Advertisement

3.341.5275.245

Installation and Maintenance Instructions

The PED Directive 97/23/EC is repealed and replaced by the new

PED Directive 2014/68/EU with effect from 19 July 2016.

E X P E R T I S E

S O L U T I O N S

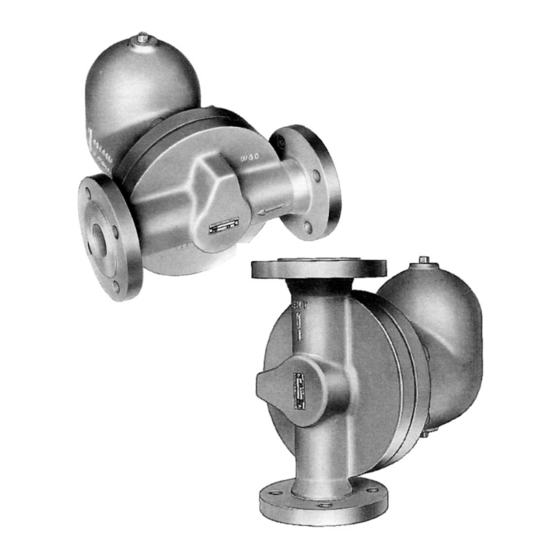

GKE ball float steam traps

S U S T A I N A B I L I T Y

1. Safety information

2. General product information

3. Installation

4. Commissioning

5. Operation

6. Maintenance

7. Spare parts

ST Issue 7 - 2013

© Copyright 2009

Advertisement

Table of Contents

Summary of Contents for Spirax Sarco GKE 10

- Page 1 ST Issue 7 - 2013 3.341.5275.245 GKE ball float steam traps Installation and Maintenance Instructions The PED Directive 97/23/EC is repealed and replaced by the new PED Directive 2014/68/EU with effect from 19 July 2016. 1. Safety information 2. General product information 3.

- Page 2 3.341.5275.245...

-

Page 3: Safe Handling

ATTENZIONE Lavorare in sicurezza con apparecchiature in ghisa e vapore Working safely with cast iron products on steam Informazioni di sicurezza supplementari - Additional Informations for safety Lavorare in sicurezza con prodotti Working safely with cast iron in ghisa per linee vapore products on steam I prodotti di ghisa sono comunemente presenti Cast iron products are commonly found on steam... - Page 4 Prevenzione dai colpi d’ariete - Prevention of water hammer Scarico condensa nelle linee vapore - Steam trapping on steam mains: Intervalli di 30÷50 m. intervals Vapore Steam Gruppo di scarico Vapore Gruppo di scarico Trap set Steam Trap set Gruppo di scarico Trap set Condensa - Condasate Condensa - Condasate...

- Page 5 Prevenzione delle sollecitazioni di trazione Prevention of tensile stressing Evitare il disallineamento delle tubazioni - Pipe misalignment: Installazione dei prodotti o loro rimontaggio post-manutenzione: Installing products or re-assembling after maintenance: Evitare l’eccessivo serraggio. Per garantire l’uniformità del carico e dell'allineamento, Utilizzare le coppie di serraggio i bulloni delle flange devono essere serrati in modo raccomandate.

- Page 6 Dilatazioni termiche - Thermal expansion: Gli esempi mostrano l’uso corretto dei compensatori di dilatzione. Si consiglia di richiedere una consulenza specialistica ai tecnici dell’azienda che produce i compensatori di dilatazione. Examples showing the use of expansion bellows. It is highly recommended that expert advise is sought from the bellows manufacturer.

-

Page 7: Safety Information

Group 2 of the above mentioned Pressure Equipment Directive. The products’ use on other fluids may be possible but, if this is contemplated, Spirax Sarco should be contacted to confirm the suitability of the product for the application being considered. - Page 8 Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to Spirax Sarco they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk.

-

Page 9: General Description

@ 300°C TMO - Maximum operating temperature 300°C Minimum operating temperature, danger of freezing considered 0°C GKE 10 10 bar g ΔPMX - Maximum differential pressure GKE 21 21 bar g Designed for a maximum cold hydraulic test pressure of 37.5 bar g... - Page 10 ASTM A194 8M Capacities (kg/h) The condensate discharge capacities shown below are based on condensate at saturation temperature Trap type Differential pressure GKE 10 GKE 10 GKE 21 GKE 21 (bar g) DN 40 - 1½" DN 50 - 2"...

-

Page 11: Installation

3. Installation Note: Before actioning any installation observe the ‘Safety information’ in Section 1. Referring to the Installation and Maintenance Instructions, name-plate and Technical Information Sheet, check that the product is suitable for the intended installation. Check materials, pressure and temperature and their maximum values. If the maximum operating limit of the product is lower than that of the system in which it is being fitted, ensure that a safety device is included in the system to prevent overpressurisation. -

Page 12: Operation

System Steam supply By-pass Trap valve 1 m minimum Sight glass Strainer Vacuum Standard installation breaker Installation for systems with low steam pressure and possible formation of vacuum Check valve Fig. 1 Fig. 2 4. Commissioning After installation or maintenance ensure that the system is fully functioning. Carry out tests on any alarms or protective devices. -

Page 13: General Information

6. Maintenance Note: Before actioning any maintenance programme observe the "Safety information" in Section 1. Safety note: These traps are installed in medium pressure steam lines. Personnel doing the adjustment and maintenance work should wear heavy gloves, long sleeve shirt and other equipment designed to protect the wearer (goggles, face shield, etc...) in the event of a leak. -

Page 14: Spare Parts

Always order spare parts by using the description given in the table and state the size and type of trap, including pressure range and type of the connections. Example: N° 1 main valve assembly for a ball float steam trap Spirax Sarco GKE 21, DN 1½". 3.341.5275.245... - Page 15 3.341.5275.245...

- Page 16 REPAIRS Please contact our nearest Branch Office or Agent, or directly Spirax-Sarco S.r.l. Via per Cinisello, 18 - 20834 Nova Milanese (MB) – ITALY - Tel.: +39 0362 49 17.1 - Fax: +39 0362 49 17 307 LOSS OF GUARANTEE Total or partial disregard of above instructions involves loss of any right to guarantee.

Need help?

Do you have a question about the GKE 10 and is the answer not in the manual?

Questions and answers