Summarization of Contents

Applications of UPE Series Pumps

Pumped Liquids for UPE Series Pumps

Details on suitable and unsuitable liquids for pumping with UPE Series pumps, including heating and hot-water systems.

Installation of UPE Series Pumps

Terminal Box Positions

Information on the orientation of the terminal box on UPE Series pumps.

Changing Terminal Box Position

Step-by-step instructions for repositioning the terminal box on UPE Series pumps.

Installation Details: Nameplate, Valves, and Protection

Nameplate Position Adjustment

Instructions for adjusting the pump nameplate position after changing the terminal box.

Non-Return Valve Installation

Considerations for installing a non-return valve in the pipe system with UPE Series pumps.

Insulation Requirements

Ensuring proper insulation for UPE Series pumps without covering essential components.

Frost Protection Measures

Steps to prevent frost damage to UPE Series pumps when not in use during cold periods.

Electrical Connection and Safety

UPE Series Pump Supply Voltage

Specifies the required supply voltage and frequency for UPE Series pumps, typically 3 x 400-415V, 50 Hz.

Electrical Connection Details

Wiring Diagram for UPE Series Pumps

Detailed wiring diagram illustrating connections for signals, sensors, and mains power to UPE Series pumps.

UPE Series Pump Functions

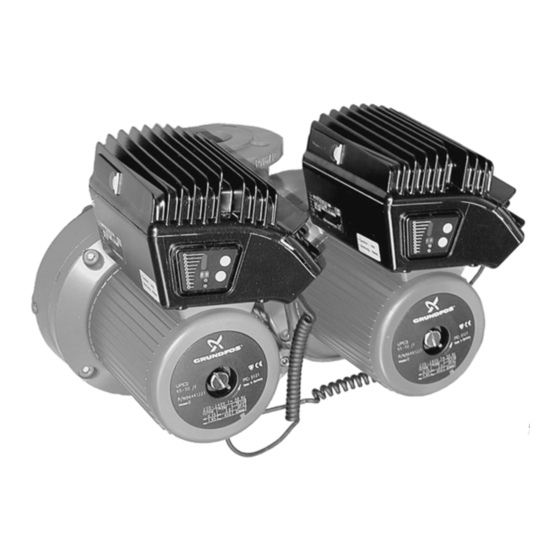

Twin-Head Pump Control Modes

Overview of operating modes for twin-head pumps, including alternating, standby, and synchronous operation.

Pump Control Modes: Proportional and Constant Pressure

Explanation of proportional-pressure and constant-pressure control modes available for UPE Series pumps.

Control Mode Selection Guidance

Selecting the Optimal Control Mode

Guidance on choosing between proportional pressure and constant pressure control based on system characteristics.

Pump Setting Adjustments

Pump Replacement Setting Guidelines

Recommendations for setting UPE Series pumps when replacing existing pumps at maximum or reduced speed.

Max. and Min. Curve Duty Settings

How to set the pump to operate according to maximum or minimum performance curves.

Constant Curve Duty Operation

Setting the pump to operate at a constant speed across a range of curves between max. and min.

Advanced Pump Functions

Temperature Influence Function

Adjusting pump head based on liquid temperature, with options for Tmax. settings.

Indicator Lights for Pump Status

Explanation of the red and green indicator lights for fault and operating status on UPE Series pumps.

External Control and Fault Signals

External Fault Signal Output

Details on the potential-free fault signal output via terminals for monitoring pump status.

External Analog 0-10V Control Input

Using an external 0-10V signal to control pump head or setpoint, including constant curve and pressure control.

Pump Control Options

External Forced Control Inputs

Using external signals for start/stop, max. curve, and min. curve duty control of the pump.

Disabling the Pump Control Panel

How to deactivate the control panel buttons on the master pump to prevent unauthorized operation.

Bus Communication and Control Systems

Connecting UPE Series pumps to GRUNDFOS Pump Management System or building management systems via RS-485.

Wireless Remote Control Operation (R100)

Using the Grundfos R100 remote control for wireless operation and data reading of UPE Series pumps.

Setting and Configuring UPE Series Pumps

UPE Series Pump Factory Settings

Default settings for control mode and twin-head pump operation in UPE Series pumps.

UPE Series Pump Control Panel Operation

Using the control panel buttons and indicator lights for setting pump functions and modes.

Grundfos R100 Remote Control Interface

Overview of the R100 remote control's menus and functions for pump operation and status display.

Control Panel Operation Details

Setting the Pump Head via Control Panel

Adjusting the desired pump head using the '+' and '-' buttons on the control panel.

Control Panel Function Settings

Setting Max. Curve Duty

Configuring the pump to operate according to its maximum performance curve using the control panel.

Setting Min. Curve Duty

Configuring the pump to operate according to its minimum performance curve using the control panel.

Starting and Stopping the Pump via Control Panel

Using the control panel buttons to start, stop, or set the pump to an inoperative state.

Resetting Fault Indications on Control Panel

Procedure for clearing fault indications displayed on the pump's control panel.

Pump Operation and Status Menus

Operation Menu: Setpoints and Modes

Navigating the OPERATION menu to set pump head, select operating modes, and view fault indications.

Status Menu: Viewing Pump Data

Accessing status information such as actual setpoint, operating mode, head, flow, speed, and temperature.

Pump Status Details

Viewing Pump Head and Flow Data

Displaying current head and flow rate of the UPE Series pump.

Viewing Pump Speed

Monitoring the current operating speed of the UPE Series pump.

Viewing Liquid Temperature

Displaying the temperature of the liquid being pumped by the UPE Series pump.

Viewing Power Input and Consumption

Monitoring the pump's current power input and accumulated power consumption.

Viewing Operating Hours

Displaying the total accumulated operating hours of the UPE Series pump.

Pump Installation Configuration Menus

Control mode

Selecting the pump's operational control mode: Proportional Pressure, Constant Pressure, or Constant Curve.

Min. curve

Choosing between two minimum curves for operation when the 'min. curve' mode is selected.

Temperature influence

Activating and configuring the temperature influence function for adjusting pump performance based on liquid temperature.

Pump System Configuration

Pump Button Configuration

Options for activating or deactivating the pump's control panel buttons for security.

Pump Number Allocation

Assigning a unique number to the pump for identification in multi-pump systems.

Twin-Head Pump Operation Settings

Configuring twin-head pumps for single-pump or twin-pump operation modes (alternating, synchronous, standby).

Priority of Pump Settings and Controls

Priority of Settings

Understanding the hierarchy of settings when multiple control signals (panel, R100, external, bus) are active.

Megging Procedure for UPE Series Pumps

High-Voltage Testing Guidelines

Follow-up instructions for high-voltage testing, referencing the megging procedure.

Technical Specifications of UPE Series Pumps

UPE Series Liquid Temperature Limits

Specifies the maximum and continuous liquid temperature ranges for UPE Series pumps in different system types.

Electromagnetic Compatibility (EMC) Standards

Details on compliance with EMC standards, sound pressure level, and leakage current for UPE Series pumps.

UPE Series Pump Inputs and Outputs

Specifications for various inputs (start/stop, analog, bus) and outputs (signal) on UPE Series pumps.

Required Inlet Pressure for UPE Series Pumps

Minimum inlet pressure requirements for UPE Series pumps based on liquid temperature.

Need help?

Do you have a question about the UPED 100-60 and is the answer not in the manual?

Questions and answers