Summary of Contents for Parker eP2 Series

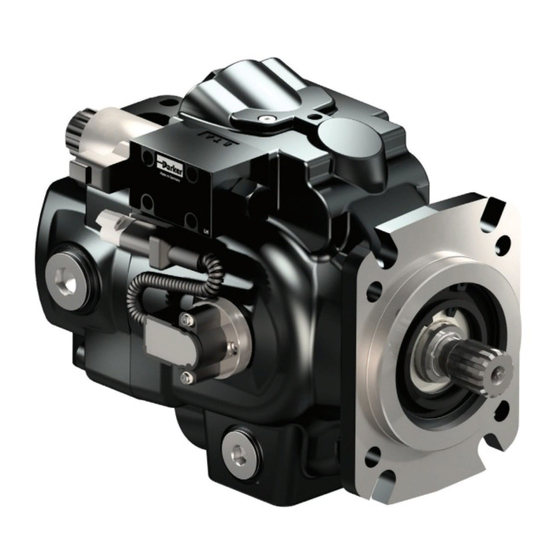

- Page 1 Bulletin MSG30-2901-INST/UK Installation and setup manual Series eP2 / eP3 Visit our homepage for additional support Electronic Controls parker.com/pmde Effective: March 01, 2019 Supersedes: March 01, 2018...

-

Page 2: Table Of Contents

4.2. Temperature ........................10 4.3. Inspection and Maintenance ..................... 10 5. Trouble Shooting ........................10 6. Appendix - System Layout with pump control module (PCM) ..........11 Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 3: Installation, Start-Up And Setup

Detailed values can be taken from the catalogs MSG30-2800 and MSG30-2900. If the pump is controlled by a Parker PMDE supplied pump control module (PCM) and the speed feedback is tied into the controller, a warning message will be Parker Hannifin Manufacturing Germany GmbH &... - Page 4 Maximum pressure optional Drain port ratings must not be exceeded (see MSG30-2800; MSG30-2900). If the pump is controlled by a Parker Pressure gage port / PMDE supplied PCM and the pressure feedback is pressure sensor con-...

-

Page 5: Electrical Interfaces, Pin Assignment

Over-/ undervoltage Diagnostic recommended for NOTICE error detection Do not treat the sensor with electro static Recommended over-/ ±500mV from painting. undervoltage threshold nominal value Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 6: Sensor Properties

All axial piston pumps of series eP2 are equipped with an adjusted and sealed displacement limiter. Do not change this setting. Maximum displacement should be limited electronically. Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 7: Ep2 / Ep3 Control Functions

(in combina- tion with Parker PCM). The PCM is also capable Fail Safe 0% (Standard control position) to manage secondary controls such as variable R/V not included torque limitation and speed compensation / flow control. -

Page 8: Typical Arrangements Ep2

Preferred arrangement for best suction character- istics and low noise level operation. istics and low noise level operation. 0.2 m MIN. 0.15 m MIN. 0.15 m MIN. Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 9: Fluid Reservoir

Open the suction valve (if installed). safety device. Switch the system to free circulation / zero pressure and allow air bleeding to enable the pump to prime. Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 10: Temperature

• Excessive pump leakage (possible causedby internal damage, fluid viscosity belowrated minimum) • Faulty heat exchanger • Reservoir issues (too little fluid, heat pickupfrom surrounding equipment Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... -

Page 11: Appendix - System Layout With Pump Control Module (Pcm)

6.Appendix - System Layout with pump control module (PCM) Displacement control R/V not included ɑ Displacement control, with pressure monitoring or pressure cut-off and optional torque limitation R/V not included ɑ Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany... - Page 12 Installation and setup manual Displacement control, with pressure monitoring or pressure cut-off and optional torque limitation as well as speed compensation (flow control) R/V not included ɑ Parker Hannifin Manufacturing Germany GmbH & Co. KG Pump & Motor Division Europe Chemnitz, Germany...

- Page 13 The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalogue and in any other materials provided from Parker or its subsidiaries or authorized distributors.

- Page 14 For additional information, spare parts or service requirements please contact: Parker Hannifin Manufacturing Germany GmbH & Co KG MSG30-2901-INST/UK Pump and Motor Division Europe Neefestraße 96 09116 Chemnitz, Germany Tel: +49 (0)371 - 3937 - 0 © Copyright 2019 Fax: +49 (0)371 - 3937 - 488 All rights reserved Email: pmde-pqd-support@parker.com...

Need help?

Do you have a question about the eP2 Series and is the answer not in the manual?

Questions and answers