engine efficiency and the exhaust emissions. The requirements on the quality of gas are specified in ”MAN data sheet - Minimum requirement on the qu ality of gas for MAN gas engines". -

Page 47: Filling Coolant

Coolant must be filled according to the filling specifications of the BHKW (combined heat and power plant) manufacturer. For suitable antifreeze agents see approved Fuels, Lubricants and Coolants according to MAN 324 NF and MAN 248. Coolant may only be filled at the filler neck. -

Page 48: Filling Engine Oil

Installation and Commissioning 6.4.3 Filling Engine Oil IMPORTANT! Component damage caused by over filling! Engine damage can occur if engine oil is filled to above the max. mark on the oil dipstick. For this reason: S Do not fill engine oil above the max. - Page 49 Installation and Commissioning Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

-

Page 50: Operation

Operation Operation 7.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage. Personal Protective Equipment The following protective equipment must be worn: S Protective Clothing S Safety Shoes... -

Page 51: Preparations Before Operation

S In the case of fire, immediately stop working. Leave hazard area until the danger is over. 1. Check the quality of the gas, see “MAN data sheet - Minimum requirement on the quality of gas for MAN gas engines". -

Page 52: Refilling Coolant

Fill the cooling system of the engine with a mixture of tap water and ethylene glycol antifreeze agent or an ticorrosion agent. NOTE! The cooling system is not included in MAN's scope of delivery. Add coolant according to the manufacturer's operating manual. Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 53: Checking Engine Oil Level

Operation 7.3.4 Checking Engine Oil Level NOTE! Check the oil level when the engine is horizontal and only after at least 20 minutes have passed since the engine was switched off. 1. Pull out oil dipstick (1). 2. Wipe off oil dipstick (1) with a lint-free, clean cloth. -

Page 54: Refilling Engine Oil

Operation 7.3.5 Refilling Engine Oil IMPORTANT! Component damage caused by over filling! Engine damage can occur if engine oil is filled to above the max. mark on the oil dipstick. For this reason: S Do not fill engine oil above the max. -

Page 55: Operation

Operation 7.4 Operation DANGER! Risk of injury caused by mechanical movements, gases and noise. There is a risk of injury during engine operation caused by moving engine parts and from engine emissions. For this reason: S Access to operating room is only allowed for maintenance/repairs. S Access to operating room is prohibited when engine is running. -

Page 56: Monitoring Operation

Operation 7.4.2 Monitoring Operation IMPORTANT! Do not overload engine. If faults occur, investigate and solve them immediately to prevent major damage from oc curring! The oil pressure and the coolant temperature are constantly monitored during engine operation. If the limits are exceeded or gone below, the engine will be automatically shut off. 7.4.3 Stopping in an Emergency An emergency-off button, for shutting down the system in an emergency, must be installed for each engine. -

Page 57: Maintenance And Care

Maintenance instructions for the engines are available to supplement these operating instructions. It contains a discription of all due turnaround maintenace work. Maintenance instruction see leaflet “Maintenance Instruction MAN Industriel Gas Engines” 8.2 Maintenance Schedule The Maintenance schedule for the engines are available to supplement the maintenance instructions. - Page 58 Maintenance and Care Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

-

Page 59: Faults

The following chapter describes the possible faults which can occur and the work to correct them. For those faults that cannot be rectified by the following information, contact the manufacturer of the entire system or MAN Service. 9.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. -

Page 60: Fault Table

Faults 9.3 Fault Table Fault Possible cause Remedy D Shutoff solenoid valve of gas supply Engine does not start closed/does not open D Zero pressure regulator of gas supply not correctly set or faulty D Air filter clogged D Exhaust clogged (exhaust back pressure too high) D Electric circuit interrupted D Set main switch to "on"... - Page 61 Faults Fault Possible cause Remedy D Spark plug faulty Engine does not start D Ignition cable faulty or poorly starts in cold D Ignition coil faulty condition D Ignition timing incorrectly set D Remedy from manufacturer ser vice D Starter turns slowly D Battery with insufficient charge or damaged D Voltage drop between battery...

- Page 62 Faults Fault Possible cause Remedy D Air filter clogged Poor performance D Exhaust pipe clogged D Air intake pipe leaks D Charge mixture cooler dirty/leaks D Charge mixture ducting leaks D Turbocharger leaks, faulty, dirty D Insufficient compression in cylinder or D Remedy from manufacturer ser...

- Page 63 Faults Fault Possible cause Remedy D Lube-oil quality does not meet the regu D See "Fluids and Lubricants..." Lube-oil consumption too high lations D Oil level in oil pan too high D Check whether the guide tube is correctly installed and the cor rect oil dipstick is being used D If coolant is discovered in the engine oil, check cylinder head...

- Page 64 Faults Starter Fault Possible cause Remedy To be repaired by a vehicle elec trician or by the manufacturer service D Pinion gear does not D Battery has insufficient charge D Terminal is loose, oxidised, poor turn or turns slowly connection to ground D Starter terminal or carbon brushes are short circuited to ground D Carbon brushes stick or have poor con...

-

Page 65: Decommissioning And Recommissioning

Decommissioning and Recommissioning Decommissioning and Recommissioning 10.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage. Personal Protective Equipment The following protective equipment must be worn: S Protective Clothing... -

Page 66: Temporary Decommissioning Of Engines

Decommissioning and Recommissioning 10.3 Temporary Decommissioning of Engines Temporary anticorrosion protection according to MAN works norm M 3069 is required for engines which are to be put out of service depending on the duration. The works norm can be obtained from our After-Sales Service department Nuremberg works. -

Page 67: Recommissioning Of Decommissioned Engines

Decommissioning and Recommissioning 10.4 Recommissioning of Decommissioned Engines 10.4.1 Commissioning of Preserved Engines according to MAN-Werknorm M 3059 1. Remove external preservation. Never use a high pressure cleaner for this. 2. Remove caps from intake and exhaust openings. 3. Check cooling system; add antifreeze according to the Fluids and Lubricants list (see “Fluids and Lubric... - Page 68 Decommissioning and Recommissioning Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

-

Page 69: Technical Data

Technical Data Technical Data 11.1 Dimensions and Weights 11.1.1 E0834 LE302 Specification Value Unit Weight (dry) E0834 LE302 1055 11.1.2 E0836 LE202 Specification Value Unit Weight (dry) E0836 LE202 1300 1030 11.1.2 E0836 LE302 Specification Value Unit Weight (dry) E0836 LE202... -

Page 70: Engine Data

Technical Data 11.3 Engine Data 11.3.1 E0834 LE302 Engine model E0834 LE302 Design Inline engine Operating Principle 4-cycle spark ignition engine Number of cylinders Bore 108 mm Stroke 125 mm Displacement 4,580 cm Compression 11:1 Rating for natural gas operation... - Page 71 Technical Data Engine lubrication Force feed lubrication Lubrication oil pressure during ope must be monitored via an oil pressure monitor or a display device ration (depends on engine speed, oil temperature and engine load) Oil filter Single-use main flow filter (easy-change filter) Oil capacity in oil sump (litres) min.

-

Page 72: 1E0834 Le312

Technical Data 11.3.1 E0834 LE312 Engine model E0834 LE312 Design Inline engine Operating Principle 4-cycle spark ignition engine Number of cylinders Bore 108 mm Stroke 125 mm Displacement 4,580 cm Compression 11:1 Rating for natural gas operation 68 kW / 92 HP at 1500 rpm The power output specifications are valid for operation with natural gas with a calorific value of 36,350 kJ/m3 and a methane number >... - Page 73 Technical Data Engine lubrication Force feed lubrication Lubrication oil pressure during ope must be monitored via an oil pressure monitor or a display device ration (depends on engine speed, oil temperature and engine load) Oil filter Single-use main flow filter (easy-change filter) Oil capacity in oil sump (litres) min.

-

Page 74: 1E0834 Le322

Technical Data 11.3.1 E0834 LE322 Engine model E0834 LE322 Design Inline engine Operating Principle 4-cycle spark ignition engine Number of cylinders Bore 108 mm Stroke 125 mm Displacement 4,580 cm Compression 11:1 Rating for natural gas operation 80 kW / 109 HP at 1500 rpm The power output specifications are valid for operation with natural gas with a calorific value of 36,350 kJ/m3 and a methane number >... - Page 75 Technical Data Engine lubrication Force feed lubrication Lubrication oil pressure during ope must be monitored via an oil pressure monitor or a display device ration (depends on engine speed, oil temperature and engine load) Oil filter Single-use main flow filter (easy-change filter) Oil capacity in oil sump (litres) min.

-

Page 76: 2E0836 Le202

Technical Data 11.3.2 E0836 LE202 Engine model E0836 LE202 Design Inline engine Operating Principle 4-cycle spark ignition engine Number of cylinders Bore 108 mm Stroke 125 mm Displacement 6,870 cm Compression 11:1 Rating for natural gas operation 110 kW / 150 HP at 1500 rpm and 1800 rpm The power output specifications are valid for operation with natural gas with a calorific value of 36,350 kJ/m3 and a methane number >... - Page 77 Technical Data Engine lubrication Force feed lubrication Lubrication oil pressure during ope must be monitored via an oil pressure monitor or a display device ration (depends on engine speed, oil temperature and engine load) Oil filter Single-use main flow filter (easy-change filter) Oil capacity in oil sump (litres) min.

-

Page 78: 2E0836 Le202

Technical Data 11.3.2 E0836 LE202 Engine model E0836 LE302 Design Inline engine Operating Principle 4-cycle spark ignition engine Number of cylinders Bore 108 mm Stroke 125 mm Displacement 6,870 cm Compression 11:1 Rating for natural gas operation 110 kW / 150 HP at 1500 rpm and 1800 rpm The power output specifications are valid for operation with natural gas with a calorific value of 36,350 kJ/m3 and a methane number >... - Page 79 Technical Data Engine lubrication Force feed lubrication Lubrication oil pressure during ope must be monitored via an oil pressure monitor or a display device ration (depends on engine speed, oil temperature and engine load) Oil filter Single-use main flow filter (easy-change filter) Oil capacity in oil sump (litres) min.

- Page 80 Technical Data Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

-

Page 81: Indices

Indices 12 Indices Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 82: Abbreviations

Indices 12.1 Abbreviations ..Amps ..Minimum ..Amp hours ..Millimetre bzw..Respectively . -

Page 83: Technical Terms

Indices 12.2 Technical Terms Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 84: Index

Indices 12.3 Index Air filter, 44 Information about Operating Instructions, 8 Installation - Engine, 43 Installation and Commissioning, 42 Check Gas Quality, 49 Installation Location and Space Requirements, 67 Checking Coolant, 49 Intake and Exhaust System, 27 Checking Engine Oil Level, 51 Intended Use, 13 Commissioning, 44 Conduct in Dangerous Situations, 22... - Page 85 Indices Recommissioning of Decommissioned Engines, 65 Technical Data, 67 Refilling Coolant, 50 Temporary Decommissioning, 64 Refilling Engine Oil, 52 Transport, 39 Responsibility of the Operator, 14 Transport Inspection, 38 Transport, Packaging and Storage, 36 Safety Equipment, 21, 43 Service, 12 Warranty Terms, 12 Signs, 23 Spare Parts, 11...

-

Page 86: Notes

Notes Notes ........................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. - Page 88 MAN Truck & Bus AG Vogelweiherstraße 33 90441 Nürnberg Germany A member of the MAN Group Printed in Germany 51.99493-8538...

- Page 90 MAN Truck & Bus AG Vogelweiherstraße 33 90441 Nuremberg Germany man-engines@man.eu www.man-engines.com MAN Truck & Bus – a member of the MAN Group...

Need help?

Do you have a question about the E0834 LE302 and is the answer not in the manual?

Questions and answers