Table of Contents

Advertisement

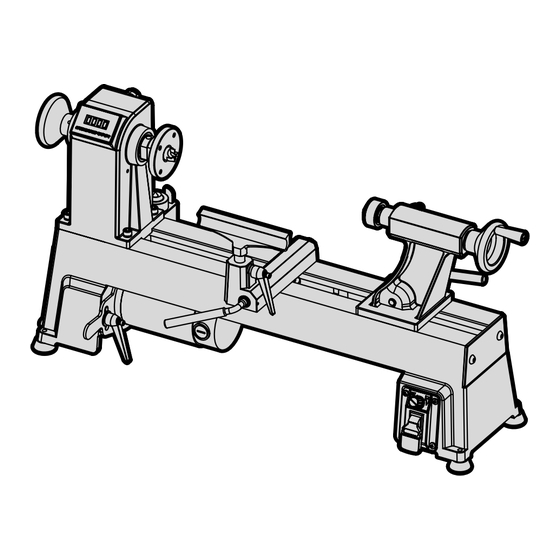

MODEL 34018

12x18-INCH VARIABLE

SPEED WOOD LATHE

Instruction Manual

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

1-800-232-1195 (M-F 8AM-5PM CST)

TECHSUPPORT@WENPRODUCTS.COM

IMPORTANT: Your new tool has been engineered and manufactured to WEN's highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use

your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

WENPRODUCTS.COM

For replacement parts and the most up-to-date instruction manuals, visit

Advertisement

Table of Contents

Summary of Contents for Wen 34018

- Page 1 1-800-232-1195 (M-F 8AM-5PM CST) TECHSUPPORT@WENPRODUCTS.COM IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability, ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged, trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

-

Page 2: Table Of Contents

CONTENTS WELCOME Introduction ..................... 3 Specifications ....................3 SAFETY General Safety Rules ..................4 Wood Lathe Safety Warnings ................6 Electrical Information ..................8 BEFORE OPERATING Unpacking & Packing List .................9 Know Your Wood Lathe ................. 10 Assembly & Adjustments ................11 OPERATION &... -

Page 3: Welcome

INTRODUCTION Thanks for purchasing the WEN Wood Lathe. We know you are excited to put your tool to work, but first, please take a moment to read through the manual. Safe operation of this tool requires that you read and understand this operator’s manual and all the labels affixed to the tool. -

Page 4: Safety

GENERAL SAFETY RULES WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool. - Page 5 GENERAL SAFETY RULES WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

-

Page 6: Wood Lathe Safety Warnings

WOOD LATHE SAFETY WARNINGS WARNING! Do not let comfort or familiarity with the product replace strict adherence to product safety rules. Failure to follow the safety instructions may result in serious personal injury. WOOD LATHE SAFETY 7. WORKPIECE REQUIREMENTS. Check the work- piece carefully for splits, knots, nails, or other ob- 1. - Page 7 WOOD LATHE SAFETY WARNINGS WARNING! Do not let comfort or familiarity with the product replace strict adherence to product safety rules. Failure to follow the safety instructions may result in serious personal injury. 13. Never perform layout, assembly or set-up 16.

-

Page 8: Electrical Information

ELECTRICAL INFORMATION GROUNDING INSTRUCTIONS In the event of a malfunction or breakdown, grounding provides the path of least resistance for an electric current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an equipment grounding conductor and a grounding plug. -

Page 9: Before Operating

UNPACKING & PACKING LIST UNPACKING With the help of a friend or trustworthy foe, such as one of your in-laws, carefully remove the wood lathe from the packaging and place it on a sturdy, flat surface. Make sure to take out all contents and accessories. Do not discard the packaging until everything is removed. -

Page 10: Know Your Wood Lathe

KNOW YOUR WOOD LATHE TOOL PURPOSE Lathes rotate workpieces on an axis so you can create various symmetrical profiles in wood by chisel- ing, sanding, and using other tools. Refer to the diagram below to become familiarized with the parts and controls of your wood lathe. -

Page 11: Assembly & Adjustments

ASSEMBLY & ADJUSTMENTS WARNING: Do not plug in or turn on the tool until it is fully assembled according on the instructions. Failure to follow the safety instructions may result in serious personal injury. REMOVING THE ANTI-RUST GREASE The lathe bed and centers have been coated with grease to prevent them from rusting. 1. - Page 12 ASSEMBLY & ADJUSTMENTS INSTALLING/REMOVING THE FACE PLATE Fig. 4 1. Mount the face plate (Fig. 4 - 3) onto the spindle by screwing it clockwise as far as it will go onto the spindle threads. 2. Insert the knockout rod (Fig. 4 - 1) into the hole to lock the spindle and use the wrench (Fig.

- Page 13 ASSEMBLY & ADJUSTMENTS REMOVING THE LIVE CENTER Fig. 8 1. Hold the live center (Fig. 8 - 1) to prevent it from falling. Use a rag to protect your hand from the sharp edges. 2. Rotate the handwheel (Fig. 8 - 2) counterclockwise to retract the quill until the live center is released from the quill.

- Page 14 ASSEMBLY & ADJUSTMENTS TOOL REST ADJUSTMENTS Fig. 12 You can adjust the height, position and angle of the tool rest assembly to suit your task at hand. To adjust the tool rest: 1. Loosen the locking lever (Fig. 12 - 1) on the tool rest base to slide the base back and forth, side to side, or to adjust its angle.

-

Page 15: Operation & Maintenance

ASSEMBLY & ADJUSTMENTS 2. Loosen the side cover knob (Fig. 16 - 1), then pull the side Fig. 16 cover (Fig. 16 - 2) up and rotate it out of the way to access the motor pulley. Tighten the knob. 3. - Page 16 OPERATION TURNING TOOLS If possible, select only quality high-speed steel turning tools. High-speed steel tools hold an edge and last longer than ordinary carbon steel. As one becomes proficient in turning, a variety of specialty tools for specific applications can be acquired. The following tools provide the basics for most wood-turning projects.

- Page 17 OPERATION SPINDLE TURNING Fig. 21 Spindle turning takes place between the centers of the lathe. It requires a spur center in the headstock and a live center in the tailstock. A cup center rather than a cone center in the tailstock will often reduce the risk of splitting the stock.

- Page 18 OPERATION CUTTING TECHNIQUES Fig. 24 Begin with a large roughing gouge. Place the tool on the tool rest with the heel of the tool on the sur- face to be cut. Slowly and gently raise the tool handle until the cutting edge comes into contact with the workpiece.

- Page 19 OPERATION SANDING - Leaving clean cuts will reduce the amount of sanding required. Move the tool rest out of the way, adjusting the lathe to a low speed. Being with find sandpaper (120 grit or finer), as coarser sandpaper will leave deep scratches and dull the features of the workpiece. Progress through each grit without skipping grits (as in, don’t jump from 120 grit to 220 grit).

- Page 20 OPERATION TO SHAPE THE OUTSIDE OF THE BOWL (FIG. 28) Fig. 28 Odd shaped burls, crotches and other irregular shaped blanks require special preparation before mounting in a chuck or onto a face plate. Remove the bark, if there is any from what appears to be the center of the top of the workpiece.

-

Page 21: Maintenance

Any attempt to repair or replace electrical parts on this tool may be hazardous. Servicing of the tool must be performed by a qualified technician. When servicing, use only identi- cal WEN replacement parts. Use of other parts may be hazardous or induce product failure. ROUTINE INSPECTION Before each use, inspect the general condition of the tool. -

Page 22: Troubleshooting Guide

TROUBLESHOOTING GUIDE WARNING: Stop using the tool immediately if any of the following problems occur. Repairs and replacements should only be performed by an authorized technician. For any questions, please contact our customer service at (800) 232-1195, M-F 8-5 CST or email us at techsupport@ wenproducts.com. -

Page 23: Exploded View & Parts List

EXPLODED VIEW & PARTS LIST... - Page 24 Retaining Ring 3424-001 wheel 3424-019 Tailstock 3424-002 Set Screw 3424-020 Set Screw Ball Bearing, Quill Locking 3424-003 3424-021 6004ZZ Handle 34018-004 Nameplate Label Tailstock Locking 3424-022 34018-005 Headstock Handle Digital Display 3424-084 Rubber Ring 34018-006 Label 3424-024 Handle Digital Display...

- Page 25 EXPLODED VIEW & PARTS LIST Part No. Description Qty. Part No. Description Qty. Speed Adjustment 34018-062 Motor Pulley 80.11 34018-080.11 Knob 34018-063 Speed Adjustment Motor Mounting 80.12 34018-080.12 34018-064 Label Screw 80.13 34018-080.13 Potentiometer 34018-065 Lock Washer 80.14 34018-080.14 Switch...

-

Page 26: Warranty Statement

WARRANTY STATEMENT WEN Products is committed to building tools that are dependable for years. Our warranties are consistent with this commitment and our dedication to quality. LIMITED WARRANTY OF WEN PRODUCTS FOR HOME USE GREAT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only, that all WEN consumer power tools will be free from defects in material or workmanship during personal use for a period of two (2) years used for professional or commercial use. - Page 27 NOTES...

- Page 28 THANKS FOR REMEMBERING V. 2020.02.07...

Need help?

Do you have a question about the 34018 and is the answer not in the manual?

Questions and answers