Table of Contents

Advertisement

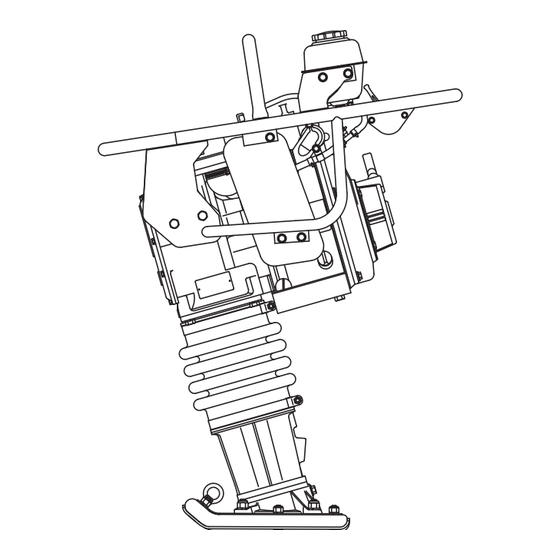

TAMPING RAMMER

MT-76D

MT-76DL

INSTRUCTION MANUAL

en

http://www.mikasas.com

We thank you for selecting Mikasa Tamping Rammer.

For your safe and proper operation,please read this manual and

be always sure to keep it ready for reference.

Contents of "Declaration of Conformity"

Please refer the EC DECLARATION OF CONFORMITY

in this manual as well.

302-00912

*302-00912*

Advertisement

Table of Contents

Summary of Contents for Mikasa MT-76DL

- Page 1 TAMPING RAMMER MT-76D MT-76DL INSTRUCTION MANUAL We thank you for selecting Mikasa Tamping Rammer. For your safe and proper operation,please read this manual and be always sure to keep it ready for reference. Contents of “Declaration of Conformity” Please refer the EC DECLARATION OF CONFORMITY in this manual as well. 302-00912 http://www.mikasas.com *302-00912*...

- Page 3 2) Manufacturer’s name and address. 4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan Takahiro Kishino, engineer 3) Name and address of the person who keeps the R. & D. Division, Mikasa Sangyo Co., Ltd. technical documentation. Shiraoka-city, Saitama, Japan 4) Type: Vibratory Rammers...

- Page 4 Italian Garanzia di Qualità totale ) DICHIARAZIONE “CE” DI CONFORMITÁ 13. Nom et adresse de l'organisme notifié Nome e indirizzo Fabbricante 14. Mandataire dans la Communaute Europeenne Nome e indirizzo della persona che conserva la 15. Directive concernee documentazione tecnica Est egalement conforme aux dispositions de la directive <<emission sonores des equipements utilises a l'exterieur Tipo: Piastre vibranti...

-

Page 5: Power Transmission

For inquiries about repair parts, parts lists, service manuals, and repair of the machine, please contact the shop where you purchased it, our sales office, or the Mikasa Parts Service Center. In addition, parts lists are available on the MIKASA website at: http://www.mikasas.com/english/... -

Page 6: Warning Labels

Before performing any maintenance, be sure to turn the engine off. ■ Mikasa does not accept any liability for accidents or problems caused as a result of not using genuine Mikasa parts (foot assembly, etc.), or if the machine has been modified. - Page 7 Precautions when adding fuel DANGER ! ■ When adding fuel. Be sure to work in a well ventilated location. Be sure to turn the engine off and wait until it has cooled down. Take the machine to a clear flat location without any combustibles nearby. Be careful not any fuel.

- Page 8 Precautions before starting work(Continued) DANGER ! ■ Take the utmost care not to allow the machine to fall during work, or when s t o p p e d o r s t o r e d . S e c u r e t h e machine with a rope or similar tie when stored or left idle so that it cannot fall.

-

Page 9: Transportation And Storage Precautions

Transportation and storage precautions DANGER ! When transporting ■ Before transporting the machine, stop the engine. ■ DO NOT try to move it before the engine and machine body have cooled down enough. ■ Drain any fuel before transporting the machine. ■... -

Page 10: Specifications

Ahv (m/sec Model ) MT-76D 18.5 MT-76DL 16.8 Vibration Level is in comply with EU Directive2002/44/EC and the value is shown as 3 axix min. vibration level. Test course ( Crushed gravel ) is in comply with EN500-4. The above values are subject to change in case that the machine is modified or/and the required regulations change. -

Page 11: Throttle Lever

Drain plug Foot 1.Definition of Tamping Rammer Preoperation Inspection: The Mikasa MT-76D diesel rammer is a powerful Rammer Gearbox and Spring Cylinder This unit compacting tool capable of applying tremendous uses an oil bath lubrication system. Check oil level force in consecutive impacts to a soil surface. - Page 12 4.Starting 4 - 1 Move the throttle lever to IDLE position. Idling position (Fig.3-1,3-2) Stop position Throttle lever is used only at three (STOP, IDLE & OPERATION) positions. In cold weather, the engine should be Throttle lever started at ope rating position or between the idle and operation position of the Fig.

-

Page 13: Operation

5 Operation 5-1 Move the throttle lever quickly from the IDLE to OPERATION position to start tamping action. DO Idling position NOT move the throttle lever slowly as this may cause damage to the clutch or spring. Stop position 5-2 The tamping rammer is designed to tamp the ground 650 to 700 times per minute for MT-76D at an engine speed of 3,100 rpm. - Page 14 7.Service CAUTION: Flammable Liquid. When refueling, stop engine and allow it to cool. Do not smoke or allow work to be performed in the immediate area. Fire or explosion could result from flames or sparks, or if fuel is spilled on a hot engine.

- Page 15 7-4-3 The interval of oil replacement INITIAL OIL CHANGE: Outer element After 20 hours of operation SECOND OIL CHANGE ANDIOR LATER: Every 100 hours of operation Inner element 7-5 Cleaning the Air Cleaner Cleaning the Air Cleaner (every 200-300 hours) (Fig. 9) * Remove element from pre-cleaner at the top of crankcase(body side).

-

Page 16: Troubleshooting

8. TROUBLE SHOOTING 1. Diesel Engine (1) Starting Problem (A) In case of compression problems ■ No compression at all Intake/exhaust valve upthrust Decompressor adjustment problems ■ Almost no compression Contact with seat not close enough. Piston ring wear Cylinder wear Cylinder, cylinder head mating surface problems Nozzle seat looseness (B) In case of inappropriate fuel injection inside the combustion chamber... - Page 17 ■ Firing problem with white smoke (when unloaded) Piston, cylinder ring wear Nozzle hole clogging Piston ring stuck Wrong assembly (upside down) of piston ring Inappropriate injection timing Inappropriate valve open/close timing Looseness of injection pump joint ■ Fuel consumption too high (black smoke) Leakage from fuel passage Clogging of the air cleaner element Inappropriate fuel due to mixing of impurities...

- Page 18 Note - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -...

- Page 20 MIKASA SANGYO CO., LTD. 1-4-3,Sarugakucho,Chiyoda-ku,Tokyo,101-0064,Japan PRINTED IN JAPAN...

Need help?

Do you have a question about the MT-76DL and is the answer not in the manual?

Questions and answers