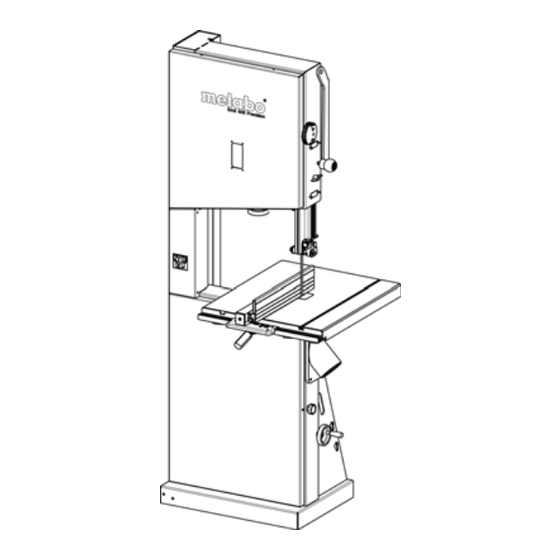

Metabo BAS 505 Precision Original Operating Instructions

Hide thumbs

Also See for BAS 505 Precision:

- Original operating instructions (52 pages) ,

- Original operating instructions (73 pages)

Table of Contents

Summary of Contents for Metabo BAS 505 Precision

- Page 1 A0309_50IVZ.fm BAS 505 Precision Originalbetriebsanleitung ....3 Original operating instructions ..15 Instructions d’utilisation originales ..27...

-

Page 2: Parts Identification

XA0046E5.fm Original operating instructions DEUTSCH ENGLISH 1. Parts Identification Twist handle for V-belt tension set- Front Rear ting Upper housing door Setting knob for blade tracking V-belt drive adjustment Upper band saw wheel Lower band saw wheel Setting knob for band saw Push stick holder blade tension Lower housing door... -

Page 3: Table Of Contents

ENGLISH − safety advised to seek competent advise devices have been Table of Contents and guidance from an experienced checked. person before operating this Parts Identification....15 − Connect the saw to the mains machine. supply only after all of the above Please Read First! .....16 −... - Page 4 ENGLISH • Do not operate the machine near with the specifications stated in the Cutting hazard, even with the inflammable liquids or gases. Technical Data. cutting tool at standstill! • • The machine shall only be started Make sure that as little as possible •...

-

Page 5: Symbols On The Machine

ENGLISH • Symbols on the machine Transport the saw with the help of a second person. • For transport use the original pack- Danger! ing where possible. Disregard of the following warnings could lead to serious personal injury or material damage. 6. -

Page 6: Aligning The Saw Table

ENGLISH Setting knob for drive belt tension Saw table lateral alignment Danger from exposed bandsaw With the setting knob (44) the drive belt Loosen lock lever (48) and hexagon blades and wheels! tension is corrected, if necessary: nut (49). If after one turn the motor does not −... -

Page 7: Mounting

ENGLISH Tensioning the Band Saw Blade Danger! Too much tension can cause the band saw blade to break. Too little tension can cause the driven band saw wheel to slip and the band saw blade to stop. Raise upper blade guide fully (see “Operation”). -

Page 8: Mains Connection

ENGLISH Adjust upper blade guide (59) to its or against the table's edge, tighten If the direction of rotation is incorrect, lowest position. knurled nut (63). the electrical connection must be changed by a qualified electrician! 13. Close housing door. After the saw and all of its safety 14. -

Page 9: Adjusting The Upper Blade Guide

ENGLISH Re-tighten the V-belt by rotating the Danger! crank clockwise (the V-belt must be able to be depressed in the middle Turn the machine OFF and wait for about 10 mm). the band saw blade to stop before adjusting the upper blade guide or Close the lower housing door. -

Page 10: Band Saw Blade Alignment

ENGLISH − a thrust bearing (supports the band Aligning the Lower Blade Danger! saw blade from the rear), Guide − two guide bearings (providing lateral If the table insert is damaged, small The lower blade guide consists of: objects may get caught between the support). -

Page 11: Replacing The Band Saw Tyre

ENGLISH Set guide bearings (77) with the in your hand when the saw is in oper- Dust collector knurled thumb screws (79) against ation! helps to protect your health and to the band saw blade. keep the shop clean. Prior to all servicing: WAXILIT Sliding Compound Turn band saw wheel by hand clock- Switch machine OFF. -

Page 12: Technical Specifications

ENGLISH − correct band saw blade tension (see Motor does not run Saw vibrates “Care and Maintenance”). Undervoltage relay tripped by power fail- Insufficient mounting: ure: Load too high: − Fasten saw properly to a suitable − switch on again. −... -

Page 13: Available Band Saw Blades

ENGLISH Noise emission value (DIN EN 1870-1*) during sawing A-sound pressure level L dB (A) 82,2 82,2 A-sound power level dB (A) 89,9 89,9 Uncertainty K dB (A) * The values stated are emission values and as such do not necessarily constitute values which are safe for the workplace. Although there is a correlation between emission levels and environmental impact levels, whether further precautions are neces- sary cannot be derived from this. - Page 14 Metabowerke GmbH, 72622 Nürtingen, Germany www.metabo.com...

Need help?

Do you have a question about the BAS 505 Precision and is the answer not in the manual?

Questions and answers