Table of Contents

Advertisement

263-13236E

Magnetically Levitated Turbo Molecular Pump

Model:TMP-3203M

(Air cooled type)

Model:TMP-3203MC (Air cooled chemical type)

Model:TMP-3203LM (Wide range type)

Model:TMP-3203LMC (Wide range chemical type)

Model:TMP-3403LMC (Wide range chemical type)

INSTRUCTION MANUAL

Read the instruction manual thoroughly before you use the product.

Keep this instruction manual for future reference.

Semiconductor Equipment Division

Advertisement

Table of Contents

Summary of Contents for Shimadzu TMP-3203MC

- Page 1 263-13236E Magnetically Levitated Turbo Molecular Pump Model:TMP-3203M (Air cooled type) Model:TMP-3203MC (Air cooled chemical type) Model:TMP-3203LM (Wide range type) Model:TMP-3203LMC (Wide range chemical type) Model:TMP-3403LMC (Wide range chemical type) INSTRUCTION MANUAL Read the instruction manual thoroughly before you use the product.

-

Page 2: Copyrights And Disclaimers

Every effort has been made to prepare an accurate and complete manual, but if an error or omission should be discovered, revisions might not be possible immediately. Shimadzu does not take responsibility for any effects that may result from the use of this manual. -

Page 3: Precautions For Safe Operation

WARNING Turbo molecular pump repair and/or power supply repair can be very hazardous. Only trained technicians who are authorized by Shimadzu may do service of products. WARNING Neither overhaul nor modify the pump proper and power supply unit without admission. - Page 4 Improper turbo molecular pump use may be hazardous to operator's health in applications not recommended or approved by Shimadzu. In the event removal of the turbo molecular pump from an application is required, full protective measures including purging of the turbo molecular pump with an inert gas and/or apparel are recommended when the turbo molecular pump has been used in applications that required the use of corrosive, reactive, stimulative, or toxic gases.

- Page 5 CAUTION After having operated the turbo molecular pump for evacuation of corrosive gas, keep the pump internal as vacuumed even after shutdown. Inflow of water content in the air to the pump internal would cause rapid erosion trouble of the pump internals. CAUTION Avoid to install the pump at the following places.

-

Page 6: Explanation Of Label

In case "this label is removed" or "there is a mark showing once this label has been removed", Shimadzu warranty shall not be applied to the product. ○ Location of label (2), (3) -

Page 7: Installation Precautions

○ Part Replacement The lifetime of parts are specified as below. The request for changing parts exceeding the estimated lifetime should be made to Shimadzu or an approved service company in order for safety and adequate performance of the pump and power supply unit. -

Page 8: Air Cooled Turbo Molecular Pump

DV24V Fig. 1 How to Change the Cooling Fan Unit ○ Warranty period 12 months on new TMP's from the date of shipment from Shimadzu, or from any of its worldwide sales offices. ○ Conditional warranty During the warranty period and under normal operation, if the TMP fails to meet its product specification due to defects in material and/or workmanship, Shimadzu will, at its discretion, either repair it or exchange it with a new one for free. -

Page 9: Disposal Of Products And Parts

○ Disposal of Products and Parts Please contact Shimadzu for proper disposal of its products or parts. There is a possibility to pollute the environment with the material of the parts, when you dispose this product in an inap- propriate way. -

Page 10: Table Of Contents

Table of contents TABLE OF CONTENTS Introduction Copyrights and Disclaimers ....... . i Precautions for Safe Operation . -

Page 11: Table Of Contents

Table of contents Section 3 CONSTRUCTION AND PRINCIPLE 3.1 Pump Construction ....... . . 10 3.2 Principle of Turbo Molecular Pumping . - Page 12 Table of contents Section 7 GAS PURGE Section 8 TURBO MOLECULAR PUMP RECONDITION 8.1 Turbo Molecular Pump Return Request ....40 8.2 Turbo Molecular Pump Decontamination....41 8.3 Touch-Down Bearing Replacement .

- Page 13 Table of contents This page is intentionally left blank. 263-13236...

-

Page 14: Section 1 Outline And Descriptions

OUTLINE AND DESCRIPTIONS 1.1 Outline 1.2 Descriptions 1.2.1 Outside drawing of Pump Main Unit 1.2.1.1 Outside drawing of series of TMP-3203 1.2.1.2 Outside drawing of TMP-3403LMC 1.2.2 Standard Accessories... -

Page 15: Outline

SECTION 1 OUTLINE AND DESCRIPTIONS Outline The turbo molecular pump is a vacuum pump. The turbo molecular pump is used with a backing vacuum pump to create a high vacuum in a vacuum chamber. Typical Applications ; Semiconductor equipments, Industrial equipments, R&D applications, The other ultra high vacuum applications. -

Page 16: Descriptions

P/N 262-78430-63 P/N 262-78430-73 287 294 289 375 420 22.5 φ425 φ395 12-φ13 Special VG300 P/N 262-78430-67 P/N 262-78430-77 307 314 309 395 440 18.5 φ400 φ370 12-φ13 VG250 P/N 262-78430-68 P/N 262-78430-78 331 338 333 419 464 18.5 φ350 φ320 12-φ13 Fig.1-1 TMP-3203M and TMP-3203MC Magnetically Levitated Turbo Molecular Pump INSTRUCTION MANUAL... - Page 17 SECTION 1 OUTLINE AND DESCRIPTIONS INLET Parts number φH φJ n-φd FLANGE TMP-3203LM TMP-3203LMC VG350 P/N 262-78430-42 P/N 262-78430-52 287 294 289 270 375 420 φ450 φ420 12-φ15 ISO320B P/N 262-78430-43 P/N 262-78430-53 287 294 289 270 375 420 22.5 φ425 φ395 12-φ13 Special VG300 P/N 262-78430-47 P/N 262-78430-57 307 314 309 290 375 440 18.5 φ400 φ370 12-φ13...

-

Page 18: Outside Drawing Of Tmp-3403Lmc

1.2 Descriptions 1.2.1.2 Outside drawing of TMP-3403LMC INLET Parts number n-φd φH φ FLANGE VG350 P/N 262-78503-52 287 294 270 375 420 φ450 360 φ420 12-φ15 ISO320B P/N 262-78503-53 287 294 270 375 420 22.5 φ425 360 φ395 12-φ13 Special VG300 P/N 262-78503-57 307 314 290 395 440 18.5 φ400 380 φ370 12-φ13 VG250 P/N 262-78503-58 331 338 314 419 464 18.5 φ350 404 φ320 12-φ13... -

Page 19: Standard Accessories

SECTION 1 OUTLINE AND DESCRIPTIONS 1.2.2 Standard Accessories Series of TMP-3203 Description Q'ty Notes Parts number O-ring gasket for VG350 036-13516 Gasket for inlet flange O-ring gasket for VG300 036-13515 (Note) O-ring gasket for ISO320B Special 036-15554-55 O-ring gasket for VG250 036-13514 VG350:Hex Head, M12 ×... -

Page 20: Section 2 Identification And Function

IDENTIFICATION AND FUNCTION 2.1 Pump Main Unit... -

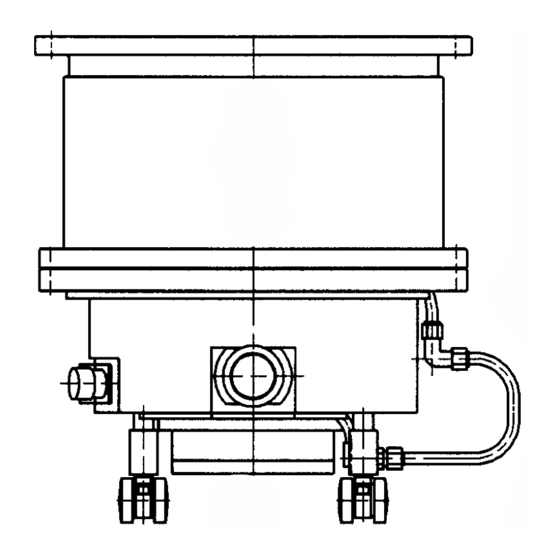

Page 21: Pump Main Unit

SECTION 2 IDENTIFICATION AND FUNCTION Pump Main Unit TMP-3203LM/LMC TMP-3403LMC TMP-3203M/MC Fig.2-1 Pump Main Unit (1) INLET FLANGE... . . Inlet flange, joint the turbo molecular pump, VG350, ISO320B Special, VG30, VG250 are also available. (2) PORT FOR GAS PURGE . - Page 22 CONSTRUCTION AND PRINCIPLE 3.1 Pump Construction 3.2 Principle of Turbo Molecular Pumping...

-

Page 23: Pump Construction

The cooling water pipe (14) is provided to cool the pump. With the air-cooled turbo molecular pumps TMP-3203M and TMP-3203MC, cooling fans are provided instead of the cooling water pipe (14). Fig. 1-1 through Fig. 1-3 show the outside dimensions of the turbo molecular pump. - Page 24 3.2 Principle of Turbo Molecular Pumping ⑬ ⑪ ④ ⑤ ⑩ ③ ⑥ ⑨ ① ⑦ ⑭ ② ⑨ ⑫ ⑧ ⑩ Fig.3-1 Pump Sectional Drawing (1) High frequency motor (6) Spacer (11) Inlet flange (2) Receptacle (7) Radial magnetic bearing (12) Outlet flange (3) Drive shaft (8) Axial magnetic bearing (13) Protective net...

- Page 25 SECTION 3 CONSTRUCTION AND PRINCIPLE The movement of an object has 6 degrees of freedom. Levitation can be achieved in a turbo molecular pump by controlling the following 5 degrees of freedom (excluding the rotational degree (Z axis) of freedom). rotational axis Parallel movement Radial displacement Axial displacement...

- Page 26 SPECIFICATIONS 4.1 Pump Main Unit 4.1.1 Specification of series of TMP-3203 4.1.2 Specification of TMP-3403LMC 4.2 Standards Fulfilled...

-

Page 27: Pump Main Unit

SECTION 4 SPECIFICATIONS Pump Main Unit 4.1.1 Specification of series of TMP-3203 Turbo molecular pump model TMP-3203M TMP-3203MC TMP-3203LM TMP-3203LMC Cooling method Cooling fan Water Ultimate pressure (Note 1) Pa order Pa order Pa order Pa order Maximum Argon gas through put... -

Page 28: Specification Of Tmp-3403Lmc

22020 rpm Start-up time 15 minutes Mounting position In any desired direction(Note 3) Bake-out temperature at an inlet 120 ℃ or less flange Vibration level (by Shimadzu's 0.01 μm or less (0-peak) method) Inlet flange VG350(Note 4) Outlet flange KF40 Mass... -

Page 29: Standards Fulfilled

SECTION 4 SPECIFICATIONS Standards Fulfilled EN61010-1; 2001 UL61010A-1 Safety SEMI S2 EN1012-2; 1996 EN61326-1; 1997 + A1; 1998 + A2; 2001 class A EN61000-3-2; 1995 + A14; 2000 SEMI F47 263-13236... - Page 30 INSTALLATION 5.1 Installation 5.1.1 Pump Mounting Direction 5.1.2 Installation of the Pump 5.1.2.1 Installation of series of TMP-3203 5.1.2.2 Installation of TMP-3403LMC 5.1.3 Example of piping connection 5.1.4 Center of gravity of the pump 5.2 Connection of the Pump to the Power Supply Unit 5.3 Interlock for Vacuum System...

-

Page 31: Installation

SECTION 5 INSTALLATION Installation 5.1.1 Pump Mounting Direction This turbo molecular pump can be installed in vertical, the horizontal, inverted, oblique position. The outlet flange of the pump should face horizontally or vertically when installing the pump horizontally and obliquely. When an installation direction is non-appropriate, reliability of operation may deteriorate. (Refer to Fig. -

Page 32: Installation Of The Pump

5.1 Installation 5.1.2 Installation of the Pump WARNING ・ Fix the pump to the device according to 5.1.2.1 and 5.1.2.2. The method to fix the pump is different depending on the pump model and the size of inlet flange of the pump. ・... - Page 33 SECTION 5 INSTALLATION CAUTION The center of gravity of the pump is indicated in Fig. 5-8. Be sure that the pump does not move or fall down during installation or storage. CAUTION The casters provided with the pump are only auxiliary equipment for installation and storage. Use a trolley etc.

-

Page 34: Installation Of Series Of Tmp-3203

5.1 Installation 5.1.2.1 Installation of series of TMP-3203 Please fix the inlet flange of turbo molecular pump to the flange of vacuum chamber , and the base bottom of the pump to the frame of the device by the bolts of regulated grade, size, number, and tightening torque for each flange. - Page 35 SECTION 5 INSTALLATION Bolt hole Vacuum chamber Inlet flange Inlet flange Spring lock washer Special washer Special washer Fixing bolt When shipping After installation Fig. 5-4 Example of the fixing method using the special washer Table 5-2 Tightening torque of the fixing bolt Size of bolt Tightening torque [N•m] 16 ~...

-

Page 36: Installation Of Tmp-3403Lmc

5.1 Installation 5.1.2.2 Installation of TMP-3403LMC Please fix the inlet flange of turbo molecular pump to the flange of vacuum chamber , and the base bottom of the pump to the frame of the device by the bolts of regulated grade, size, number, and tightening torque for each flange. -

Page 37: Example Of Piping Connection

SECTION 5 INSTALLATION 5.1.3 Example of piping connection Connect a backing vacuum pump or its related pipe connection flange to the outlet flange of the pump. (See Fig. 5-6) * VACUUM CHAMBER * MAIN VALVE TURBO MOLECULAR PUMP * FOREVACUUM VALVE *... -

Page 38: Center Of Gravity Of The Pump

5.1 Installation Connection of Cooling Water Line: Connect cooling water pipes to these pumps. When connecting the cooling water pipes, screw the pipe joint while also holding the nozzle of the pump with a spanner in order to avoid deforming the cooling water pipe, as illustrated in Fig. 5-7. PIPE JOINT Fig. -

Page 39: Connection Of The Pump To The Power Supply Unit

SECTION 5 INSTALLATION Connection of the Pump to the Power Supply Unit CAUTION Insert straight the control cable connector after checking its key direction. Inserting it in oblique direction would cause damage of the connector pins. After the insertion, turn the cable connector clockwise until the rotation lock clicks. CAUTION Don't disconnect each cable while the pump is running. -

Page 40: Interlock For Vacuum System

5.3 Interlock for Vacuum System Interlock for Vacuum System (1) When using, as a backing vacuum pump, a vacuum pump with no check mechanism (backstream flow prevention) such as dry vacuum pump, etc., install a forevacuum valve between the turbo molecular pump and the backing vacuum pump to prevent rapid inverse flow of exhausted gas. - Page 41 SECTION 5 INSTALLATION This page is intentionally left blank 263-13236...

- Page 42 OPERATION 6.1 Outline 6.1.1 Introduction 6.2 Start-up Preparation 6.2.1 Start-up Preparation 6.3 Start-up 6.3.1 Start-up Sequence 6.4 Shutting Down 6.5 Baking Operation...

-

Page 43: Outline

SECTION 6 OPERATION Outline CAUTION Neither disconnect and reconnect each cable while the pump is running. Particularly for unplugging the control cable from the receptacle, check complete shutdown of the pump by ROTATION lamp goes out and, thereafter, turn off the POWER switch. CAUTION Do not turn the power off while the pump is running. -

Page 44: Start-Up Preparation

6.2 Start-up Preparation Start-up Preparation Please select "LOCAL" or "REMOTE" at the switch of the Power Supply Unit. For more information regarding operation, please refer to the Power Supply Unit Instruction Manual. 6.2.1 Start-up Preparation (1) Feed the cooling water into the cooling line. (for cooling water method) (2) Turn on the POWER switch of the power supply unit and check if the POWER lamp lights. -

Page 45: Shutting Down

SECTION 6 OPERATION Shutting Down CAUTION After having operated the turbo molecular pump for evacuation of corrosive gas, keep the pump internal as vacuumed even after shutdown. Inflow of water content in the air to the pump internal would cause rapid corrosion trouble of the pump internals. The pump corrosion may result in damaging the vacuum vessel interior and other units, causing pressure fluctuation by stopping the pump and dispersal of parts. - Page 46 6.4 Shutting Down REFERENCE ROTATION lamp goes out or "ROTATION" signal turns off when the pump rotational speed is 60rpm or less. Turning off the POWER switch permits the pump rotor to be supported by the touch-down bearings. Magnetically Levitated Turbo Molecular Pump INSTRUCTION MANUAL...

-

Page 47: Baking Operation

SECTION 6 OPERATION Baking Operation CAUTION During baking operation, cool down the turbo molecular pump in either cooling water or cooling fan. NOTICE Baking temperature is not allowed to exceed 120 ℃ . The baking heater is installed near the inlet flange. INLET FLANGE BAKING HEATER Fig. - Page 48 GAS PURGE...

- Page 49 Nitrogen is the most popular purge gas. A purge gas flowrate between 20 and 30 mL/min is appropriate. Please consult your shimadzu representative, during evacuation of corrosive gas. The gas-purge adaptor is available without an orifice (recommended) or with an orifice (option).

- Page 50 OPTION A gas purge adaptor with an orifice is available as an option. The gas purge adaptor with an orifice maintains the purge gas flow between 20 and 30 mL/min if the gas-supply pressure lies within the range below. Flow control with a flowmeter is not required. Note: Gas purge adaptors with no orifice are recommended for applications in which large amounts of reaction products are generated (e.g., metal etchers).

- Page 51 SECTION 7 GAS PURGE This page is intentionally left blank. 263-13236...

- Page 52 TURBO MOLECULAR PUMP RECONDITION 8.1 Turbo Molecular Pump Return Request 8.2 Turbo Molecular Pump Decontamination 8.3 Touch-Down Bearing Replacement 8.4 Check of the rotor blades...

-

Page 53: Turbo Molecular Pump Return Request

Shimadzu will accept and perform service only on turbo molecular pumps that have been properly prepared as stated in (1) and (2) above. Shimadzu will advice the customer of any failure precaution/prevention procedures that are appropriate to each individual turbo molecular pump service request. -

Page 54: Turbo Molecular Pump Decontamination

Touch-Down Bearing Replacement The touch-down bearing (Fig. 3-1 (9)) is the only component of Shimadzu's turbo molecular pump that is subjected to friction and wear, normally occurring only during electrical power failure. Repeated and/or frequent rotor touch down will cause wear and bigger rotational resistance and require replacement of touch down bearings. - Page 55 SECTION 8 TURBO MOLECULAR PUMP RECONDITION This page is intentionally left blank. 263-13236...

-

Page 56: Section 9 Troubleshooting

TROUBLESHOOTING 9.1 Vacuum Pressure Rise 9.2 Abnormal Noise and/or Vibration... -

Page 57: Vacuum Pressure Rise

SECTION 9 TROUBLESHOOTING Vacuum Pressure Rise A rapid rise of vacuum pressure in the turbo molecular pump causes the internal motor of the turbo molecular pump to start braking and the ALARM lamp lights. Abnormal Noise and/or Vibration Should the turbo molecular pump ever generate abnormal noise and/or vibration, the turbo molecular pump operation is to be stopped immediately. - Page 58 Index Index backing vacuum pump ...... 8 、 14 、 15 、 24 CE MARKING ............16 Cooling fan ............vi 、 vii cooling water .............8 、 25 corrosive gas ............41 gap sensor ............. 10 gas purge ........14 、 15 、 36 、 37 inlet flange ............8 、...

- Page 59 Index This page is intentionally left blank. Magnetically Levitated Turbo Molecular Pump Index-2 263-13236 INSTRUCTION MANUAL...

- Page 60 Excerpt from No. FE8A-0049F Declaration of Conformity SHIMADZU CORPORATION SEMICONDUCTOR EQUIPMENT DIVISION Address :380-1,HORIYAMASHITA,HADANO-CITY, KANAGAWA, 259-1304, JAPAN as the Manufacturer declares in sole responsibility that the following product Product Name Turbo Molecular Pump Model name , P/N Vacuum Pump Power Supply...

- Page 61 TMP Evaluation Form Please fill out this evaluation form and attach to the product when you send it back to Shimadzu Service Center for repair service, etc. When you fill out this form, please describe the details as much as possible.

- Page 62 SHIMADZU (ASIA PACIFIC) PTE LTD. 16 Science Park Drive #01-01 The Pasteur Singapore Science Park, Singapore 118227, Republic of Singapore Phone:65-778-6280 Fax:65-779-2935 SHIMADZU INTERNATIONAL TRADING (SHANGHAI) Co., LTD. Floor, Shanghai Xin-Hualian Building No.755 Huaihai Zhong Lu, Shanghai 200020 Phone:86(21)6472-8442 Fax:86(21)6472-8648...

Need help?

Do you have a question about the TMP-3203MC and is the answer not in the manual?

Questions and answers