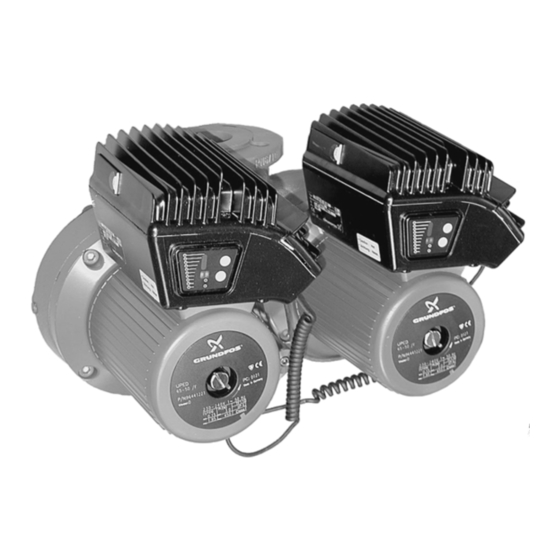

Grundfos UPE 2000 Series Installation And Operating Instructions Manual

Hide thumbs

Also See for UPE 2000 Series:

Need help?

Do you have a question about the UPE 2000 Series and is the answer not in the manual?

Questions and answers