Summary of Contents for Hatz 3H50 Series

- Page 1 CREATING POWER SOLUTIONS. 3H50 | 4H50 MANUAL for diesel engine Hatz Diesel www.hatz-diesel.com...

-

Page 3: Table Of Contents

Coolant .......................... 26 Fuel............................ 31 Engine overview.................... 32 Designation of components .................... 32 Fuses .......................... 42 HATZ instrument box...................... 44 Transport, assembly and commissioning ............ 48 Transport ........................... 48 Installation notes........................ 51 Preparations for commissioning .................. 52 Filling engine oil (first filling).................... 53 Filling the cooling system.................... - Page 4 Resetting the maintenance interval indicator.............. 116 Faults........................ 117 Troubleshooting ....................... 117 Start support ........................ 120 Storage and disposal.................. 125 10.1 Storing the machine...................... 125 10.2 Disposing of the machine .................... 127 Installation declaration ................... 128 Declaration of the manufacturer.............. 129 Manual HATZ...

-

Page 5: Notices

All rights reserved! Copyright The copyright for this manual rests entirely with Motorenfabrik HATZ, Ruh- storf. This manual may only be copied or distributed if written approval has been received. This also applies to the copying or distribution of excerpts of this manual. -

Page 6: General Information

HATZ tools. The global HATZ service network is at your disposal to ad- vise you and supply you with spare parts. For the address of the Hatz ser- vice station nearest you, please see the enclosed spare parts list or visit us in the Internet at: www.hatz-diesel.com... -

Page 7: Safety

Any other use is not intended and therefore not permitted. Violations com- promise the safety of the personnel working with the machine. Motorenfabrik HATZ does not accept any liability for damage resulting from this. The operational safety of the machine is only guaranteed if it is used as in- tended. -

Page 8: Machine User Or Machine Manufacturer Obligations

Machine manufacturer obligations If you have an engine that is not yet installed in a machine, it is imperative that you follow the Assembly Instructions for HATZ Diesel Engines be- fore installing the engine. These assembly instructions contain important in- formation on how to safely install the engine and are available at your near- est HATZ service station. -

Page 9: Representation Of Safety Notes

Structure of the safety notes The safety notes consist of: ▪ Danger symbol ▪ signal word ▪ Description of danger ▪ Possible consequences ▪ Preventative measures General danger symbol The general danger symbol is used to identify the danger of personal injury. HATZ Manual... -

Page 10: Meaning Of Safety Symbols

Explanation of symbols The following table describes the meanings of the safety symbols used in this manual. Symbol Meaning Smoking, fire, and open flames are prohibited! Warning of personal injury! Warning of hot surfaces! Warning of flammable substances! Manual HATZ... - Page 11 Warning of toxic engine exhaust! Warning of corrosive substances! Warning of heavy loads! Warning of environmental damage! Comply with this manual or additional documentation from other manufacturers or the carrier. Additional information that is useful to the reader. HATZ Manual...

-

Page 12: Safety Notes

Personal protective equipment During operation and maintenance of the machine, personal protective equipment must be available and must be used if necessary. The required personal protective equipment is specified in the descriptions of the operat- ing steps. Manual HATZ... - Page 13 The warning labels and information signs on the machine must be followed (see chapter "Labels" 3.3 Labels, page 19). The warning labels and information signs must be kept legible and must be replaced if necessary. For this purpose, contact your nearest HATZ service station. Maintenance work...

- Page 14 Danger of injury from overloading the body. Lifting the machine to transport it or to move it to another loca- tion can lead to injuries (of the back, for example). ▪ Only lift the machine with a hoist (see chapter 6.1 Transport, page 48). Manual HATZ...

-

Page 15: Machine-Specific Safety Instructions For Operation

If you have an engine that is not yet installed in a machine, it is imperative that you follow the Assembly Instructions for HATZ Diesel Engines be- fore installing the engine. These assembly instructions contain important information on safe installa- tion. -

Page 16: Machine-Specific Safety Instructions For Maintenance Work

Replacing parts ▪ When replacing defective components, we recommend that you use gen- uine HATZ original spare parts (see chapter 2 General information, page ▪ When disposing of parts that can no longer be used, do so in accordance with local environmental regulations or send them to a recycling center. - Page 17 For engines with an electric starter: Disconnect the negative battery terminal. Protect the starting key against unauthorized access. CAUTION Danger of burns. There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. HATZ Manual...

-

Page 18: Electrical Equipment

Immediately rinse areas affected by splashed acid with clear water and consult a physician if necessary. ▪ Promptly replace faulty indicator lamps. ▪ Do not disconnect the battery while the machine is running. Resulting volt- age peaks could destroy the electronic components. Manual HATZ... -

Page 19: Labels

NOTICE ▪ We cannot be held liable for electrical equipment that is not designed according to HATZ wiring diagrams. Labels Warning labels and information signs on the engine Label... - Page 20 Do not tilt the battery; acid may spill out of the vent openings. 7. Do not dispose of the battery with the household trash. 8. Take the used battery to a collec- tion center. Manual HATZ...

-

Page 21: Technical Data

Sense of rotation Left (view toward flywheel) Tappet clearance Automatic hydraulic valve adjustment (mainte- nance-free) Max. perm. continuous HATZ radiator with integrated expansion tank sloping position radiator low: 20°, other parts: 30° HATZ radiator with external expansion tank 30° 30°... - Page 22 3H50 TI 133 * 3H50 TIC 154 * 3H50 TICD 161 * 4H50 Ti 152 * 4H50 TIC 173 * 4H50 TICD 180 * * Without radiator. Screw tightening torque Designation Oil drain screw Drain plug on the radiator Manual HATZ...

-

Page 23: Engine Type Plate

3H50, 4H50 Technical data Designation Screws for the breather cap of the crankcase ventilation Engine type plate EMISSION CONTROL INFORMATION MOTORENFABRIK HATZ GMBH KG ¬ D-94099 RUHSTORF www.hatz-diesel.com Model: Build: S/N: Power: Displ: Eng.Fam: Emission Control System: Power Category: ULTRA LOW SULFUR DIESEL FUEL ONLY. - Page 24 DOC (see section 4.3 Engine oil, page 25and section 4.5 Fuel, page 31. The following table shows which engine types are equipped with DOC. Engine type number Type number 3H50TIC 4H50TIC 4H50TI 3H50TI 3H50TICD 4H50TICD 3H50T Manual HATZ...

-

Page 25: Engine Oil

(for details, see section 4.2.1 Engine serial number, page 24). ▪ ACEA E6, E7 or E9 ▪ ACEA C1, C2, C3 or C4 ▪ API CK-4, CJ-4 or CI-4 Oil viscosity Select the recommended viscosity depending on the ambient temperature at which the engine will be operated. HATZ Manual... -

Page 26: Coolant

Only use engine oil that fulfills the specifications stipulated above. Coolant Introduction Liquid-cooled engines require a coolant specified by HATZ for engine cool- ing. Coolant is prepared in accordance with manufacturer's instructions, please comply with the information on the packaging label. - Page 27 5 liters 0000 055 413 00 The H-series Coolant concentrate is exactly matched to the requirements of your HATZ diesel engine. Alternative radiator protection fluids If no H-series Coolant is available, other radiator protection fluids are ap- proved by HATZ:...

- Page 28 Minerva Oil PERMA UNIVERSAL LL -37 °C Mitan Alpine C12, Alpine C12+, Alpine C30, Alpine C40 Mofin MOFIN Kühlerschutz M40 Extra MOL-LUB EVOX Premium Concentrate Moove Comma Xstream G40 Lubricants Nalco Nalcool NF40 Nils NILS POLAR PLUS, NILS POLAR S-O Manual HATZ...

- Page 29 Tedex Tedex Antifreeze OT LL Tirreno TIRRENO ORGANIC COOL G 300 Industria TIRRENO ORGANIC COOL G 400 Total Total Glacelf Auto Supra, TOTAL GLACELF Si-OAT Valvoline Zerex G 30, Zerex G 40 YORK SAS YORK 718, YORK 816 HATZ Manual...

- Page 30 Radiator protection Water Frost-resistant to ap- fluid prox. * min. 40 vol% 60 vol% -24 °C max. 50 vol% 50 vol% -36 °C * These details depend on the product in question. Be sure to comply with the packaging label. Manual HATZ...

-

Page 31: Fuel

▪ The use of fuel that does not meet specifications requires approval by Motorenfabrik HATZ (main plant). CAUTION Danger of malfunctions due to old fuel. When diesel fuel is stored in a fuel tank or canister for lengthy periods, deposits may form on account of fuel aging. -

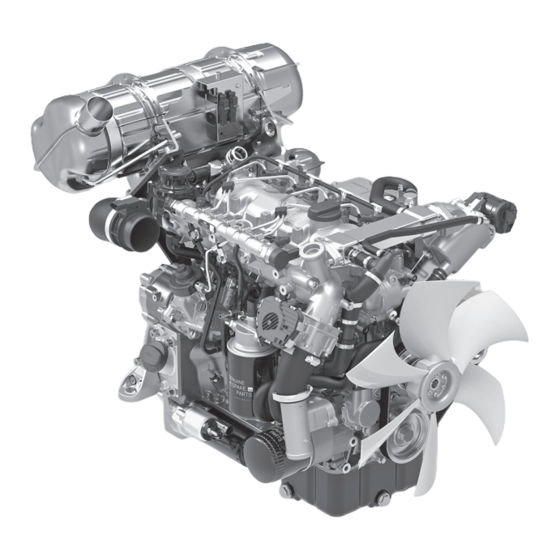

Page 32: Engine Overview

Engine overview 3H50, 4H50 Engine overview Designation of components Model – TIC intake side Intake opening for combustion air Oil filler plug, top (option) Oil filter Fuel main filter Side oil drain screw Manual HATZ... - Page 33 3H50, 4H50 Engine overview Fuel prefilter Drain plug with integrated water level sensor Electric fuel pump Engine type plate Starter (low mounting position) Dipstick Oil filler plug, bottom Oil filler plug, middle (option) Crankcase ventilation HATZ Manual...

- Page 34 DPF system with diesel oxidation catalytic converter and diesel particulate filter (TICD model) Turbocharger Engine foot Diesel oxidation catalytic converter DOC (TIC model) Exhaust outlet Starter (high mounting position) Three phase alternator Poly v belt Oil drain screw, front Manual HATZ...

- Page 35 Model – OPU intake side NOTICE The Open Power Unit (OPU) is a complete system which, in ad- dition to the engine, also includes all of the components required for cooling. Intake opening for combustion air Rain cap HATZ Manual...

- Page 36 Fuel main filter Side oil drain screw Fuel prefilter Drain plug with integrated water level sensor Electric fuel pump Engine type plate Starter (low mounting position) Dipstick Oil filler plug, bottom Vibration damper Oil filler plug, middle (option) Crankcase ventilation Manual HATZ...

- Page 37 Model – OPU exhaust side Radiator with integrated expansion tank Sealing cap for coolant Oil filler plug, top (option) Turbocharger Diesel oxidation catalyst (DOC) Exhaust outlet Starter (high mounting position) Three phase alternator Belt guard (option) Oil drain screw, front HATZ Manual...

-

Page 38: Hatz Instrument Box

(4) and (6) can be removed for daily maintenance work. The individual maintenance positions are shown on the figures of the OPU. Intake opening for combustion air Rain cap Air filter (optional) Top maintenance cover Clamp-type fasteners Side maintenance cover HATZ instrument box Manual HATZ... - Page 39 3H50, 4H50 Engine overview Speed adjustment Engine type plate Drain plug with integrated water level sensor Fuel prefilter Components of the electronic engine control unit Pos. Designation Figure Crankshaft speed sensor HATZ Manual...

- Page 40 Air filter differential pressure sensor Rail pressure sensor Rail pressure control valve EGR valve Coolant level sensor (integrated in external expan- sion tank) Coolant temperature sensor Coolant level sensor (for radiator with integrated expansion tank) Camshaft speed sensor Intake throttle (TICD model) Manual HATZ...

- Page 41 Exhaust gas temperature sensor (TICD model) Differential pressure sensor (TICD model) Low fuel pressure and fuel temperature sensor Water level sensor Oil pressure and oil temperature sensor Metering unit on the high pressure pump Ambient pressure sensor (integrated in the engine control unit) HATZ Manual...

- Page 42 Engine overview 3H50, 4H50 Fuses Overview - fuse assignment 3H50TIC, 4H50TI, 4H50TIC Pos. Consumer Fuse Voltage supply for control unit Signal inputs for control unit Glow plugs Voltage supply for additional consumers Fuel pump Starter, terminal 50 Manual HATZ...

- Page 43 Voltage supply for control unit Ignition, terminal 15 Starter, terminal 50 Ignition, terminal 15 (for additional consumers that are switched via the ignition lock) Voltage converter (only for 24 V system) Power module (option) Exhaust gas heating 1 Exhaust gas heating 2 HATZ Manual...

- Page 44 Engine overview 3H50, 4H50 HATZ instrument box Overview Starting key Pushbutton Pre-glow indicator Operating indicator Charge control Oil pressure indicator Air filter service indicator Engine temperature indicator Maintenance interval indicator Engine fault Regeneration of diesel particulate filter required (TICD model)

- Page 45 Oil pressure indicator Engine oil pressure too low. Danger of engine damage. Stop the engine immediately and check the oil level (see section 7.5 Check the oil level, page 66). Contact HATZ Service if the oil level is correct. HATZ Manual...

- Page 46 For details of troubleshooting, see section 9.1 Troubleshooting, page 117. Maintenance interval indicator This indicator lights when the 500-hour maintenance visit is due. After completion of maintenance work, reset the maintenance interval indicator (see section 8.2.17 Resetting the maintenance interval indicator, page 116). Manual HATZ...

- Page 47 Avoid staying in the vicinity of the running engine if possible. Switch off the engine and correct the fault promptly or contact a HATZ service cen- ter. ▪ Engine stop The engine switches off automatically.

-

Page 48: Transport, Assembly And Commissioning

(of the back, for example). ▪ Only lift the machine with a hoist. NOTICE Danger of environmental damage from leaking fluid. If the machine is tilted, engine oil and fuel can run out. ▪ Only transport the machine in an upright position. Manual HATZ... - Page 49 Transport, assembly and commissioning Access to the lifting eyes with the Silent Pack Overview Control side maintenance lid Top maintenance cover Holder for the air filter Clamp-type fasteners for control side maintenance cover Clamp-type fasteners for top maintenance cover HATZ Manual...

- Page 50 3 lifting eyes) in this chapter. Mount all parts again after completing the transport activities. Make sure that the seal lip (3) of the maintenance cover (B) is not trapped! Lifting points (engines with 2 lifting eyes) Lifting points Manual HATZ...

-

Page 51: Installation Notes

HATZ service station. For contact data, see chapter 1 Impres- sum, page 5 or www.hatz-diesel.com. Installation notes HATZ diesel engines are efficient, robust, and have a long service life. Therefore, they are usually installed in machines that are used for commer- cial purposes. -

Page 52: Preparations For Commissioning

▪ After the engine is installed in the machine, rotating parts must be pro- tected against contact. HATZ safety equipment is available for the belt drive of the cooling fan and alternator. ▪ Comply with all notices and warning labels on the engine and keep them in a legible condition. -

Page 53: Filling Engine Oil (First Filling)

When checking the oil level, the engine must be horizontal and have been switched off for a few minutes. Overview Dipstick (depending on the model) Oil filler plug, top (option) Oil refilling container Oil filler plug, bottom Oil filler plug, middle (option) HATZ Manual... -

Page 54: Filling The Cooling System

CAUTION Danger of later engine damage. ▪ Operating the engine with a coolant level below the MIN. mark can lead to engine damage. ▪ When checking the coolant level, the engine must be hori- zontal and switched off. Manual HATZ... - Page 55 Step Activity Open the sealing cap (2). HATZ radiator with integrated expansion tank Top up the coolant to the edge (3) of the pipe section. For preparation of the coolant, see section 4.4 Coolant, page HATZ radiator with external expansion tank Top up the coolant to the MAX mark on the expansion tank.

-

Page 56: Starting The Engine For The First Time Or After A Fuel Filter Replacement

Ensure sufficient ventilation. CAUTION Danger of engine damage from the use of starting fluid. ▪ Engine damage from the use of starting fluid can lead to un- controlled ignition. ▪ Engine damage from uncontrolled ignition. ▪ Never use starting fluid. Manual HATZ... - Page 57 Radiator and radiator hoses are free from leaks (see the chapter 8.2.5 Checking the cooling system, page 83). No persons are located in the danger zone of the engine or ma- chine. All safety equipment is in place. Overview — HATZ instrument boxes Starting key Pre-glow indicator HATZ Manual...

- Page 58 Charge control Oil pressure indicator Ignition lock Operation Start NOTICE For further details on the instrument box, see section 5.3 HATZ instrument box, page 44. Procedure NOTICE ▪ Start for max. 20 seconds. If the engine is still not running after that, turn the starting key back to position "0" and elimi- nate the cause (see section 9.1 Troubleshooting, page 117).

- Page 59 ▪ The operating indicator (3) lights up and signals that there is no engine fault. NOTICE ▪ In case of irregularities, switch off the engine immediately. ▪ Identify the fault and eliminate it. ▪ For details of troubleshooting, see chapter 9.1 Trou- bleshooting, page 117. HATZ Manual...

-

Page 60: Operation And Use

For de- tails on engine faults and fault diagnosis, see chapter 5.3 HATZ instrument box, page 44. ▪ Avoid staying in the vicinity of the running engine if possible. -

Page 61: Performing Tests

Radiator and radiator hoses are free from leaks (see the chapter 8.2.5 Checking the cooling system, page 83). No persons are located in the danger zone of the engine or ma- chine. All safety equipment is in place. HATZ Manual... -

Page 62: Starting The Engine

Engine damage from the use of starting fluid can lead to un- controlled ignition. ▪ Engine damage from uncontrolled ignition. ▪ Never use starting fluid. NOTICE See also starting instructions in the documentation for the com- plete machine. Overview — HATZ instrument boxes Starting key Pre-glow indicator Manual HATZ... - Page 63 Oil pressure indicator Engine temperature indicator Ignition lock Operation Start NOTICE For further details on the instrument box, see section 5.3 HATZ instrument box, page 44. Procedure NOTICE ▪ Start for max. 20 seconds. If the engine is still not running after that, turn the starting key back to position "0"...

-

Page 64: Switching Off The Engine

Allow the engine to cool down for approx. 5 min at reduced speed and load. NOTICE Danger of exhaustive battery discharge. ▪ When the machine is switched off, always turn the starting key to position "0" or else the battery may become fully dis- charged. Manual HATZ... - Page 65 3H50, 4H50 Operation and use NOTICE See also instructions in the documentation for the complete ma- chine. Overview — HATZ instrument boxes Starting key Ignition lock Operation Procedure Step Activity Turn the starting key (1) to position "0". The engine switches off.

-

Page 66: Check The Oil Level

Operating the engine with an oil level below the min. mark or above the max. mark can lead to engine damage. ▪ When checking the oil level, the engine must be horizontal and have been switched off for a few minutes. Overview Manual HATZ... - Page 67 Pull out the dipstick and check the oil level. If the oil level is close to the min. mark, add engine oil to the max. mark. For the specification and viscosity, see chapter 4.3 Engine oil, page 25. Reinsert the dipstick. HATZ Manual...

-

Page 68: Refueling

Only use the fuel specified in chapter 4.5 Fuel, page 31. ▪ The use of fuel that does not meet specifications requires approval by Motorenfabrik HATZ (main plant). NOTICE Never run the tank empty if possible, as otherwise air can enter the fuel system. -

Page 69: Regenerating The Diesel Particulate Filter

If inflammable materials come into contact with the exhaust gas flow or the hot exhaust gas system, these materials can ignite. ▪ Keep inflammable materials away from the exhaust gas sys- tem. ▪ Do not operate and place the engine in the direct vicinity of inflammable materials. HATZ Manual... - Page 70 This can mean that neither automatic nor manual regeneration can be started. In these cases, a service regeneration is re- quired by HATZ Service. In addition, there is a danger that the diesel particulate filter will be damaged or destroyed.

- Page 71 See also instructions in the documentation for the complete machine. The regeneration block must be switched off. Let the engine run and adjust it to a low engine speed. HATZ Manual...

- Page 72 Pressing the button again deactivates the block and indicator (5) goes out. Note: Switching off the engine also deactivates an activated regenera- tion block. Manual HATZ...

-

Page 73: Maintenance

▪ Installation of unsuitable spare parts can lead to problems. We cannot ac- cept responsibility for direct damage or secondary damage that results from this.We therefore recommend the use of Hatz original spare parts. ▪ Closely adhere to the maintenance conditions prescribed in this manual. -

Page 74: Maintenance Work

▪ After the necessary maintenance and repair work is completed, perform a function test (test run). ▪ For maintenance work that is not listed and described in the maintenance documentation, please contact your nearest HATZ service station. Maintenance work Safety note... - Page 75 Clean the engine 8.2.7 Engine cleaning, page Every 500 operat- Change the air filter cartridge 8.2.15 Servicing ing hours or when (primary filter) the air filter (op- indicated, at least tional), page 111 every 2 years HATZ Manual...

-

Page 76: Additional Work On The Silent Pack

▪ Only operate the engine when all covers are installed. CAUTION Danger of burns. There is a danger of burns when working on a hot engine. ▪ Let the engine cool. ▪ Wear safety gloves. Manual HATZ... - Page 77 3H50, 4H50 Maintenance Overview HATZ Manual...

- Page 78 Access cover to the drain plug on the radiator Clamp-type fasteners for control side maintenance cover Clamp-type fasteners for top maintenance cover Sealing lip Fixing screws for holder for the air filter (4) Fixing screws for side panel exhaust side (12) Fixing screws for access lid (5 pieces) Manual HATZ...

- Page 79 Remove the air filter fastening (C) Unscrew the fixing screws (4). Remove the side panel on the exhaust gas side (D) Remove the top maintenance cover (B) Remove the air filter fastening (C). Unscrew the fixing screws (5). Remove the side trim panel (D). HATZ Manual...

-

Page 80: Checking The Intake Area Of The Combustion Air

There is a danger of burns when working on a hot engine. ▪ Let the engine cool. ▪ Wear safety gloves. NOTICE In case of heavy contamination, shorten the maintenance inter- vals accordingly (see chapter 8.2.1 Maintenance plan, page 74). Manual HATZ... - Page 81 3H50, 4H50 Maintenance Overview (HATZ air filter) Intake opening for combustion air Dust discharge valve Rubber lips OK Rubber lips deformed Procedure Step Activity Check the intake opening (1) for coarse contamination such as leaves, heavy dust deposits, etc., and clean if necessary.

-

Page 82: Checking The Radiator Fins For Dirt Accumulation

The engine temperature indicator lights up as soon as the en- gine becomes inadmissibly hot. ▪ Switch off the engine and eliminate the cause. NOTICE In case of heavy contamination, shorten the maintenance inter- vals accordingly (see chapter 8.2.1 Maintenance plan, page 74). Manual HATZ... -

Page 83: Checking The Cooling System

Never top up coolant above the MAX - mark on the expan- sion tank. ▪ Never stop escaping coolant with your bare hands. CAUTION Danger of burns. There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. HATZ Manual... - Page 84 Procedure for checking the coolant level Step Activity The coolant must be between the MIN and MAX marks on a switched-off and cooled-down engine. For a warm engine, the level can also be slightly above the MAX mark. Manual HATZ...

- Page 85 Overview Hose clip Procedure Step Activity Check the cooling system for leaks and rectify the cause imme- diately - in case of doubt consult HATZ Service for advice. When hose connections are loose, retighten the hose clips (1). HATZ Manual...

-

Page 86: Changing The Engine Oil And Oil Filter

Operating the engine with an oil level below the min. mark or above the max. mark can lead to engine damage. ▪ When checking the oil level, the engine must be horizontal and have been switched off for a few minutes. Manual HATZ... - Page 87 Dispose of the old filter in accordance with local environmental regulations. Thoroughly clean the sealing surface (2). Lightly oil the sealing lip (3) of the new oil filter. Screw in the oil filter and tighten it by hand. HATZ Manual...

- Page 88 (2) of the oil filter is at the same level as the shaped element (3). In this position, a valve releases the oil return into the crankcase which allows the oil filter to empty. Fully unscrew the oil filter after a waiting period of approx. 30 seconds. Manual HATZ...

- Page 89 Depending on accessibility, the engine oil can be drained at oil drain screw (1) or (2). Unscrew the oil drain screw and drain the used oil entirely. Screw in the cleaned oil drain screw with the new gasket (3) and tighten. Tightening torque: 50 Nm. HATZ Manual...

- Page 90 Remove the screw plug (1). Place the oil drain hose (2) on the drain valve and tighten by hand. ▪ During tightening, the drain valve opens allowing the used oil to drain. Remove the drain hose and reattach the sealing screw. Manual HATZ...

- Page 91 Oil filler plug, top (option) Oil refilling container Oil filler plug, bottom Oil filler plug, middle (option) Procedure Step Activity Pull out the dipstick (1) and clean it. Depending on the model, unscrew oil filler plug (2), (4) or (5). HATZ Manual...

-

Page 92: Engine Cleaning

Danger of environmental pollution due to oil and cleaning agents. Oil and cleaning agents are hazardous to the environment. ▪ Do no allow them to enter the ground water, water bodies, or sewage system. ▪ Only clean the machine at the washing area intended for this. Manual HATZ... - Page 93 Damage to the radiator fins due to improper cleaning. ▪ Never clean the radiator fins with a tool such as a spatula or screwdriver. A reduction in radiator performance through bent radiator fins or radiator leaks may be the result. HATZ Manual...

- Page 94 On the radiator, first work against the direction of flow of the cooling air and then in the direction of flow. Identify the cause of the oiling and seal the leak. After the cleaning Let the engine run warm until it has completely dried to prevent rust formation. Manual HATZ...

-

Page 95: Checking The Poly V Belt

Safety notes CAUTION Danger of burns. There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. Preparation Step Activity Unscrew the optional belt guard (1). Unscrew the fixing screws (2) for this. HATZ Manual... - Page 96 ▪ Oily dirt contamination. ▪ Transverse cracks in multiple ribs. ▪ Broken ribs. If one or more of these instances of damage are present, re- place the poly v belt immediately (see section 8.2.9 Replacing the poly v belts, page 99). Manual HATZ...

- Page 97 Regularly check the belt tension, retension the poly v belt if required. Overview Alternator Upper fixing screw on the generator Lower fixing screw on the generator "Facom DM.16" belt tension meter Display on the belt tension meter Measuring point for belt tension HATZ Manual...

- Page 98 For this, we recommend the use of the DM.16 belt tension meter from Facom or a frequency meter. If neither of these me- ters are available, please contact your nearest HATZ Service. Belt tension Display (5) on the "Fa- Vibration frequency com"...

-

Page 99: Replacing The Poly V Belts

There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. Belt run Engine without A/C compressor Engine with A/C compressor Alternator Water pump Crankshaft Poly-V belt Belt tensioner A/C compressor Pulley HATZ Manual... - Page 100 Step Activity Unscrew the optional belt guard (1). Unscrew the fixing screws (2) for this. Remove the left half of the optional protective guard (3) by un- screwing the screws (4) and (5) (at the top and bottom). Manual HATZ...

- Page 101 Feed a new poly v belt over the fan blade in the same way from the radiator side. Lay the poly v belt over the pulleys wheels and tension (see 8.2.8 Checking the poly v belt, page 97). Mount the protective guard and belt protection again. HATZ Manual...

- Page 102 Slowly relieve the tension of the belt tensioner. Carefully lift the poly v belt over a fan blade. Turn the fan further in the counterclockwise direction and lift the belt over the re- maining fan blades until it is completely free. Manual HATZ...

-

Page 103: Changing The Oil Separator Of The Crankcase Ventilation

8.2.10 Changing the oil separator of the crankcase ventilation Safety note CAUTION Danger of burns. There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. Overview Mounting bolts (captive) Breather cap Oil separator cartridge Vent hose HATZ Manual... -

Page 104: Checking The Screw Connections

▪ Do not retighten the screws for attaching the cylinder head. Procedure Step Activity Check the condition of all screw connections and ensure that they are tight (for exceptions, see note). Tighten any lose screw connections. Manual HATZ... -

Page 105: Draining The Water Separator

The fuel prefilter has a water separator. An electronic water level sensor sig- nals when the maximum permissible water level is reached in the water sep- arator (see explanation of symbols/engine fault, section 5.3 HATZ instrument box, page 44). Overview... -

Page 106: Changing The Fuel Prefilter

There is a danger of burns when working on a hot engine. ▪ Let the engine cool before maintenance. CAUTION Danger of injury Repeated contact with diesel fuel can cause chapped and cracked skin. ▪ Wear safety gloves. Manual HATZ... - Page 107 ▪ Only install fuel filters dry and do not prefill in order to avoid contamination. Overview Hose clip on fuel feed line Fuel prefilter Drain plug with integrated water level sensor Water level sensor cable Strap wrench Gasket HATZ Manual...

-

Page 108: Changing The Main Fuel Filter

Fire hazard from fuel Leaked or spilled fuel can ignite on hot engine parts and cause serious burn injuries. ▪ Do not spill fuel. ▪ No open flames when working on the fuel system. ▪ Do not smoke. Manual HATZ... - Page 109 CAUTION Dirt particles can damage the injection system. ▪ Maintain clean conditions to ensure dirt does not enter the fuel line. ▪ Only install fuel filters dry and do not prefill in order to avoid contamination. HATZ Manual...

- Page 110 NOTE: When starting the engine, adhere to the procedure in "6.6 Starting the engine for the first time or after a fuel filter re- placement, page 56". After the test run, check the main fuel filter for leaks and tighten by hand if necessary. Manual HATZ...

-

Page 111: Servicing The Air Filter (Optional)

▪ The filter cartridge may not be washed out or beaten out. ▪ The filter cartridge may be blown out only in exceptional cases. The pressure must not exceed 5 bar. Overview HATZ Manual... - Page 112 Use an air gun with an extension tube (7) with the end bent by approx. 90°. The end of the extension tube must not touch the filter paper. Check the sealing surfaces (9) of the filter cartridge for damage. Manual HATZ...

-

Page 113: Changing Coolant

Never stop escaping coolant with your bare hands. CAUTION Danger of burns. There is a danger of burns when working on a hot cooling sys- tem. The cooling system is pressurized when the engine is hot. ▪ Let the engine cool. ▪ Wear safety gloves. HATZ Manual... - Page 114 Collect the coolant and dispose of it according to local envi- ronmental regulations. Overview Expansion tank for coolant Sealing cap MAX - Maximum coolant level MIN - Minimum coolant level Drain plug on the radiator Seal ring Screw plug for drain valve Manual HATZ...

- Page 115 As contaminants in the coolant could be an indication of a larger problem, we recommend having the rinsing of the cooling system carried out by trained specialist personnel. Filling the cooling system See section 6.5 Filling the cooling system, page 54 HATZ Manual...

-

Page 116: Resetting The Maintenance Interval Indicator

Release the button (2) after a wait time of at least 5 seconds but no longer than 10 seconds. The maintenance interval indicator is now reset. NOTICE If a HATZ instrument box is not used: Comply with the instructions in the documentation for the com- plete machine. Manual... -

Page 117: Faults

General troubleshooting notes If the cases listed below have been worked through but the fault continues to persist, please contact your nearest Hatz service station. Indicator for engine fault on the HATZ instrument box is flashing. Possible causes Remedy Section Coolant level too low. - Page 118 Engine switches off spontaneously during operation. Possible causes Remedy Chapter The tank ran out of fuel Fill with fuel. 7.6 Refueling, during operation. page 68 Mechanical faults. Contact HATZ Service. Electrical defects. Check wiring or contact HATZ Service. Manual HATZ...

- Page 119 Drain water from the fuel pre- 8.2.12 Draining filter. the water separa- tor, page 105 If the engine fault persists, con- tact a HATZ Service immedi- ately. The tank ran out of fuel Add fuel. 7.6 Refueling, during operation. page 68 The engine loses power and speed, and black smoke emerges from the ex- haust.

-

Page 120: Start Support

Faults 3H50, 4H50 Possible causes Remedy Chapter Thermostat or water Contact HATZ Service. pump faulty. Coolant level too low. Check the cooling system. 8.2.5 Checking the cooling sys- tem, page 83 Start support Safety notes DANGER Danger of explosion due to the generation of sparks. - Page 121 ▪ A discharged battery can freeze even at temperatures just a few degrees below zero. If the battery is frozen or thawed, do not carry out a start support. Replace the battery. Overview – 12 volt model HATZ Manual...

- Page 122 1–2–3–4 (see Overview – 12 volt model). Do not start the external device. Start the machine with the discharged battery. Let the engine run for several minutes. Disconnect the start support cable in the sequence 4–3–2–1. Manual HATZ...

- Page 123 Clamp pliers on the positive (+) terminal of the current emitting battery Black start support cable (negative (–) terminal) Clamp pliers on the negative (–) terminal of the current emitting battery Clamp pliers on the negative (–) terminal of the discharged bat- tery HATZ Manual...

- Page 124 1–2–3–4 (see Overview – 24 volt model). Do not start the external device. Start the machine with the discharged battery. Let the engine run for several minutes. Disconnect the start support cable in the sequence 4–3–2–1. Manual HATZ...

-

Page 125: Storage And Disposal

CAUTION Danger of burns. There is a danger of burns when working on a hot cooling sys- tem. The cooling system is pressurized when the engine is hot. ▪ Let the engine cool. ▪ Wear safety gloves. HATZ Manual... - Page 126 *FAME = Fatty Acid Methyl Ester Ambient conditions during storage ▪ Max. permissible storage temperature: -25 °C to +60 °C ▪ Max. permissible humidity: 70% ▪ Protect the engine from direct sunlight Manual HATZ...

-

Page 127: Disposing Of The Machine

The brand new engine can normally be stored for up to 12 months. The pro- tection lasts up to approx. 6 months at very high humidity and in sea air. For storage periods of more than 12 months, please contact the nearest HATZ Service. 10.2 Disposing of the machine... -

Page 128: Installation Declaration

Motorenfabrik Hatz GmbH & Co.KG Ernst-Hatz-Straße 16 D-94099 Ruhstorf a. d. Rott hereby declares that the incomplete machine: product description: Hatz diesel engine Type designation and as of serial number: 3H50TIC = 13510, 3H50TI = 16310, 3H50TICD = 16410, 3H50T = 17810, 4H50TIC = 13610, 4H50TI = 16110, 4H50TICD = 16510 satisfies the following basic safety and health protection requirements in acc. -

Page 129: Declaration Of The Manufacturer

3/4H50TICD-cs 855.39 NRSC-D2 3H50TICD 3000 3/4H50TICD-vs 736.59 NRSC-C1 3H50TICD-HT 2800 787.30 NRTC 3H50TICD-HT 2800 H50TIC-IWA-cs 704.91 NRSC-D2 4H50TIC 1800 H50TIC-IWA-vs 751.80 NRSC-C1 3H50TIC 2800 H50TIC-IWP-vs 734.02 NRSC-E3 4H50TIC 2800 *According to EU Regulation 2016/1628, Article 43 Paragraph (4) HATZ Manual... - Page 130 Make (trade name(s) of manufacturer): Hatz-Diesel 1.2. Commercial name(s) (if applicable): 1.3. Company name and address of manufacturer: Motorenfabrik Hatz GmbH & Co. KG, Ernst-Hatz-Str. 16, 94099 Ruhstorf a.d. Rott 1.4. Name and address of manufacturer's authorised representative (if any): – 3/4H50TICD-cs, 3/4H50TICD-vs 1.5.

- Page 131 Hatz-Diesel 1.2. Commercial name(s) (if applicable): 1.3. Company name and address of manufacturer: Motorenfabrik Hatz GmbH & Co. KG, Ernst-Hatz-Str. 16, 94099 Ruhstorf a.d. Rott 1.4. Name and address of manufacturer's authorised representative (if any): – 1.5. Engine type designation/ engine family designation/ FT (*):...

- Page 132 Motorenfabrik Hatz GmbH & Co. KG Ernst-Hatz-Str. 16 94099 Ruhstorf a. d. Rott Deutschland Tel. +49 8531 319-0 Fax. +49 8531 319-418 marketing@hatz-diesel.de www.hatz-diesel.com 0000 436 004 03 - 09.2019 - 0.1 Printed in Germany CREATING POWER SOLUTIONS.

Need help?

Do you have a question about the 3H50 Series and is the answer not in the manual?

Questions and answers